K-WANG

Siemens SIMATIC ET 200SP Distributed I/O System

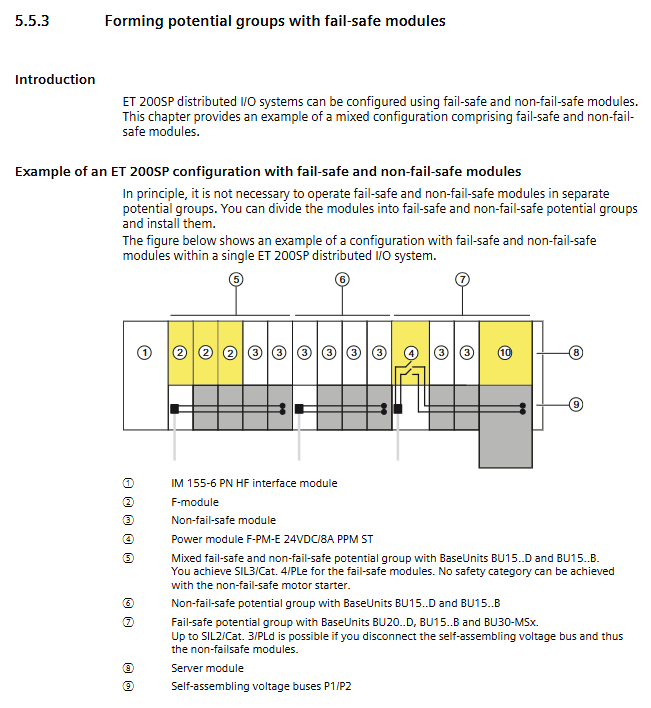

Siemens SIMATIC ET 200SP Distributed I/O System

SIMATIC ET 200SP is a scalable and highly flexible distributed I/O system that supports multiple bus protocols such as PROFINET and PROFIBUS. Its core components include CPU/interface modules, I/O modules, motor starters, base units, etc. It has core features such as safety integration, hot plugging, and redundant R1, covering multiple types of modules such as digital/analog/fault safety/explosion-proof, and is suitable for multiple scenarios of industrial automation. It needs to be configured through STEP 7, follows specific installation and wiring specifications, and supports online parameter modification and full lifecycle maintenance.

Overview of System Core

1. System positioning and value

Essence: Distributed I/O system, used to connect process signals with upper level controllers, supporting modular expansion

Core advantages: high flexibility (supporting 1-64 I/O modules), safety integration (fail safe modules), multi scenario adaptation (explosion-proof/redundant/conventional industrial)

Key features: tool free wiring, hot swapping, flexible division of potential groups, multi bus compatibility

2. Core tools and supporting resources

Tool Name Core Function Applicable Scenarios

STEP 7 (TIA Portal) Hardware Configuration, Programming, Parameter Download System Configuration and Debugging

PRONETA PROFINET Network Analysis, Topology Scanning, IO Testing, Network Diagnosis and Debugging

MFCT multi bus configuration, firmware batch update, multi protocol device configuration

SIMATIC Automation Tool for batch debugging, firmware updates, backup recovery, and centralized maintenance across multiple sites

Hardware component details

1. Classification and Parameters of Core Modules

Component type, core model/series, key parameters, functional positioning

CPU 1510SP-1 PN, 1512SP F-1 PN firmware V1.6+, PROFINET 3 port independent control or I-device, supporting fault safety

Interface module IM 155-6 PN HF, IM 155-6 DP HF up to 64 I/O modules, bus protocol adaptation distributed I/O and controller communication bridge

Fault safety module F-DI/F-DQ, F-PM-E SIL3, PL e, Cat.4 safety related signal processing and disconnection

Explosion proof module Ex I/O module, Ex base unit adapted to Zone 0/1 hazardous environment explosion-proof scene signal acquisition and control

Motor Starter DS/RS/F-DS/F-RS 0.1-12A, 5.5kW Maximum Motor Power Motor Start Stop Control and Overload/Short Circuit Protection

2. Key auxiliary components

Base Unit (BU): divided into A0/A1/B0/B1/C0 and other types, adapted to different modules, supporting potential group opening/continuation

PotDis module: 15mm width, supports P1/P2 potential distribution, saves installation space

Server module: Configure the closing component and provide 3 spare fuse installation positions

Bus adapter: Supports PROFINET fiber/Ethernet connections, allowing for free selection of communication media

Core functions and technical parameters

1. Communication and security functions

Communication protocol: Supports PROFINET IO (real-time synchronization), PROFIBUS DP (long-distance transmission), Modbus TCP/EtherNet/IP, etc., to meet different networking requirements

Safety performance: The fault safety module supports SIL2/SIL3 safety levels, complies with IEC 61508 and ISO 13849-1 standards, and achieves safe communication through the PROFIsafe protocol

Redundancy function: R1 system redundancy requires 2 IM 155-6 PN R1 interface modules, which automatically switch in case of failure, and the switching time can be optimized

2. Key performance parameters

Category specific parameter notes

The maximum module capacity of 64 I/O modules and 31 motor starters depends on the interface module model

Power supply specifications: Control power supply 24V DC (19.2-28.8V), motor starter AC 48-500V, in compliance with SELV/PELV safety standards

Environmental conditions: Installation temperature -25~+60 ℃, storage temperature -40~+75 ℃. Vertical installation temperature reduced to 50 ℃

Mechanical specifications protection level IP20, 35mm DIN rail installation minimum installation spacing 10-20mm

Switching performance R1 system switching time optimization, reducing the number of I/O modules can shorten the switching time. Specific module types require separate site configuration

3. Configure control functions

Core: Support Configuration Control, achieve multi configuration level switching through controlling data recording (No. 196)

Application: Switching between different configurations of standard machines (such as baking/packaging/decoration modes) without modifying the project

Rule: Control data recording must include slot allocation, potential group information, and support dynamic/static binding

Implement key processes

1. Planning and installation

Planning points: Select the base unit (such as BU A0 adaptive digital module) according to the load type, divide the potential group (light colored BU opens a new group, dark colored BU continues the group)

Installation specifications:

Rail requirements: 35 × 7.5/15mm DIN rail or SIMATIC system rail (R1 system specific)

Spacing requirement: Reserve 10mm between modules and 20mm above and below for heat dissipation space

Fixed requirements: The vibration environment requires mechanical fixation at both ends, and the vertical installation of the motor starter requires end fixing components

2. Wiring and Identification

Wiring rules:

Wire specifications: 0.2-2.5mm ² (flexible wire), 1-6mm ² (main circuit of motor starter)

Stripping length: 8-15mm (depending on terminal type), multi strand wires need to be crimped at the end

Shielding treatment: Use shielded connectors for grounding to avoid signal crosstalk

Identification requirements: Factory identification (module type/firmware version), optional identification (color label/reference label/label strip)

3. Configuration and Debugging

Configuration steps:

Software requirements: STEP 7 V13 SP1+, Safety Advanced package (fail safe configuration)

Core settings: address allocation, process image partitioning (up to 32), security parameters (F - address)

Control data recording: Create PLC data types, define slot mapping, and transmit through WRREC instructions

Debugging tools:

PRONETA: Network topology scanning, IO wiring testing

SIMATIC Automation Tool: Batch Device Launch, Firmware Update

Diagnostic function: Module LED status indication, diagnostic buffer, Get_SIM-Data command to read maintenance data

4. Maintenance and troubleshooting

Daily maintenance:

Module replacement: supports hot swapping, directly replaces faulty modules, and automatically downloads parameters

Firmware update: Batch update via network, supporting fault recovery

Data backup: Backup hardware configuration, user programs, I&M data, support one click recovery

Common faults:

Configuration mismatch: Check for consistency between control data records and actual modules

Communication failure: Verify bus connection, IP address configuration, firmware version compatibility

Safety malfunction: Confirm the power supply of the fault safety module, F-address allocation, PROFIsafe parameters

Safety and compliance requirements

Electrical safety: It must comply with IEC 60364 and IEC 60204 standards, and the emergency stop device must remain effective

Explosion proof requirements: The Ex module group must be thermally isolated and comply with Zone 0/1 environmental standards

Static protection: Module operation requires anti-static measures, disconnect the power supply before wiring

Password protection: CPU access permission classification (no access/read-only/HMI access/full access), block knowledge protection, copy protection

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923