K-WANG

MOOG M3000 ® Control system and MSC servo controller

MOOG M3000 ® Control system and MSC servo controller

MOOG M3000 ® It is a modular distributed intelligent control system, consisting of MSC (Moog Servo Controller) servo controller, Q series local expansion module, R series remote module and supporting software. It supports Ethernet, CANopen, TIA/EIA 232/422/485 multiple communication interfaces, equipped with 8 digital I/O (configurable), 8 analog inputs, 2 analog outputs and 2 digital sensor interfaces. It requires 24VDC SELV power supply and has a working temperature range of * *+5 ℃ to+55 ℃. It is programmed and configured through MACS development environment * * (compatible with IEC 61131 standard) and has safety functions such as watchdog and output enable. It can form multiple control groups through E-bus/LocalCAN/WideCAN, which is widely applicable. In high-end control scenarios such as electro-hydraulic drive and industrial automation.

Overall Overview of the System

Moog M3000 ® The control system is a modular solution for mid to high end industrial control scenarios. Its core advantages lie in distributed intelligent architecture, multi-dimensional scalability, and high safety. By combining different functional modules, it can quickly build complex systems ranging from single axis control to multi axis collaboration. It is suitable for various applications such as hydraulic drive, automated production lines, and precision motion control, and meets international standards such as CE and IEC 61131-2, with EMC electromagnetic compatibility.

Detailed explanation of core hardware components

(1) MSC servo controller (core module)

Detailed explanation of key parameters for categories

Core configuration processor 40MHz 32-bit PowerPC RISC with floating point unit (FPU)

Storage system flash/memory 4MB Flash EEPROM (storing boot items/RETAIN variables), 2/4MB RAM

Number/configuration of 8 digital I/O channels, each channel can be independently configured as input or output, supporting open collector electrode/development emitter output

Analog input specification: 8-channel differential input, configurable as ± 10V/± 10mA/4-20mA, 16 bit resolution, maximum error ± 0.5% FS

Analog output specifications include 2 channels, with a voltage output of ± 10V (load ≥ 1k Ω) and a configurable current output of ± 10mA/± 50mA/4-20mA

Sensor interface type: 2-channel TIA/EIA 422 interface, supporting SSI sensors (master/slave mode) and incremental sensors (up to 8MHz pulse frequency)

Communication interface type Ethernet(RJ45)、CANopen(LocalCAN/WideCAN)、TIA/EIA 232/422/485、E-bus

Power requirements: Input/power consumption 24VDC SELV (compatible with 18-36V), static current ≤ 0.5A, digital I/O independent power supply (L2+/M2)

Environmental characteristics Working conditions Temperature+5 ℃ to+55 ℃, humidity 10% -95% (non condensing), protection level IP20, altitude ≤ 2000m

(2) Expansion module classification

Module Series Type Core Function Connection Method

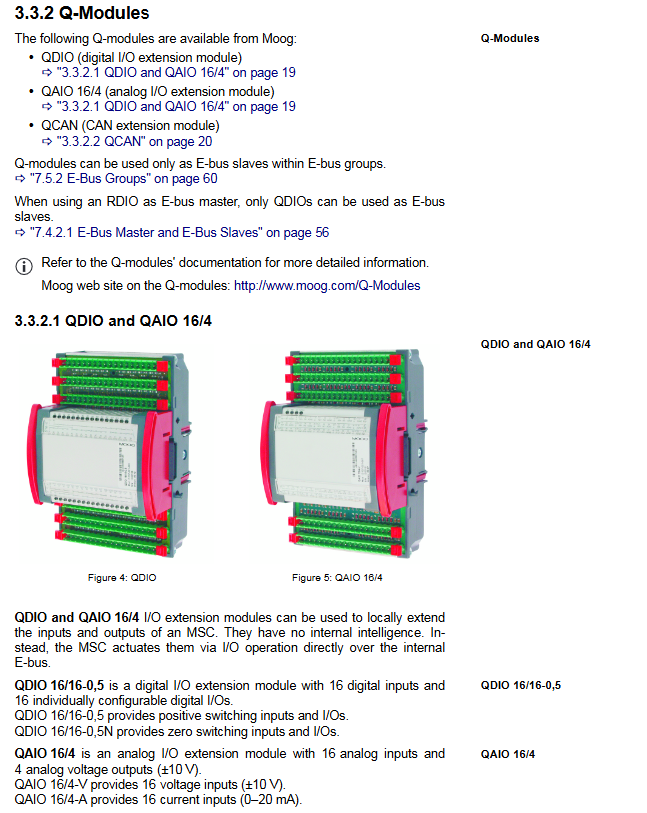

Q series (local expansion) QDIO 16 channel digital input+16 channel digital I/O, supporting positive/zero switching E-bus

QAIO 16/4 16 channel analog input+4 channel analog output (voltage type) E-bus

QCAN LocalCAN bus extended to external devices, D-sub interface E-bus

R series (remote module) RDIO 16 channel digital input+16 channel digital I/O, with CANopen interface CAN bus

RTEMP 8-channel temperature control, supporting TIA/EIA 232/CANopen CAN bus

RDISP 22 key display operation terminal with graphic LCD CAN bus

(3) Starter Kit configuration

Component specifications and usage

MSC controller 2MB RAM, developing control core for emitter output system

Power supply 24VDC 10A, DIN rail installation system power supply

QDIO module 16/16-0,5 type digital I/O expansion

Software MACS development environment+1-year maintenance contract programming configuration

Cable cross Ethernet (10m), TIA/EIA 232 (5m), CAN bus (3m) equipment interconnection

Terminal block 18 poles x 11, 9 poles x 1 signal wiring

System Software and Programming

MACS development environment

Compatibility standard: IEC 61131, supports 6 programming languages including IL (instruction list), ST (structured text), LD (ladder diagram), etc

Core functions: hardware configuration, program writing/compilation/download, online debugging (breakpoints/single steps), visual monitoring

Communication parameters: Ethernet default IP 10.49.40.1 (port 1200), TIA/EIA 232 baud rate 38400bps

supporting software

MACS HMI: Independent visualization package, can run without development environment, supports 1-50 system authorizations

CPRTEMP: RTEMP temperature module dedicated configuration software

CPRDISP: RDISP Display Terminal Specific Configuration Software

Authorization mechanism

Required components: License key (divided into Controls gray/Motion green, storing CANopen node ID/IP address)

Functional difference: Green authorization supports PLCopen motion control library, while gray authorization only includes basic control library

System networking and expansion

(1) Control group type

Control group type, connection method, maximum number of nodes, core usage

E-bus group module lateral Q-connector MSC up to 7 slave stations, RDIO up to 6 slave stations local I/O expansion, short distance high-speed communication

The LocalCAN group module has a built-in Q-connector for 64 network stations to collaborate with local devices, supporting QCAN extension to external devices

WideCAN front-end WCAN interface with 64 network stations for cross regional control group synchronization, connected to remote R module

(2) Security function

Watchdog monitoring: Implement software and hardware fault detection through the M-WATCHDOG function block, disable all outputs after timeout

Output Enable (OutEN): It must meet the three conditions of "valid authorization+fault free program+normal watchdog" before it can be activated, and the LED indicates the status in real time

Low voltage detection: When the voltage is below 16V (typical value), the SAVE state is triggered, and the output is disabled after saving key data

Wiring protection: Digital I/O supports reverse polarity protection, and analog channels have ± 36V overvoltage protection

Installation and maintenance

Installation requirements

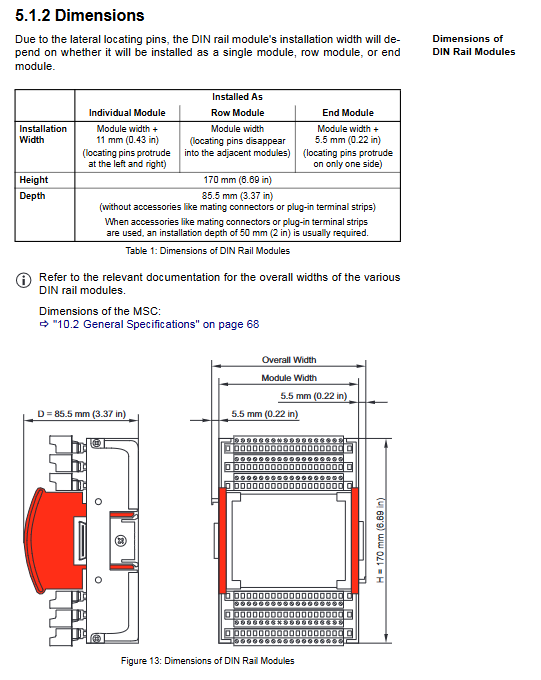

Mechanical installation: 35mm DIN top cap guide rail (TH 35-7.5), vertically mounted board grounded, module spacing ≥ 30mm

Grounding specification: centralized single point grounding, DIN rail and protective earth (PE) low resistance connection

Cable requirements: Shielded twisted pair (copper core ≥ 0.25mm ²) for analog signals, CAN bus impedance 120 Ω

Maintenance points

Module features: maintenance free design, no built-in battery, Flash data retention>10 years

Fault diagnosis: Front end LED indicates power, communication, I/O status, and line faults, supporting MACS online diagnosis

Repair service: Only Moog authorized service providers provide Authentic Repair, with a dedicated seal affixed after repair

Product Resources and Accessories

Category Core Product Specifications/Usage

Interface cable cross Ethernet cable 10m, RJ45 connector, used for connecting MSC and PC

CAN bus cable 3/10m, 9-pin D-sub, impedance 120 Ω

Terminal block plug-in terminal block with 8/9/18 poles, supporting screw/spring wiring (wire diameter ≤ 2.5mm ²)

CAN accessory terminal resistor 120 Ω, 9-pin D-sub, used for matching the two ends of the bus

USB-CAN adapter USB1.1 to CAN, supports computer debugging

Training service software training in both English and German, including IEC 61131 programming and MACS operation

Hardware training in both English and German, including module configuration, networking, and control library usage

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923