K-WANG

MOOG G123-825-001 DIN rail buffer amplifier

MOOG G123-825-001 DIN rail buffer amplifier

Moog G123-825-001 is a compact DIN rail mounted buffer amplifier designed to address signal compatibility issues between PLC/servo amplifiers and Moog servo/proportional valves. It requires a 24VDC power supply (22-28V compatible) and supports three input signals: 4-20mA, 0- ± 10V, and 0- ± 100mA. Multiple output signals, including 4-20mA, 0- ± 10V, and 0- ± 5 to ± 100mA, can be selected through a switch (supporting output value superposition). It comes with a built-in 7/16/34/72/723Hz optional single pole active filter to remove noise and is equipped with Vv/Iv LED indicator lights and front-end test points for easy debugging. The protection level is IP20 and the working temperature is 0-40 ° C. It is widely used for replacing old and new valves. (MFB to EFB) and industrial servo valve control scenarios.

Product basic information

Product positioning: Moog G123-825-001 is a buffer amplifier designed specifically for industrial servo systems. Its core function is to build a signal bridge between PLC/servo amplifiers and Moog servo valves and proportional valves, solving compatibility issues of different signal types. It also supports the replacement of old mechanical feedback (MFB) valves with modern electrical feedback (EFB) valves without the need to modify the original servo amplifier.

Certification and protection: CE certification (compliant with EN50081.1 emission standard, EN50082.2 immunity standard), C tick certification (compliant with AS4251.1 emission standard); Protection level IP20, suitable for the environment inside industrial control cabinets.

Delivery list: Buffer amplifier body, DIN rail fuse holder, 2 M205 250mA slow melting fuses, 4 pages of application instructions.

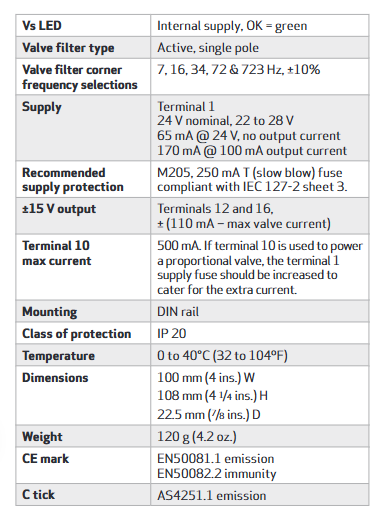

Core technical specifications

Specification category specific parameter remarks

Power supply parameters rated voltage: 24VDC; Voltage range: 22-28VDC

Static current: 65mA (without output)

Working current: 170mA (100mA output) Recommended fuse: M205 250mA slow melting (compliant with IEC 127-2 sheet 3)

Input signal current input: 4-20mA (terminals 4-8, 50 Ω impedance)

Voltage input: 0- ± 10V (terminal 3100k Ω impedance; Low Rin mode 1k Ω)

Other inputs: 0- ± 100mA (mfb signal) Low Rin mode selected through switch S2:5

Output signal voltage output: 0- ± 10V (minimum load 1k Ω)

Current output: 4-20mA (maximum load 500 Ω); 0- ± 5/10/20/30/50mA (stackable, maximum ± 100mA) Output stacking example: 30mA+50mA=± 80mA full-scale output

Filter characteristic type: unipolar active filter

Cut off frequencies: 7Hz, 16Hz, 34Hz, 72Hz, 723Hz (± 10%)

Time constants: 22mS, 10mS, 4.7mS, 2.2mS, 0.22mS can be selected through switches S2:6-S2:10

Physical and environmental dimensions: 100mm (width) x 108mm (height) x 22.5mm (depth)

Weight: 120g (4.2oz)

Working temperature: 0-40 ° C (32-104 ° F)

Installation method: 35mm standard DIN rail-

Auxiliary Function Test Point: Valve Drive Signal Test Point (Zo=10k Ω)

LED indicator light: Vs (power OK, green); Vv (voltage output, red+green -); Iv (current output, red+green -) Vv lamp has maximum brightness at ± 10V; Iv lamp has maximum brightness at ± 5mA - ± 100mA

Other parameters ± 15V output: Terminal 12/16, maximum current=110mA - maximum valve current

Terminal 10 maximum current: 500mA (cannot supply power to DDV valve) If Terminal 10 supplies power to a proportional valve, the power fuse needs to be increased

Core functions and application scenarios

core functionality

Signal adaptation and conversion: Supports flexible switching between three input signals and multiple output signals, covering the signal requirements of most Moog servo/proportional valves, and solving the problem of signal incompatibility between PLC/servo amplifiers and valves.

MFB to EFB upgrade: It can convert the current output of the original servo amplifier into an EFB valve compatible signal, achieving seamless replacement of old MFB valves without the need to modify the original control system.

Noise filtering: Equipped with a multi level single pole active filter, the appropriate cut-off frequency can be selected according to the on-site environment, effectively removing interference noise from the input signal and ensuring valve control accuracy.

Convenient debugging and monitoring: The front-end panel is equipped with test points and status LED indicators, which can quickly determine the power status, output signal polarity and amplitude, simplifying the system debugging and troubleshooting process.

Typical application scenarios

Adaptation of signal interface between PLC and Moog servo valve in industrial automation production line;

Upgrade old equipment and replace mechanical feedback (MFB) valves with electrical feedback (EFB) valves;

Servo valve control in high noise environments, optimizing signal quality through filters;

In a control cabinet with limited space, a compact layout is achieved using DIN rail installation characteristics.

Installation and wiring precautions

Installation requirements: It needs to be installed on a 35mm standard DIN rail to ensure a secure installation and avoid vibration affecting equipment stability;

Power supply protection: Recommended specifications of slow melting fuses must be equipped to prevent overcurrent damage to equipment; If the valve is powered through terminal 10, the fuse specification should be increased according to the valve current;

Wiring specification: The cable shielding layer should be connected to the cable sealing sleeve of the shell to reduce electromagnetic interference; Strictly distinguish input, output, and power terminals according to the wiring diagram to avoid equipment failure caused by reverse connection;

Resistance configuration: R21 and R25 on the PCB are 1/4W plug-in resistors used to select the MFB input current. The default value is 390K and can be replaced according to actual needs.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923