K-WANG

Foxboro Evo ™ Compact 200 Series I/O subsystem of the system

Core function: Provides analog measurement, digital sensing, analog/discrete control capabilities, supporting continuous, batch, and discrete control solutions

Compatibility: Fully compatible with existing I/A Series ® The system's 200 Series I/O devices and traditional 100 Series I/O devices support upgrading and replacing existing standard 200 Series subsystems

Core value: Distributed deployment reduces on-site wiring, trunking, and conduit installation costs, and adapts to the flexible deployment needs of industrial scenarios

Foxboro Evo ™ Compact 200 Series I/O subsystem of the system

System core positioning and compatibility

Product ownership: Foxboro Evo ™ Compact 200 Series I/O subsystem for process automation systems, launched by Schneider Electric

Core function: Provides analog measurement, digital sensing, analog/discrete control capabilities, supporting continuous, batch, and discrete control solutions

Compatibility: Fully compatible with existing I/A Series ® The system's 200 Series I/O devices and traditional 100 Series I/O devices support upgrading and replacing existing standard 200 Series subsystems

Core value: Distributed deployment reduces on-site wiring, trunking, and conduit installation costs, and adapts to the flexible deployment needs of industrial scenarios

Core Components and Classification

Component type, key product, core function, key parameters

Control processor FCP280 200/100 Series FBMs control interface, supporting 4 HDLC buses and up to 128 FBMs

FCP270 is compatible with dual baud rates (2Mbps/268Kbps) and requires FBI100 to adapt to 100 Series. It supports 32 200 Series FBMs without FEM100

ZCP270 is compatible with 100 Series racks and supports up to 128 FBMs per module through FCMs communication

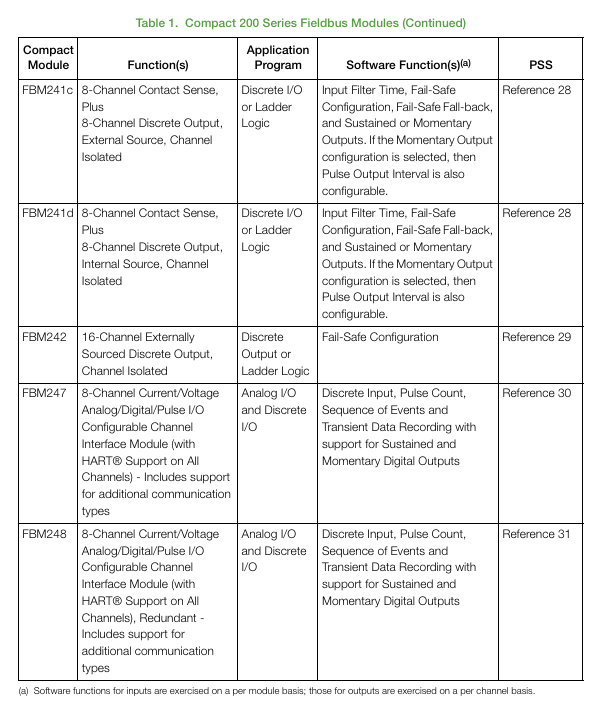

Fieldbus Modules (FBMs) Analog Input Class FBM201 (0-20mA), FBM214b (HART) ® Input channel isolation/differential isolation, 8-32 channels

Analog output class FBM215 (HART) ® Output), FBM237 (redundant 0-20mA) and other fail safe configurations (hold/fallback), 4-8 channels

Discrete I/O class FBM217 (32 channel input), FBM219 (24DI+8DO) and other group isolation/channel isolation, 8-32 channels

Hybrid I/O classes such as FBM227 (analog+discrete) and FBM247 (current/voltage/pulse) support HART ®、 Multi signal type adaptation

Auxiliary component base plate 16 slot horizontal base plate (RH101AA) supports 16 FBMs, DIN rail/19 inch rack installation

Communication module FCM100E/Et (fiber to bus conversion), FCM2F (fiber extension) FCM2F supports up to 10km single-mode fiber

Isolator FBI200 extends bus distance to 305m, isolation filtering

Shell G/K series G13/G14 (system/terminal shell), K13/K14 IP43/54 protection, suitable for ordinary/harsh environments

Key technical characteristics and advantages

performance

The analog input adopts SigmaDelta fast integration ADC, with an update speed of up to 25ms, suitable for high-speed regulation and control

Built in configurable moving average filter effectively removes electromagnetic noise

System communication speed: 100Mbps Ethernet (control network), 2Mbps/268Kbps HDLC module bus

Reliability Design

Integrating logic functions into a single ASIC chip reduces the number, volume, heat dissipation, and cost of components

Single module availability 0.999974 (redundant power supply+2-hour MTTR), redundant module availability 0.9999964

Optional redundancy: power supply, control network FCMs、 Control processors, module bus cables, and some FBMs

Deployment flexibility

Compact size: 1 16 slot compact base plate+16 FBMs space<2 standard 200 Series base plates+16 standard FBMs

Installation method: Horizontal DIN rail installation or 19 inch rack installation, supporting distributed small cabinet deployment

Cable length: shielded twisted pair 0.12-60m, fiber optic extension up to 20km (2 pairs of FCM2F10)

environmental adaptability

Pollution protection: Class G3 (ISA S71.04), suitable for harsh industrial pollution environments

Working temperature: FBMs up to 60 ℃ (140 ° F)

Safety certifications: UL (US Canada), ATEX (Explosion proof), CE (Low Voltage/EMC/ATEX Directive), RoHS compliance

System configuration and upgrade requirements

configuration scheme

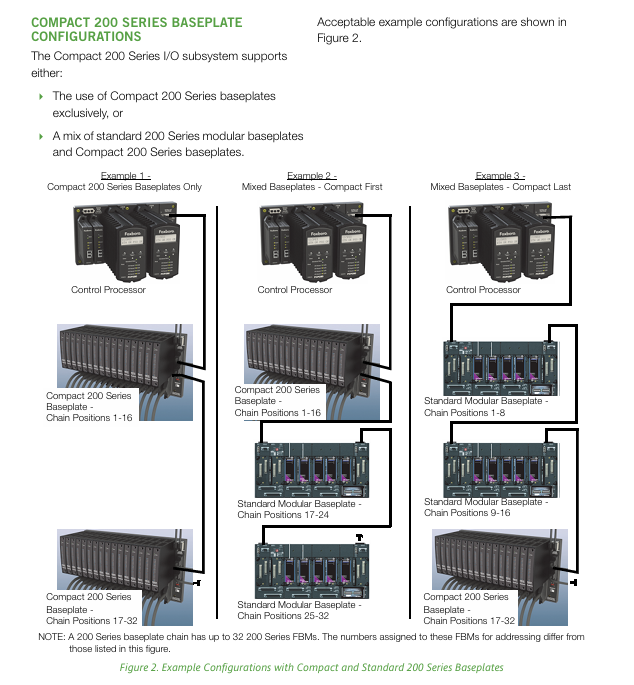

Pure compact chassis configuration: only using Compact 200 Series chassis

Mixed configuration: Compact mixed with standard 200 Series baseboard (supports compact in front/back)

Maximum scale: Up to 32 FBMs per single bottom chain, 4 bottom chains supported per FCP280

Upgrade requirements

Space requirement: The installation location should have sufficient horizontal DIN rails

Power Requirements: Supports FPS480-24/FPS400-24/FPS220-24/FPS120-24 power supplies

Cooling requirement: 1 fan tray is required for every 2 adjacent compact baseboards (1 for each baseboard when deployed separately)

Cable replacement: The terminal cable of the standard 200 Series FBMs needs to be replaced with a Compact series adapter cable

Electrical and safety regulations

Grounding requirements: comply with IEC 61000-5-1/5-2 standard (or regional equivalent standard)

Power configuration: 24V DC power supply, supports single/redundant power distribution, triggers icon color change, system alarm, and print notification in case of power failure

Isolation level: FBMs support channel isolation, differential isolation, and group isolation, with some terminal components (TA) providing additional channel isolation

Wiring characteristics: FBMs are hot swappable and do not affect external field device wiring and internal cable connections

Key questions and answers

Question 1: What are the core advantages of the Compact 200 Series I/O subsystem? What scenarios are applicable?

Answer: The core advantages are concentrated in three points: ① High reliability and availability, achieved through ASIC integrated design with high availability of single module 0.999974 and redundant module 0.9999964, suitable for continuous operation requirements; ② Flexible deployment and compact design, with a volume only half of the standard 200 Series, supporting distributed DIN rail/rack installation, reducing wiring costs; ③ Strong environmental adaptability and compatibility, Class G3 pollution protection, 60 ℃ high temperature tolerance, and compatibility with existing 100/200 Series I/O devices, supporting seamless system upgrades. Applicable scenarios include: continuous/batch/discrete control tasks in industrial sites, harsh polluted environments (such as chemical and metallurgical industries), large factories that require remote distributed deployment, and existing I/A Series ® System upgrade project.

Question 2: What are the core components of this subsystem? What are the differences in the carrying capacity of FBMs with different control processors?

Answer: The core components include: ① Control processor (FCP280/FCP270/ZCP270); ② 20+FBMs (analog/digital/hybrid I/O types); ③ 16 slot horizontal bottom plate, FBI200 isolator, FCM communication module; ④ G/K series protective casing and terminal components (TA). The differences in the carrying capacity of FBMs among different processors are as follows:

FCP280: Supports up to 128 200 Series FBMs, or 128 (100+200 Series) hybrid FBMs (up to 64 for 100 Series);

FCP270: Up to 32 200 Series FBMs without FEM100, up to 128 with FEM100, and up to 64 with 100 Series;

ZCP270: Supports up to 128 FBMs (100/200 Series) through FCM100E, with a single FCM100Et pair supporting 32 FBMs.

Question 3: What are the components of the system's redundant configuration? What is the cable length limit during deployment?

Answer: ① Redundant configuration coverage: power supply, control network, FCMs (communication modules), control processors, module bus cables, and some FBMs (such as FBM216b/FBM218); Redundant design can avoid single point failures and ensure the continuous operation of critical process circuits. ② Cable length limit:

Shielded twisted pair cable (module bus/backplane interconnection): 0.12-60m (single segment), total length of the entire 2Mbps HDLC bus ≤ 60m (including FBI200 connection);

Fiber optic cables (FCM2F series): FCM2F2 (2km), FCM2F4 (4km), FCM2F10 (10km), 2 pairs of FCM2F10 can be extended up to 20km;

Terminal Assembly (TA) and Base Plate Connection Cable: 0.5-30m.

Question 2: What are the core components of this subsystem? What are the differences in the carrying capacity of FBMs with different control processors?

Answer: The core components include: ① Control processor (FCP280/FCP270/ZCP270); ② 20+FBMs (analog/digital/hybrid I/O types); ③ 16 slot horizontal bottom plate, FBI200 isolator, FCM communication module; ④ G/K series protective casing and terminal components (TA). The differences in the carrying capacity of FBMs among different processors are as follows:

FCP280: Supports up to 128 200 Series FBMs, or 128 (100+200 Series) hybrid FBMs (up to 64 for 100 Series);

FCP270: Up to 32 200 Series FBMs without FEM100, up to 128 with FEM100, and up to 64 with 100 Series;

ZCP270: Supports up to 128 FBMs (100/200 Series) through FCM100E, with a single FCM100Et pair supporting 32 FBMs.

Question 3: What are the components of the system's redundant configuration? What is the cable length limit during deployment?

Answer: ① Redundant configuration coverage: power supply, control network, FCMs (communication modules), control processors, module bus cables, and some FBMs (such as FBM216b/FBM218); Redundant design can avoid single point failures and ensure the continuous operation of critical process circuits. ② Cable length limit:

Shielded twisted pair cable (module bus/backplane interconnection): 0.12-60m (single segment), total length of the entire 2Mbps HDLC bus ≤ 60m (including FBI200 connection);

Fiber optic cables (FCM2F series): FCM2F2 (2km), FCM2F4 (4km), FCM2F10 (10km), 2 pairs of FCM2F10 can be extended up to 20km;

Terminal Assembly (TA) and Base Plate Connection Cable: 0.5-30m.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923