+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

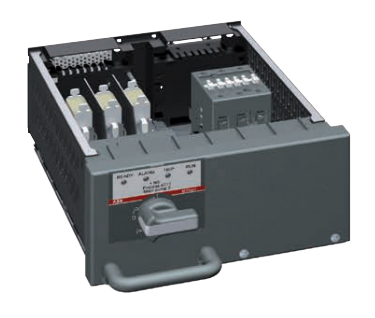

ABB MNS iS motor control center

ABB MNS iS motor control center

ABB MNS iS motor control center

ABB’s innovative MNS iS conceptcombines the long term experience,

energy efficiency, grid reliability and

industrial productivity of the well known

MNS system with advanced design in

hardware and software technologies.

High protection and safety

MNS iS and its clear segregation of power and

control compartments offers highest personal,

system and supervision safety possibilities.

Standardization

Maximum simplicity due to standardized power

modules – fully assembled and ready to use for

a wide range of motor starter and energy

distribution modules.

Lower lifecycle costs

These are defined in three ways; less downtime,

less fault finding and less inventory.

Information variety

MNS iS offers latest HMI technology, remote

management, innovative plug and produce

technology and real time plant condition

monitoring.

Complete solution

ABB offers the possibility to provide an all in

one solution when MNS iS is used in conjunction

with other power and automation technologies

from ABB.

Pro-active maintenance

MNS iS with Condition Monitoring indicates

conditions before a failure occurs, enabling

pro-active maintenance possibilities.

User friendliness

MNS iS provides integrated user tasks, like

module supervision, lifecycle management,

contact temperature supervision and

power loss supervision.

Less engineering complexity

MNS iS is the easiest way to plan, engineer and

manage a low voltage switchgear system.

Project implementation

MNS iS helps you to reduce your project costs by

offering a shorter project duration due to high

standardization and reduced engineering.

Measurement variables

Selectable temperature, current and voltage

measurement for various protection needs

for both motor and the switchgear itself.

No traditional transformers are utilized

for any measurements.

Information distribution as required

Industry standard communication interfaces,

such as Profibus DP, ProfiNet, Modbus RTU,

Modbus TCP and OPC are available, enabling site

wide distribution of information (operator,

maintenance, management).

System accessibility with ‘off the shelf’

web browser based devices

With an inbuilt web server functionality, the user

can select any web browser based device to

interrogate the system.

User friendliness

Self supervision of module location, module type,

power rating and automatic installation onto the

communication network.

MNS iS motor control center solution delivers

all the functions for control, protection and

monitoring of the motors and motor starters

using software and hardware modules for the

specific tasks. Right information is provided to

the right people at the right time.

Hardware modules are designed to fulfill desired

tasks (power module containing electrical parts

e.g. to isolate power, control module containing

software applications etc. to control a motor).

System functions are provided as functional

modules to be downloaded to the control module.

Only required functions are downloaded while

others are available as options.

System functionality may be enhanced at any

time without the requirement for additional

hardware or wiring.

Time synchronization with a time server in the

plant or locally in the switchboard allows accurate

time stamps of alarms and events collected in the

control module.

Module and location supervision are available

as a standard. These functions ensure the

corresponding power and control modules are

installed to the correct location for the particular

motor/feeder application.

Maintenance functions are an integral part of

the system. Asset monitors measuring system

performance data (e.g. outgoing line

temperature, number of insertions) allow

scheduling of maintenance activities only if

they are really required.

The flexibility of the system allows modifications

by a simple “plug and produce” concept.

Exchanging the modules or changing the

parameter settings is easily achieved by using

system inherent functions and tools.

The power module MStart/MFeed comprises:

• The electrical isolator.

• The short circuit protection device (fuses or

circuit breaker).

• Contactor and any electrical control equipment

and status indication.

• The sensor module (measuring the electrical

values, which are then available to the process

via the MControl module).

The integrated motor controller module MControl

(located in the control compartment) comprises:

• The processor performing all the protection,

control functions and monitoring functions. It

exchanges information with the MStart/MFeed

via an internal bus.

• I/O interface modules providing an interface to

external components for control, protection

and indication.

The interface module MLink serves as the

gateway to higher level systems which

communicate via the internal bus to

all MControl modules.

A local human system interface MView is available

to monitor the MNS iS status and display

information on each connected motor/feeder.

MNS iS as part of the ABB low voltage switchgear

solution uses the well proven ABB MNS standard

design aspects. MNS aspects described in this

section are fully applicable to MNS iS.

MNS system is a verified low voltage switchgear

design in accordance with IEC 61439 series and

IEC 61641.

The consistent application of the modular

principle both in electrical and mechanical design

as well as the use of standardized components

allows its flexible and compact design.

Depending on operating and environmental

conditions different design levels are offered.

Notable system advantages with regard to

design aspects:

• Optimum personal protection

• Design verified by testing

• Arc fault containment acc. criteria 1-7

• High operational reliability and availability

• Earthquake-, vibration- and shock-proof

designs are available

• Maintenance-free busbar construction

• Simple retrofitting procedures

• Compact, space-saving design

• Easy project and detail engineering through

standardised components

Multifunction wall

The multifunction separation wall (MFW) with the

embedded distribution bars is a unique ABB

design. It constitutes a complete barrier between

the main busbars and the equipment

compartment.

The distribution bars are fully phase segregated

and insulated. This design makes it virtually

impossible for an arc to pass between

distribution bar phases or between main busbars

and equipment compartment. The insulation

material is CFC and halogen free, it is also flameretardant and self-extinguishing.

Contact openings are finger proof (IP 2X) so that

personal safety is guaranteed even when modules

are removed.

With the use of MNS specific power contact

housings full individual phase segregation is

assured prior to the connection of the power

contacts to the distribution bars (see page 23

for details).

System highlights

• Maintenance free busbar construction

• Easy switchgear extension

• Main busbar arrangement at the rear

thus assuring

- maximum safety to personnel

- effective withstand against highest stresses

in case of short circuit

- optimum heat dissipation

• Gas tight seals for connection from the

equipment compartment to the main

busbar system

• Option for Form 4 separation for both incoming

and outgoing assemblies

• Active and passive arc fault prevention tested

according to IEC 61641

• Isolating materials are free of CFC

and halogens

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

51

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive