K-WANG

Honeywell Searchline Excel Infrared Open Circuit Gas Detector

Industry benchmark: In 1987, Honeywell first launched the first generation Searchline open circuit infrared combustible gas detector. After upgrading to Searchline Excel in 1998, it became the industry standard in the field of open circuit gas detection with performance that meets and exceeds customer needs. It is often paired with Searchpoint Optima Plus point detectors as the main combustible gas detection solution.

Honeywell Searchline Excel Infrared Open Circuit Gas Detector

Product positioning and market position

Core positioning: A globally leading infrared open circuit combustible gas detector with over 25000 units installed as of document release. It is widely used in various harsh industrial environments, deployed from the Arctic Circle to the Middle East desert, and is the preferred product for many customers.

Industry benchmark: In 1987, Honeywell first launched the first generation Searchline open circuit infrared combustible gas detector. After upgrading to Searchline Excel in 1998, it became the industry standard in the field of open circuit gas detection with performance that meets and exceeds customer needs. It is often paired with Searchpoint Optima Plus point detectors as the main combustible gas detection solution.

Core application scenarios

Suitable for industrial scenarios with high requirements for combustible gas detection, including:

Offshore platforms and vessels (such as floating production storage and offloading units FPSO)

Downstream chemical processing plants

Natural gas transportation and pipeline system

Large storage areas and factories

Perimeter detection scenario

Core features and advantages of the product

1. Environmental adaptability and reliability

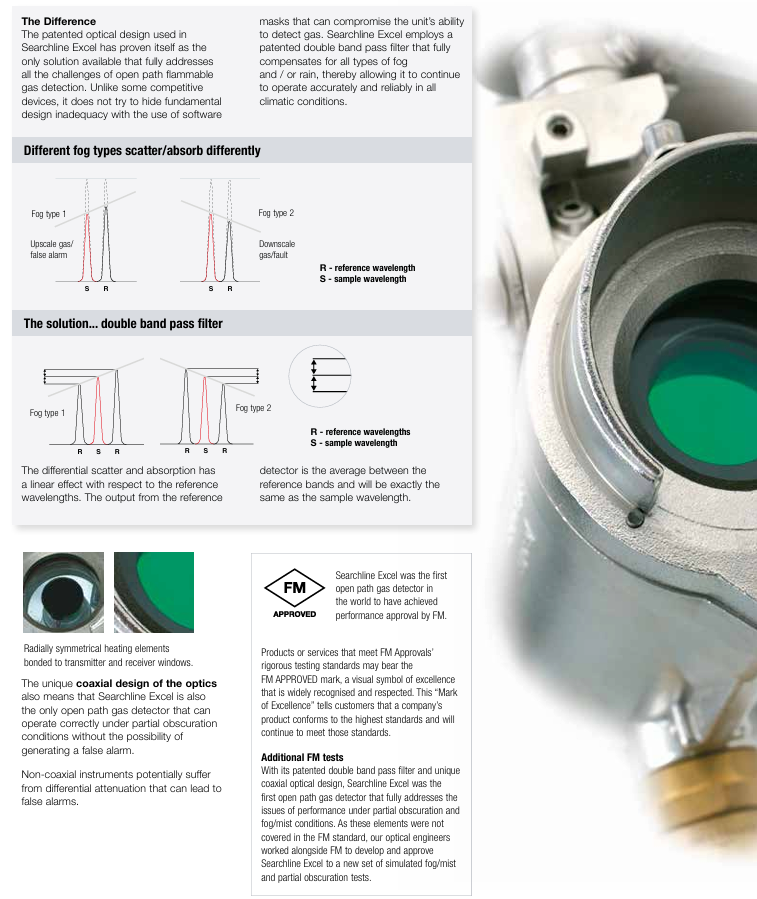

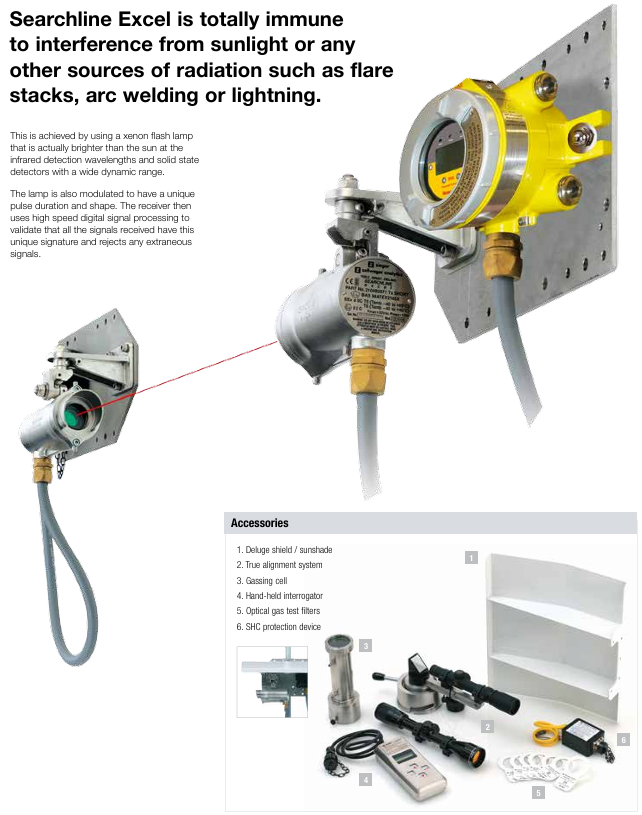

Climate compensation: Using patented dual bandpass filters, it can fully compensate for various weather disturbances such as fog, rain, and mist, ensuring accurate detection under different climate conditions; Simultaneously possessing 100% resistance to light interference, avoiding the influence of sunlight on the detection results.

Endurance to harsh environments: Radial symmetrical and bonded window heating design ensures stable performance in low-temperature environments; High vibration resistance (2-60Hz, maximum peak to peak amplitude 1mm), suitable for industrial equipment vibration scenarios; The shell is made of 316 stainless steel material, with a protection level of IP66 and IP67, and is dustproof and waterproof.

Partial occlusion compatibility: The coaxial optical design is unique to the industry and can work normally when detecting partial occlusion in the path without the risk of false alarms; Similar products with non coaxial designs are prone to false alarms due to differential attenuation.

2. Performance and efficiency testing

High sensitivity and fast response: The detection range is 0-5 LEL · m (lower explosive limit · m), with a recommended low alarm threshold of 1.0 LEL · m and a high alarm threshold of 3.0 LEL · m. The response speed is fast, with T90 (time to reach 90% of the detection value) less than 3 seconds (under normal operating conditions).

Wide coverage and precise positioning: Supports three path lengths - short (5-40m), medium (40-120m), and long (120-200m). A single device can cover a wider area, reducing the deployment requirements of multi-point detectors; Can indicate the size of the danger zone and help staff quickly determine the risk range.

3. Installation and maintenance convenience

Easy calibration and alignment: equipped with a "locked" alignment tool and high-power, high magnification telescope, the alignment operation is simple and accurate, without the need for additional "software alignment" steps; The True Alignment system can achieve high-precision alignment without the need for subsequent software adjustments.

Low power consumption and convenient monitoring: Low power consumption under all operating conditions (maximum 3.5-5.0W for short-range transmitters, maximum 10-13W for medium and long-range transmitters, and maximum 8W for receivers); Optional Modbus RS485 multi station output, supporting 32 detectors sharing one communication cable, significantly reducing installation and wiring costs; By using XNX universal transmitter or SHC-1 handheld interrogator, local/remote configuration, status monitoring, and fault diagnosis can be achieved, reducing on-site maintenance frequency.

4. Safety certification and compliance

Obtained FM (Factory Mutual) hazardous area certification and performance certification, making it the world's first open circuit gas detector to pass FM performance certification; It also complies with multiple international safety standards such as ATEX, UL, CSA, and is suitable for Class I hazardous areas (such as Class 1 Div 1/Zone 1).

Additional customized testing through FM: Honeywell engineers collaborate with FM to develop specialized simulation tests for scenarios not covered by FM standards such as "partial occlusion" and "fog/mist" to further validate product performance.

Advantages of open circuit gas detection technology (compared to point type detectors)

As a supplementary solution to point detectors, open circuit detectors have the following irreplaceable advantages:

The reliability of the detection has been verified through practical applications, reducing the risk of missed detections (for example, point detectors may miss pipeline leaks, while open circuit detectors can accurately capture them)

Covering a wider area makes it easier to detect leakage points at any location

The response speed is much higher than that of point detectors

Fault safety design: No unexposed fault modes, no problem of detector gas path blockage

The installation position requirements for detectors are lower, and there is no need to strictly align with potential leakage points

Easy installation and debugging, can replace multiple point detectors, and reduce overall deployment costs

Technical specifications and parameters

Category specific parameters

Detect gases such as methane, ethane, propane, butane, pentane, ethylene, propylene, and butadiene

Path length: Short distance: 5-40m; Medium distance: 40-120m; Long distance: 120-200m

Output signal 4-20mA (maximum loop resistance 600 Ω, supports source/drain output); RS485; 21mA over range, 2-3mA fault signal (user programmable)

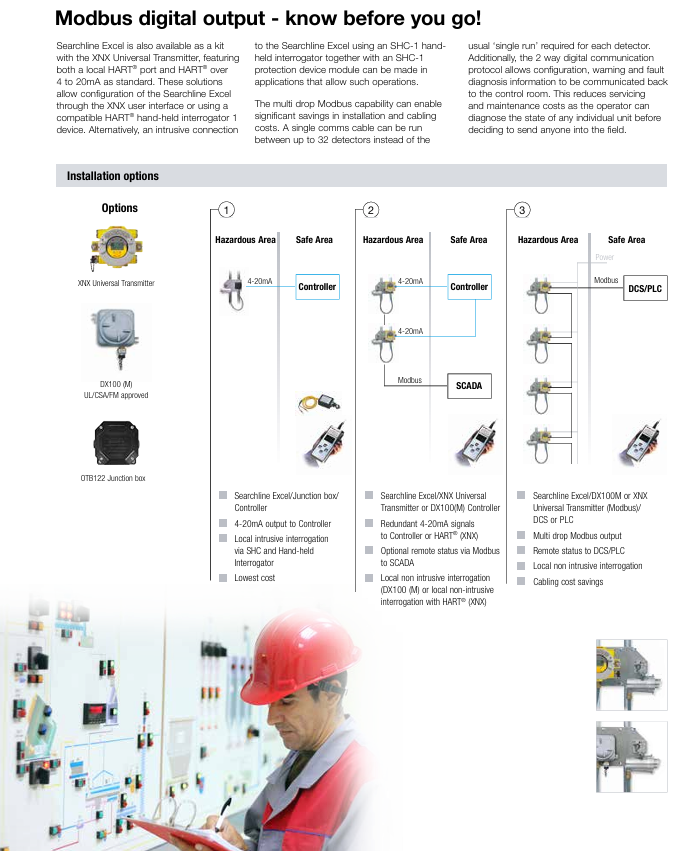

Digital output needs to be paired with DX100 (M) or XNX universal transmitter with Modbus option, supporting Modbus RS485 multi station output

Environmental parameters: Operating humidity: 0-99% RH (non condensing); Work pressure: 91.5-105.5kPa (without pressure compensation)

Power supply and power consumption: 18-32VDC; Power consumption: Short range Tx 3.5-5.0W, medium to long range Tx 10-13W, Rx 8W (all maximum values)

Physical specifications and weight (including installation bracket): Short distance Tx 3.5kg, medium to long distance Tx 7kg, Rx 3.5kg; Alignment tolerance ± 0.5 °

Certification and Standard Performance Certification: FM; Safety Certification: ATEX, UL, CSA, GOST; EMC standard: EN50270

Preheating time ready:<5 minutes; Completely stable:<1 hour

Installation configuration and accessories

1. Installation options

Support multiple installation combinations for hazardous and safe areas, adapting to different control systems. Common solutions include:

Searchline Excel+DX100 (M) (UL/CSA/FM certified)+Controller/DCS/PLC

Searchline Excel+junction box (such as OTB122)+controller

Searchline Excel+XNX universal transmitter+controller/DCS/PLC (supports redundant 4-20mA signal, HART protocol)

Multi station Modbus output: Connect 32 detectors with a single cable to reduce wiring costs and support bidirectional digital communication (configuration, alarm, fault diagnosis)

2. Core accessories and functions

XNX universal transmitter: provides local display and supports HART ®、 Modbus、 Foundation Fieldbus ™) Waiting for interfaces to enhance compatibility between devices and control systems

SHC-1 handheld interrogator: equipped with a protection module, it can perform local invasive configuration and diagnosis of the detector in allowed scenarios

Telescope installation mechanism: a unique three-point installation benchmark ensures alignment accuracy; The perspective can be adjusted to the most convenient position without the need for subsequent software adjustments

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923