K-WANG

Watlow thermocouple products

Watlow thermocouple products

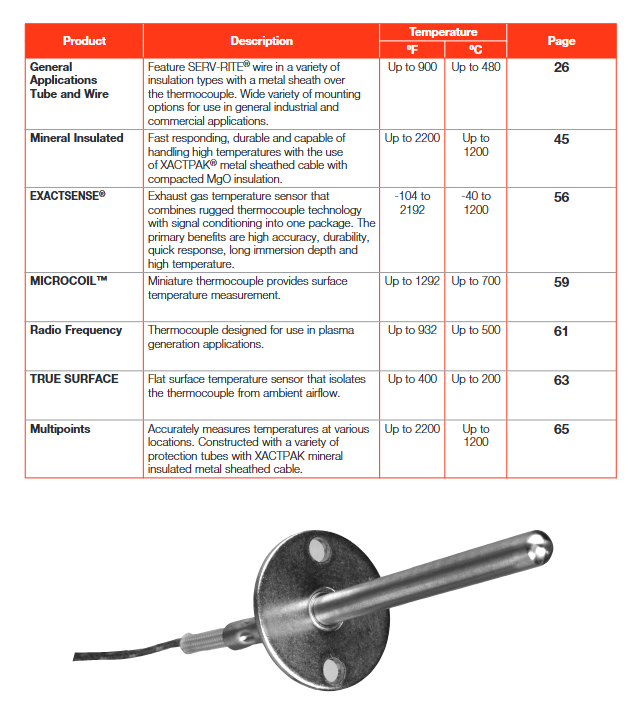

Product Core Overview

The Watlow thermocouple product line covers multiple scenarios such as general industry, high temperature, and precision measurement. It adopts ASTM standard calibration types (J/K/E/T/N/R/S/B, etc.) and is based on structural designs such as mineral insulation (MI), metal sheath, and fiberglass/PFA insulation. It has characteristics such as fast response, corrosion resistance, and high temperature resistance. The temperature measurement range covers -40 ° C to 1700 ° C and is suitable for various fields such as food processing, heat treatment, semiconductor manufacturing, and diesel engine post-processing.

Core advantages:

Diversified structure: including universal tube wire type, mineral insulation type, and micro coil (MICROCOIL) ™)、 Radio frequency compatible (TR), multi-point temperature measurement, etc., suitable for different installation and environmental requirements.

Accurate and stable: Following ASTM E230 calibration tolerances, some models have an accuracy of ± 1 ° C and a repeatability of 1% -2%. It supports three types of junctions: grounded/ungrounded/bare.

Durable protection: Sheath material can be selected from 304/316 stainless steel Alloy 600、Haynes ® 230, some products come with PFA coating or fiberglass weaving protection, which is corrosion-resistant and resistant to electromagnetic interference.

Classification and Characteristics of Key Products

(1) Universal thermocouple (Tube and Wire)

Application scenarios: Food processing, medical equipment, oven/refrigerator temperature control, pipeline tracking, and other routine temperature measurements.

Core features: Temperature range -200 ° C to 900 ° C, using SERV-RITE ® The wire is made of insulation materials such as fiberglass and PFA, and supports straight and 45 °/90 ° bending designs. The installation methods include adjustable springs, flanges, pipe clamps, and ring terminals.

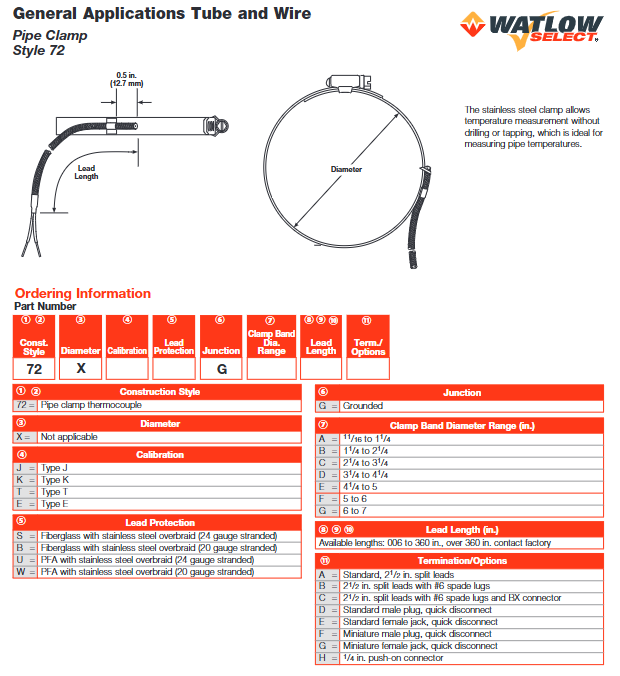

Typical models: Style 10/11 (spring adjustable), Style 20/21/22 (rigid shear), Style 72 (clamp type), Style 74/75 (gasket type).

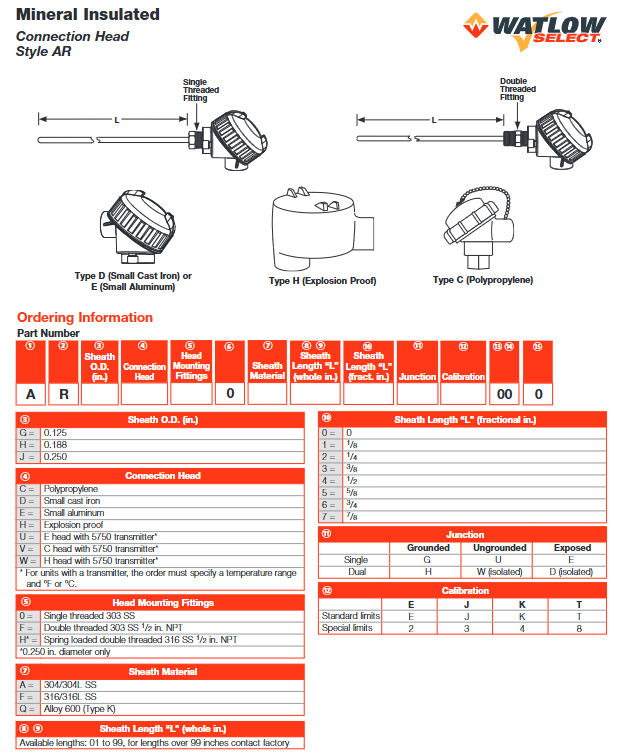

(2) Mineral Insulated (MI) Thermocouples

Application scenarios: Extreme environments such as high-temperature furnaces, turbines, nuclear reactors, semiconductor manufacturing, etc.

Core feature: Adopting XACTPAK ® Mineral insulated metal sheathed cable, compacted MgO insulation, temperature range -40 ° C to 1200 ° C (some up to 1700 ° C), minimum sheath diameter of 0.02 inches, fast response time (0.02 inch sheath grounding response time<0.02 seconds).

Typical models: Style AB (cutting and stripping type), Style AC (plug terminal type), Style AR (connector type), Style AT (thermowell adaptation type).

(3) Special function thermocouple

EXACTSENSE ® Series: Integrated electronic components, convert thermocouple signals into 0-5V analog signals or LIN/CAN digital signals, compatible with diesel engine aftertreatment systems (DPF/DOC/SCR), temperature range -40 ° C to 1100 ° C, accuracy ± 7 ° C - ± 12.5 ° C, immersion depth 25-200mm.

MICROCOIL ™ Series: Micro spiral design, suitable for surface temperature measurement, isothermal measurement area ensures accuracy, temperature range -40 ° C to 700 ° C, coil diameter 0.125 inches, spring loaded design suitable for uneven surfaces.

TR RF compatible type: designed for plasma applications, resistant to electromagnetic interference, dielectric strength of 3000VDC, temperature range of 260 ° C-500 ° C, tip material can be silver plated copper or aluminum nitride.

Multi point temperature measurement type: The single sheath is equipped with multiple temperature measurement points, suitable for scenarios such as distillation towers and furnaces that require gradient temperature measurement. The diameter of the sheath is 0.125-0.25 inches, supporting 2 to multiple temperature measurement points, and the spacing can be customized.

Core technical parameters

(1) Calibration type and temperature range

Calibration Type Measurement Range (° C) Typical Application Scenarios Key Characteristics

J-200 to 760 general industrial, moisture free environment iron constantan material, commonly used for medium and low temperatures

K-200 to 1260 high temperature furnace, heat treated nickel chromium nickel silicon material, corrosion-resistant, widely used

E-200 to 900 vacuum, inert environment nickel chromium copper nickel material, with the highest EMF output

T-200 to 350 low temperature, cryogenic scene copper copper nickel material, good low-temperature stability

N -200 to 1260 sulfur containing environment NiCrSi NiSi material, anti-aging

R/S 0 to 1480 high temperature precision measurement of platinum rhodium alloy, resistant to high temperature oxidation

B 870 to 1700 ultra-high temperature furnace platinum rhodium 30- platinum rhodium 6 material, excellent high temperature stability

(2) Key performance parameters

Response time: Depending on the diameter of the sheath and the type of junction, a 0.032-inch mineral insulated grounding junction takes less than 0.02 seconds, while a 1-inch rigid sheath without grounding junction takes about 4 seconds.

Wire resistance: The resistance per foot of the 24 gauge double wire is 0.3-1.5 Ω (depending on the calibration type), and it is recommended to use a thick wire gauge for long-distance wiring.

Voltage resistance and protection: Some models are resistant to electromagnetic interference (100V/m 20MHz-2GHz), with a waterproof rating of IP65 (NEMA 4X), and some are equipped with explosion-proof connectors.

Key points for installation and selection

(1) Selection of core dimensions

Temperature range: Select the calibration type based on the highest/lowest temperature of the operating conditions (such as B/R/S type for ultra-high temperature and T type for low temperature).

Environmental medium: Choose PFA coating or 316 stainless steel sheath for corrosive environments; Choose N-type for sulfur-containing environments; Choose K-type oxidation environment.

Installation method: Choose micro curved type (Style 12) for narrow spaces; Pipeline temperature measurement using clamp type (Style 72); Choose pad type (Style 74) or MICROCOIL for surface temperature measurement ™。

Signal requirement: Select EXACTSENSE for digital signal ®; Choose thick wire gauge or shielded wire for long-distance transmission.

(2) Installation precautions

Wiring: The thermocouple extension wire should be matched with the calibration type (such as J-type iron constantan wire) to avoid polarity reversal. For long-distance wiring, the influence of wire resistance should be considered.

Junction selection: Grounding junction for corrosive environments (welded with sheath to prevent medium intrusion); Avoid using ungrounded connections for grounding loops; The fastest response is required to select a bare junction (without sheath protection).

Interference protection: TR type for RF environment; Choose twisted pair cables and shielding layer for strong electromagnetic environment, with the shielding layer grounded at one end.

Typical application scenarios

Industry recommended product types, core requirement matching

Food processing universal tube wire type (Style 20/72) sanitary grade, easy to install, medium and low temperature measurement

Heat treatment/high temperature furnace mineral insulation type (Style AR/AT), high temperature resistance, thermal shock resistance, long-term stability

Semiconductor Manufacturing MICROCOIL ™/ True SURFACE precision surface temperature measurement, installation in narrow spaces

Diesel engine EXACTSENSE ® Exhaust gas temperature measurement, digital signal compatible with ECM

Chemical/petroleum multi-point temperature measurement type, Alloy 600 sheath type corrosion environment, gradient temperature measurement requirements

Plasma application TR RF compatible anti electromagnetic interference, precise temperature measurement

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923