K-WANG

Watlow EZ-ZONE ® PM PID controller

Watlow EZ-ZONE ® PM PID controller

Product Overview

EZ-ZONE ® The PM PID controller is a high-precision process control device launched by Watlow, which has multifunctional integrated features such as PID control and limit control, and is suitable for precise control of various process parameters such as temperature and pressure. The product complies with the ISO 9001 quality standard and has multiple international certifications such as UL, CSA, CE, etc. It supports AC (85-264VAC) or DC (12-40VDC) power supply and is suitable for the diverse needs of industrial scenarios.

Core advantages include TRU-TUNE+ ® The adaptive tuning algorithm, 15A high ampere power output, parameter storage and recovery function, and NEMA 4X/IP65 protection level sealing design can operate stably in harsh environments such as dust and humidity, and are widely used in industrial heating, refrigeration, chemical and other fields.

Safety information and symbol description

(1) Definition of Security Level

NOTE: Provides key operational details to help optimize device performance.

CAUTION: Important information related to equipment protection and performance assurance must be strictly followed in accordance with operating procedures.

Warning: Key reminders related to personnel safety, equipment, and surrounding property protection that require high attention.

Electrical hazard symbol (lightning symbol within triangle): Indicates the risk of electric shock, and related operations must comply with electrical safety regulations.

(2) Meaning of core symbols

Symbol Explanation

-Warning/danger tips that need to be further explained in the user guide

-Static sensitive products require grounding and anti-static measures during installation or maintenance

-Double/reinforced insulation design to prevent electric shock risk

-Cannot be discarded at will, must be recycled according to regulations or consulted with the manufacturer for disposal

-The shell is made of polycarbonate material and requires standardized recycling or contacting the manufacturer for disposal

-Support AC or DC power supply

-Certified by UL, compliant with the US Canada process control equipment standards (UL 61010, CSA C22.2 No.61010)

-Certified by UL, suitable for Class I, Zone 2 hazardous environments (Groups A, B, C, D), in compliance with ANSI/ISA 12.12.01-2007 standard

-Compliant with EU directives, see conformity declaration for details

Installation and wiring

(1) Installation preparation

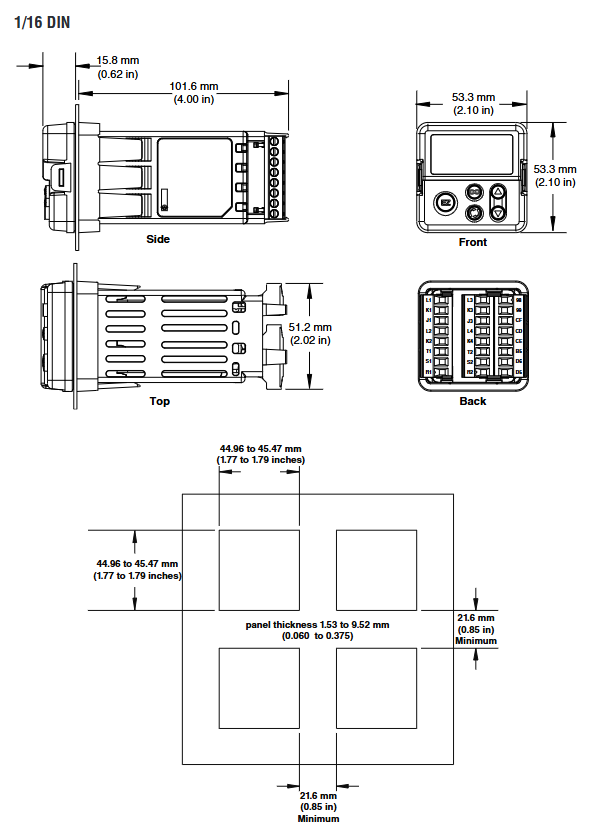

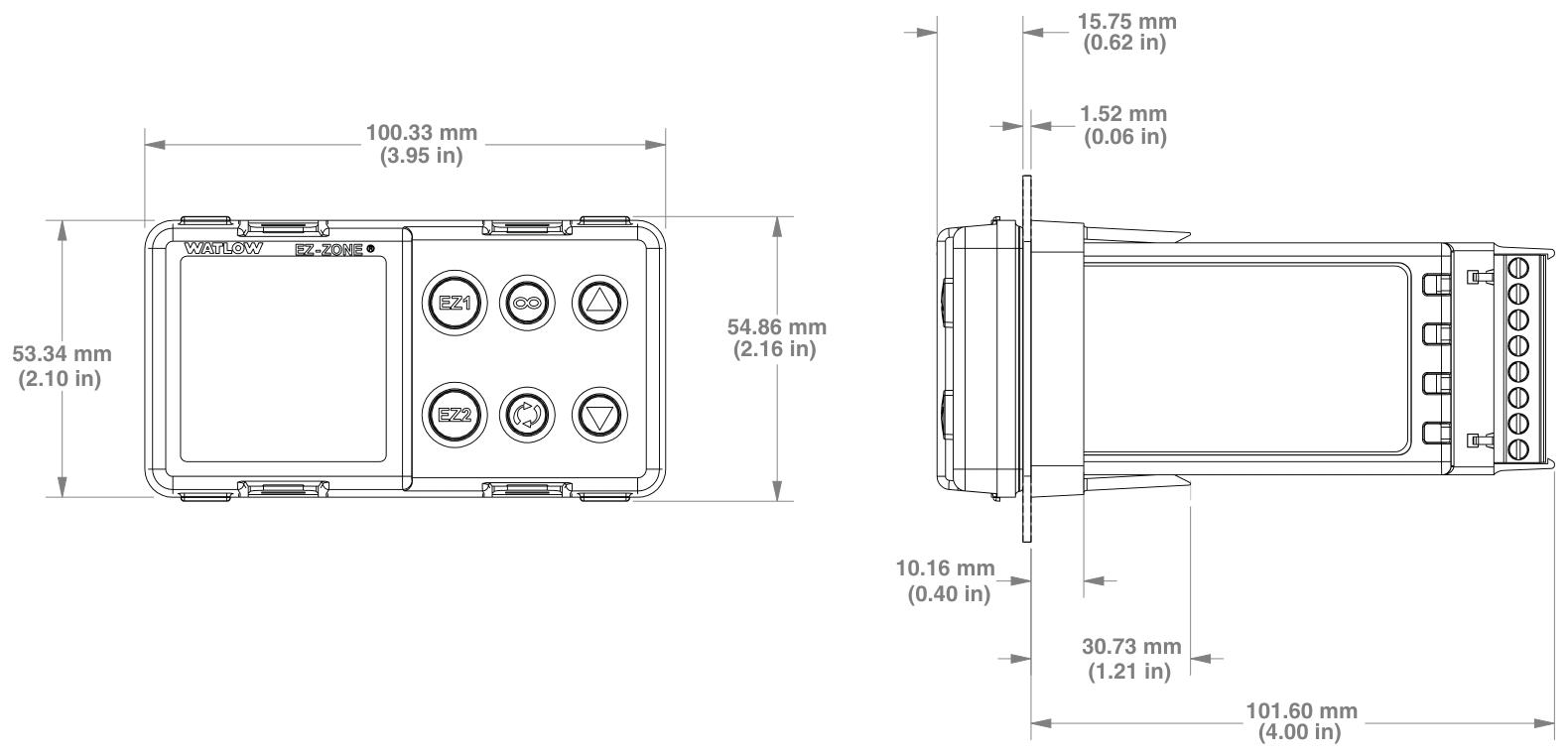

Process panel cutouts according to the size requirements of the corresponding model (1/32 DIN to 1/4 DIN), ensuring that the installation space meets the recommended spacing (such as the recommended panel spacing of 44.96-45.60mm for 1/8 DIN vertical type).

The panel thickness should be between 1.53-9.52mm to ensure a stable installation of the controller.

When installing, press the controller housing, slide the installation ring and tighten it. If NEMA 4X sealing effect is required, press the four corners of the installation ring alternately until it cannot shake.

(2) Wiring specifications

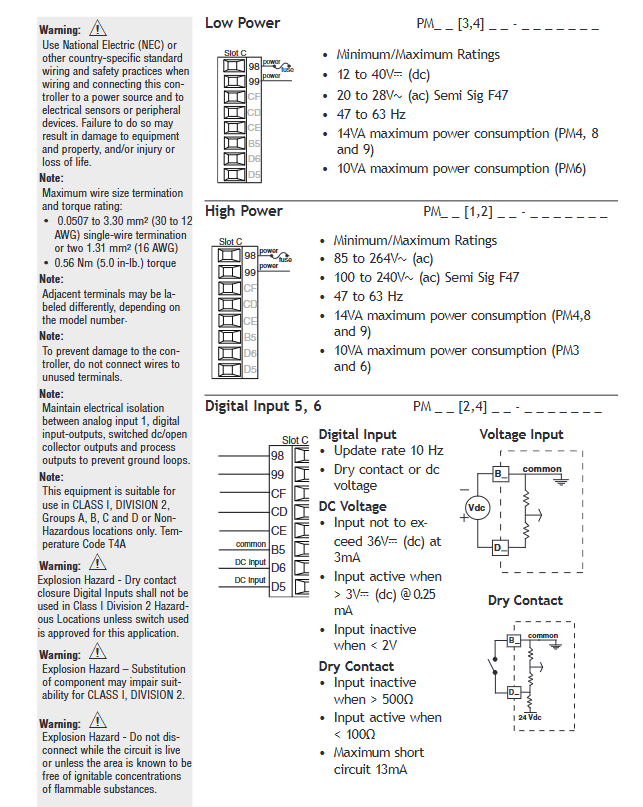

Before wiring, all power sources must be disconnected to avoid the risk of electric shock and follow NEC or local electrical standards.

Terminal wiring specifications: single wire 0.0507-3.30mm ² (12-30 AWG), or two 1.31mm ² (16 AWG) wires, with a tightening torque of 0.56 Nm (5.0 in lb).

Core terminal function:

Analog input terminal (Slot A): Supports thermocouples RTD、 Potentiometers and other inputs need to be wired correctly according to the type of sensor (such as the negative terminal of a thermocouple usually connected to the S1 terminal).

Power terminal (Slot C): Pin 98 is connected to the positive pole of AC/DC, and Pin 99 is connected to the negative pole of AC/DC.

Communication terminal: EIA-485 communication requires connecting T -/R - to terminal A and T+/R+to terminal B, using a daisy chain connection method, supporting up to 16 controllers in a network, with a maximum distance of 1200 meters.

(3) Environmental compatibility

Applicable media: acids, weak bases, alcohol, gamma rays, ultraviolet rays.

Avoid contact with strong alkalis, organic solvents, fuels, aromatic hydrocarbons, chlorinated hydrocarbons, etc.

Operation interface and navigation

(1) Key function

Key function

Adjust parameter values and switch menu options using the up/down keys; Long press for 3 seconds to enter the operation page, long press for 6 seconds to enter the settings page

Press the forward button (‰) to enter the submenu and confirm the selection; Long press for 6 seconds to enter the configuration file page

Infinite key (ˆ) returns to the previous menu; Long press for 2 seconds to return to the homepage; Clear Clearable Alarm/Error

(2) Core page navigation

Home: Default page for device power on, displaying process values (PV) and set values (SP), which can be directly adjusted.

Operation page: Press and hold the up/down keys for 3 seconds to enter, used for real-time monitoring (such as thermal power, cooling power) and temporary parameter adjustment (such as PID parameters, alarm status).

Settings page: Press and hold the up/down keys for 6 seconds to enter, used for basic configuration (such as sensor type, output mode, communication protocol).

Configuration file page: Long press the forward button for 6 seconds to enter, used for editing the slope insulation program (up to 4 files, 40 steps).

Factory page: Press and hold the forward key+infinite key for 6 seconds to enter, used for advanced functions such as calibration, password locking, and customizing the homepage.

Core functional configuration

(1) Input configuration (Settings page - Analog Input menu)

Sensor type (sEn): Select thermocouple (such as J-type), RTD (100 Ω/1k Ω), potentiometer, etc.

Range setting (r. Lo/r. hi): defines the measurement range of the input signal, such as 0-100 ° C.

Filter time (fiL): 0.0-60.0 seconds, used to smooth the input signal and reduce interference.

(2) PID control configuration

Control mode (C. ∧Џ): Supports automatic (closed-loop) and manual (open-loop) modes.

PID parameter adjustment:

Proportional band (h.pb/C.pb): 25.0 ° F (default), the smaller the value, the more sensitive the control.

Integral time (ti): 180 seconds/time (default), eliminating static errors.

Differential time (td): 0 seconds (default), suppresses overshoot.

Self tuning function (aUt): After activation, the controller automatically optimizes PID parameters, suitable for initial configuration or changes in operating conditions.

(3) Alarm configuration (Settings page - Alarm menu)

Alarm type (a.ty): Process alarm (triggered by fixed value) or deviation alarm (relative to set value).

Alarm threshold (a.Lo/a.hi): Set the trigger value for high and low alarms, such as a high temperature alarm of 300 ° F.

Alarm action (a.Lg): When an alarm occurs, output Energize (engaged) or De energize (disconnected).

Auxiliary functions: Supports locking (a. La), muting (a. Si), blocking (a. bL), etc., to avoid false alarms.

(4) Configuration file (slope insulation)

Step types: including heating (ti), insulation (SoAH), waiting for events (Ø І. E), jump (JL), etc.

Editing process: Enter the configuration file page, select the step type, and set parameters such as target temperature, time, and event output.

Startup method: The configuration file can be launched through the homepage, operation page, function keys, or numerical input.

Maintenance and troubleshooting

(1) Daily maintenance

Regularly check the tightness of the wiring to avoid looseness caused by vibration.

Sensor calibration: Use the calibration menu (CaL) on the factory page to input standard signals for offset and slope calibration.

Parameter backup: Save the parameters to User Set 1/2 through the Settings page Global menu (gLbL) for easy recovery after a failure.

(2) Common fault handling

Possible causes and solutions for fault indication

No display, power supply not connected, fuse blown. Check the power supply and replace the fuse

Alarm cannot be cleared. Alarm lock is activated, not restored to safe range. Release lock or wait for process value to return to threshold

No output action output function setting error, wiring error check output function configuration, rewiring

Process value deviates from set value, PID parameters are not optimized, sensor failure executes self-tuning, sensor inspection

Communication failure protocol mismatch, wiring error Unified communication protocol (such as Modbus RTU), check wiring

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923