K-WANG

SEW MOVIDYN ® servo controller

SEW MOVIDYN ® servo controller

MOVIDYN ® The servo controller is an industrial grade servo drive device launched by SEW-EURODRIVE, designed specifically for permanent magnet synchronous AC servo motors. It covers three core products: power module (MPB/MPR), shaft module (MAS), and compact controller (MKS). It supports 380-500V three-phase power input, rated current of 5-60A, power of 11-55kW, and has speed/torque/position control functions. It has passed EMC, UL and other certifications and is suitable for high-precision control scenarios such as machine tools and automated production lines. It also has complete safety protection and fault diagnosis capabilities.

Product System and Basic Parameters

(1) Core product types

Product Type Core Function Key Parameter Example Applicable Scenarios

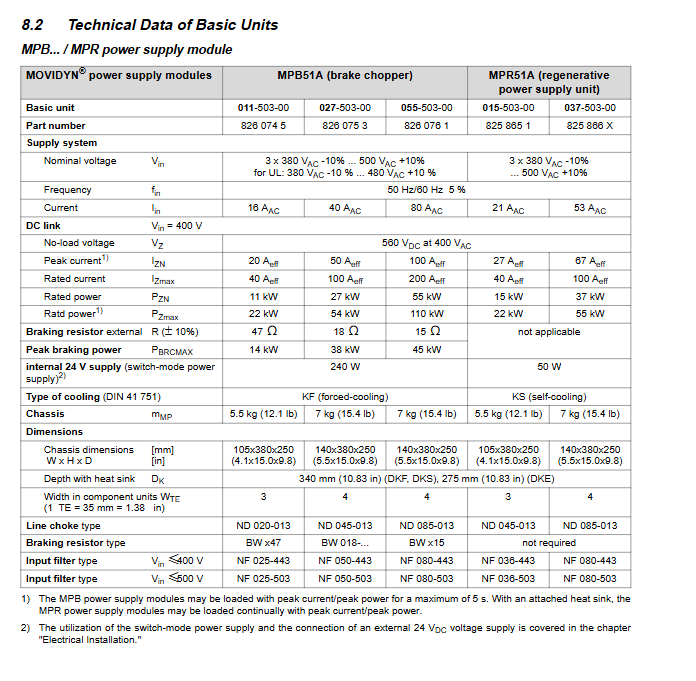

MPB power module with brake chopper, providing DC bus power with rated power of 11~55kW, braking power of 14~45kW, multi axis system power supply, requiring braking energy recovery scenario

MPR power module regenerative power supply, energy feedback to the grid rated power of 15-37kW, no external braking resistor, high energy-saving requirements for multi axis systems

MAS axis module single axis drive control, supporting expansion options with rated current of 5~60A, suitable for 500V motor multi axis linkage equipment (such as assembly lines, robots)

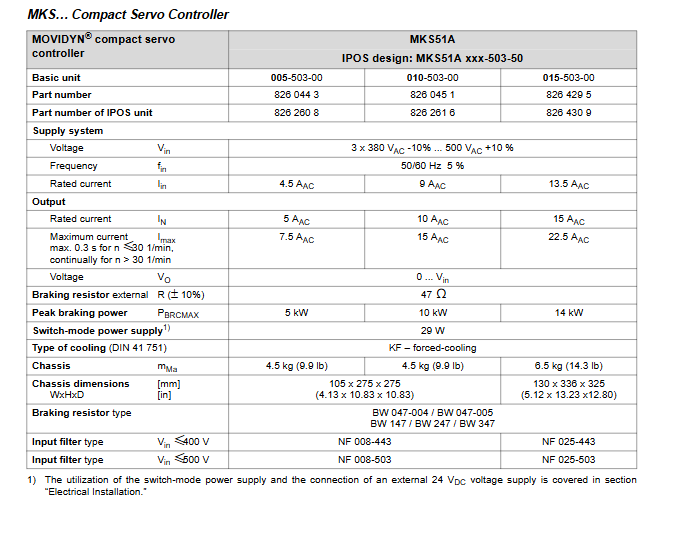

The MKS compact controller integrates power and drive functions, with a small size and a rated current of 5-15A. It is equipped with built-in heat dissipation single axis high-precision equipment (such as CNC machine tools)

(2) Basic technical parameters

Power specification: 3 × 380~500V AC (± 10%), frequency 50/60Hz (± 5%)

Control accuracy: speed range 0~5000rpm (resolution 0.2rpm), position control supports 1024 pulses/rotary encoder

Environmental conditions: Operating temperature range of 0~45 ℃ (output capacity reduction of 3%/K at 45~60 ℃), protection level of IP20

Installation altitude: ≤ 1000m (after exceeding 1000m, the current drops by 1% every 100m)

Core functions and operations

(1) Control mode

Basic mode: speed control, torque control, supporting analog (-10~+10V)/digital set value input

Expansion mode: IPOS positioning control (optional), master-slave synchronous control (RS-485 interface linkage)

Protection functions: 24 types of fault protection, including overcurrent (F01), ground fault (F06), thermal overload (F03/F11), encoder fault (F14), etc

(2) Debugging and operation methods

Applicable scenarios for operating methods, tools/carriers, core processes

Software debugging MD_SHELL software (≥ 4.20 version) connects PC and controller → sets axis address → inputs motor parameters → automatically calculates control parameters → downloads effective system integration and batch configuration

Panel operation S1 button+7-segment digital tube short press S1 to view address → long press for 2 seconds to enter settings → adjust tens/units bit → confirm and save on-site quick address configuration and status viewing

External control binary/analog terminal (X21) terminal allocation function (such as enable, emergency stop, limit) → external signal triggering → operation monitoring industrial PLC linkage, automation production line

(3) Key Option Expansion

Option Model Type Core Function Adaptation Scenarios

AIO11 analog I/O expansion card expands analog input/output, supports oscilloscope monitoring, multi signal interaction, parameter optimization

AFC11A/AFP11A bus module supports CANopen/Profibus protocol for multi device networking and centralized control

API12/APA12 positioning control card for high-precision position positioning, supporting reference operation of machine tools and robot positioning scenarios

USS21A communication adapter enables software debugging and data transmission between PC and controller via RS-232/RS-485 connection

Installation and wiring specifications

(1) Mechanical installation requirements

Installation position: Fixed installation inside the switchgear, the power module and shaft module need to be tightly attached to the heat sink (35mm grid mounting hole)

Heat dissipation gap: Reserve ≥ 100mm heat dissipation space above and below, and the multi axis module heat sink needs to be grounded with copper bars/braided wires for conduction

Braking resistor: Installed on a well ventilated area (such as the top of a cabinet), avoiding proximity to thermal sensitive components, and the wire cross-section is adapted to the maximum braking current

(2) Key points of electrical installation

Wiring specifications: Power lines (L1/L2/L3, U/V/W) should be wired separately from signal lines, with a spacing of ≥ 20cm; encoder/rotary transformer cables should use twisted pair shielded wires (up to 100m in length), with both ends of the shielding layer grounded

EMC compliance: NF series filters are required for the input end, and HD00X output chokes can be selected for the output end; The distance between the filter and the controller is ≤ 400mm

UL compliance: Only use 60/75 ℃ copper wire, power terminal tightening torque of 3.5Nm (MKS is 1.5Nm), fuse specification ≤ 30A/600V

Fault diagnosis and maintenance

(1) Common faults and solutions

Fault code, fault type, typical cause, handling measures

F01 overcurrent motor short circuit, output stage fault troubleshooting cable short circuit, replace faulty module

F07 DC bus overvoltage brake resistor fault, short deceleration slope check brake resistor wiring, extend deceleration time

F14 rotary transformer fault cable breakage and poor shielding inspection of rotary transformer wiring, repair of shielding layer

F27 limit switch is missing and not connected, or the wiring is disconnected and connected to the limit switch, or X21.7/X21.8 is short circuited to 24V

(2) Maintenance points

Regular maintenance: Power on for at least 5 minutes every 2 years (when stored for a long time), clean the dust on the heat sink

Reset method: Supports power restart, terminal reset, software reset. Automatic reset requires enabling P630 parameter (default off)

Spare parts and services: If the fault cannot be resolved, please contact SEW Electronic Service Department to provide the equipment model, fault code, and application scenario

Core advantages and application scenarios

Core advantages: high integration (MKS compact model does not require additional power modules), high control accuracy (supports IPOS positioning), flexible expansion (rich bus/IO options), complete protection (24 types of fault protection)

Typical applications: Industrial scenarios requiring high-precision speed/position control, such as CNC machine tools, automated assembly lines, robot joint drives, precision conveying equipment, etc

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB AX411/511010/STD pH/ORP Analyzer Controller

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923