K-WANG

YOKOGAWA CENTUM VP Distributed Control System

System: Yokogawa Oprex Control and Safety System

Manufacturer: Yokogawa Electric Corporation

Core positioning: Yokogawa's most advanced integrated production control platform, which has undergone more than 40 years of technological evolution, aims to create value with customers through "process collaborative innovation" and meet the needs of digital transformation and integration of new technologies (such as IoT) in multiple industries

YOKOGAWA CENTUM VP Distributed Control System

Product core positioning

CENTUM VP is a distributed control system with over 40 years of technological accumulation. As a core component of the Yokogawa OpreX ecosystem, it features "integration, high reliability, scalability, and ease of operation" as its core characteristics, achieving integrated collaboration in production control, safety management, and asset operation and maintenance. It supports the integration of new technologies such as IoT and provides enterprises with automation solutions throughout the entire lifecycle.

System historical evolution and compatibility

(1) Development History

The Yokogawa CENTUM series always adheres to independent research and development, and each generation of products reserves an upgrade path. The key milestones are as follows:

Year Product Version Core Progress

The first product of the CENTUM V series in 1983 laid the foundation for the control architecture

1988 CENTUM-XL technology iteration to enhance system scalability

1993 CENTUM CS new generation control system, optimized control performance

In 1998, the CENTUM CS 3000 improved integration and adapted to more complex industrial scenarios

2001 CENTUM CS 3000 R3 version optimized to enhance compatibility and stability

In 2008, CENTUM VP R5 launched the first VP series, equipped with Vnet/IP control network

In 2011, CENTUM VP officially released its core version

In 2015, CENTUM VP R6 continued to upgrade, improving its functional modules and adapting to the ecosystem

(2) Compatibility advantage

Backward compatibility: CENTUM VP can directly control and monitor all Yokogawa legacy systems (including CENTUM V、CENTUM-XL、CENTUM CS、CENTUM CS 3000 By controlling the network, cross version collaboration can be achieved without the need for large-scale replacement of existing hardware

Third party migration: 350+non Yokogawa system migration projects have been successfully completed, covering mainstream brands such as Bailey INFI90、Foxboro I/A、Emerson RS3/PROVOX/DeltaV、Honeywell TDC2000/3000/PKS、Siemens SIMATIC Wait, the migration process is simple and efficient, ensuring business continuity

Detailed explanation of the core functional modules of the system

(1) Operation module: Focus on efficient collaborative operation

1. Integrated management architecture

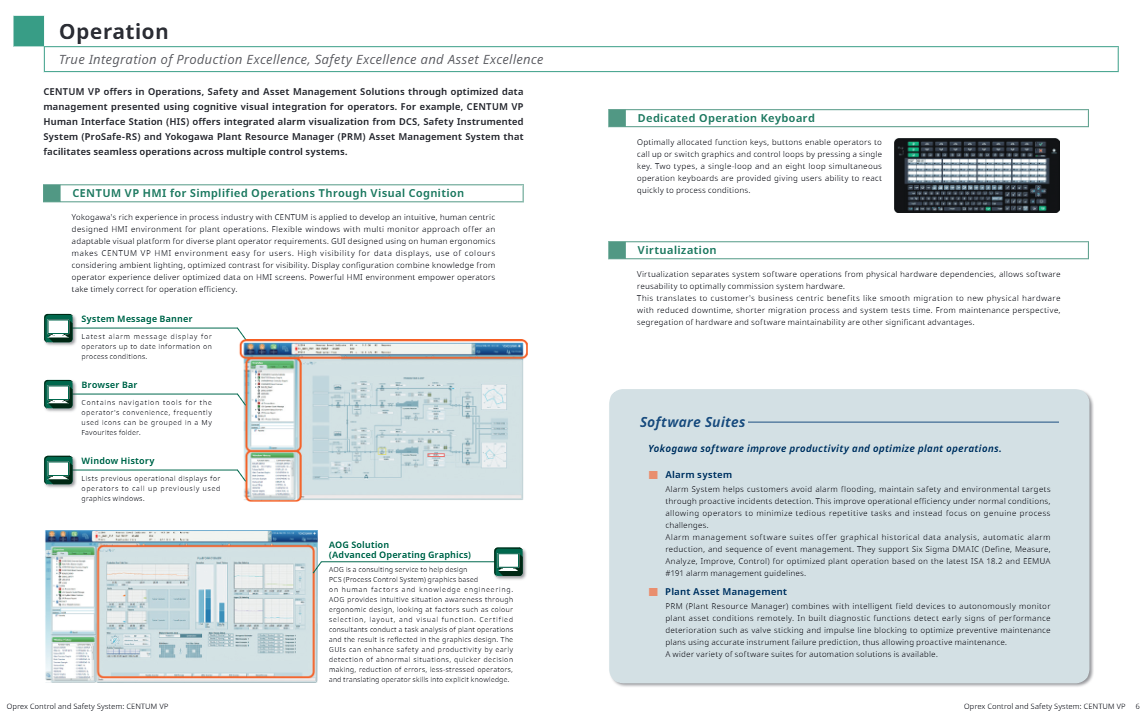

The deep integration of the three major goals of "production excellence, safety excellence, and asset excellence" is achieved through cognitive visual integration technology to optimize data presentation. For example, HIS (Human Machine Interface Station) can unify the visualization of alarm information from DCS, Safety Instrumented System (ProSafe RS), and Factory Resource Manager (PRM), breaking down barriers to multi system operation and achieving seamless collaboration.

2. Humanized Human Machine Interface (HMI)

Design concept: Based on ergonomics and experience in Yokogawa Industries, create an intuitive and easy-to-use operating environment that adapts to the usage habits of different operators

Core features:

Flexible configuration: supports multi screen display and custom window layout to meet the visualization needs of complex production scenarios

High visibility: sufficient data display brightness, color matching suitable for industrial lighting environment, contrast optimization to improve readability

Convenient navigation: including system message bar (displaying the latest alarm information in real time), browser bar (supporting common function collection and grouping), window history (quickly calling past operation interfaces)

AOG solution: Advanced Operating Graphics consulting service, where certified consultants design PCS graphics based on human factors and knowledge engineering. By optimizing color, layout, and visual functions, it achieves early anomaly detection, rapid decision-making, and reduces operational errors, while transforming operator experience into explicit knowledge

3. Specialized operation keyboard

Provide two types of dedicated keyboards, with optimized function key layout that supports one click calling of graphics or control circuits, helping operators quickly respond to process changes:

Single loop operation keyboard: suitable for precise operation of a single control loop

Simultaneous operation keyboard with eight circuits: meeting the efficient requirements of multi circuit collaborative control

4. Virtualization technology

Decoupling system software and physical hardware, improving software reusability, brings multiple advantages:

Convenient Migration: Supports smooth migration to new physical hardware, reducing downtime

Efficient testing: Shorten the system testing cycle and reduce the limitations caused by hardware dependencies

Maintenance optimization: independent maintenance of software and hardware to enhance operational flexibility

5. Core software suite

Alarm Management System: Compliant with ISA 18.2 and EEMUA # 191 standards, supporting Six Sigma DMAIC (Definition Measurement Analysis Improvement Control) method, with graphical historical data analysis, automatic alarm filtering, and event sequence management functions, effectively avoiding alarm proliferation and allowing operators to focus on core process issues

Factory Resource Manager (PRM): Linked with intelligent on-site devices, it enables remote autonomous monitoring of asset status, identifies signs of equipment performance degradation (such as valve jamming and pulse line blockage) in advance through built-in diagnostic functions, accurately predicts instrument failures, optimizes preventive maintenance plans, and achieves proactive operation and maintenance

(2) Control module: ensuring high reliability and stable operation

1. High availability design

Dual redundancy architecture: The processor module, power supply, I/O module, and I/O network of FCS (Field Control Station) all adopt a dual redundancy design, with the main and backup modules running synchronously, seamlessly switching to the backup module in case of failure, ensuring control continuity and no downtime losses

Online maintenance capability: supports online modification of FCS application logic and parameters, allows for online replacement of faulty modules without interrupting process control, and adapts to scenarios such as factory expansion and process adjustment

2. Core Control Unit (FCS)

100% independently developed and manufactured by Yokogawa, continuing the high reliability genes of the CENTUM series

Equipped with powerful processing capabilities and large capacity application storage, fully adapted to advanced on-site digital technology, ensuring efficient, safe, and stable control of the production process

3. Security Control Network (Vnet/IP)

Technical specifications: Compliant with IEEE802.3 Ethernet standard, with a transmission rate of 1Gbps, supporting both star and ring topologies

Core advantages: It combines openness and security, does not affect the efficiency of process control data transmission, and has built-in security mechanisms such as anti fraud, anti tampering, and anti DoS attacks to ensure the stability and reliability of the control network; Regardless of project size and complexity, it can ensure HIS data updates every second

4. Multi factor I/O module solution

I/O module type, core characteristics, applicable scenarios

N-IO (Network I/O) next-generation software can configure intelligent I/O, with a single module supporting AI/AO/DI/DO signals; The signal type of each I/O point is configured through adapter software to adapt to design changes; No need for traditional wiring grouping, saving installation space and cost; Can be deployed as a remote I/O module in on-site remote junction boxes that require flexible adaptation of signal types, pursuit of installation efficiency and cost optimization scenarios

FIO (Field Network I/O) divides various modules according to process signal types, and can be connected to field equipment through pressure clamp terminal blocks, dedicated terminal boards, or MIL cables in traditional industrial scenarios that require configuration through terminal blocks

RIO system upgrade I/O includes Remote I/O module and RIO system upgrade dedicated I/O module, maximizing the utilization of existing assets and achieving rapid system upgrade. Based on the expansion and upgrade scenarios of the existing RIO system

5. Function blocks and control capabilities

Provide rich functional blocks, covering monitoring, control, operation, calculation, logic functions, and sequence control, supporting continuous control, advanced control, complex sequence control, and batch control. The control system can be flexibly designed through the combination of functional blocks to maintain modularity and scalability

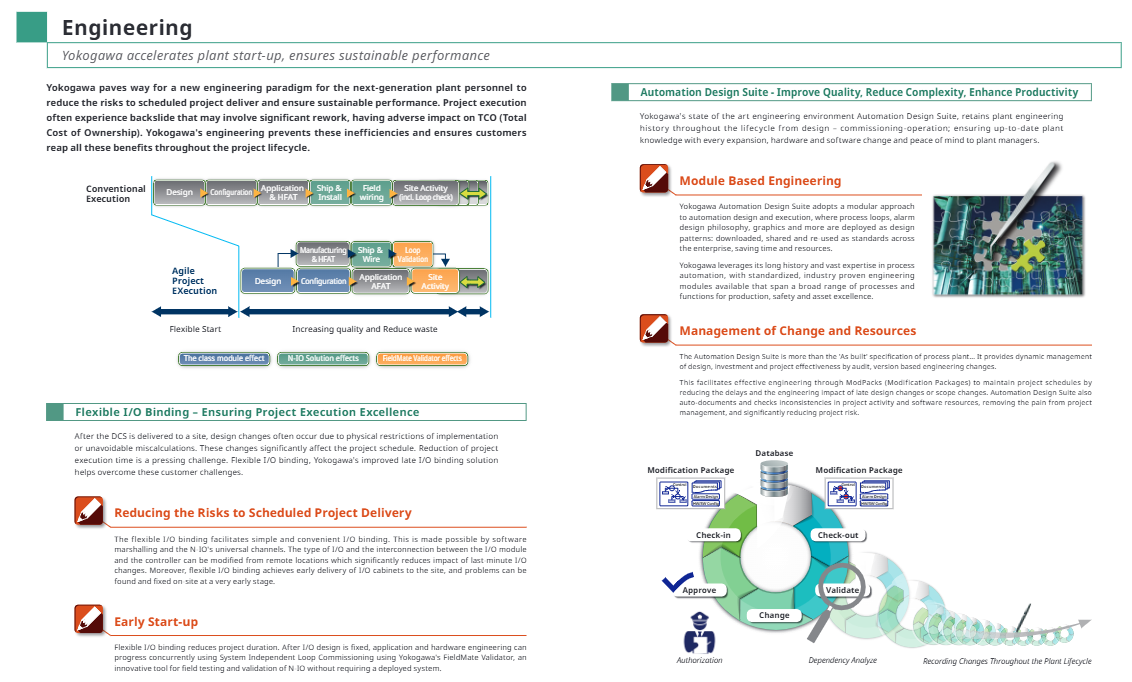

(3) Engineering module: Accelerating project delivery and quality improvement

1. Core engineering environment: Automation Design Suite

Full lifecycle data management: Record the complete engineering history from design, debugging to operation, ensuring data integrity and consistency during system expansion, software and hardware changes, and providing reliable engineering archives for factory managers

Modular engineering: Encapsulate process loops, alarm design, graphics, etc. into standardized design modules that can be downloaded, shared, and reused across enterprises, reducing repetitive work and saving time and resources

Change and Resource Management: Implement version based engineering change management through ModPacks, automatically document project activities and detect data inconsistencies, reducing project delays and risks caused by later changes

2. Flexible I/O binding technology

Core advantage: Based on software grouping and N-IO universal channels, it supports remote modification of I/O types and module controller connection relationships, greatly reducing the impact of later design changes on project progress

Project Value:

Early delivery of I/O cabinets to the site, early detection and resolution of installation issues

Combined with FieldMate Validator debugging tool, it supports independent loop debugging of the system, eliminating the need to deploy a complete system and shortening project duration

Engineering design and hardware installation can be carried out in parallel to improve project execution efficiency

3. Agile project execution

Compared to traditional project processes (design configuration manufacturing and factory acceptance testing shipping installation on-site activities), CENTUM VP reduces rework and waste, improves project quality and delivery efficiency, and lowers total cost of ownership (TCO) through modular design, flexible I/O binding, and other technologies

(4) Sustainable Plant: Ensuring Long Term Value

1. Full lifecycle services

Yokogawa provides service support covering the entire lifecycle of the system, including online upgrades, patch updates, migration services, security solutions, etc. Through deep collaboration with customers, it ensures the sustainable return on investment of control system assets

2. Long term stable operation guarantee

Component updates and upgrades: By updating outdated components, replacing outdated supported peripherals, upgrading FCS (improving processing speed and adding new features), etc., seamless system transition can be achieved. Maintenance activities can be synchronized with factory downtime without taking up additional production time

Lifecycle performance assurance services: covering planning and execution, maintenance, protection, analysis, modernization upgrades, and other aspects, providing services such as engineer dispatch, workbench maintenance, equipment status monitoring, seamless upgrades, etc., to prevent unexpected failures

3. Network security protection system

Security certification: CENTUM VP on-site control unit obtained ISASecure certification ® EDSA (Embedded Device Security Assurance) certification, rigorously tested by CSSC (Control System Security Center) certified laboratory, meets the security requirements of industries such as petroleum, petrochemical, and power

Endpoint Security Services: Provides USB port locking, security information services, antivirus software, whitelist software, etc., verifies the compatibility of Yokogawa products with antivirus software, Microsoft security updates, and ensures system endpoint security

Security network design: Vnet/IP control network has multiple built-in security mechanisms to resist various network attacks, and Windows PC/Server provides security configuration options

System architecture and core components

(1) Hardware components

Component Name Abbreviation Core Function Hardware Configuration

The core interface for HIS operator control and monitoring in the human-machine interface station is based on the Windows operating system, using commercially available PC hardware, and can be optionally equipped with a dedicated operation keyboard

The ENG system configuration, programming, debugging, and maintenance of the engineering station are consistent with the HIS hardware configuration, and are equipped with the complete CENTUM VP engineering suite

The core control unit of the FCS system in the on-site control station is independently developed and manufactured by Yokogawa, with dual redundancy design, high reliability and processing capability

Unified gateway station/general subsystem gateway UGS/GSGW system interface and subsystem control UGS to achieve docking with STARDOM or third-party subsystems; GSGW is used to operate and monitor the subsystems connected to CENTUM VP

Bus converter BCV network domain connection and system compatibility connect multiple control network domains, achieving compatible docking between the previous generation CENTUM system and CENTUM VP

(2) Network and Communication Architecture

Control network: Vnet/IP (1Gbps, redundant design), responsible for real-time transmission of core control data, safe and reliable

Digital fieldbus: supports FOUNDATION ™ fieldbus、HART、PROFINET、PROFIBUS-DP、DeviceNet、Modbus、Modbus/TCP、EtherNet/IP Multiple industrial bus protocols are available to adapt to different brands and types of field devices

(3) Key software components

UACS (Unified Alarm and Status Server): Complies with IEC 62682 (Ed1, 2014)/ISA18.2-2016 standards, standardizes alarm management, and improves alarm response efficiency

Operational Excellence Software Suite: Based on the Windows platform, it covers functions such as factory security, asset operation and maintenance, production management and optimization, providing comprehensive support for efficient plant operations

Safety Control Station (SCS) - ProSafe RS: A T Ü V SIL3 certified safety instrumented system that integrates Yokogawa Pair&Spare and Vnet/IP technologies, with strong synergy with CENTUM VP

STARDOM Network Control System: Intelligent Hybrid Remote Communication Controller, suitable for the upstream oil and gas market, can be seamlessly integrated with CENTUM VP through UGS

Applicable industries and scenarios

Core industries: Process industries such as petroleum, petrochemical, power, chemical, metallurgical, pharmaceutical, water treatment, etc

Key scenarios:

Real time control and monitoring of continuous production processes

Safety protection and emergency response in high-risk industrial scenarios

Remote operation and preventive maintenance of industrial assets

Collaborative operation and data management of multi system integration

Upgrading, expanding, and migrating existing systems to third-party systems

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923