K-WANG

TEKTRONIX P6022 Current Probe

TEKTRONIX P6022 Current Probe

Basic Information and Product Positioning

This document is the official manual for the Tektronix P6022 current probe (document number 070-0948-05). Its core function is to convert the AC current waveform into a voltage signal that can be measured by an oscilloscope, enabling current measurement without disconnecting the tested circuit. It is suitable for grounded general-purpose oscilloscopes with an input impedance of 1 M Ω and is mainly used in scenarios that require high-precision and wide frequency range current detection.

Core parameters of the product

1. Key electrical parameters (including guaranteed and typical characteristics)

Parameter Category Specific Indicator Remarks

Sensitivity options are available in two levels: 1 mA/mV and 10 mA/mV, controlled by the terminal sensitivity switch

Bandwidth (-3 dB) 1 mA/mV range: 8.5 kHz -100 MHz; 10 mA/mV range: 935 Hz-120 MHz requires an oscilloscope with a bandwidth ≥ 300 MHz

Intermediate frequency accuracy ± 3% calibration environment: 20 ° C-30 ° C (68 ° F-86 ° F)

Maximum current pulse current: 100 A peak (≤ 9 A · ms, if exceeded, the magnetic core will saturate); Continuous current: The reference frequency derating curve is 6 A p-p in the range of 3 kHz to 10 MHz at 10 mA/mV

Insertion impedance ≤ 0.03 Ω at 1 MHz and ≤ 0.2 Ω at 120 MHz affects high-frequency signal measurement, and attention should be paid to load effects

Rise time 1 mA/mV ≤ 3.2 ns; 10 mA/mV ≤ 2.9 ns reflects high-frequency response speed

Signal delay of about 9 ns with 5-foot probe cable and terminal

2. Environmental and mechanical parameters

Specific indicators for parameter categories

Working temperature: 0 ° C-50 ° C (32 ° F-122 ° F); Non working temperature: -40 ° C -65 ° C (-40 ° F -149 ° F)

Working altitude 2000 m (6561 ft); Non working altitude: 15240 m (50000 ft)

Cable length 5 feet (1.5 meters)

Weight probe+cable: 2.5 oz (≈ 71 g); Terminal: 1.7 oz (≈ 48 g)

The maximum wire diameter of 0.11 inches (2.79 mm) exceeding the specification will damage the probe clamp

Safety operation standards

1. General safety warning

Maintenance restrictions: Only qualified personnel are allowed to carry out repairs, avoiding separate operations. Before repairing, the power must be disconnected and refer to the safety summary.

Connection taboos: Do not plug or unplug probes/test wires with power on; The connection sequence is "connect the terminal to the oscilloscope first, then connect the probe to the circuit", and the disconnection sequence is reversed; The common terminal of the probe can only be grounded, and it is prohibited to connect to voltages higher than the ground potential.

Usage environment: Do not open the lid or use in damp/explosive environments; When measuring with bare wires, the voltage should not exceed 30 Vrms, 42 Vpk, or 60 VDC. Insulated wires are required above this voltage.

2. Probe operation safety

Sliding operation: When opening the sliding block, it should be held, and after placing the wire, it should be closed and locked (pushed to the transformer end about 1/8 inch) to ensure good contact between the two halves of the transformer.

Terminal protection: When measuring high currents, it is forbidden to disconnect the probe from the terminal (otherwise the secondary of the transformer will generate high voltage, causing electric shock or equipment damage).

Installation and usage guide

1. Installation steps

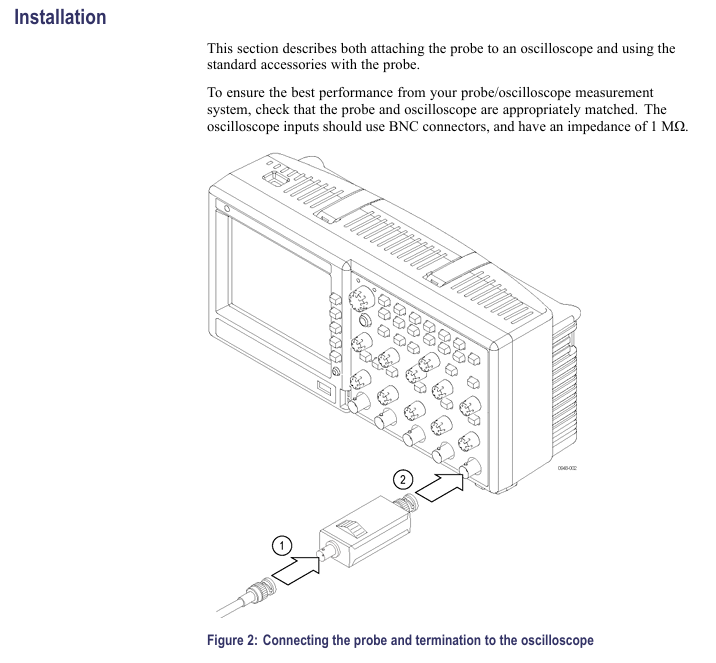

Terminal connection: Connect the BNC female head of the terminal to the probe output cable, and connect the BNC male head to the BNC input interface of the oscilloscope.

High frequency grounding: When measuring signals of ≥ 2 MHz, attach a 6-inch grounding wire to the probe transformer column and clamp it to RF ground to reduce interference and ringing.

Probe clamping: Open the slider → Place the measured wire into the transformer core (arrow direction is consistent with current direction, ensure correct waveform direction) → Close and lock the slider.

2. Usage skills

Reduce load effect: Prioritize clamping the probe at the low potential or ground terminal of the component to reduce its impact on the tested circuit.

Improve sensitivity: Increase the number of turns of the wire around the probe (e.g. 2 turns), doubling the sensitivity (e.g. 10 mA/division → 5 mA/division), but note that impedance increases with the square of the turns, which may affect high-frequency signals.

Anti magnetic field interference: In a strong magnetic field environment, use two probes to connect the positive and negative inputs of the oscilloscope, one clip the tested wire and one empty clip, and set the oscilloscope to "subtraction mode" to cancel out interference.

Performance validation and calibration

1. Required equipment

Equipment name, specification requirements, recommended model

Oscilloscope bandwidth ≥ 300 MHz, vertical sensitivity ≥ 1 mV/div, supports average amplitude TDS 303X, TDS 305X

Calibration generator fast edge (≤ 1 ns), sine wave (5 V) p-p@50 Ω, 935 Hz-120 MHz) Wavetek 9100, Tektronix PG 506A

Digital multimeter (DMM) AC voltage range, with an accuracy of 5.5 digits or higher, and an error of ≤ 0.5% at 50 kHz. Keithley 2000, HP 3458A

Auxiliary accessories BNC "T" type adapter, 50 Ω precision coaxial cable (36 inches), BNC to double banana head adapter, calibration fixture Tektronix corresponding models (see Table 6)

2. Core validation projects (including calculation methods)

(1) Mid frequency accuracy test (50 kHz)

Qualification criteria for step calculation method

1. Set the terminal to 1 mA/mV, calibrate the generator output to 50 kHz, 5 V p-p, connect BNC "T" → DMM, record the reading M1 I test=M1/50 Ω (test current). 2. Disconnect the DMM from "T", connect the probe+terminal, calibrate the probe clamp fixture, record the DMM reading M2% Error=[(M2 − I test)/I test] × 100 ± 3%

3. Set the terminal to 10 mA/mV, repeat step 2, and record the DMM reading M3% Error=[(10 × M3 − I test)/I test] × 100 ± 3%

(2) Low frequency bandwidth test

Qualification criteria for sensitivity gear step calculation method

1 mA/mV 1. Measure the output M1 at 50 kHz; 2. Set the generator to 8.5 kHz and measure the output M2 low-frequency ratio=M2/M1 ≥ 0.707

10 mA/mV 1. Measure the output of M3 at 50 kHz; 2. Set the generator to 935 Hz and measure the low frequency ratio of M4 output=M4/M3 ≥ 0.707

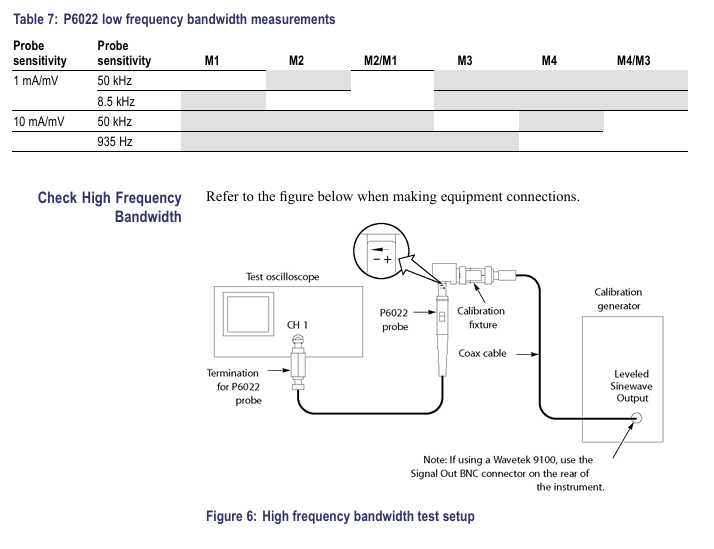

(3) High frequency bandwidth testing

Qualification criteria for sensitivity gear step calculation method

1 mA/mV. Set the oscilloscope to 20 mV/div and measure the amplitude M1 at 50 kHz. 2. Set the generator to 100 MHz and measure the amplitude M2. High frequency ratio=M2/M1 ≥ 0.707

10 mA/mV. 1. Set the oscilloscope to 2 mV/div and measure the amplitude M3 at 50 kHz. 2. Set the generator to 120 MHz and measure the amplitude M4. High frequency ratio=M4/M3 ≥ 0.707

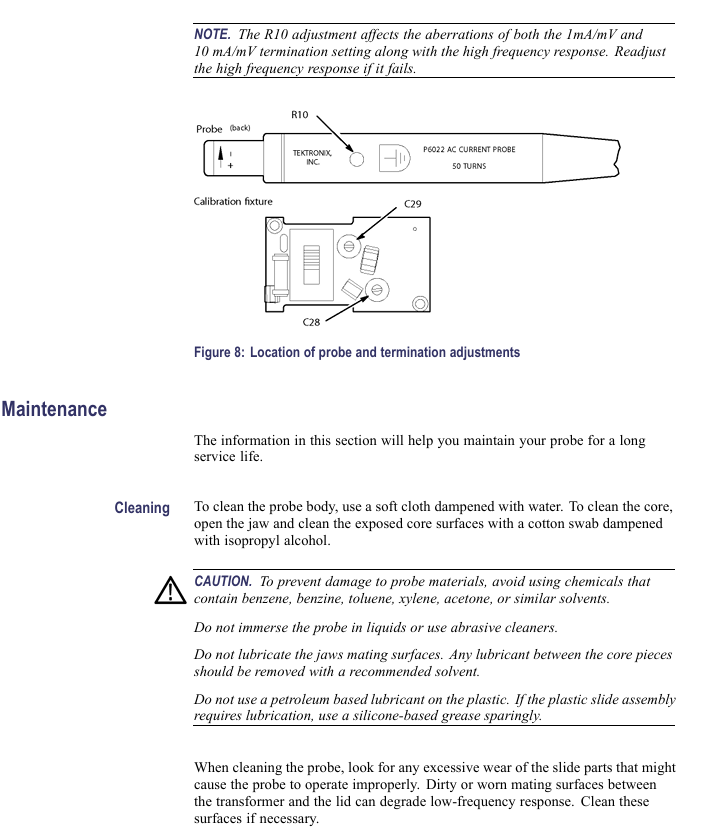

3. Calibration adjustment (if verification fails)

Remove terminal cover: Use a small screwdriver to gently pry open the top snap cover of the terminal (keep the bottom cover).

Oscilloscope settings: CH1, DC coupling, 2 mV/div, 4-5 ns/div, average 5-10 times, trigger set AC, positive slope.

Adjust parameters: calibrate the generator to output a 1 V p-p fast edge signal and connect it to the calibration fixture; Adjust the C28 and C29 capacitors of the terminal and the R10 resistance of the probe to minimize waveform distortion and ensure optimal flat top response.

Maintenance and Repair

1. Daily maintenance

Cleaning: Wipe the probe body with a damp cloth; Clean the magnetic core with cotton swabs soaked in isopropanol (solvents such as benzene, toluene, acetone, etc. are prohibited); Do not soak or use abrasives.

Lubrication: The slider component can only be coated with a small amount of silicon-based grease, and petroleum based grease is prohibited; Lubrication is prohibited on the contact surface of the magnetic core.

Inspection: Regularly check the wear of the slider and the cleanliness of the magnetic core contact surface (dirt can reduce low-frequency response).

2. Disassembly and maintenance

(1) Probe disassembly (requires soldering iron)

Pull back the strain relief boot, gently pry on the probe body and remove it forward.

Take out the ball bearing and spring retainer, and remove the upper half of the slider, spring, and transformer.

Remove the grounding terminal of the circuit board and gently remove the circuit board, transformer, and cable components (to avoid damaging the cable solder joints).

(2) Terminal maintenance

Replace connector: remove cover → protect circuit with heat sink → solder off old connector → replace with new connector → solder reset.

Replace the circuit board: Remove the front and rear covers → solder off the connector wires → remove the circuit board screws → assemble in reverse after replacement.

3. List of replaceable parts (core)

Electrical components (excerpt from Table 10)

Component Number Tektronix Part Number Name and Description

A1 670-1112-00 Probe Circuit Board Component

A2 011-0106-00 P6022 Coaxial Terminal

A1T1 120-0603-00 Current Transformer

A2C28/A2C29 281-0123-00 Variable capacitor (5-25 PF, 100 V)

Mechanical components (excerpt from Table 11)

Drawing number/index Tektronix part number name and description quantity

12-1 204-0360-01 Probe Upper Shell 1

12-3 351-0174-00 Probe Slide (Acetal Material) 1

12-9 175-1027-00 RF Cable Assembly (62.5 Ω, 60 inches) 1

12-18 196-3120-01 Probe Grounding Wire (23 AWG, 6 inches) 1

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923