K-WANG

REXRTOH DIAX04 HDD and HDS Drive Controllers 2nd Generation

REXRTOH DIAX04 Second Generation HDD and HDS Driver Controller: A Full Analysis Engineering Guide

In the field of modern industrial automation, drive control systems are the core power source for mechanical processing, packaging printing, robotics technology, and various production lines. The DIAX04 series digital intelligent drive system launched by Bosch Rexroth's Mannesmann Rexroth has become a high-performance benchmark in the industry with its excellent modular design and powerful control capabilities. Especially the HDD (dual axis drive) and HDS (single axis drive) second-generation controllers in this series, with their compact drive package structure and flexible configuration options, are widely used in machine tools, textile machinery, and processing systems. This article will be based on a detailed engineering project planning manual, delving into the technical architecture, safety specifications, electrical connections, control cabinet design, and maintenance points of DIAX04 HDD and HDS drive controllers, providing engineers with a unique professional technical guide.

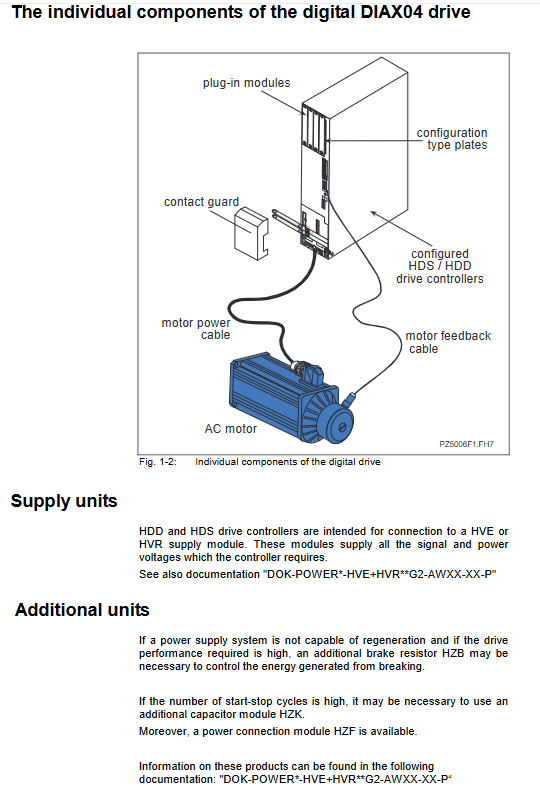

System Overview and Modular Architecture

The core advantage of the DIAX04 drive system lies in its highly modular design. This system is not a single driving unit, but an organic whole composed of different functional modules working together. A complete DIAX04 driver package mainly consists of a power supply unit, a driver controller (HDS or HDD), and various additional units.

HDS (single axis drive) and HDD (dual axis drive) controllers serve as the execution terminals of the system, responsible for directly controlling the motors and monitoring their operating status. They are typically used in conjunction with HVE or HVR power supply modules, which provide all the signals and power voltages required by the driver. This design allows for flexible combination of multiple axes under a single power supply unit, greatly saving control cabinet space and simplifying wiring.

In addition, according to system requirements, it is also possible to integrate a braking resistor HZB (for processing braking energy), a capacitor module HZK (for energy buffering at high start stop frequencies), and a power connection module HZF. This "building block" component combination method endows the DIAX04 system with strong adaptability and scalability, which can meet various application requirements from simple point-to-point positioning to complex multi axis collaborative control.

Strict safety regulations and risk prevention and control

In industrial environments involving high pressure and high-speed movement, safety is always the top priority. The design and operation of the DIAX04 drive controller must strictly follow safety instructions to prevent personal injury and property damage.

1. Electrical contact protection and high voltage hazards

The drive controller contains high-voltage components exceeding 50V inside, and the capacitor still carries dangerous charges after power failure. According to the EN 50178 standard, strict grounding measures must be taken. Due to equipment leakage current exceeding 3.5mA, protective wires (PE) must use copper wires with a cross-sectional area of at least 10mm ² and be permanently connected to the power supply network. Before carrying out any maintenance work, the power must be disconnected and wait for at least 5 minutes until the capacitor is fully discharged and the voltage must be measured to confirm safety before touching. It is strictly prohibited to operate the equipment without installing grounding protection, and it is also strictly prohibited to use residual current operated protective devices (RCD) as direct protection for the driver. Overcurrent protection devices should be used to prevent indirect contact.

2. Dangerous sports and mechanical safety

Incorrect wiring, parameter settings, or sensor malfunctions may cause the motor to lose control and move. This danger may occur immediately after the device is started, or it may suddenly appear after long-term trouble free operation. Although the drive integrates monitoring functions internally, it must not rely solely on this function to ensure personnel safety. Superior monitoring measures must be implemented, such as installing protective fences, light curtains, etc., to ensure that personnel cannot enter dangerous areas by mistake. For the vertical axis, relying solely on the built-in brake of the motor is not enough. Additional mechanical locking, external braking, or balancing devices must be added to prevent heavy objects from falling after power failure.

3. Electromagnetic field and thermal surface protection

Electrical conductors and permanent magnets inside motors can generate strong magnetic fields, posing a serious health threat to individuals wearing pacemakers, metal implants, or hearing aids. Such personnel are strictly prohibited from entering the equipment operation, storage, or maintenance area. In addition, the drive housing, heat sink, and resistor may experience extreme high temperatures (up to 60 ° C) during operation. Operators must wait for the equipment to cool down for at least 10 minutes before coming into contact and wear protective gloves.

Product Technical Specifications and Model Analysis

1. HDS single axis drive controller

The HDS series is a basic single axis controller that covers multiple power levels from 40A to 300A (such as HDS02.2, HDS03.2, HDS04.2, HDS05.2). The model code has a clear logic, for example, in HDS03.2-W100N-HS01:

HDS stands for single axis drive.

03: Represents the serial number (corresponding to grades 75A-100A).

W: Represents internal air cooling.

100: Represents a rated current of 100A.

N: Represents no special version.

H: Representing the DIAX04 series.

S: Represents SERCOS interface (A represents analog interface).

HDS drives allow operation in environments ranging from+5 ° C to+45 ° C at rated data. If the ambient temperature or altitude exceeds the standard (altitude>1000 meters), the equipment must be downgraded according to the load factor to prevent overheating and damage. The power loss is mainly composed of control unit loss, configuration related loss, and power part loss. When calculating, it is necessary to consider the current intensity and switching frequency (4kHz/8kHz).

2. HDD Dual Axis Drive Controller

HDD02.2-W040N-HD32 is a special dual axis drive controller that can control two motors simultaneously. It integrates the SERCOS interface command communication module and provides an additional interface for each axis to connect to a 1Vpp sine wave signal incremental measurement system. This means that HDD drives can not only achieve high-speed digital communication through SERCOS fiber ring networks, but also directly connect to high-precision external measurement systems, making them particularly suitable for applications that require dual axis synchronization or high-precision positioning.

Electrical connection planning and interface detailed explanation

Correct electrical connections are the cornerstone of stable system operation. The DIAX04 driver controller provides rich and standardized interface terminals, each with its specific technical specifications.

1. Power supply and intermediate circuit connection (X1, X5)

The X1 terminal is an internally integrated bus connector that obtains the power required to control electronic devices from adjacent power supply units through a flat cable. The X5 terminal is a critical interface for connecting the DC bus (L+, L -) and the motor power supply (A1, A2, A3). According to different power levels, X5 supports wires with different cross-sectional areas (such as HDS02 supporting 0.2-4mm ², while HDS05 supporting 16-50mm ²), and has strict requirements for tightening torque (such as HDS02 being 0.5-0.6Nm and HDS04 being 4Nm). It is necessary to ensure that the polarity of the DC bus is correct, and the shielding layer of the motor connection wire must be reliably grounded through the XS1 terminal.

2. Communication and feedback interfaces (X2, X4, X7)

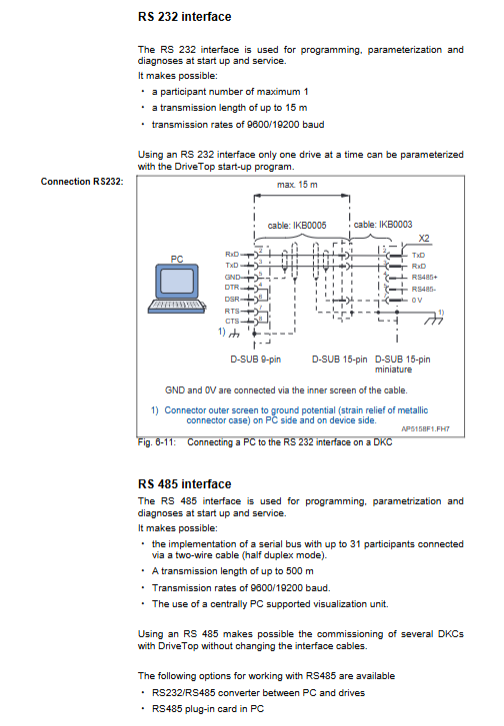

X2 (serial interface): Supports RS232 and RS485 modes, mainly used for debugging and parameterization. RS232 is suitable for direct connection between a single drive and a PC (up to 15m), while RS485 supports networking of multiple drives (up to 500m), which is convenient for centralized debugging with software such as DriveTop.

X4 (Motor Encoder 1): Used to connect HSF or parser feedback of Rexroth Indramat. If using other types of encoders, additional insertion modules need to be installed.

X7 (Motor Encoder 2): mainly found in HDD drives, used to connect 1Vpp sine wave measurement systems and provide high-resolution positioning interfaces.

3. Control and monitoring interfaces (X3, X6, X12)

X3 (Analog Output and Status): Contains two analog diagnostic outputs (AK1, AK2) for monitoring internal variables, as well as "Ready to Run" and "Start Blocked" contacts. When Bb is closed, it indicates that the driver is ready to connect to the main power supply; Startup blocking is a security mechanism to prevent accidental startup.

X6 (Braking and Temperature Monitoring): Used to connect motor holding brakes (BR+, BR -) and motor temperature sensors (PTC/NTC). The document emphasizes that the standard motor brake is not sufficient to ensure personnel safety, and an external 24V power supply must be provided with a maximum current not exceeding 2A.

X12 (External Input): Only present in HDD drives, used to connect reference switches, travel limit switches, measuring probes, and emergency stop signals. Its input circuit has a clear voltage level definition (high level 16-32V, low level 0-5.5V).

4. SERCOS fiber optic interface (X10/X11)

HDD drives come standard with SERCOS (Serial Real time Communication System) fiber optic interfaces. This interface complies with the IEC/EN 61491 standard and is connected to the upper control system through optical cables to achieve high-speed data transmission with strong anti-interference ability. Users can adjust the transmission power (-7dBm to 0dBm) and data rate (2 Mbaud or 4 Mbaud) through switch S4 to accommodate different cable lengths and transmission requirements.

Control cabinet design and thermal management planning

1. Size and installation

The installation of the DIAX04 driver controller must use a dedicated mounting rail (SUP-M01-HD). To ensure heat dissipation, sufficient space must be reserved around the device: at least 80mm at the top and at least 100mm at the bottom (taking into account the bending radius of the motor cable). When deploying in the control cabinet, high-power and high current drivers should be placed as close as possible to the power unit, and the loads on each axis should be evenly distributed to balance the power load.

2. Power loss and cooling system

The heat generated by the drive system is the core challenge in the design of the control cabinet. Power loss includes the total loss of power supply units, series switching devices, and each driver. When calculating, it is necessary to add the control electronic losses, configuration related losses (insertion module power consumption), and power part losses (obtained based on the average continuous current chart).

If the ambient temperature exceeds 45 ° C, a cooling system must be introduced. When using a cooling system, it is necessary to strictly prevent the harm of condensed water. The cooling device should be arranged in a location that avoids condensation water droplets falling or splashing onto electronic devices, and the set temperature of the cooling system should not be lower than 40 ° C to prevent condensation caused by the temperature inside the cabinet being lower than the ambient temperature. If the cabinet door is opened for debugging and then closed, it is necessary to ensure that the cooling system continues to operate until the temperature difference between the inside and outside is eliminated.

3. Electromagnetic compatibility (EMC) measures

In order to meet the RF interference limits of EN 55011, strict shielding measures must be taken:

The motor cable must use shielded cable and be grounded extensively on the driver side through XS1 terminal.

The power cord and signal/feedback cable must maintain a minimum distance of 100mm or be physically isolated using metal cable trays.

Avoid using varistors at inductive loads such as contactor coils. Instead, use RC damping modules or freewheeling diodes and install them as close to the load as possible.

Identification, transportation, and maintenance

1. Product identification

Each drive is equipped with a basic unit nameplate and a configuration nameplate. The basic unit nameplate is located on the top of the equipment and includes the product model; The configuration nameplate is inserted next to the insertion module, detailing the module models inserted in each slot of U1-U4 (such as DSS02.1M SERCOS interface, HSM software module, etc.). This is an important basis for quickly identifying equipment configuration, ordering spare parts, and conducting troubleshooting.

2. Transportation and Storage

During transportation and storage, attention must be paid to electrostatic protection. Components that are susceptible to damage from electrostatic discharge, such as plug-in modules, must be stored in conductive packaging. The allowed storage temperature range is -30 ° C to+85 ° C, and it must be kept dry, dust-free, and free from severe vibrations.

3. Service and Diagnosis

Rexroth Indramat provides comprehensive service support. When a malfunction occurs, the device generates error messages through the status display H1 and SERCOS interface. Users should record detailed model data, fault status, and software status of drives, motors, and gearboxes in order to contact the service hotline for efficient troubleshooting. Any repair work is only allowed to be performed by trained personnel or Rexroth Indramat customer service centers, and must be restarted and debugged after unit replacement.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923