K-WANG

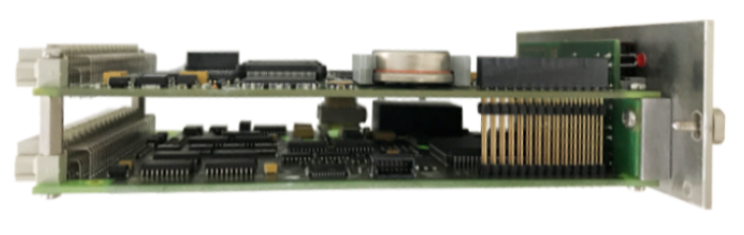

HIMA F8650X Central module

HIMA F8650X Central module

Central module with two clock-synchronized microprocessors

Microprocessors:INTEL 386EX, 32 bits

Clock frequency:25 MHz

Memory per microprocessor

Operating System:Flash-EPROM 1 MB

User program:Flash-EPROM 1 MB

Data:SRAM 1 MB

Interfaces Diagnostic display Shutdown on fault:Two serial interfaces RS 485 with electric isolation

Four digit matrix display with selectable information Safety-related watchdog with output 24 V,

loadable up to 500 mA, short-circuit proof Two European standard PCBs,one PCB for the diagnostic display

For the serial interface only the bus station no. 1-31 can be set.

Within an Ethernet network the bus station no. can be set from 1 to 99. Therefore the switches S1-6/7 must be set in addition to the switches S1-1/2/3/4/5.

The number of the communication partners within a network is still limited to 64.

This enhanced setting of the bus station no. is only possible from operating system BS41q/51q V7.0-8 (05.31) of the central module.

Applications with the communication module F 8627X:– connection of the central module to a PADT (ELOP II TCP)– connection to other communication partners within an Ethernet network (safeethernet, Modbus TCP)

The communication runs from the central module via the backplane bus to the communication module F 8627X and from the Ethernet ports of the F 8627X into the Ethernet network and vice versa.

Special features of the central module:– Self-education: from operating system BS41q/51q V7.0-8 (05.31)– ELOP II TCP: from operating system BS41q/51q V7.0-8 (05.31)

Further informations about the bus station no., ELOP II TCP, loading of operating systems and application programs (self-education) et al. corresponding to the central module you will find in the data sheet of the F8627X as well as the operating system manual of H41q/H51q and the safety manual of H41q/H51q

Diagnostic display of the central module– Four digit alphanumerical display,– two LEDs for the general display of errors (CPU for the central modules, IO for the testable

input/output modules),– two toggle switches to request detailed error information,– push-button ACK resets the error indication; in failure stop ACK behaves like restarting the system.

For further information on the diagnostic display and lists of error codes, refer to the documen tation "Functions of the operational system BS 41q/51q" (also on ELOP II CD).

Notes for start-up and maintenance– Lifetime of the buffer battery (without voltage feeding):

1000 days at TA = 25 °C

200 days at TA = 60 ° C– It is recommended to change the buffer battery (CPU in operation) at the latest after 6

years, or with display BATI within three months

(Lithium battery, e.g. type CR 2477N, HIMA part no. 44 0000018)– Check the bus station no. and transmission rate at switch S1 for correct settings– Important: When upgrading an F 8650 to an F 8650X module the fan concept has also to be changed!

Specification parameters

Processor: Adopting a dual core ARM Cortex-A9 processor, some data shows that there is also an Intel 386 ex (32-bit) processor with dual clock synchronization, with a clock frequency of 25MHz. This high-performance processor configuration ensures excellent performance and reliability in complex industrial environments, meeting the computational requirements of various complex control tasks.

Memory: Equipped with 2GB of RAM and 8GB of Flash, there are also data indicating that each microprocessor has 1MB of Flash EPROM (for shared space between the operating system and user programs) and 1MB of SRAM. Adequate memory space provides a guarantee for storing critical programs and data, ensuring efficient operation even under high load conditions.

Communication port: It has rich communication interfaces, including Ethernet, USB, RS 232, and RS485. These communication ports support multiple communication protocols, facilitating seamless integration with various control systems, promoting efficient data exchange, improving system response speed, and meeting the connection requirements of different industrial network architectures.

Working temperature: The working temperature range is -20 ° C to 60 ° C. Its sturdy design enables it to withstand harsh environmental conditions, whether it is a high-temperature industrial production site or a cold outdoor environment, ensuring stable operation of the equipment and reducing the risk of failure caused by changes in environmental temperature.

Power supply: 24V DC power supply is used, and some mentioned working data is 5V/2A. The stable power input ensures that the module continues to work stably under various working conditions, ensuring the reliable operation of the entire control system.

Size and weight: The size is approximately 4cm x 18.5cm x 12.7cm (1.6in x 7.3in x 5in), with a weight of 0.32kg (0.7lb). The lightweight design and reasonable size make it easy to install and layout in various control cabinets, saving space without affecting their performance.

Key Features

High performance processing capability: With powerful processor configuration, it can quickly process large amounts of complex data and control instructions, meet the strict requirements for real-time and accuracy in industrial automation, and ensure the efficient and stable operation of the production process.

Redundant architecture: By adopting redundant design, the reliability of the system has been improved. When some components fail, redundant parts can take over the work in a timely manner, ensuring the uninterrupted operation of the system, greatly reducing the risk of production interruption caused by system failures, and improving the continuity and stability of production.

Integrated safety function: certified to SIL 3/Cat. 4 safety level, following the IEC 61508 international safety standard, with multiple safety mechanisms built-in, such as safety related watchdogs that can output signals in a timely manner for safe shutdown in case of faults, effectively preventing accidents and providing reliable safety protection for industrial production.

Flexible communication options: Rich communication interfaces and widely supported communication protocols enable convenient communication with devices and systems of different brands and types, facilitating the construction of complex industrial automation networks and achieving interconnectivity and collaborative work between devices.

Easy to configure and maintain: With intuitive programming functions and user-friendly interface, engineers and technicians can quickly configure and troubleshoot the system without extensive training, reducing the difficulty and cost of system maintenance and improving maintenance efficiency.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

-

BENTLY NEVADA 3500/15 133292-01 Power Supply Module

-

ABB PM877 3BDH000777R1 Central_Unit Controller

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor