K-WANG

KOLLMORGEN E/H Series Stepper Motor

KOLLMORGEN E/H Series Stepper Motor

Brand and Product Positioning

Kollmorgen is a brand under Regal Rexnord, and is one of the few companies in the world that can independently research and produce a full range of motion control products such as servo motors, stepper motors, drivers, controllers, etc. Its core advantage is precise torque, speed, and position control, which can improve equipment OEE (overall equipment efficiency). The products are widely used in high-end industries such as aerospace, warehouse automation, medical imaging, pharmaceuticals, oil and gas, robots, and even suitable for high-precision scenarios such as Mars exploration and artificial heart. This guide is the exclusive selection material for its E/H series stepper motors, which focuses on solving the design, procurement, and time barriers of OEM engineers, supporting standard product modification and fully customized solutions.

Series Core Basic Features

The E/H series is a circular frame stepper motor, divided into two types: * * E3/H3 (NEMA 34, 90mm) and E4/H4 (NEMA 42110mm) * *. The core features are as follows:

Performance: Maintaining a maximum torque of 27.95 N-m (3958 oz in), the E series is equipped with SIGMAX ™ Technology, with higher torque and acceleration rate, the H series is the standard model;

Sports foundation: 200 full steps per revolution, step accuracy of E series ± 1.5%, H series ± 3.0% (single step without load);

Environment and certification: UL, CE compliance, RoHS certification; NEMA 34/42 is UL approved, IP65 protection (C/M/L structure+shaft seal), insulation class B (130 ° C), insulation voltage 340 Vdc, insulation resistance 100 M Ω;

Working temperature: -20 ° C~+40 ° C, supporting high-speed and fast movement scenarios.

Key Technical Parameters and Structure

Winding and Connection Method

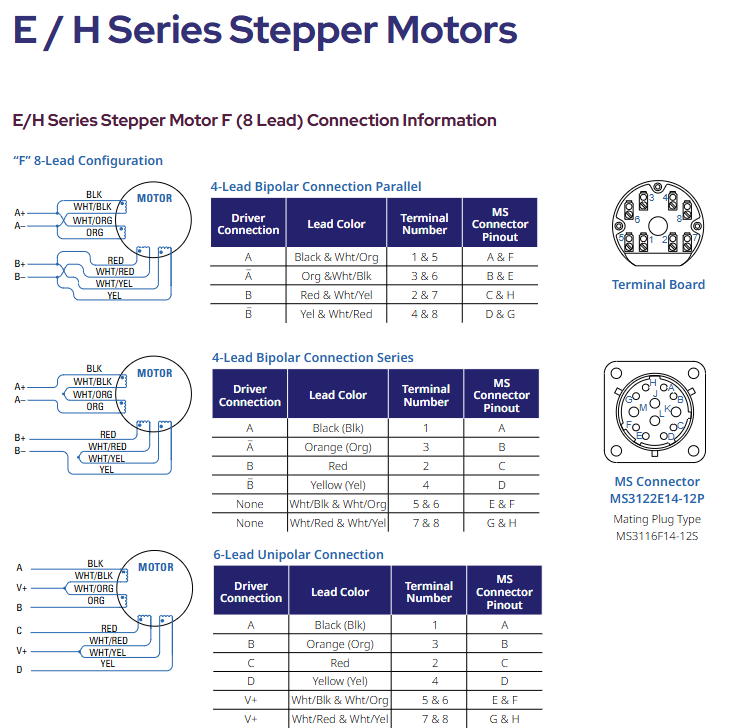

Supports unipolar/bipolar winding, providing three core configurations of 4/6/8 leads, including parallel/series bipolar connection, unipolar connection, and matching MS connectors (such as MS3122E14-12P), terminal boards, and flying wires. Different connection methods correspond to clear lead colors, terminal numbers, and connector pin definitions, as shown in the table below:

table

Connection type, lead number adaptation, driver core connector

Bipolar parallel/series 4/8 bipolar driver MS3122E14-12P

Single pole 6/8 single pole driver terminal board (1/2 NPSC pipe thread)

Universal 8 Single/Double pole Flywire (# 18/# 22 AWG)

Motor Structure and Customization

Installation method: Standard NEMA/Heavy NEMA, with 3 stacks available for heavy duty and 4 stacks standard for heavy duty;

Axis configuration: single axis/dual axis, with support for flat keys, # 303 wood ruff keys, optical axis and other modifications at the shaft end. Dual axis is only suitable for standard installation (non splash proof);

Protection and packaging: splash proof (L/M structure) with 1/2 NPSC/PG11 threaded terminal board, standard version with fly wire/MS connector;

Customization options: special shaft modification, customized winding, lead length/connector, encoder installation position, etc., supporting full process collaborative design.

Core Performance Parameters (Stacked Type)

E3/H3 is divided into 1/2/3/4 stacks, E4/H4 is divided into 1/2/3 stacks. The core performance indicators include holding torque (2 phases connected to the power), rated phase current, phase resistance, phase inductance, rotor inertia, weight, etc., and the E series (enhanced version) has significantly higher performance than the H series (standard version) of the same specifications. The key core data are as follows (selected from typical models):

table

Type Stack Number Holding Torque (oz in/Nm) Rated Phase Current (A DC) Rotor Inertia (kg-m ² × 10 ⁻ ³) Weight (kg)

E31xxHP-L 1 344/2.43 8.4 0.0586 1.45

E33xxHP-L 3 995/7.03 7.9 0.177 3.45

E41xxHA-L 1 1380/9.74 10.6 0.565 4.94

E43xxHC-L 3 3720/26.3 13.3 1.69 11.7

Note: The entire E4/H4 series needs to be installed on a 10 × 10 × 1/4 inch thick aluminum plate to meet the torque rating and not exceed the allowable temperature rise.

Encoder Options

Equipped with optical incremental encoder (PF/PD) as standard, it is a dedicated feedback accessory for the E/H series. Core parameters:

Resolution: 1000 lines/rev, dual channel orthogonal output+index (Z) signal;

Output type: differential line drive (with complementary), output frequency of 100 kHz;

Environment: working/storage temperature * * -40 ° C~100 ° C * *, power supply voltage ± 10%;

Connection: 10 pin IDC connector, equipped with 18 inch minimum length ribbon cable, matched with MS3122E12-10P connector.

Model Naming Rules

The E/H series models are a combination of multiple encoding segments, with core dimensions (taking E 3 3 H C H P-L E K - M2-01 as an example):

Basic Series: E (SIGMAX) ™ Enhanced version/H (standard version);

Frame number: 3 (NEMA34)/4 (NEMA42);

Number of rotor stacks: 1/2/3/4 (H series optional half stack H);

Installation method: N (standard NEMA)/H (heavy-duty NEMA);

Structure/Connection: R (Flywire)/C (MS connector)/L/M (splash proof terminal board);

Number of leads: H (4 in parallel)/L (4 in series)/E (6)/8 (8);

Winding type: P (high-speed high torque)/A/B/C (standard)/S (customized);

Rotor type: L (laminated)/low inertia (NEMA23 only);

Axis configuration: N (single axis)/D (dual axis)/E (encoder dual axis);

Axis modification: N (optical axis)/F (flat key)/K (straight key)/W (wood ruff key);

Encoder options: NS (no feedback)/M2 (HP installation position)/M3 (BEI installation position);

Special sequence: 00 (no shaft seal)/01 (with shaft seal, only 3/4 frames).

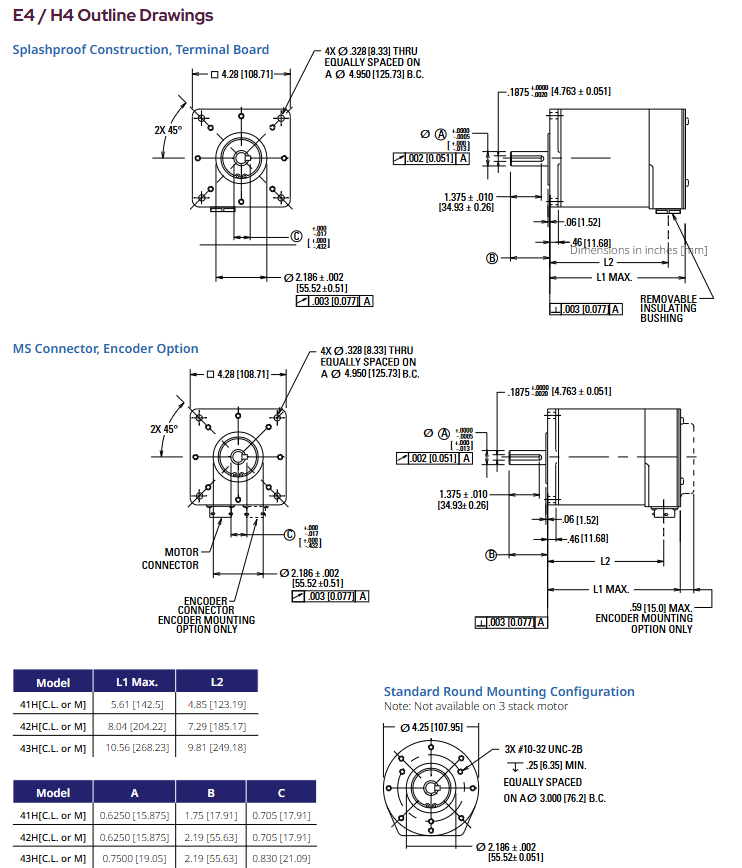

Dimensional Drawings

The document provides detailed two-dimensional dimension drawings of the full structure of E3/H3 and E4/H4, all marked in inches/millimeters, with different installation methods (standard/heavy-duty), connection structures (flying wire/MS connector/splash proof terminal board), and encoder installation positions. The dimensional parameters include key indicators such as external dimensions, shaft diameter, installation hole position, and lead length. For example, the maximum length of E31NR (1-stack standard version) is 2.58 inches (65.5 millimeters), and the maximum length of E43HC (3-stack heavy-duty MS connector version) L1 is 7.62 inches (193.6 millimeters).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923