K-WANG

TRICON ®/ Installation and maintenance of E/E2/E3 transmitters

TRICON ®/ Installation and maintenance of E/E2/E3 transmitters

Product Overview

core functionality

For Neptune ® The series of water meters provide electronic interfaces for water consumption monitoring and support various process controls based on water consumption, which can be integrated with SmartTrol ® Integrate controllers or third-party instrument devices to build complex measurement and monitoring systems.

Product Model and Classification

Divided by signal type

Digital Pulse

Basic model: 3-terminal design, outputting electrical pulses corresponding to water flow rate, requiring 12-24VDC power supply, suitable for scenarios that only require digital signals.

E2/E3 models: 5-terminal design, retaining basic features, new high-resolution output terminal and counting direction terminal, supporting high-speed bidirectional counter connection, also requiring 12-24VDC power supply, suitable for high-resolution digital signal demand scenarios.

Adaptation types: divided into two categories: Disc specific and Turbine specific, which can adapt to all Neptune disc or turbine watches.

Simulate 4-20mA type

5-terminal design, with digital pulse type basic functions, providing additional 4-20mA analog signal output proportional to water flow rate, requiring 24VDC power supply, suitable for scenarios that require both analog and digital signals.

Adaptation requirements: Strictly match the size and type of the water meter, confirm the compatible model when purchasing, and contact the manufacturer for technical support if necessary.

Special Model Description

The TRICON/E3 transmitter is not submersible and is not recommended for pit installation scenarios.

The T-8 disc gauge has been discontinued. Currently, all TRICON/E transmitters compatible with disc gauges are T-10 type. When compatible with T-8 gauges, it may not be possible to achieve a 20mA output level. The relevant values are only for calibration reference.

Key technical parameters

environmental conditions

Working temperature: 0 ° C~70 ° C (32 ° F~158 ° F)

Storage temperature: -40 ° C~85 ° C (-40 ° F~185 ° F)

Working humidity: 0~95% RH, no condensation

Electrical specifications (classified by model)

Pulse output (working temperature 0-70 ° C)

Low level output voltage (Vol): typical value 0.4V

High level output voltage (Voh): minimum value 8.5V, maximum value 12V, typical value is the power supply voltage minus 1.0V

Low level output current (Iol): typical value -10mA

High level output current (Ioh): typical value+10mA

Output rise time (tr l-h): maximum value 2 μ S (RL=2.4K Ω, CL=50pF)

Output decay time (tf h-l): maximum value 2 μ S (RL=2.4K Ω, CL=50pF)

4-20mA model (working temperature 0-50 ° C)

Power supply voltage (VCC): 22.5~26.5VDC

Power supply current (IS): 20~80mA

Loop resistance (RL): 0~600 Ω

Range accuracy (Gain): maximum 0.5% FS

Zero offset accuracy (Zero): maximum 0.2% FS

The digital pulse output parameters are consistent with the pulse output model

HF and UP/DN models (working temperature 0-70 ° C)

Power supply voltage (VCC): 11.5~26.5VDC

Power supply current (IS): 20~50mA

Low level output voltage (Vol): maximum value 0V

High level output voltage (Voh): typical value 24V, maximum value 26.5V

Low level output current (Iol): minimum value -1.0A

High level output current (Ioh): typical value 0.04A, maximum value 1.0W/Voh

Output rise/fall time: maximum value 2 μ S (RL=2.4K Ω, CL=50pF)

Absolute limit values for all models

Working temperature: 0~85 ° C

Storage temperature: -40~85 ° C

Power supply voltage: -30~30V

Pulse output load resistance: minimum 1200K Ω

Pulse output current: maximum 10mA

Note: Exceeding the above limit values may result in equipment damage

Performance data (classified by water meter type)

T-10 Disk Watch

Water meter size (inches) Maximum flow rate (gpm) Continuous maximum flow rate (gpm) Minimum flow rate (gpm) Number of pulses per gallon Maximum flow rate Pulse output (Hz) 4-20mA Output flow range (gpm)

⅝ 20 10 ¼ 578.10 192.70 0–20

¾ 30 15 ½ 322.60 161.30 0–30

1 50 25 ¾ 150.80 125.67 0–50

1½ 100 50 1½ 67.57 112.62 0–100

2 160 80 2 37.30 100.00 0–160

Note: The high-resolution output of TRICON/E2 requires multiplying the number of pulses per gallon and the maximum flow pulse output value by 36, and E3 requires multiplying by 40

T-8 Disc Watch (discontinued)

Water meter size (inches) Maximum flow rate (gpm) Continuous maximum flow rate (gpm) Minimum flow rate (gpm) Number of pulses per gallon Maximum flow rate Pulse output (Hz) 4-20mA Output flow range (gpm)

⅝ 20 10 ¼ 473.60 157.87 0–24.41

¾ 30 15 ½ 329.14 164.57 0–29.40

1 50 25 ¾ 126.55 105.46 0–59.58

1½ 100 50 1½ 47.86 79.77 0–141.18

2 160 80 2 25.60 68.27 0–234.37

Note: The high-resolution output coefficient is the same as the T-10 table; When the T-10 transmitter is adapted to the T-8 meter, the theoretical flow rate corresponding to the 20mA output is greater than the maximum allowable flow rate of the water meter, which cannot be achieved in actual operation

Trident ® Turbine gauge (TT)

Water meter size (inches) Continuous maximum flow rate (gpm) Minimum flow rate (gpm) Pulses per gallon Maximum flow rate Pulse output (Hz) 4-20mA Output flow range (gpm)

2 200 3 4.6080 15.36 0–200

3 450 5 2.8900 21.68 0–450

4 1000 10 1.5900 26.50 0–1000

6 2000 20 0.4640 15.47 0–2000

8(S/N≤31918014) 3500 35 0.2493 14.54 0–3500

8(S/N≥31918274) 3500 35 0.2253 13.14 0–3873

10(S/N≤31919282) 5500 50 0.1600 14.67 0–5500

10(S/N≥31919300) 5500 50 0.1472 13.49 0–5981

Note: E2 high-resolution output requires multiplying the number of pulses per gallon and the maximum flow pulse output value by 9, while E3 requires multiplying by 10

High Performance Turbine Meter (HPT)

Water meter size (inches) Continuous maximum flow rate (gpm) Minimum flow rate (gpm) Pulses per gallon Maximum flow rate Pulse output (Hz) 4-20mA Output flow range (gpm)

1½ 160 4 6.09500 16.25 0–160

2 200 4 6.09500 20.32 0–200

3 450 5 11.20000 84.00 0–450

4 1200 10 7.55600 151.1 0–1200

6 2500 20 0.72730 30.30 0–3000

8 4000 35 0.75560 50.37 0–4000

10 6500 50 0.75560 81.86 0–6500

12 8000 120 0.75560 100.75 0–8000

16 13500 200 0.07556 17.00 0–13500

20 22000 300 0.07556 27.71 0–22000

Note: The high-resolution output coefficient is the same as Trident's ® Turbine watch

Compound Meters

Core composition: Composed of a combination of turbine components and disk components, the components of different models of composite watches are matched differently (such as 3 "TRU/FLO consisting of 3" TT turbine components and ⅝ "T-10 disk components).

Performance reference: It is necessary to separately refer to the performance specifications of the corresponding turbine components and disc components. The 4 "/6"/8 "/10" HP TECTUS III turbine components have dedicated performance parameter tables.

Installation process

Pre-installation preparation

Tools and Materials

Essential tools: Medium sized flathead screwdriver, wire stripping pliers, hammer, ⅛ "diameter punch (or similar tools).

Essential material: # 22 AWG multi-core solid copper wire.

Optional material: Dow Corning ® # 4 moisture-proof compounds (or equivalent products).

Inspection and Storage

After unboxing, check whether the transmitter components (including the transmitter body, terminal cover, and installation ring) are intact, without damage or missing.

Before installation, the components need to be stored in a clean and dry environment, with a temperature maintained between -40 ° C and 85 ° C.

Safety and wiring specifications

Avoid placing instrument circuits near electrical noise sources such as contactors, motor starters, radio transmitters, and high-voltage power lines.

Separate the wiring of instrument circuits from other circuits and prioritize the use of independent metal conduits or metal cable trays; Long distance cabling (up to 1000 feet) requires # 22 AWG shielded twisted pair cables, with the shielding layer only grounded at the receiving device end.

When wiring needs to intersect, maintain a right angle intersection to reduce noise coupling; Use dedicated power sources (such as independent circuit breakers, isolation transformers) to ensure grounding in accordance with local electrical regulations.

Specific installation steps

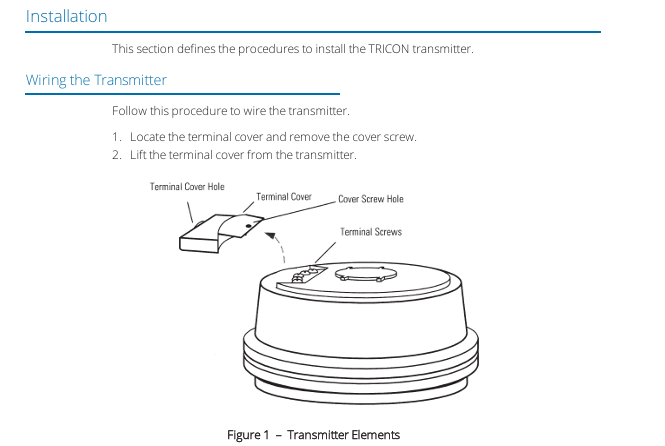

1. Wiring operation

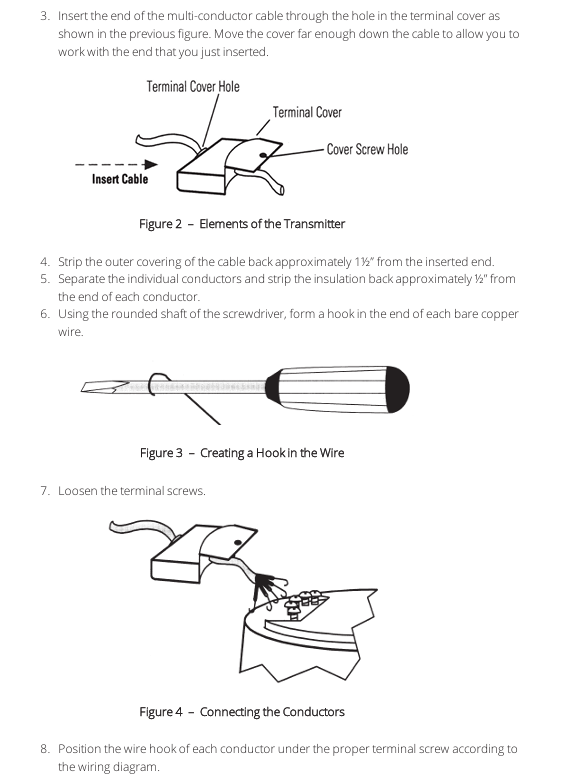

Unscrew the terminal cover screws, remove the terminal cover, thread the multi-core cable through the hole on the terminal cover, and move the terminal cover down along the cable to a convenient operating position.

Peel off the outer sheath of the cable by about 1.5 inches, separate the core wires and strip off the insulation layer of each core wire by about 0.5 inches. Use a screwdriver with a round handle to bend the bare copper wire into a hook shape.

Loosen the terminal screw of the transmitter, and wrap the hooks of each core wire clockwise around the corresponding terminal screw according to the wiring diagram (ensuring that the insulation layer is not pressed under the screw), and tighten the screw firmly (avoiding over tightening).

2. Wiring code (divided by pins)

Pin number TRICON ®/ E digital pulse type (before January 1996) TRICON ®/ E2/E3 digital pulse type (after January 1996) TRICON ®/ E/E2/E3 4-20mA type

1 connectionless high-resolution output 4-20mA source (+)

2 unconnected counting direction (ground contact closed, powered by pull-up resistor) 4-20mA return (-)

3 12-24VDC power input (+) 12-24VDC power input 24VDC power input (+)

4 Public Grounding (-) Public Grounding (-) Public Grounding (-)

5 pulse output pulse output pulse output

Note: The typical value of the pull-up resistor is 2K Ω for every 5VDC; "+" indicates that the regular current flows out of the transmitter.

3. Line testing

Connect the transmitter power and verify the output signal according to the following standards:

When there is no flow: there is no pulse at the digital output terminal, and the 4-20mA circuit current is 4mA.

At half flow rate: the pulse frequency of the digital output terminal is 1/2 of the maximum pulse frequency, and the 4-20mA circuit current is 12mA.

At maximum flow rate: The pulse frequency of the digital output terminal is equal to the maximum pulse frequency, and the 4-20mA circuit current is 20mA.

4. Final assembly

Turn off all power and apply sufficient Dow Corning on exposed wires and terminals ® # 4 compounds, the interior of the terminal cover is also filled with this compound (for moisture resistance).

Reset the terminal cover, tighten the fixing screws (to avoid over tightening), fasten the stress relief accessory onto the cable and push it into the cable entry hole, and wipe off excess compound.

5. Installation of transmitter

If the water meter has installed a register: align the punch with the center of the sealing pin at the bottom of the register, strike with a hammer to break the pin head, and rotate the register counterclockwise by 1/4 turn to remove it.

Install the TRICON transmitter on the water meter and rotate clockwise to lock it; Place the register mounting ring (with four sets of circular grooves facing upwards) on top of the transmitter, align it with the notch on the transmitter terminal cover, and tighten it.

Place the register on the transmitter and mounting ring, rotate clockwise until locked; Insert the new sealing pin into the register base and transmitter base to prevent tampering.

Maintenance and troubleshooting

Core scenarios for troubleshooting

When the electronic flow indication is inconsistent with the mechanical register indication, follow the following steps to troubleshoot:

Abnormal handling measures for items to be verified

Whether the size and type of the transmitter, register, and water meter match, replace them with transmitters or registers that are compatible with the water meter

Does the register rotate smoothly after being installed on the transmitter? Replace or repair the register to solve the problem of excessive torque

Whether the transmitter wiring and power supply are correct, correct wiring errors, and troubleshoot power supply faults

Adjust and calibrate the compatibility and calibration status of the transmitter connection device as required

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923