K-WANG

TOSHIBA TOSBERT VF-S15 series frequency converter

TOSHIBA TOSBERT VF-S15 series frequency converter

Document Overview

This document is a detailed manual for Toshiba TOSBERT VF-S15 series industrial frequency converters, suitable for controlling three-phase induction motors, built-in permanent magnet synchronous motors (IPMSMs), and surface permanent magnet synchronous motors (SPMSMs) in the general industrial field. It is explicitly prohibited to use them in equipment that may directly endanger life, such as nuclear power, aviation, medical life support, as well as in scenarios with significant public impact, such as power plants and railways. The document covers the voltage and power range of the product model, as shown in the table below:

Voltage level, phase, power range

240V level 3-phase 0.4-15kW

240V level 1-phase 0.2-2.2kW

500V level 3-phase 0.4-15kW

600V level 3-phase 1.5-15kW

Safety precautions

1. Definition of Warning Signs

The document clarifies the meanings of different warning signs through tables to ensure that users identify the risk level:

Meaning of identification

Warning operation errors can result in death or serious injury, such as electric shock or fire caused by disassembling the frequency converter

CAUTION operation error will result in minor injuries (no hospitalization/long-term outpatient service required), such as burns caused by touching the heat sink

Incorrect operation of NOTICE will result in property damage, such as equipment damage caused by dropping during transportation

2. Core security rules

Prohibited operation: Do not open the power circuit terminal cover (including high-voltage components inside) when powered on; Do not insert wires, tools, etc. into the frequency converter (to prevent short circuits); It is prohibited to use a frequency converter to drive single-phase motors (only supports specified three-phase motors).

Mandatory operation: Before installation/operation, it is necessary to read the manual; After power failure, wait for at least 15 minutes and confirm that the capacitor voltage (PA/+and PC/-) is ≤ 45V before wiring/maintenance; An emergency stop device that meets the system specifications must be installed to prevent the inability to stop the machine.

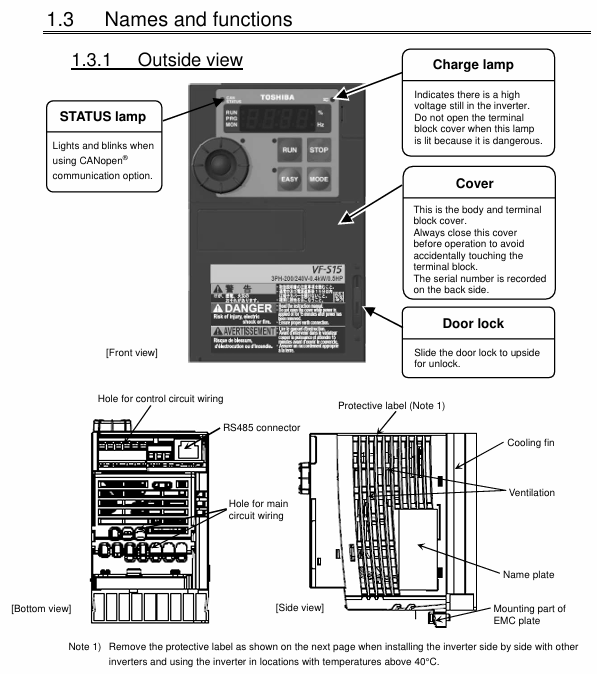

Installation and connection specifications

1. Transportation and installation requirements

Transportation taboos: It is prohibited to handle the power circuit terminal cover by hand to prevent the cover from falling off and causing the equipment to fall off; When transporting, it is necessary to wear a cover to avoid hands from entering the wiring holes (to prevent pinch injuries).

Installation environment: The ambient temperature should be between -10 ° C and 60 ° C, avoiding high humidity, dust, corrosive gases, and oil mist environments; When multiple frequency converters are installed side by side, the spacing should be ≥ 3cm, and the top protective label should be removed when the ambient temperature exceeds 40 ° C.

Load bearing and fixing: It should be installed on a metal plate that can bear the weight of the equipment, and it is prohibited to install it on flammable materials (fire prevention); Areas with significant vibration require additional anti vibration treatment.

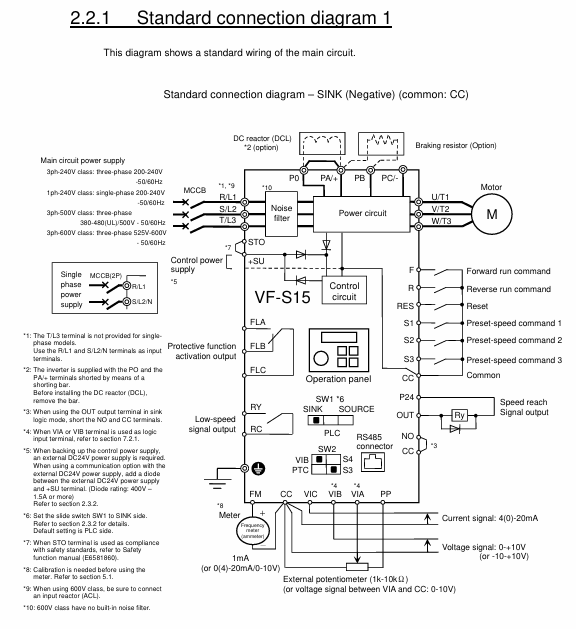

2. Wiring details

Main circuit wiring: power input terminal (3-phase is R/L1, S/L2, T/L3; The 1-phase (R/L1, S/L2/N) and motor output terminals (U/T1, V/T2, W/T3) cannot be reversed, otherwise it will damage the frequency converter and cause a fire; The braking resistor should be connected according to the manual and should not be directly connected between the DC terminals (PA/+and PC/- or PO and PC/-).

Terminal torque: The tightening torque of screws of different specifications must be strictly followed to avoid poor contact and fire hazards, as shown in the table below:

Recommended torque for screw specifications (N · m) corresponds to torque (lb · in)

M3.5 1.0 8.9

M4 1.4 12.4

M5 2.4 20.8

M6 4.5 40.0

M4 (Grounding) 1.4 12.4

M5 (Grounding) 2.8 24.8

Control circuit: The control circuit terminal block needs to be disassembled and assembled in a power-off state. The wire specification is 0.3-1.5mm ² (twisted wire), and the stripping length is 6mm. It is recommended to use a specified type of wire nose (such as the AI series of PHOENIX CONTACT).

Operation and parameter settings

1. Basic operating mode

Command mode (cmod): Used to select the control source for motor start stop, with a default value of 1 (panel operation), which can be set to 0 (terminal block), 2 (RS485 communication), 3 (CANopen communication), etc. Switching should be performed when the motor is stopped (switching is prohibited during operation when f736=1).

Frequency setting mode (fmod): used to select the input method for frequency commands. The default value is 0 (set dial 1, save frequency after power failure), and can be set to 1 (0-10V signal of terminal VIA), 4 (RS485 communication), 11 (pulse sequence input), etc.

2. Core parameter configuration

Acceleration/deceleration time: Acceleration time 1 (acc) defaults to 10.0s, deceleration time 1 (dec) defaults to 10.0s, and the unit can be changed to 0.01s through parameter f519; supports automatic acceleration and deceleration (au1=1), and the time can be automatically adjusted according to the load.

Frequency parameters: The maximum frequency (fh) defaults to 80.0Hz, the upper limit frequency (ul) defaults to be related to the setup menu, and the lower limit frequency (ll) defaults to 0.0Hz; the jump frequency (f270-f275) can be set in three groups to avoid mechanical resonance, such as f270=50Hz and f271=2Hz (jump width).

Motor protection: Electronic thermal protection level 1 (thr) defaults to 100% (based on the rated current of the frequency converter), and needs to be adjusted according to the rated current of the motor. If the rated current of the motor is 42% of the frequency converter, thr needs to be set to 42%; The overload characteristic selection (aul) can be set to 1 (constant torque 150% -60s) or 2 (variable torque 120% -60s).

Special function: Automatic restart (f301=1) can detect the motor speed and smoothly restart after an instantaneous power outage; The retry function (f303=1-10) can automatically retry after overcurrent, overvoltage, and other trips, with retry intervals increasing from 1 second to 10 seconds.

Monitoring and fault handling

1. Status monitoring

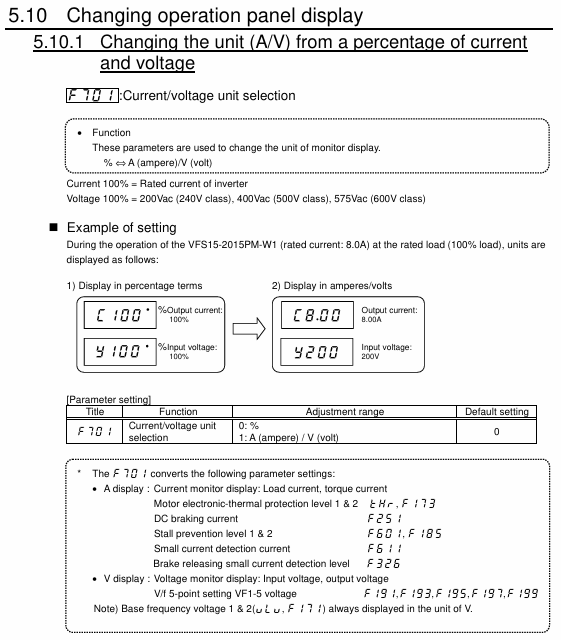

Standard monitoring mode: default display output frequency (f710=0), switchable display of output current, input voltage, etc; Supports peak hold (f709=1) and minimum hold (f709=2), triggered by EASY key (f750=3).

Status monitoring mode: It can view frequency command values, terminal input/output status, PID feedback values, etc., to help determine whether the inverter is operating normally.

2. Troubleshooting and Handling

Common causes of tripping: overcurrent (OC1-OC3, need to check motor short circuit and excessive load), overvoltage (OP1-OP3, need to check brake resistance and deceleration time), overload (OL1-OL3, need to check motor rated current and THR setting), overheating (OH, need to clean heat sink and reduce carrier frequency).

Reset requirement: After tripping, the cause of the fault must be eliminated first, and the operation command must be confirmed to be turned off (to avoid sudden motor start-up). Reset twice through the panel STOP button or terminal RES reset.

Maintenance and disposal

1. Regular inspection

Daily inspection: Check the appearance of the frequency converter daily for any damage, abnormal sounds/odors, and whether the cooling fan is operating normally.

Regular inspection: Clean the heat sink and cooling fan every 6 months; Check the tightness of the terminal screws (tighten them to the specified torque); Confirm that the grounding wire is securely connected.

2. Component replacement and lifespan management

Cooling fan: The accumulated running time can be viewed through status monitoring, and after replacement, typ=9 needs to be reset to zero; Fan failure can cause the frequency converter to overheat and trip.

Capacitor: The lifespan is calculated based on the ambient temperature (f634, default 21-30 ° C). When the accumulated operating time reaches the alarm value, it needs to be replaced in a timely manner (to avoid capacitor explosion).

3. Disposal of waste

The frequency converter needs to be disposed of by an industrial waste disposal specialist (such as "industrial waste collection and transportation personnel"), and it is prohibited to disassemble it by oneself to prevent capacitor explosion or harmful gas generation.

Compliance and Appendix

Standard compliance: The document includes compliance measures for CE certification, UL standards, and CSA standards, such as installing EMC boards and shielding wire connections; 600V level requires mandatory connection of input reactor (ACL).

Appendix information: Provide parameter default value table, terminal function table, fault code table, and differences in setup menu settings in different regions (such as EU, Asia, Japan).

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive