K-WANG

Siemens SIMATIC TI505/TI500 MODNIM module

Siemens SIMATIC TI505/TI500 MODNIM module

The user manual for Siemens SIMATIC TI505/TI500 series MODNIM (Modbus Network Interface Module) introduces the installation configuration, communication protocol, functional instructions, and diagnostic maintenance of the module. It supports both ASCII/RTU transmission modes, covers 17 core Modbus function codes, adapts to 50-19200 bps baud rates, and can set network addresses (1-247) and communication parameters through dip switches. It has functions such as power on self-test and runtime diagnosis, and can achieve master-slave data exchange between PLC and Modbus network. It is suitable for point-to-point or multi-point connection scenarios in industrial automation.

Module Core Overview

1. Basic information

Module models: PPX: 505-5184 (TI505 series), PPX: 500-5184 (TI500 series)

Core positioning: Modbus network interface module, realizing bidirectional data transmission between SIMATIC TI series PLC and Modbus network

Network architecture: master-slave network, supporting 1 master node+up to 247 slave nodes, supporting point-to-point or multi-point connection topology

Power requirement: Get+5 VDC power supply from the I/O dock, maximum power consumption 8 W

2. Key specifications

Category Core Parameter Details

Communication interface RS-232-C/423 2 communication ports (A/B), DTE configuration

15 selectable baud rates ranging from 50-19200 bps, set via dip switch

Either ASCII/RTU transmission mode, which requires the unified mode of the whole network

The verification methods LRC (ASCII) and CRC (RTU) are automatically calculated to ensure data integrity

Address range 1-247 0 is a broadcast address, 248-255 is invalid

Environmental conditions Working temperature 0-60 ℃ Relative humidity 5% -95% Non condensing, anti electromagnetic interference

Installation and Configuration

1. Installation process

Pre requirement: Disconnect the power supply of the I/O base, check that the module is not physically damaged, and wear an anti-static wristband

Installation steps:

Set up dip switch (address+communication parameters)

Insert the corresponding model I/O slot (TI505 single slot, TI500 dual slot)

Tighten panel screws (torque 0.3-0.6 N-m)

Connect communication cables to power supply

Key note: TI500 series requires installation of slot keys to prevent accidental insertion of other modules

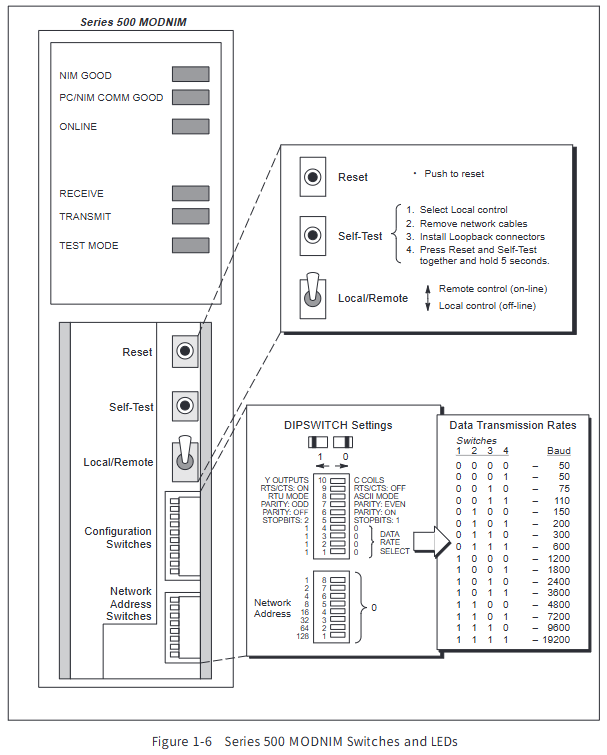

2. Configuration of dip switch

Details of the configuration of the dialing group function

8-bit address dialing set network address binary encoding, address range 1-247 (0 and 248-255 disabled)

10 bit communication dial-up 1-4 baud rate selection, 4-bit combination corresponding to 15 baud rates (50-19200 bps)

10 digit communication dialing code, 5 stop bits, left=1 digit, right=2 digits

10 bit communication dial code 6-7 parity check dial code 6 left=enable check, dial code 7 left=even check/right=odd check

10 bit communication dial-up with 8 transmission modes: left=ASCII, right=RTU

10 bit communication dial-up 9 handshake protocol left=disabled, right=enabled RTS/CTS (adaptive modem)

10 bit communication dial code, 10 memory selection, left=C control relay, right=Y output coil

3. Wiring specifications

Cable requirements: 26 AWG tinned stranded copper wire with aluminum foil+65% braided shielding, PVC outer sheath (UL 30V/60 ℃)

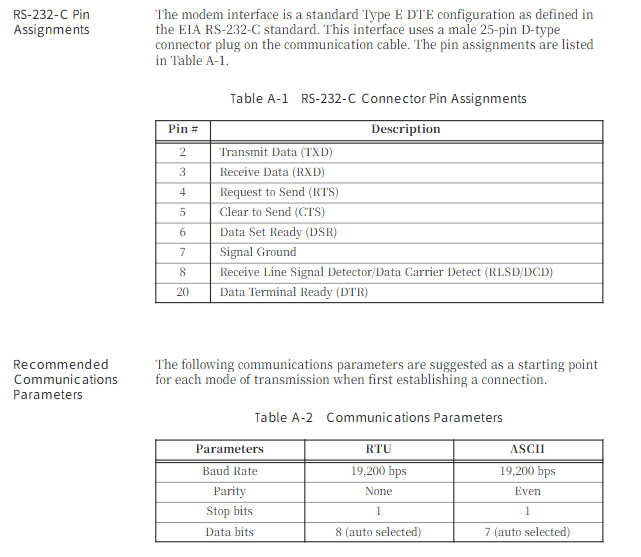

Interface standard: RS-232-C 25 pin D-type connector, supporting three connection methods: no handshake/handshake/modem

Recommended cables: 9-pin crossover cable (P/N: 2601094-8001), 25 pin crossover cable (P/N: VPU200-3605)

Pin definitions: 2=TXD, 3=RXD, 4=RTS, 5=CTS, 7=signal ground, 20=DTR

Modbus communication protocol

1. Comparison of transmission modes

Characteristic ASCII mode RTU mode

Data bits 7 (hexadecimal printable) and 8 (binary)

Verification method LRC (Vertical Redundancy Check) CRC (Cyclic Redundancy Check)

Frame separator start character ":"+end character "CR/LF" 3.5 character silence time

Low transmission efficiency and high efficiency

Applicable scenarios: Low noise environments, industrial complex interference environments

2. Core function codes (17 types)

Function code, function description, maximum number of operations for operating objects

01 Read coil status Y/C coil 2000 pieces

02 Read input status discrete input X 2000

03 Read and hold register V variable memory 125

04 Read Input Register WX Word Input 125

05 Write a single coil Y/C coil 1 (supports broadcasting)

06 Write a single register V variable memory 1 (supports broadcasting)

07 Read 8 status coils inside the abnormal state-

08 Perform diagnostic module self-test/counter reset, etc-

11. Obtain communication event counter, successful message count-

Retrieve the communication event log for the last 64 events-

15 write multiple coils Y/C coils 800 (supports broadcasting)

16 write multiple registers V variable memory 100 (supports broadcasting)

Report 17: Station ID, PLC model/operating status, etc-

3. Abnormal response

Exception identifier: Function code highest position 1 (e.g. 01 → 81)

Core Exception Codes (8 types): 01 (Illegal Function), 02 (Illegal Address), 03 (Illegal Data Value), 04 (Associated Device Failure), 06 (Memory Parity Error), etc

Response mechanism: No response in broadcast mode, single address request returns exception code+checksum

Diagnosis and maintenance

1. Diagnostic testing

Power on self-test: After the module is powered on or reset, it checks the RAM/ROM/processor. If it passes, the NIM GOOD light will turn on

Run time diagnosis: Continuously monitor ROM integrity, PLC communication, watchdog timer, and enter offline mode if there is a fault

User triggers self-test: disconnect network cable → connect loop connector → reset+long press test button for 5 seconds, determine fault through LED status

LED status indicator: 6 LEDs (NIM GOOD/PC GOOD/ON LINE/REC/XMT/TEST), providing intuitive feedback on module status

2. Maintenance tools and operations

MODASST software: DOS environment configuration diagnostic tool, supporting communication parameter settings, function code testing, and troubleshooting

Module reset: Press the reset button to initialize the module, clear the counter and buffer

Firmware version: Supports reading software versions (Release 1.0-3.0) through function code 17

Replacement process: Power off → Pull out old module → Set new module dip code → Insert base → Power on self-test

3. Environment and Protection

Working environment: temperature 0-60 ℃, humidity 5% -95%, non condensing, pollution level 2

Anti interference capability: compliant with IEC 801 standard, anti-static 15 kV, radiation interference level 3

Protection certification: UL 508, CSA 142, FM Class I Div. 2 certification

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923