K-WANG

REXROTH IndraControl VEP30.2/40.2/50.2 series embedded terminals

REXROTH IndraControl VEP30.2/40.2/50.2 series embedded terminals

The REXROTH IndraControl VEP30.2/40.2/50.2 series embedded terminal is a PC based human-machine interaction device suitable for industrial scenarios, covering three models: 8.4-inch (VEP30.2), 12.1-inch (VEP40.2), and 15 inch (VEP50.2). It comes standard with 128MB memory and 128MB Compact Flash card, and is equipped with Windows CE 4.2. NET operating system. It supports RS232/USB/Ethernet/VGA multiple interfaces, with a front protection level of IP65. It is compatible with food processing, machine tools, printing and other equipment, and can configure parameters through Rexroth CE Settings. It needs to be paired with IndraLogicWinCE (authorized) and WinStudio visualization software to achieve control functions.

Product Overview

Core positioning: The IndraControl VEP series is an industrial grade embedded terminal launched by Bosch Rexroth, which combines human-computer interaction (operation/display) and control functions. Based on PC architecture design, it is suitable for the on-site operation needs of industrial equipment in multiple industries.

Product model differentiation

|Model | Display Size | Resolution | Operation Method | Front Size (Width × Height) | Weight|

|VEP30.2CC | 8.4 inches | 800 × 600 | Touch screen | 296 × 200mm | 2.2kg|

|VEP30.2CG | 8.4 inches | 800 × 600 | Touch screen+5-key keyboard | 306 × 241mm | 3.0kg|

|VEP40.2CE | 12.1 inches | 800 × 600 | Touch screen | 350 × 290mm | 3.8kg|

|VEP50.2CH | 15 inches | 1024 × 768 | Touch screen | 407 × 370mm | 4.5kg|

Core strengths

Reliable protection: IP65 protection on the front, suitable for industrial dust and slight splashing, meeting the needs of the food industry.

Comprehensive interface: covering RS232 (COM1), USB 1.1 × 2, Ethernet (10/100Base-T), VGA, PS/2, etc., supporting PROFIBUS DP master station expansion.

Software adaptation: Pre installed Windows CE 4.2. NET, compatible with IndraLogicWinCE software PLC and WinStudio visualization software, supports FTP/WEB/Telnet servers.

Flexible installation: Embedded installation, supports multi posture deployment, and reserves sufficient heat dissipation space.

Key technical parameters

(1) Hardware core parameters

Category specific indicators

Processor Intel Ultra Low Voltage Celeron 400MHz, integrated graphics controller (8MB shared memory)

Storage configuration: Main memory 128MB, Compact Flash card 128MB (supports expansion)

Display system TFT color touch screen, 262144 colors, backlight life of 8000-40000 hours (depending on size)

Power specifications input 24VDC (19~30VDC), maximum input current 2.5A, output+5V (5A),+12V (1.8A)

Environmental parameters: working temperature of 5-45 ℃, storage temperature of -20~60 ℃, relative humidity ≤ 75% (no condensation), altitude ≤ 2000m

Mechanical characteristics anti vibration: 0.075mm amplitude at 10~57Hz, 1g acceleration at 57~150Hz; 15g (6ms) impact resistance

(2) Interface parameter details

Interface type specification parameters

Ethernet RJ45 interface, 10/100Base-T, maximum cable length 100m

RS232 (COM1) 9-pin D-Sub interface, maximum transmission rate 115200bps, supports hardware/software handshake, maximum cable length 15m

USB 2 USB1.1 Type A interfaces, maximum power supply per device 500mA

VGA 15 pin HD Sub interface, maximum resolution 1024 × 768, maximum cable length 1.5m

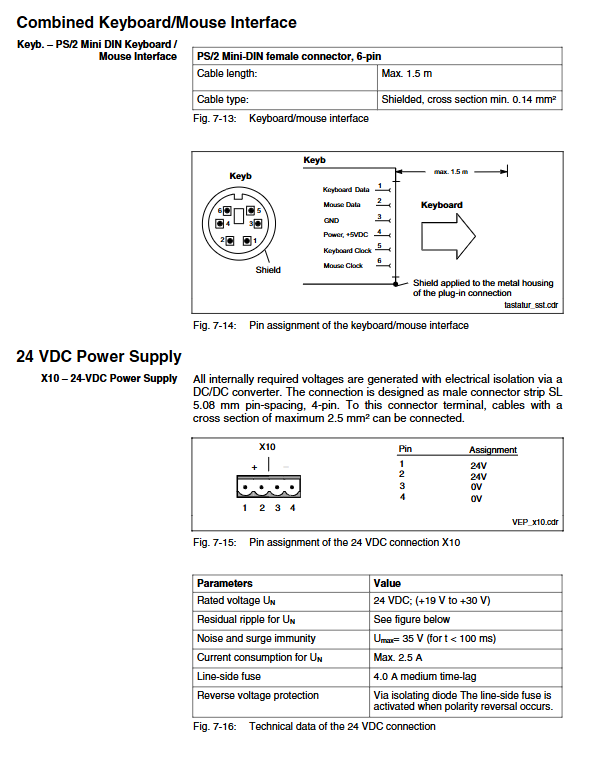

PS/2 6-pin Mini DIN interface, supports keyboard/mouse, maximum cable length 1.5m

PROFIBUS DP optional, 9-pin D-Sub interface, up to 12Mbaud, supports DP V0/V1 protocol

Software and Configuration

Operating system and pre installed software

System: Windows CE 4.2. NET, pre installed IndraLogicWinCE (license activation required) and WinStudio "lite" visualization software.

Core tools: Rexroth CE Settings, Touch Calibration, Save Registry.

Software licensing requirements

|Software Components | Authorization Requirements | Sample Order Number|

|IndraLogicWinCE | License must be ordered separately | R911308258|

|WinStudio Runtime | "lite" version limited to 200 variables, extensions require authorization | R911306951 (4000 variables)|

|Firmware package | Includes system and pre installed software | R911310115|

Key configuration functions

Network configuration: Supports DHCP automatic acquisition or static IP settings, configured through Rexroth CE Settings.

Application self start: You can set up self start programs such as WinStudio, Web Browser, Remote Desktop, etc.

Data interaction: Supports FTP/WEB/Telnet server self startup, enabling remote file transfer and control.

Installation and wiring specifications

Installation requirements

Installation method: Embedded installation of the control cabinet, with corresponding hole sizes according to the model (such as VEP30.2CC hole size of 264 × 16mm).

Space reservation: A heat dissipation gap of ≥ 50mm should be reserved around the device to avoid direct sunlight.

Fixed torque: Use M4/M5 screws with a tightening torque of 3.1~8.1Nm (depending on the model).

Wiring specifications

Power wiring: The 24VDC power supply requires a double OV wire, with a protective conductor (PE) cross-section of ≥ 4mm ² and a maximum cable length of 4m.

Signal wiring: Power cables and signal cables are laid separately, and the shielding layer of shielded cables is only grounded at the controller end.

Interface taboo: It is forbidden to plug and unplug connectors with power on. The PROFIBUS bus requires terminal resistors to be connected at both ends.

Maintenance and Accessories

routine maintenance

Cleaning: Wipe the screen with an anti-static cloth or a cleaning agent containing denatured alcohol every week, and do not use solvents.

Replacement of consumables: For CMOS batteries with a lifespan of ≥ 5 years, it is recommended to replace the capacitor pack (UPS) every 5 years and contact Bosch Rexroth service.

Connection inspection: Check the tightness of cables and plugs annually, and replace damaged parts immediately.

Core accessory list

|Accessory type | Model/Order number | Purpose|

|PROFIBUS cable | IKB0033 (R911291808) | Controller and terminal PROFIBUS connection|

|USB Memory Stick | MC OSFLASHUSB-064M | Data Storage and Transfer|

|Compact Flash Card | CFM01.1-0128 (R911308469) | Storage Expansion|

|Power connector | Weidm ü ller SL 5.08mm | 24VDC power connection|

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB IMDSM04 Distributed System Module | Industrial Automation Controller

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923