K-WANG

Schneider Tricon ™ V9-v11 Systems High Fault Tolerant Programmable Logic and Process Controllers

Core architecture: Triple Modular Redundancy (TMR) is adopted, with three independent channels executing control programs in parallel. Digital inputs and outputs are subject to majority voting through hardware/software mechanisms, while analog inputs are selected using median selection to ensure data integrity.

Key features: Supports online installation and maintenance, remote I/O expansion (up to 12 kilometers through SRXM module), enhanced diagnostic monitoring, and multi protocol communication interconnection.

Schneider Tricon ™ V9-v11 Systems High Fault Tolerant Programmable Logic and Process Controllers

Overview of System Core

Product positioning: Tricon v9-v11 is a high tolerance error controller under Schneider Electric, designed specifically for safety critical applications. Its core advantage is fault tolerance, which can maintain error free control in the event of component hard or transient faults.

Core architecture: Triple Modular Redundancy (TMR) is adopted, with three independent channels executing control programs in parallel. Digital inputs and outputs are subject to majority voting through hardware/software mechanisms, while analog inputs are selected using median selection to ensure data integrity.

Key features: Supports online installation and maintenance, remote I/O expansion (up to 12 kilometers through SRXM module), enhanced diagnostic monitoring, and multi protocol communication interconnection.

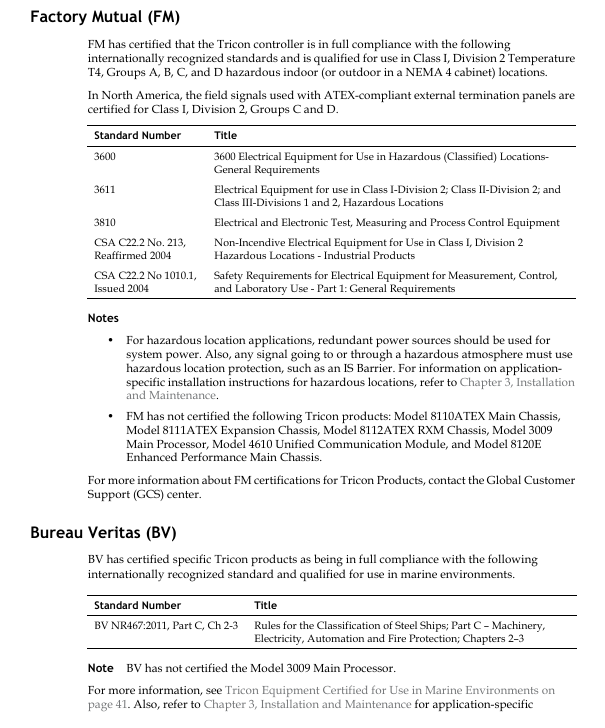

International certification: Passed multiple certifications such as CSA in Canada, FM in the United States, T Ü V Rheinland in Germany, and the Nuclear Regulatory Commission (NRC) in the United States, and meets standards such as IEC 61508 (SIL 1-3) and ATEX Zone 2.

Hardware Components and Configuration

Component type, key models/parameters, core functions

The main chassis 8110 (supporting 6 sets of I/O modules) and 8120E (enhanced, supporting UCM modules) accommodate the main processor, power module, and provide I/O expansion bus

Expansion chassis 8111 (8 sets of I/O modules), 8121 (low density, supporting HART modules) to expand I/O capacity, with a distance of ≤ 30 meters from the main chassis

Remote chassis RXM 8112 supports remote I/O expansion, up to 12 kilometers away

Main processors (MP) 3006/3007 (v9.0-9.5), 3008 (v9.6-10. x), 3009 (v11. x) execute control programs, manage I/O and communication, TriBus speed up to 1000 Mbps

The power module 8310 (120 VAC/DC), 8311 (24 VDC), and 8312 (230 VAC) are designed with dual redundancy. A single module can support the entire chassis load and output 6.5 VDC

The I/O module supports analog input (3700A/3703E), digital output (3604E/3625), thermocouple input (3708E), and supports analog input (0-10 VDC/4-20 mA), digital input (24-115 VAC/DC), pulse signal acquisition and output

Communication modules TCM (supporting Ethernet/Modbus), UCM (compatible with Foxboro Evo), and HART modules (2770H/2870H) enable communication with DCS systems and external devices, and support OPC and GPS time synchronization

Working principle and fault-tolerant mechanism

Redundant workflow: Three main processor channels independently execute control programs, synchronize data through TriBus, perform "2/3 voting" on digital input and output, and take the median of analog input to ensure that faulty channel data does not affect the final result.

Fault tolerance: When a single channel hardware fails, the other two channels automatically take over the function, and the faulty module can be replaced online without interrupting the controlled process; The power module and communication link both support redundant configuration.

Data processing: The input module microprocessor filters signals and diagnoses faults, the output module verifies output status and diagnoses wiring issues, and the main processor achieves data synchronization and error correction through TriBus.

Core functions and technical specifications

Hardware scalability

Chassis extension: up to 15, main chassis+extension chassis+remote chassis combination

I/O Capacity: Analog input/output up to 1024/512 points, digital input/output up to 2048 points, pulse input up to 80 points

Remote Expansion: Supports remote I/O connections up to 12 kilometers through RXM/SRXM modules

Communication and Interconnection

Supported protocols: Modbus (RTU/ASCII), TSAA, HART, TCP/IP, SNTP, etc

Interconnected systems: Foxboro I/A Series/Evo, Honeywell TDC-3000/UCN and other DCS

Communication speed: TriBus (4-1000 Mbps), I/O bus (375 Kbps), Ethernet (10/100 Mbps)

Diagnosis and maintenance

Diagnostic tool: EnDM software integration, real-time monitoring of hardware status, communication links, and program operation

Status indication: Each module is equipped with PASS/AULT/CTIVE indicator lights, supporting fault location

Online maintenance: The module is hot swappable and can be replaced without interrupting the on-site I/O signal

environmental adaptability

Working temperature: 0-60 ℃, storage temperature: -40-75 ℃

Humidity: 5% -95% (without condensation)

Corrosion grade: Class G3 (compliant with ISA S71.04 standard)

Vibration shock: 1 G (8.4-150 Hz), 15 G (6-11 ms)

Applicable scenarios and authentication

Typical Applications

Safety Instrumented System (SIS): Emergency Shutdown Interlock for Chemical and Petroleum Refining

Nuclear power applications: 1E level nuclear safety related controls

Marine environment: Ship automation certified by BV classification society

Other: Fire gas detection, semiconductor manufacturing safety control

Key certification

Electrical safety: CSA C22.2 No. 61010-1, UL 61010-1

Functional safety: T Ü V Rheinland IEC 61508 (SIL 1-3)

Hazardous environment: ATEX Zone 2, Class I Division 2

Nuclear Power Certification: NRC 1E Application Certification

Key issue

Question 1: What is the core redundancy mechanism of the Tricon v9-v11 system? How to ensure fault tolerance?

Answer: The core adopts a Triple Modular Redundancy (TMR) architecture, with three independent channels executing control programs in parallel. Input and output are processed through a hardware voting mechanism - digital quantities use "2/3 majority voting", and analog quantities use "median selection"; When a single channel fails, the other two channels automatically take over the function, and the faulty module can be replaced online without interrupting the controlled process. The power module and communication link support redundant configuration to ensure that the system has no single point of failure.

Question 2: What key hardware extensions does the Tricon v9-v11 system support? What is the maximum configuration limit?

Answer: Hardware expansion includes chassis expansion (main chassis/expansion chassis/RXM remote chassis), I/O module expansion (analog/digital/pulse/thermocouple, etc.), communication module expansion (TCM/UCM/ACM, etc.), and remote I/O expansion (up to 12 kilometers through SRXM module); The maximum configuration limit is 15 chassis and 118 I/O modules, supporting up to 2048 digital input/output points, 1024 analog input points, and 512 analog output points.

Question 3: What are the applicable scenarios and core certifications for the Tricon v9-v11 system?

Answer: Suitable for safety critical scenarios such as chemical safety instrumented systems (SIS), petroleum refining process control, nuclear power 1E level applications, marine automation, and fire gas detection; Core certifications include electrical safety (CSA, UL), functional safety (T Ü V Rheinland IEC 61508 SIL 1-3), hazardous environments (ATEX Zone 2), nuclear power certification (NRC), marine certification (BV), etc., meeting compliance requirements for industrial applications in multiple global locations.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923