K-WANG

DEIF PPU-3 Parallel and Protection Unit

Stand alone operation: independent power supply control for a single generator;

Parallel with other generators: Multiple generators are synchronized in parallel to achieve load distribution and coordinated control.

Its core value lies in simplifying the generator control chain, which can be connected to the PLC control system through digital/analog I/O or serial communication, and has flexible functional expansion capabilities.

DEIF PPU-3 Parallel and Protection Unit

Product basic positioning and core applications

PPU-3 is a compact microprocessor control unit launched by DEIF, which integrates the protection and control functions of synchronous/asynchronous generators in an "integrated" design. It has a built-in galvanized separated three-phase measurement circuit and is designed for ship application scenarios. It supports two core working modes (which can be combined):

Stand alone operation: independent power supply control for a single generator;

Parallel with other generators: Multiple generators are synchronized in parallel to achieve load distribution and coordinated control.

Its core value lies in simplifying the generator control chain, which can be connected to the PLC control system through digital/analog I/O or serial communication, and has flexible functional expansion capabilities.

Core functional modules

(1) Display and operation unit

Display configuration: The display unit (DU-2) is independently designed and can be directly installed on the host or at the front end of the distribution cabinet door (with a standard 3m display cable). A single PPU-3 can expand up to 2 additional display units (up to 200m away);

Display content: Real time display of all measured values, calculated values, alarm information, and event logs;

Extended operation panel: Optional AOP-1 (16 configurable LEDs+8 configurable buttons) or AOP-2 (16 configurable LEDs+8 configurable buttons+1 status relay), supporting CAN bus communication.

(2) Regulation Modes

According to the control object (governor/automatic voltage regulator), provide multiple types of switchable standard regulation modes to meet different operational requirements:

Specific functions of control object adjustment mode

Governor maintains a fixed frequency to maintain stable generator output frequency

Fixed power (base load) setting for fixed active power output

Frequency droop automatically adjusts the frequency as the load changes, adapting to parallel load distribution

Load sharing: Balanced allocation of active loads when multiple machines are connected in parallel

Automatic voltage regulator (AVR, optional option D1) with fixed voltage to maintain stable generator output voltage

Fixed reactive power setting for fixed reactive power output

Fixed power factor maintains power factor stability

Reactive load sharing: Balanced allocation of reactive load when multiple machines are connected in parallel

Voltage droop automatically adjusts voltage with changes in reactive load, suitable for parallel scenarios

(3) Self checking and configuration tools

Self test: Perform periodic self tests at startup, display fault information in plain text on the screen, and trigger alarms through relay outputs (status outputs);

M-Logic (Micro PLC): Free integration into PC tool software, supports custom input/output functions and logic conditions, and adapts to personalized application scenarios;

Configuration method:

Local: configured through the password protection menu of the display unit;

Remote: Connect to a PC via USB and use the free Windows version PC tool software (available from the DEIF download center), which supports parameter monitoring, configuration saving/downloading, and firmware updates.

(4) Engine control and protection (optional function)

After installing the engine control and protection module, the PPU-3 can achieve:

Engine start stop sequence control;

Engine protection function: Provides a complete backup of the engine shutdown channel in case of main processor failure, ensuring equipment safety.

(5) CANshare function (optional G9 option)

CANshare provides:

Digital load distribution and line fault (disconnection, short circuit) monitoring;

Support position feedback and monitoring of up to 4 bus circuit breakers (BTBs);

Manage up to 5 load distribution segments;

Monitoring of active/reactive load distribution;

Dead bus closing and first startup discrimination;

Simulation testing mode before debugging.

Standard protection functions (Protections)

PPU-3 is equipped with multiple protection functions that comply with IEEE Std. C37.2-1996 (R2001) standards, covering core fault scenarios of generators and busbars. Some functions support multiple threshold settings:

Protection Function ANSI Number Threshold Order Core Function

Generator reverse power (32) 2nd order to prevent the generator from absorbing grid power (such as when the turbine loses steam)

Generator over current (50/51) 6th order protection of the generator from overload current damage

Voltage dependent overcurrent (51V) 1st order combined with voltage state to determine overcurrent and avoid false triggering

Inverse time over current (51) The larger the first-order current, the shorter the action time, making it suitable for different overload scenarios

Generator over/under voltage (59)/(27) 2nd/3rd order protection for generator insulation and load from overvoltage/undervoltage impact

Generator over/under frequency (81) 3rd/3rd order to prevent frequency deviation caused by abnormal generator speed

Busbar over/undervoltage (59)/(27) 3rd/4th order protection for busbars and downstream loads from overvoltage/undervoltage damage

Busbar over/under frequency (81) 3rd/4th order to maintain bus frequency stability

Busbar voltage imbalance (60) 1st order prevention of equipment failure caused by three-phase voltage imbalance

Generator overload (32) 5th order to avoid long-term operation of the generator beyond rated load

Current/Voltage Imbalance (60) 1st order protection for generators and loads from damage caused by unbalanced current/voltage

Overexcitation/Loss of excitation (40/32 RV) 1st order protection generator excitation system to avoid magnetic field anomalies

Hardware and interface specifications

(1) Hardware architecture and slot allocation

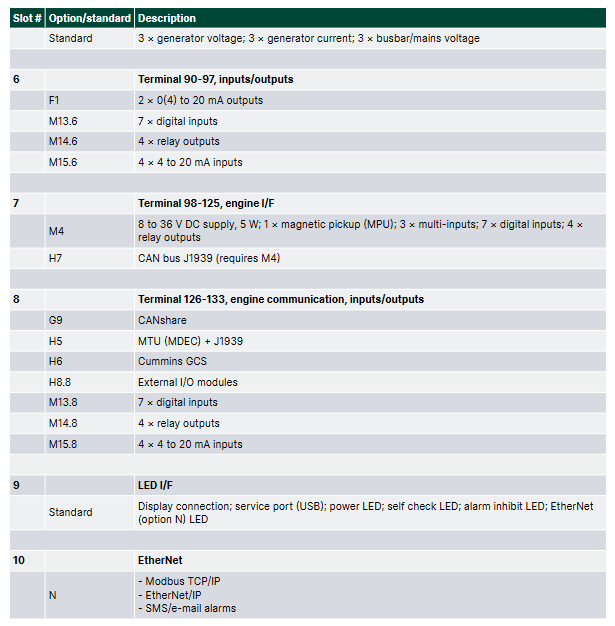

The PPU-3 adopts a "slot based" hardware design, with fixed slots corresponding to different functional modules. Each slot only supports one hardware option, and the core slot functions are as follows:

Slot Number Function Category Standard Configuration/Optional Options Core Interface and Parameters

1. Power supply and basic I/O standard 8-36V DC power supply (11W); 1 status output relay; 5 relay outputs; 2 pulse outputs (kWh, kvarh); 5 digit inputs

Communication options include H2 (Modbus RTU/ASCII, RS-485), H3 (Profibus DP), etc., which are responsible for serial communication with external systems such as PLCs

3 load distribution standards with 13 numerical inputs; 4 relay outputs; 1 P (active) load distribution line; 1 Q (reactive power) load distribution line; 2 external set point inputs (GOV/AVR)

4 GOV/AVR/transmitter output standards (4 relay outputs); Optional E1 (2-channel+/-25mA), E2 (2-channel 0 (4) -20mA) and other output control signals can be sent to the speed regulator/AVR, or used as transmitter signal output

5 AC measurement standards, 3 generator voltage inputs; 3-channel generator current input; 3-channel bus/grid voltage input

6 Analog Output Expansion Optional F1 (2-channel 0 (4) -20mA transmitter output) to expand analog output channels

7 engine control and I/O expansion options include M4 (engine control, digital/analog I/O) and H7 (software level engine communication) to achieve engine start stop control, I/O expansion, and specific engine protocol docking

8. Advanced communication and load distribution options include G9 (CANshare), H5 (specific engine protocols such as Caterpillar, MTU), digital load distribution, and engine specific communication protocol docking

9 Ethernet communication options include N (Ethernet TCP/IP, supporting Modbus TCP/IP, EtherNet/IP, SMS/email alarms) to achieve remote monitoring and alarm notification over Ethernet

(2) Key technical parameters

Parameter category specific specifications

Working environment temperature: -25~70 ° C (-25~60 ° C with N option; UL/cUL certified environment maximum 55 ° C); Humidity: 97% RH (IEC 60068-2-30); Altitude: 0-4000m (downgraded for use from 2001 to 4000m)

Measurement range voltage: 100~690V AC (± 20%, UL/cUL certified maximum 600V AC); Current: 1/5A AC (from CT); Frequency: 30~70Hz

Auxiliary power terminal 1-2:12/24V DC nominal (8-36V DC operation, maximum 11W); Terminal 98-99:12/24V DC nominal (8-36V DC operation, maximum 5W); 2A slow melting fuse protection is required

Input/output digital input: optocoupler isolation, 8-36V DC conduction (impedance 4.7k Ω); Analog input: 0 (4) -20mA (impedance 50 Ω) RPM(MPU:2-70V AC,10-10000Hz); Relay output: 250V AC/30V DC (5A, UL/cUL certified 2A resistive load); Analog output: 0 (4) -20mA/± 25mA (isolated, maximum load 500 Ω)

Electrically isolated AC voltage from other I/O: 3250V AC (50Hz, 1min); AC current and other I/O: 2200V AC (50Hz, 1min); Analog output and other I/O: 550V AC (50Hz, 1min)

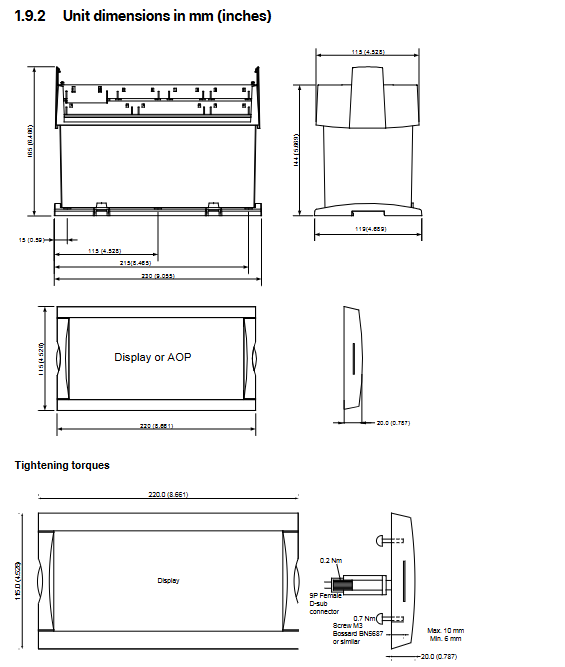

Protection level host: IP20; Display unit: IP40 (optional L gasket can be upgraded to IP54, required for RS certification applications)

Certified ship certification: certified by all mainstream classification societies; Safety certification: EN 61010-1, UL 508, CSA 22.2 No.14-05; EMC certification: EN 61000-6-2/4, IEC 60255-26

Optional Features and Accessories

(1) Core optional options (some key options)

Specific description of option code function category

A-series power grid protection package A1 (limited time undervoltage 27t, undervoltage+low reactive power 27Q, etc.), A5 (directional overcurrent 67)

C2 Generator Extended Protection Package Negative Sequence Voltage High 47, Negative Sequence Current High 46, Zero Sequence Voltage High 59, etc

D1 Voltage Control Fixed Voltage, Fixed Reactive Power, Fixed Power Factor, Reactive Load Distribution, Voltage Drop

G9 CANshare digital load distribution+line monitoring, multi BTB monitoring, dead bus closing

H2/H3 serial communication H2 (Modbus RTU/ASCII, RS-485), H3 (Profibus DP)

N Ethernet Modbus TCP/IP, EtherNet/IP, SMS/email alerts

Y1/Y11 display and control Y1 (engine and GB control), Y11 (display unit without local control button)

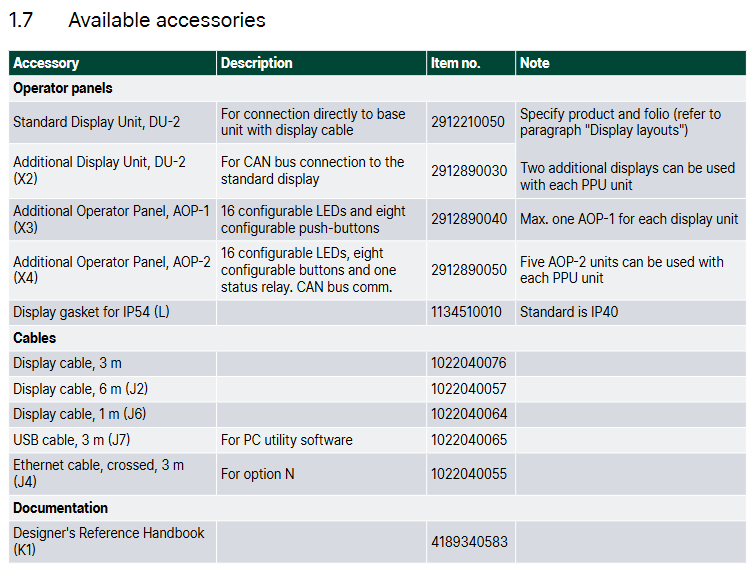

(2) Standard and optional accessories

Accessory type, specific product usage, model/remarks

Display Unit DU-2 (Standard): The host is equipped with Display 2912210050, and the display layout needs to be specified

DU-2 (extension) additional extension display 2912890030, supports CAN bus

AOP-1 expansion operation buttons and LED 2912890040 on the operation panel, with a maximum of one unit per display

AOP-2 expansion panel with status relay 2912890050, up to 5 units per PPU-3

Cable display cable (3m/6m/1m) connects the display unit to the host 1022040076 (3m), 1022040057 (6m), etc

USB cable (3m) PC configuration connection 1022040065

Cross Ethernet cable (3m) N option Ethernet connection 1022040055

IP54 display gasket (L) enhances the protection level of the display unit 1134510010, required for RS certification

Ordering and Disclaimer

(1) Order specifications

Required information: model (such as PPU-3 Marine), variant number (such as 01 with display/07 without display), product number (such as 2912210030-01);

Optional information: Please specify the selected functional options (such as M4, Y1, H2) and accessories (such as AOP-2, IP54 gasket);

Example: Product number 2912210030-01 (PPU-3 Marine 01 with display)+option M4 (engine control)+Y1 (engine and GB control)+H2 (Modbus RTU).

(2) Disclaimer

DEIF reserves the right to modify document content without prior notice;

The English version of the document is the latest authoritative version, and there may be delays in the translated version. In case of any conflicts, the English version shall prevail;

DEIF is not responsible for the accuracy of the translated version.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB AX411/511010/STD pH/ORP Analyzer Controller

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923