K-WANG

SCHNEIDER Back-UPS ™ Pro 550/900/1200/1500 230V Installation and Operation

SCHNEIDER Back-UPS ™ Pro 550/900/1200/1500 230V Installation and Operation

The installation and operation manual for APC by Schneider Electric Back UPS Pro 550/900/1200/1500 230V series UPS covers five core modules: safety specifications, hardware connections, functional configuration, fault diagnosis, and after-sales service. It specifies that the UPS needs to be used indoors and supports core functions such as battery backup (the longest endurance depends on the model), surge protection, and automatic voltage regulation. Power saving, sensitivity, and other parameters can be configured through the front panel button or PowerChute software. The battery life is usually 3-5 years. In case of a fault, the problem can be located through the fault code, and official after-sales maintenance should be contacted. Different models correspond to specific replacement batteries (such as BR550GI corresponding to APCRBC110)

Safety and Installation Standards

(1) Safety requirements

Usage environment: For indoor use only, avoid direct sunlight exposure, contact with liquids, excessive dust, or environments with excessive humidity.

Power connection: The UPS power cord should be directly plugged into a wall socket, and the use of surge protectors or extension cords is prohibited.

Heat dissipation requirements: The ventilation openings must not be obstructed, and sufficient space should be reserved to ensure normal heat dissipation.

Battery Attention: The battery life is usually 3-5 years. High ambient temperatures, poor power quality, and frequent short-term discharges can shorten the lifespan.

(2) Hardware connection

Connection type operation instructions applicable to devices

Battery connection: Follow the manual instructions to complete the installation of the built-in battery (some models are pre installed at the factory) for all models

Connect critical devices (computers, monitors, modems) to "Battery Backup outlets", and non critical devices (printers, scanners) to "Surge Protected outlets" for all models

Connect the data port of UPS to the USB/serial port of the computer using the matching cable for data connection, and install PowerChute software (to achieve automatic file storage and shutdown) for all models

Expand the connection of the telephone line to the "Telephone In" port, and connect the modem to the "Telephone Out" port; Ethernet cable connected to "Ethernet In", computer connected to "Ethernet Out" (only supports 10/100/1000BASE-T) for some models (such as BR550GI/900G-FR)

Ground Screw "BR1200GI/1500GI, BR1200G-FR/1500G-FR for additional surge suppression equipment grounding connection

External battery connection BR1500GI/1500G-FR extends battery life by connecting the external battery pack through the "External Battery Pack connector"

Core functions and configurations

(1) Power saving function

Enable/Disable: Long press the "MUTE" and "PLAY" buttons on the front panel for 2 seconds, the UPS beeps and the "leaf icon" on the display screen lights up/goes out to indicate whether the function is enabled/disabled.

Threshold calibration: When the main device (such as a computer) is in sleep/shutdown mode, long press "MUTE" and "PLAY" for 6 seconds, the leaf icon will flash 3 times and beep 3 times to complete threshold saving (adapted to different device sleep power consumption).

(2) Display mode configuration

Mode Type Operation Method Function Description

Long press and hold "PLAY" for 2 seconds in constant light mode, and the display screen will continue to light up with a beep confirmation

Power saving mode: Long press and hold "PLAY" for 2 seconds without any operation. After 60 seconds, the display screen will darken. Press any button to restore brightness

(3) Sensitivity adjustment

Operation steps: 1 UPS connected to AC power but turned off; 2. Long press "POWER" for 6 seconds, and the "LOAD CAPACITY" indicator light will flash to enter programming mode; 3. Press "POWER" to switch between low/medium/high sensitivity and beep to confirm.

Sensitivity Description: Low sensitivity (switching battery when input voltage is extremely low, not recommended for computer loads), medium sensitivity (default, suitable for most devices), high sensitivity (suitable for voltage fluctuation sensitive devices, frequent battery switching).

(4) Other key operations

Notes on Function Operation Methods

Manual self-test: Press and hold "POWER" for 6 seconds to automatically perform a self-test when the device is turned on

Silent alarm. Short press "MUTE" to only turn off the alarm triggered by the current event

When clearing the event count display event interface, long press "PLAY"+short press "POWER" to clear only the AC fault counter

Fault reset: Long press "POWER" for 2 seconds to clear the visual prompt of the fault and restore standby mode

Status indication and troubleshooting

(1) Sound warning and status icon

Suggestions for handling the corresponding status of sound prompts

Every 30 seconds, there are 4 battery powered sounds to save the current work progress

Continuous buzzing, low battery, immediately save work, close applications and operating systems

Continuous beeping, battery backup output overload, disconnection of non essential equipment

Every 5 hours, beep for 1 minute. Battery diagnosis fails. Replace battery

Suggestions for handling the meaning of status icons

Overload (flashing) When AC power is supplied, overload and disconnect non essential equipment until the icon goes out

Overload (always on) When the battery is powered on, unload the device immediately to avoid battery damage

Replace Battery Failure/End of Life Replace the corresponding model battery

On Battery: The battery is supplying power. Please restore AC power or save data as soon as possible

(2) System fault code

Fault code, fault type, and handling method

F01 battery power overload shutdown → disconnect non essential equipment → restart UPS

F02 battery output short circuit shutdown → Disconnect all devices → Reconnect one by one to locate the faulty device

F03-F09 capacitor overload/clamp short circuit/charging fault cannot be handled by oneself, contact official technical support

(3) Common problem troubleshooting

Possible causes and solutions for the problem phenomenon

UPS cannot start up, AC power not connected/circuit breaker tripped/battery not connected. Check power connection → reset circuit breaker → confirm battery installation

After a power outage, if there is no backup power supply device, connect it to the wrong socket (plugged into the surge protection port) and move the critical equipment to the battery backup socket

Backup battery life shorter than expected, non essential devices occupying battery load/battery not fully charged, unloading non critical devices → charging for 16 hours → checking battery status

Some sockets have no power supply and the power saving function is enabled. The controlled sockets have been turned off and the power saving function is disabled or the threshold is recalibrated

The battery replacement indicator light is on. When the battery life expires, replace the backup battery of the corresponding model (such as APCRBC124 for BR1500GI)

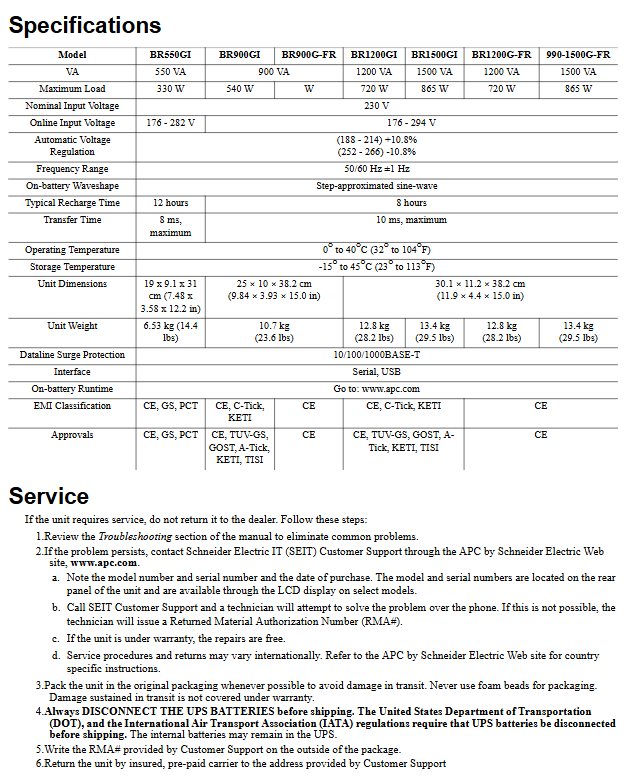

Product specifications

Model Capacity (VA) Maximum Load (W) Input Voltage Range (V) Typical Charging Time (hours) Conversion Time (maximum)

BR550GI 550 330 176-282 12 8 ms

BR900GI 900 540 176-294 8 10 ms

BR1200GI 1200 720 176-294 8 10 ms

BR1500GI 1500 865 176-294 8 10 ms

BR900G-FR 900 540 176-294 8 10 ms

BR1200G-FR 1200 720 176-294 8 10 ms

BR1500G-FR 1500 865 176-294 8 10 ms

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923