K-WANG

Schneider Electric Foxboro ™ DCS FPS480-24 Compact Power Supply

Schneider Electric Foxboro ™ DCS FPS480-24 Compact Power Supply

Product positioning and core applications

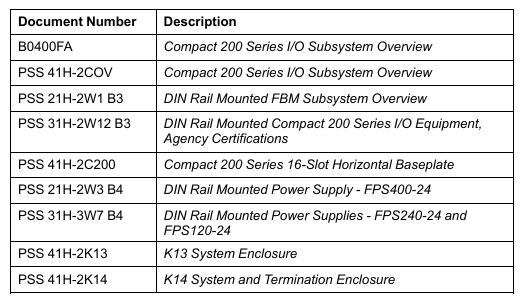

Foxboro ™ DCS FPS480-24 is a 480W compact DC power supply launched by Schneider Electric, belonging to the Foxboro DCS system supporting equipment under the EcoStruxure architecture. Its core function is to provide stable 24V DC power supply for DCS system loads (such as FCP280 controller, Compact/Standard 200 series I/O subsystem equipment), and can also be expanded to power external field devices. Its design is compatible with K13 system enclosures and K14 system and terminal enclosures, supports customized configurations (meeting power consumption and wattage requirements), and has passed ATEX, UL, UL-C certifications. It can be used in Class 1, Division 2 (North America), and Zone 2 (International) hazardous areas, especially suitable for DCS system power supply needs in harsh industrial environments.

Core Features and Advantages

(1) Wide range input and high efficiency

Flexible input adaptation: automatically compatible with alternating current (AC) and direct current (DC) inputs, with an AC input range of 85-264V AC (47-63Hz, single-phase) and a DC input range of 120-264V DC (output reduced to 90% when 108-119V DC), meeting the voltage standards of power grids in different regions around the world without the need for additional transformers.

High efficiency and energy saving: With an efficiency of up to 94% (at 230V AC input), low energy consumption reduces operating costs. Based on average electricity prices and load calculations, the return on investment (ROI) can be less than 2 years; Built in power factor correction (PFC) circuit, with a power factor close to 1 when AC input (0.98 at 115V AC and 0.92 at 230V AC), reducing harmonic interference in the power grid.

(2) Security protection and reliability

Multiple protection mechanisms

Overcurrent protection: dual stage current limitation, automatically shuts down when the load current exceeds 105% of the rated value (at 25 ° C) for more than 4 seconds; The typical value of short-circuit current is 48A, and the output constant current setting value is about 32.5A to avoid short circuit damage to the equipment.

Overvoltage protection: When the output voltage is abnormally high, it will automatically shut down. The input power supply needs to be disconnected (within 30 seconds) to reset, and the power supply will be restored after troubleshooting.

Isolation and Insulation: The insulation resistance between input-output, output casing, and input-output casing is greater than 100M Ω (tested at 500V DC), and the insulation strength meets industrial safety standards to prevent leakage risks.

Environmental adaptability: The shell is coated with a conformal coating to prevent corrosion; The protection level and environmental tolerance meet the G3 level harsh environment standard, supporting working temperatures of -25~70 ° C (load linearly reduced to 75% at 60-70 ° C), relative humidity of 5-95% (no condensation), altitude of -300~3000m (storage altitude up to 12000m), no need for fans, and reducing mechanical failure points through natural convection heat dissipation.

(3) Compliance in hazardous areas

Complete certification: UL/UL-C certification (compliant with UL60950-1 and UL508 standards), ATEX certification (Ex nA IIC T3), IECEx certification, can be used in Class 1, Division 2 (Groups A-D), Zone 2 (IIC explosion group) hazardous areas, as an "associated device" to power non flammable communication circuits (requires coordination with designated processor modules, refer to the DIN Rail Installation Subsystem User Guide).

Technical specifications

(1) Input and output parameters

Category specification details

Input specifications - AC input: 85-264V AC (47-63Hz, single-phase), input current 4.5A at 115V AC, 2.3A at 230V AC

-DC input: 120-264V DC (108-119V DC with 90% derating), input current 4.5A

-Starting voltage: typical value 71.6V AC, shutdown voltage: typical value 66.7 V AC

Output specification - Output voltage: 24.0V DC (factory set ± 0.2V DC)

-Voltage regulation rate: Line regulation rate 96mV, load regulation rate 240mV

-Output current: rated 20A (480W), maintained at 20A at 60 ° C, reduced to 15A (360W) at 70 ° C

-Ripple and noise: typical value of 240mVpp, maximum value of 600mV (at -25~0 ° C)

-Temperature coefficient:<0.02%/° C

-Soft start time:<1 second (115V AC input)

-Holding time: 14ms (full power, 115/230V AC input)

(2) Physical and installation specifications

Installation method: Horizontal DIN rail installation (standard DIN rail bracket and fixture), detachable bracket supports panel installation.

Dimensions and Weight: The nominal dimensions are approximately 123mm (length) x 88mm (width) x 82mm (height), with a net weight of 1.3kg (2.87lb) and a gross weight of 1.45kg (3.2lb). The compact design saves cabinet space.

Connection method: M3 screw terminal connection, input and output cables need to be provided by the user. It is recommended to use 14AWG (high current circuit) or 18AWG (low current circuit) wires.

(3) Status monitoring and alarm

LED indication: Green "DC OK" LED indicates output voltage>19.2V (normal operation); The red "Peak" LED indicates that the output voltage is less than 80% of the rated value (under voltage or overload).

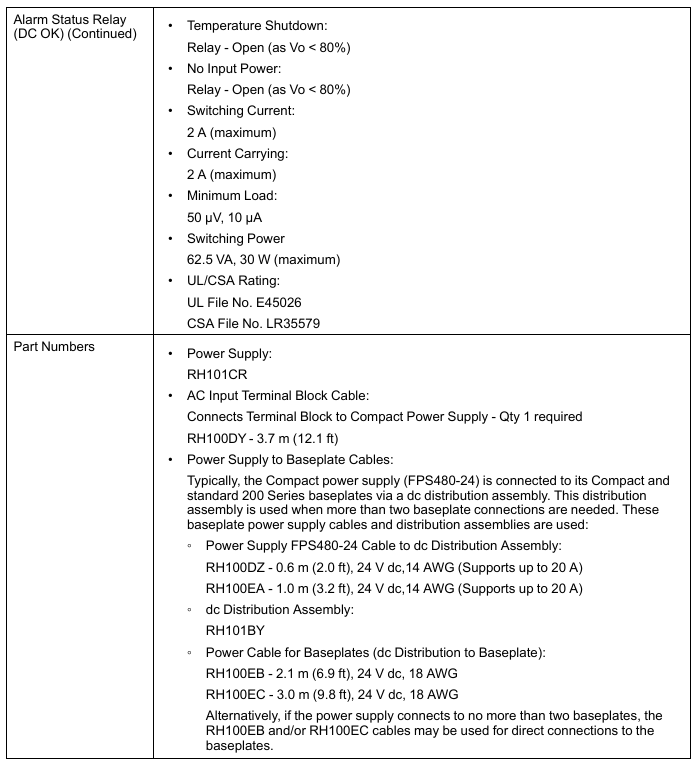

Relay alarm: The "DC OK" normally closed (NC) relay contacts close when the output voltage is greater than 80% of the rated value, and disconnect when it is less than 80% (such as short circuit, overload, or no input power). External alarm can be triggered by external modules such as FBM207b. The rated load of the relay contacts is 30V DC/1A, 110V DC/0.3A, 125V AC/0.5A, with insulation strength of 1000V AC (between contacts) and 1500V AC (between coils and contacts).

Environment and Compliance

(1) Environmental tolerance

Environmental indicators, operating range, storage range

Temperature -25~70 ° C (-13~158 ° F), linear load derating at 60-70 ° C -40~70 ° C (-40~158 ° F)

Relative humidity 5-95% (no condensation) 5-95% (no condensation)

Altitude -300~3000m (-1000~10000ft) -300~12000m (-1000~40000ft)

Vibration<19.6m/s ² (2G)-

(2) Electromagnetic Compatibility (EMC) and Safety Certification

EMC compliance: Compliant with IEC/EN 60950, UL60950-1, UL508, Semi F47 (only 200V AC) and other standards, with conducted emission (EN55022-B/CISPR22-B), radiated emission (EN55022-B/CISPR22-B), harmonic current (IEC61000-3-2 Class A) and other indicators meeting standards. Anti interference capabilities include: 8kV contact discharge/15kV air discharge (ESD), 2kV electrical fast transient (EFT), 2kV line to ground/4kV line to neutral lightning surge, 10V conducted RF common mode interference, etc.

Safety certification: UL file number E45026, CSA file number LR35579; ATEX certification (Ex nA IIC T3), CENELEC certification, meeting the requirements for use in hazardous areas; California Proposition 65 Warning: Products containing lead and lead compounds may cause cancer or reproductive harm. For more information, please refer to www.p65warnings. ca.gov.

Accessories and Connection Configuration

(1) Core accessory model

Accessory name, model, and purpose

The RH101CR core power supply unit of the power host provides 24V DC/20A output

AC input terminal block cable -1 cable is required to connect the terminal block to the power host

Connect the power supply to the Compact/Standard 200 series motherboard using RH100DY (3.7m), RH100DZ (0.6m), and RH100EA (1.0m) cables, with 14AWG supporting 20A current

DC distribution component RH101BY is used for multi board connection to achieve power distribution

Bottom board power cable (distribution component to bottom board) RH100EB (2.1m), RH100EC (3.0m) 18AWG, directly connecting the distribution component to the bottom board, supporting up to 2 bottom board direct connections

(2) Connection precautions

If only 1-2 base plates are connected, RH100EB/RH100EC cables can be directly used; If more than 2 baseboards are connected, power must be distributed through the RH101BY distribution component to avoid current overload.

It is recommended to use an independent power supply for external on-site equipment to avoid non system loads affecting the stability of DCS system power supply; All wiring must be fastened with M3 screw terminals to ensure reliable contact.

Key points for use and maintenance

Calibration requirements: The power supply is pre-set with a 24.0V DC output at the factory, which does not require user calibration or voltage adjustment, reducing maintenance workload.

Fault handling: After shutting down due to overvoltage/overcurrent, the input power supply should be disconnected first (within 30 seconds), and load faults (such as short circuits and overloads) should be checked before powering on again to restore power; When the "DC OK" relay is disconnected, it is necessary to check whether the output voltage is less than 80% of the rated value (19.2V DC), and troubleshoot input power supply, load, or internal power supply faults.

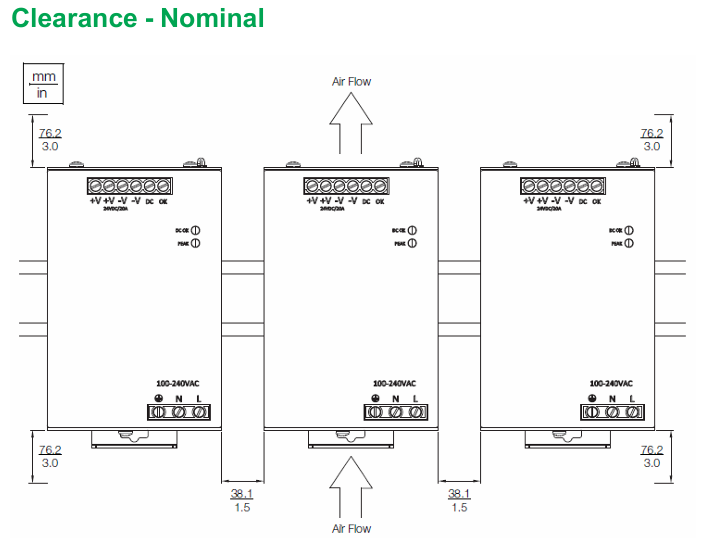

Installation spacing: To ensure natural convection heat dissipation, a ventilation gap of at least 76.2mm (3.0in) should be reserved around the power supply to avoid installation in close proximity to heating equipment.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923