K-WANG

KOLLMORGEN P70360 High Performance Microstep Driver

KOLLMORGEN P70360 High Performance Microstep Driver

Basic Information

Core positioning: P70360 is an AC input micro stepper driver that supports 120/240 VAC power supply, with a maximum output current of 2.5 A RMS (peak 3.5 A RMS) and integrated Dynamic Smooth ™ (Dynamic smoothing) Multi-Stepping ™ (Multi step) Encoderless Stall Detection ™ (No encoder blockage detection) and other patented technologies should be used in conjunction with Kollmorgen recommended stepper motors (such as T2x/N3x/K3x series), and parameter configuration can be achieved through switches or P7000Tools software.

Version iteration: The document has undergone 7 revisions (1-G version), with the latest G version mainly updating outdated pin numbers, adding J4-18 pin warnings, updating brand logos, and revising the motor selection section to ensure compatibility with firmware version 2.10 and above.

Core technical parameters and hardware characteristics of the driver

(1) General Technical Parameters

Category parameter item specification

Power characteristics: Input voltage 120/240 VAC (50/60 Hz), corresponding to DC bus voltage of 320 VDC (optional 160 VDC bus)

Maximum output power 350 W (240 VAC input)

Bus voltage protection undervoltage fault 130 VDC, overvoltage fault 440 VDC, regenerative voltage 420 VDC

Surge current peak 30 A (pulse width 4 ms), recommended slow melting fuse 7 A

Motor adaptation motor inductance range: 320 VDC bus: 50~200 mH; 160 VDC bus: 7~30 mH

The maximum length of motor cable is 20 meters (24 AWG cable)

Step resolution of 200~50000 steps per motor rotation (set through S2-2~S2-4 switches)

I/O Characteristics Step/Direction Input Voltage 2.5~5.5 VDC, Current 5~20 mA, Maximum Frequency 2 MHz, Minimum Pulse Width 250 ns

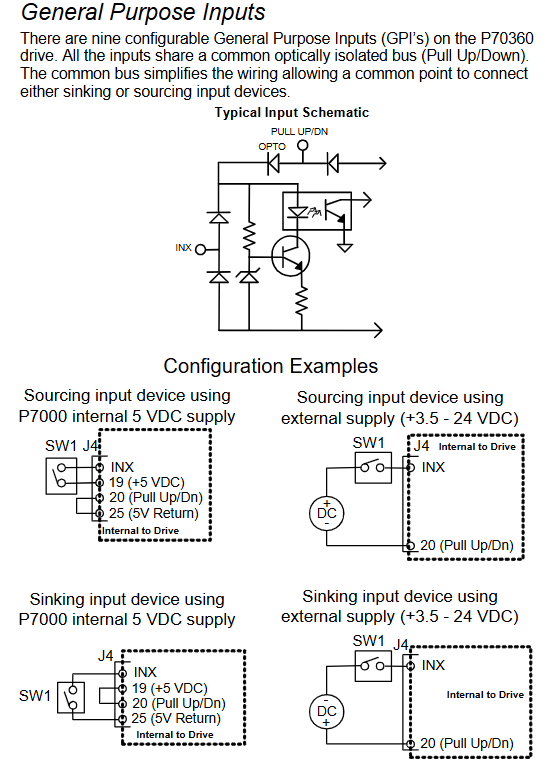

Universal input (9 channels) voltage 3.5~24 VDC, current 10 mA, response time ≤ 250 μ s

Universal output (2 channels) maximum voltage 30 VDC, maximum current 10 mA, response time ≤ 250 μ s

Environmental adaptability working temperature 0~40 ° C

Storage temperature -20~+70 ° C

Humidity 90% relative humidity (no condensation)

Altitude ≤ 1500 m (5000 ft)

Pollution level II

(2) Hardware features and optional configurations

core functionality

Dynamic Smoothing ™): The second-order low-pass filter reduces motion impact and mechanical resonance, and sets the smoothing level (minimum/moderate/severe/aggressive) through S2-8/S2-9 switches.

Encoder less Stall Detection ™): By monitoring the deviation between the instruction position and the actual position through the internal motor model, if the deviation exceeds 2 full steps, a fault will be triggered and activated through the S2-12 switch.

Current Reduction: After the motor is stationary for 100 ms, it automatically reduces the current to 75% of the rated value (the ratio and delay can be adjusted through software), and the S2-10 switch controls enable/disable.

Multi Stepping ™): Enhanced filtering function, smoothing low resolution input (such as 200/400 steps/rev) into micro step output, with S2-11 switch enabled.

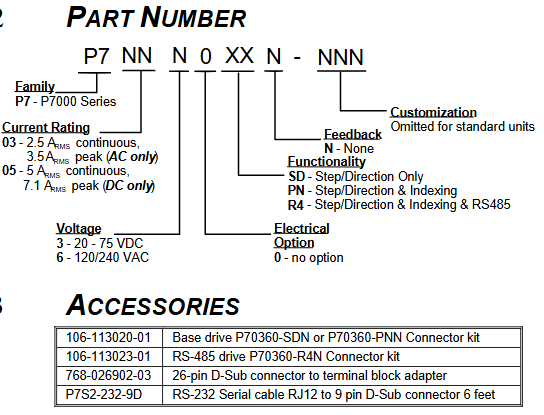

Model difference

P70360-SDN: Basic version, only supports step/direction control, default universal input configuration is Jog ±/EOT ±/fault reset.

P70360-PNN: Advanced version, supporting step/direction and indexing functions, with additional MV SEL 1-4 inputs for multi speed selection.

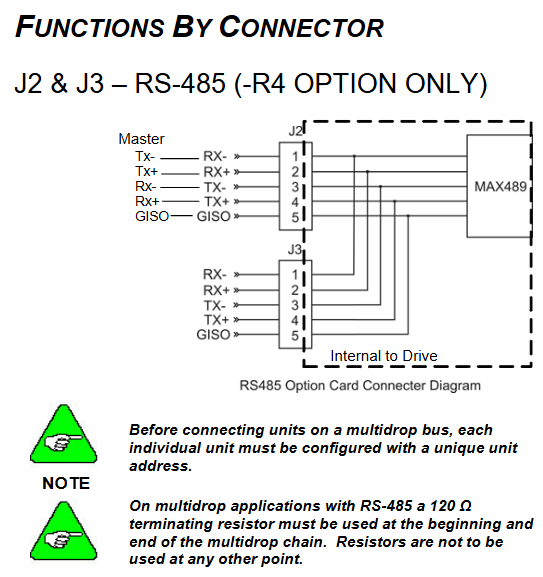

P70360-R4N: Equipped with RS-485 communication version, supports multi machine networking (requires unique node address configuration), and adds J2/J3 connectors for RS-485 bus.

Hardware installation and electrical wiring specifications

(1) Mechanical installation requirements

Installation preparation

Installation surface: It should be a cold plate (recommended aluminum), fixed with 8-32 or M4 screws, and the driver should be installed upright (with the heat sink fins facing left), leaving at least 25.4 mm (1 in) of heat dissipation space around to avoid direct exposure to heat sources.

Temperature control: When the temperature of the heat sink exceeds 70 ° C, the driver will overheat and shut down. If the ambient temperature exceeds 40 ° C, it is necessary to increase fan cooling or reduce the load duty cycle.

installation dimensions

Basic version (without RS-485): Length 170.18 mm (6.700 in), Width 132.21 mm (5.205 in), Height 52.324 mm (2.060 in).

Equipped with RS-485 version: length 170.18 mm (6.700 in), width 132.21 mm (5.205 in), height 58.217 mm (2.292 in).

(2) Electrical wiring specifications

Wiring safety and sequence

Power off operation, ensure that the drive capacitor is discharged (after power off for ≥ 2 minutes, measure the DC bus voltage<40 V), all power cables and control cables need to be separately shielded, and both ends of the shielding layer should be grounded.

The distance between the power cable (motor/power supply) and the control cable (step/direction/I/O) should be ≥ 20 cm to avoid cross interference; When the cable length exceeds 25 meters, Kollmorgen 3YL-20 choke coil is required (such as SERVOSTAR 601-606 with 4 × 1 mm ² cable).

Core connector definition

J4 (26 pin command I/O): includes step (J4-1/2), direction (J4-3/4), enable (J4-5/6) inputs, fault output (J4-7/8), 9-channel universal input (J4-10~18), universal output (J4-21/22), and 5V power supply (J4-19/25).

J6 (motor power supply): 4-pole connector, A+/A - (black/orange), B+/B - (red/yellow) connected to the motor winding, PE (green and yellow stripes) connected to the motor casing, pay attention to the motor direction (swapping A ± or B ± can be reversed).

J7 (AC power supply): 4-pin connector, J7-1 is connected to 120/240 VAC live wire, J7-2 is connected to 240 VAC neutral wire, J7-3 is connected to 120 VAC neutral wire, J7-4 is connected to protective earth (PE), and it is forbidden to connect 240 VAC to J7-3.

J2/J3 (RS-485, R4N version only): 5-pin connector, J2-1/RX+, J2-2/RX -, J2-3/TX -, J2-4/TX+, J2-5/GOS (isolated ground), with 120 Ω terminal resistors connected at the beginning and end of the bus.

Typical wiring scheme

Differential step forward/direction: The controller differential output is connected to J4-1 (STEP+)/J4-2 (STEP -), J4-3 (DIR+)/J4-4 (DIR -), and the cable uses shielded twisted pair, with both ends of the shielding layer grounded.

Open collector electrode single ended signal: The controller's open collector electrode output is connected to J4-1 (STEP+)/J4-3 (DIR+), J4-2/J4-4 are grounded, and an external pull-up resistor is required (when the voltage is greater than 5V, a current limiting resistor needs to be connected in series, the formula R CL=(V s − 5) × 100).

Universal input (such as Jog+): When using an internal 5V power supply, connect J4-14 (DIN5) to one end of the button and J4-20 (Pull Up/Dn) to the other end of the button; When using an external 24V power supply, a current limiting resistor should be connected in series (as above).

Parameter configuration and software operation

(1) Switch configuration (hardware quick setting)

Basic parameter settings can be made through the S1 (motor selection) and S2 (function configuration) switches on the top of the driver, and can be started without software:

Motor selection (S1+S2-1): S1 selects the motor series (e.g. S1=1 corresponds to T21... C series, S1=4 corresponds to N31... G series), S2-1 selects the motor type (OFF is the standard series, ON is CTM/CTP series), CTP motors require additional heat dissipation plates (equivalent to 4.125 × 4.125 × 0.25 inch aluminum plates), otherwise the rated current needs to be reduced by 25%.

Step resolution (S2-2~S2-4): Supports 8 levels of resolution, such as ON/ON/ON corresponding to 200 steps/revolution, OFF/OFF/OFF corresponding to 25000 steps/revolution.

Load inertia ratio (S2-5~S2-7): Set according to the load rotor inertia ratio (0-1 to 20-32), used to optimize anti resonance gain, such as OFF/OFF/OFF corresponding to 0-1, ON/ON/ON corresponding to 20-32.

Function switches (S2-8~S2-12): Dynamic smoothing (S2-8/S2-9), current reduction (S2-10), multi-step (S2-11), locked rotor detection (S2-12), ON is enabled, OFF is disabled.

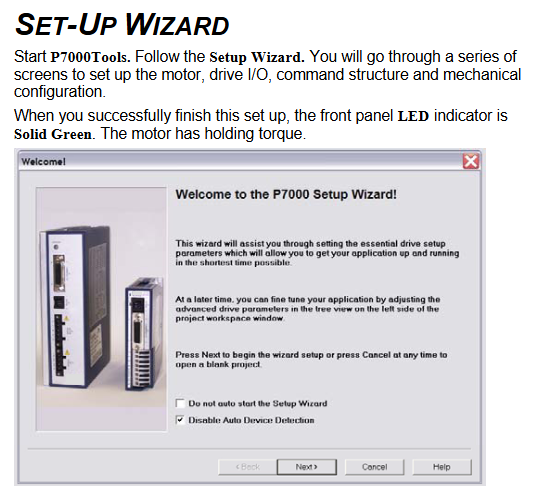

(2) P7000Tools software configuration (advanced settings)

Software installation and connection

Install P7000Tools (supporting Windows system), connect the PC to the J5 interface of the driver through an RS-232 cable (P7S2-232-9D, RJ12 to 9-pin D-Sub), with a default baud rate of 19200, data bit 8, even parity, and stop bit 1.

After starting the software, scan the drive through "Scan for Connected". For the first connection, configure the node address (1-99) to ensure that there is no conflict with the hardware switch.

Core configuration module

Motor configuration: Select the motor model (or create a custom motor through the "Motor File Editor", enter parameters such as rated current, number of poles, peak torque, etc.), execute the "Probe Stepper Motor" to detect the motor inductance, and optimize the control algorithm.

Mechanical parameters: Set user units (steps/revolutions/millimeters/inches), gear ratio (e.g. 2:1 gearbox set to 2 motor revolutions/load revolutions), and load inertia for motion profile calculation.

Command configuration: Set step resolution (consistent with hardware switch), rotation polarity (reverse motor direction), enable polarity (Active Open/Lost), speed/acceleration/deceleration limits. Jog speed is divided into high and low gears (such as 20 revolutions per second for high speed and 0.5 revolutions per second for low speed).

I/O configuration: Customize 9 universal inputs (such as Jog+/Jog -/EOT+/EOT -/fault reset/start movement), input debounce time (default 1 ms), and universal output functions (such as motor operation/stall/EOT latch).

Advanced settings: Adjust anti resonance frequency (formula)

AResFrequency= 100⋅J Rotor ToothCount⋅T max)、 Dynamic smoothing frequency (formula SmoothingFrequency=9 ⋅ J Rotor ToothCount ⋅ T max), current reduction ratio, and delay.

Sports Profile Generation

Supports 63 independent motion profiles, divided into two modes: AVD (acceleration velocity distance) and T/D (time distance), which can set acceleration and deceleration, target speed, motion distance, delay time, and jump index (chain motion).

Select Profile through "Move Select" input (up to 6 channels, binary encoding). If inputting 1+2 triggers Profile 3, configure "Start Move" input to trigger motion (edge triggered).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923