+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

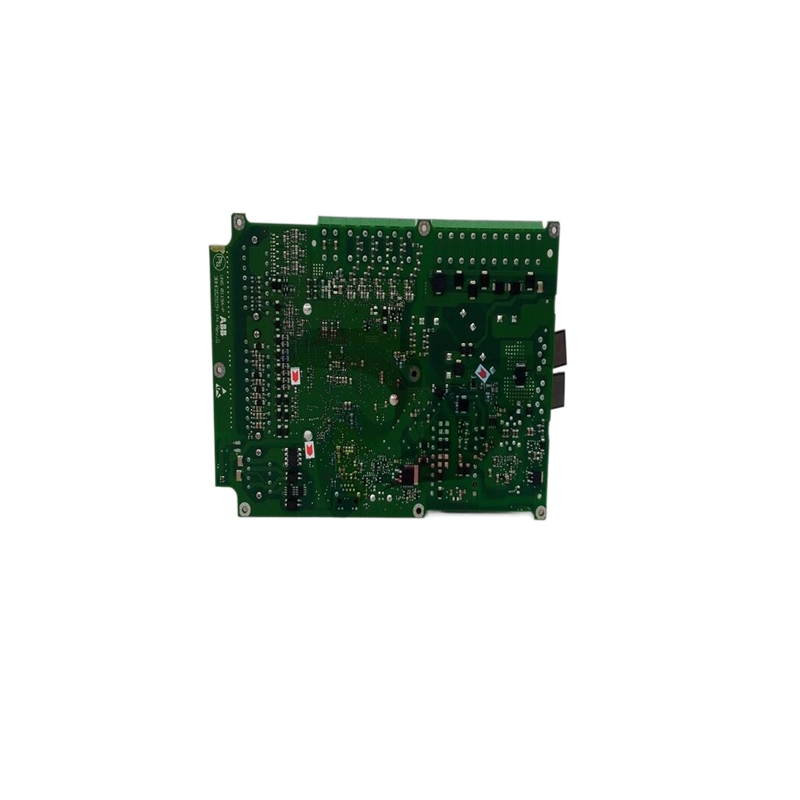

ABB SC610 OCS processor input and output unit

ABB SC610 OCS processor input and output unit

ABB SC610 OCS processor input and output unit

The user is responsible for ensuring a quality electrical supply to the equipment. Natural lightning strikes, fast high voltage transients, low voltage

conditions, or an unstable line voltage frequency may cause instrument performance degradation, function loss, or damage to the equipment. The

manufacturer recommends that the installation include a suitable surge suppressor to protect the equipment, and that the user provide an instrument grade

supply power that is free from potential electrical supply problems.

- Warning - the neutral and ground (earth) connections to the equipment must be at earth (0 volts) potential. Failure to maintain earth (0 volts) potential at

these connection points constitutes a serious safety hazard.

- Caution – it is the responsibility of the user to ensure that all connections to the equipment are approved for area classification, that all field wiring,

including signal wiring, has proper separation or insulation rated at 300V minimum to protect the conductors from potentially higher voltages, and that

equipment is securely fastened to protective earth.

- Caution – installation must ensure adequate protection from potential overpressures of supply gas. Severe damage to the equipment, property or injury

to personnel may result if the equipment is exposed to pressures greater than 200 psi (13.78 bar). Protection against pressure regulator bleed through, or

regulator failure, is an absolute requirement for safe operation.

No equipment vent should connect to a collection header without engineering review. Proper installation of equipment requires consideration of possible

ingress of toxic or hazardous materials into the analyzer or shelter via a sample system stream select valve. A failure in an air-operated manifold style

stream select valve can allow sample to flow into the air lines connected to the stream select solenoids internal to the analyzer, thus contaminating the

solenoid vent and causing damage to the solenoid valve.

Red plastic plugs are threaded in to all unused conduit hubs to protect the enclosure from debris during shipping and storage. These plugs are for

temporary use only and are not intended for normal operation. The installer’s responsibility is to remove all plastic plugs and then close each hub with

rigid conduit, cable gland, or plug that is suitable for the area classification.

The equipment is not susceptible to radio frequency when properly installed in a Class A industrial environment. All interconnect devices must be

properly grounded and their interconnect cables must be shielded and terminated at the entry point of the equipment. Assurance of electromagnetic

compatibility for the complete system is by isolating the equipment from all interconnected devices with a recommended minimum distance of three

meters.

Zone 1 only: Intrinsic safety circuit of purge control device is 200 nF capacitance maximum / 1 mH inductance maximum.

Recorder jacks are not to be used unless area is known to be non-hazardous.

Warning – this equipment is air purged. Enclosure shall not be opened unless the area is known to be non-hazardous, free of any flammable materials, or

unless all devices within the enclosure have been de-energized. Power shall not be restored after enclosure has been opened, or after switching off

overpressure, until enclosure has been purged for either 5.46 minutes @ 50 Hz or 4.55 minutes @ 60 Hz at the flow rate noted.

-Warning (PGC2009) – this equipment is air purged. Enclosure shall not be opened unless the area is known to be non-hazardous, free of any flammable

materials, or unless all devices within the enclosure have been de-energized. Power shall not be restored after enclosure has been opened, or after

switching off overpressure, until enclosure has been purged for either 10.90 minutes @ 50 Hz or 9.10 minutes @ 60 Hz at the flow rate noted.

The user is responsible for ensuring a reliable supply of protective gas, which is required for the purging system. In the event of purge / pressurization

failure, normal electrical potential within the enclosure will remain non-incendive; however, their electrical circuits may not be intrinsically safe. The

purge control device, therefore, provides an alarm contact to monitor the purge / pressurization status and to alert the user of a failure. Such a failure may

require the isolation of remaining hazardous live circuits to ensure a safe area.

- Warning - do not open any enclosure in the presence of an explosive atmosphere; do not open any flameproof enclosure while energized.

Type PGC2007 and PGC2009 with T3 marking: the internal liquid sample valve may be factory set to operate at a temperature above the external area

temperature code. The user’s responsibility is to examine the equipment label for a possible wait time before opening the pressurized enclosure: enclosure

shall not be opened unless the area is known to be non-hazardous, or unless all devices within the enclosure have been de-energized for 30-minutes.

Equipment includes Ex components as described in the repair section of the operation and service manual.

Any modification affecting the essential health and safety requirements of the equipment, or the integrity of a type protection, shall be defined as

substantial. It is the responsibility of the person conducting such modification to ensure a unit verification and approval by a Notified Body.

This controlled compliance document is incomplete without all pages and is subject to change without notice.

Il incombe à l’utilisateur de s'assurer que les conditions spéciales pour une

utilisation sûre sont satisfaites :

L’utilisateur a la responsabilité d'assurer une alimentation électrique de qualité à l'appareil. Des impacts de foudre, des phénomènes transitoires rapides,

des conditions de faible tension ou une fréquence de tension de secteur instable peuvent causer une dégradation de rendement de l’instrument, une perte de

fonctionnement ou des dommages à l'appareil. Le fabricant recommande la pose d’un limiteur de surtension approprié pour protéger l'appareil. De plus,

l’utilisateur doit assurer une alimentation électrique de classe instrument exempte de perturbations.

- Avertissement - les connexions du neutre et de la masse (terre) à l'appareil doivent présenter une différence de potentiel de terre de 0 volt. Le fait de ne

pas maintenir un potentiel de terre de 0 volt à ces points de connexion présente un danger grave pour la sécurité.

- Attention – il est de la responsabilité de l’utilisateur de s’assurer que tous les raccordements de l'appareil sont approuvés pour la classification de zone,

que le câblage du site, y compris le câblage de signal, présente une séparation ou une isolation nominale d'au moins 300 V pour protéger les conducteurs

contre les hautes tensions et que l'appareil est correctement raccordé à la terre.

- Attention – l’installation doit assurer une protection adéquate contre une surpression possible du gaz d’alimentation. L'appareil ou les biens peuvent être

gravement endommagés et le personnel risque d’être blessé si l'appareil est exposé à une pression supérieure à 200 psi (13,78 bar). Le régulateur de

pression doit être absolument protégé contre toute infiltration ou défaillance pour assurer un fonctionnement sécuritaire.

Aucun évent de l'appareil ne doit être raccordé à un collecteur sans être soumis à une analyse technique. Pour bien installer l'appareil, il faut tenir compte

de l’infiltration possible de matière toxique ou dangereuse dans l’analyseur ou l’abri en passant par la vanne de sélection de voie du système

d’échantillonnage. Une défaillance de la vanne de sélection de voie (collecteur à commande pneumatique) risque de laisser l’échantillon circuler dans les

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923