K-WANG

Siemens medium voltage vacuum switch technology and components

Siemens medium voltage vacuum switch technology and components

Basic Information

Siemens medium voltage vacuum switch technology and components are mainly aimed at the medium voltage power system and industrial application fields, providing a comprehensive introduction to vacuum switch technology and related components. The document mentions that all Siemens related products have passed ISO 9001 (Quality Management), ISO 14001 (Environmental Management), OHSAS 18001 (Occupational Health and Safety) system certification, and comply with international standards such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers). Some products are compatible with Chinese GB/DL standards.

Medium Voltage Core Concepts and Application Scenarios

1. Definition of voltage level

Medium voltage: AC voltage ranging from 1kV to 52kV, mainly used for power distribution and industrial networks;

Low voltage: AC voltage ≤ 1kV or DC voltage ≤ 1.5kV;

High voltage: used for power transmission (specific scope not specified in the document, focus on medium voltage).

2. Typical application scenarios

Common voltage levels for specific scenarios in the field

Power system power station (generator circuit, ≤ 24kV), primary distribution station (high voltage to medium voltage), secondary distribution station (medium voltage to low voltage) 10kV-40kV (distribution network)

Industrial plants (powered by motors), mining, ships, 3kV-15kV (motor operating voltage)

Special fields (traction power supply) Germany/Austria/Switzerland (AC 15kV, 16.7Hz), other regions (AC 25kV, 50Hz), DC railways (≤ 3kV) AC 15kV/16.7Hz, AC 25kV/50Hz

3. Operating stress of medium voltage equipment

Medium voltage equipment needs to withstand various operating stresses, which is the core basis for selection and design:

Dielectric loss strength: able to withstand normal operating voltage (including fluctuations) and overvoltage (operation/lightning overvoltage);

Current carrying capacity: continuously carrying normal current, short-term carrying overcurrent, and instantaneous carrying short-circuit current;

Current on-off: on-off normal current, fault current, and special current (capacitive/inductive current, high-frequency transient current);

Isolation requirements: In the disconnected state, the safety isolation distance specified by the standard must be met for easy maintenance;

Operation frequency: It is necessary to adapt to multiple on-off operations in a short period of time (such as multi segment reclosing of the recloser).

Core technology: Vacuum arc extinguishing technology

Vacuum arc extinguishing technology is the core of Siemens medium voltage switchgear, which has the advantages of high reliability, long life, and low maintenance. The specific characteristics are as follows:

1. Arc extinguishing principle

When the contacts separate in the vacuum arc extinguishing chamber, a metal vapor arc is generated, and current flows through the metal vapor plasma; The arc automatically extinguishes when the current crosses zero, and the remaining metal vapor loses conductivity within a few microseconds. The insulation ability of the contact gap quickly recovers (with a recovery speed of 5kV/μ s), and can immediately withstand external voltage.

2. Key technological advantages

Low current cutoff: Using special contact materials, the cutoff current is only 2A-3A, avoiding excessive overvoltage when small currents are turned on and off;

Low arc voltage: The arc voltage is only 20V-200V, with low arc energy, minimal contact wear, and long equipment life;

Maintenance free: The vacuum environment is free of oxidation and impurities, and the arc extinguishing system does not require regular maintenance.

3. Contact type and applicable scenarios

Contact type, structural characteristics, current adaptability range, advantages, application product examples

Radial magnetic field contact cup-shaped/spiral structure, generating radial magnetic field ≤ 10kA (diffusion arc); >10kA (contraction arc, arc rotation) universal circuit breaker (3AH5) to avoid local overheating and uniform wear of contacts

Axial magnetic field contact disc-shaped structure, generating high axial magnetic field current (arc always spreads), uniform force on the contact surface, no local melting, high-capacity circuit breaker (3AH3)

Classification and Technical Parameters of Medium Voltage Equipment

Medium voltage equipment is divided into switch devices (for current switching) and non switch components (for protection, measurement, and auxiliary functions). The specific classification and key parameters are as follows:

1. Switchgear

(1) Vacuum circuit breaker

Vacuum circuit breakers can switch between normal and short-circuit currents, suitable for indoor and outdoor scenarios. The core models and parameters are as follows:

Type, Model, Series, Applicable Scenarios, Key Parameters (Maximum), Operating Mechanism

Indoor Circuit Breaker SION 3AE General Scenario (Industrial/Distribution) Rated Voltage 24kV, Rated Current 2000A, Short Circuit Breaking Current 40kA Spring Energy Storage Mechanism

3AH5 economical type, rated voltage for small capacity scenarios is 17.5kV, rated current is 2000A, short-circuit breaking current is 31.5kA, spring energy storage mechanism

3AH3 high-capacity scenario rated voltage 40.5kV, rated current 4000A, short-circuit breaking current 63kA, spring energy storage mechanism/magnetic operation mechanism

3AH36/37/38 generator circuit rated voltage 24kV, rated current 8000A, short-circuit breaking current 72kA, spring energy storage mechanism

3AH47 traction power supply (1/2 pole) compatible with 16.7Hz/25Hz/50Hz/60Hz, mechanical life of 60000 times, spring energy storage mechanism

Outdoor circuit breaker 3AF0 (tank type) for outdoor distribution, rated voltage for harsh environments of 40.5kV, rated current of 2500A, short-circuit breaking current of 31.5kA, spring energy storage mechanism, compliant with IEC 62271-100 S2 level

SDV (Dead Can) outdoor power distribution, including anti arc rated voltage of 38kV, rated current of 3000A, short-circuit breaking current of 40kA, spring energy storage mechanism/magnetic operation mechanism

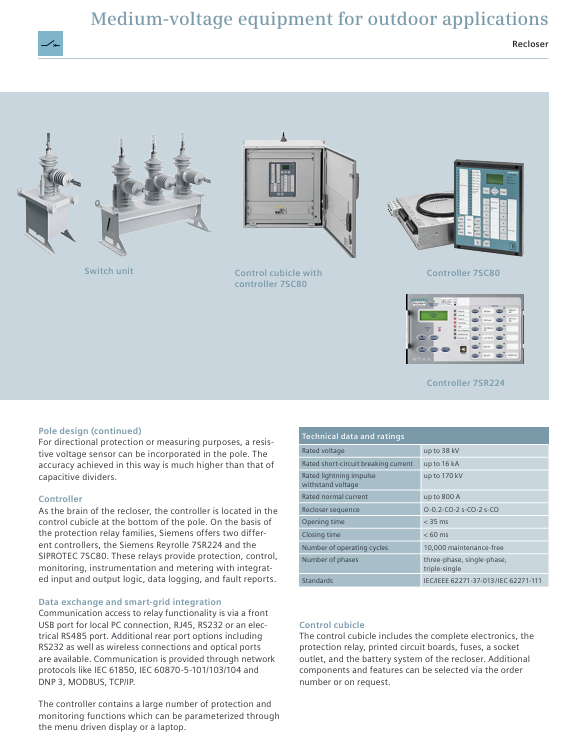

(2) Recloser (3AD series)

Function: Integrated switch unit and controller, can automatically detect faults and complete multi segment coincidence, reducing power outage time caused by temporary faults;

Core parameters: rated voltage ≤ 38kV, rated current ≤ 800A, short-circuit breaking current ≤ 16kA, typical coincidence sequence O-0.2s-CO-2s-CO-2s-CO;

Controller: Provides 7SR224 (Reyrolle series) and 7SC80 (SIPROTEC series), supports communication protocols such as IEC 61850 and MODBUS, and is compatible with smart grids.

(3) Vacuum contactor (3TL series)

Function: High frequency switching (≤ 3 million mechanical lifetimes), suitable for loads such as motors, transformers, capacitors, etc;

Core model parameters:

Model Rated voltage Rated current Mechanical life Electrical life (rated current) Suitable load type

3TL81 7.2kV 400A 1 million times 250000 times motor (AC-3/AC-4), transformer

3TL61 7.2kV 450A 3 million times 1 million times motor (AC-3/AC-4), capacitor

3TL65 12kV 400A 1 million times 500000 times motor (AC-3/AC-4), reactor

3TL71 24kV 800A 1 million times 500000 times large capacity motor and transformer

Contactor fuse combination (3TL62/63/66): Integrated high-voltage HRC fuse, short-circuit breaking current ≤ 50kA, suitable for high current scenarios (such as 450A rated current).

(4) Switch - Isolation switch

Arc extinguishing principle: using hard gas to extinguish the arc. When the arc is generated, the insulating material releases gas to quickly extinguish the arc (the gas is non renewable and the number of operations is lower than that of vacuum equipment);

Function: It combines the functions of switching (on/off load current) and isolation (safe isolation distance), with high cost-effectiveness;

Application scenario: Industrial distribution and substation auxiliary circuits require the use of fuses to achieve short-circuit protection.

2. Non switch components

(1) Lightning arrester and voltage limiter

Function: Protect equipment from lightning overvoltage (external) and operation/grounding fault overvoltage (internal) damage;

Core model parameters:

Type, Model, Applicable Scenarios, Rated Voltage (Maximum), Nominal Discharge Current, Shell Material

Voltage limiter 3EF motor, dry-type transformer, frequency converter 12kV 1kA polyethylene

Lightning arrester 3EK4 distribution network, medium voltage switchgear 45kV 10kA (AC) silicone rubber

Line lightning arrester 3EK7 outdoor line protection 72.5kV 10kA silicone rubber

(2) High voltage fuse (3GD series)

Function: Short circuit protection, which melts when the current exceeds the threshold, cuts off the fault current, and protects equipment such as transformers, motors, capacitors, etc;

Classification:

Backup fuse: suitable for 7.2kV-36kV, rated current 6.3A-315A, short-circuit breaking current 40kA-63kA;

Motor protection fuse: suitable for 7.2kV-12kV, rated current 50A-315A, short-circuit breaking current 50kA;

Installation: Supports 1-phase/3-phase installation and can be combined with switchgear (such as switch fuse combination).

(3) Protection and measurement transformers

Current Transformer (CT):

Function: Convert high current proportionally to low current (for measurement/protection equipment use) to achieve electrical isolation;

Key requirements: Cannot operate in an open circuit (to avoid overvoltage), can have multiple secondary windings (measurement/protection separated);

Types: Indoor support type, indoor sleeve type, outdoor type.

Voltage Transformer (VT):

Function: Convert high voltage proportionally to low voltage (for measurement/protection equipment use);

Key requirements: Do not short-circuit operation (to avoid overheating), some windings with residual voltage (ground fault detection);

Type: Indoor, Outdoor.

(4) Auxiliary switch (3SV9 series)

Function: Auxiliary contacts for mechanical operation, used for electrical interlocking, auxiliary contactor/coil control, and motor operating mechanism drive;

Key parameters: rated voltage 230V AC/240V DC, rated thermal current 10A, mechanical life 100000 times, electrical life 30000 times;

Configuration flexibility: Switching levels 2-26, contacts can be customized as normally closed (NC), normally open (NO), or switch contacts, supporting different switching angles and overlapping contacts.

Selection guide and cooperation support

1. Selection criteria

Select the appropriate equipment based on the operating scenario (normal operation/fault operation) and load type (inductive/capacitive/resistive), and provide a detailed selection table in the document (example: inductive load selection under normal operation scenario):

Load type, current range, and equipment adaptation notes

No load transformer ≤ 0.03I, circuit breaker, contactor, switch isolator, recloser with neutral grounding transformer

When the motor is running and the circuit breaker and contactor are started, the current is ≤ 7Ir (cos π≤ 0.3)

Compensation reactor ≤ 2000A, transient recovery voltage rise rate of circuit breaker ≤ 6kV/μ s

2. Siemens cooperation and support

Collaboration Plan: Provide standardized testing systems (compliant with IEC 62271-200), design drawings, technical consulting, production training, and software tools (engineering design/document management) for switchgear manufacturers;

Supporting equipment:

SIMOPRIME: Medium voltage air insulated switchgear, compatible with SION 3AE circuit breakers, 7.2kV-24kV;

SIVACON S8: Low voltage distribution panel, rated current ≤ 7000A, in compliance with IEC 61439-2;

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923