K-WANG

Yokogawa Motor YS1700 Programmable Indicator Controller

Compact design: The standard version has a smaller volume and lighter weight (the base model weighs 1.6kg), with low installation space requirements. At the same time, it provides models with the same panel opening size and depth as the old controller, making it easy to replace and upgrade.

International Compliance: Compliant with CE certification, FM/CSA non flammable (optional) and other international safety standards, suitable for industrial scenarios in multiple regions around the world.

Yokogawa Motor YS1700 Programmable Indicator Controller

Core positioning and overall advantages of the product

YS1700 is a programmable indicator controller that can be adapted to multiple scenarios through user programs. It belongs to the YS1000 series and its core advantages are reflected in high reliability, ease of use, and scalability. Specific features include:

Compact design: The standard version has a smaller volume and lighter weight (the base model weighs 1.6kg), with low installation space requirements. At the same time, it provides models with the same panel opening size and depth as the old controller, making it easy to replace and upgrade.

International Compliance: Compliant with CE certification, FM/CSA non flammable (optional) and other international safety standards, suitable for industrial scenarios in multiple regions around the world.

Dual CPU and Fault Safety: Dual CPU design for control and display, allowing for display and manual operation even in the event of a single CPU failure; A hard manual circuit independent of digital circuits (excluding suffix code -2xx options) that can manually adjust the output when both CPUs fail.

Maintenance free backup: using non-volatile memory to backup data, without the need for batteries or capacitors, reducing maintenance costs.

Wide voltage adaptation: Supports AC/DC dual power supply (such as 100V AC or 24V DC, 220V AC needs to be customized), DC power supply has no polarity limitation and strong resistance to voltage fluctuations.

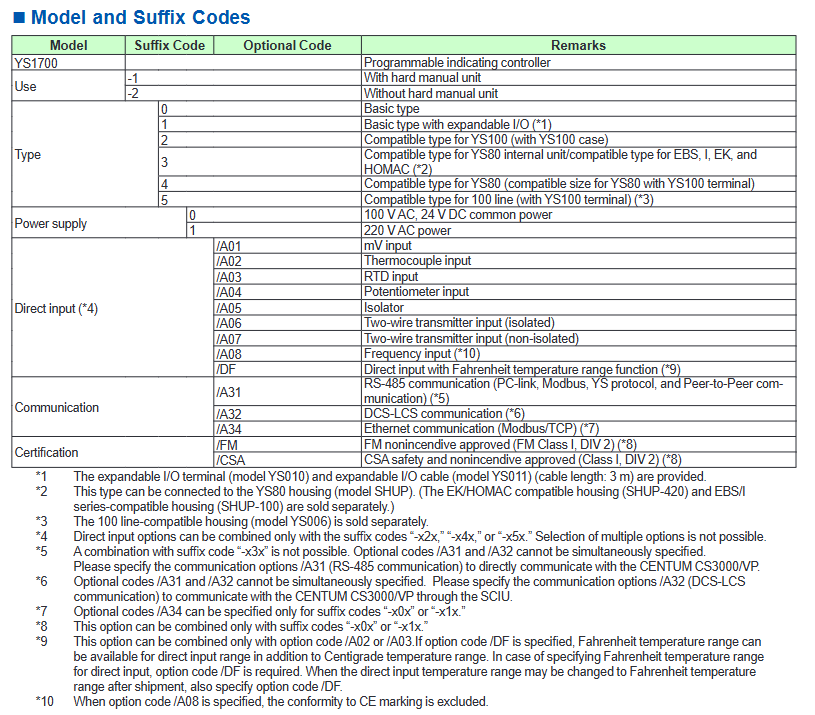

Product Model Classification and I/O Configuration

YS1700 is divided into multiple models based on functionality and compatibility, with the core difference reflected in the number of I/O interfaces and compatibility with older devices. The specific parameters are shown in the table below:

Model Type Model Identification Analog Input (AI) Analog Output (AO) Digital Input/Output (DI/DO) Core Features

Basic YS1700-x0x 5 (1-5V DC) 2-channel 1-5V DC (1 channel can be changed to 4-20mA) 6 (DI/DO shared) Basic function, no expansion I/O, protection level IP54

Scalable I/O Basic YS1700-x1x 8 (including 3 extensions) 3 1-5V DC+1 4-20mA 14 (including 4 extensions) Supports I/O extensions, suitable for complex signal acquisition scenarios

YS100 compatible YS1700-x2x (/Ax) 5 (4 channels available) 2 channels 1-5V DC (1 channel can be changed to 4-20mA) 6 compatible YS100 series, signal terminal layout close to the old model

YS80 internal unit compatible YS1700-x3x 5 2-channel 1-5V DC (1 channel can be changed to 4-20mA) 6 compatible with old devices such as YS80, EBS, I, EK, HOMAC, etc

YS80 (YS100 terminal) compatible YS1700-x4x (/Ax) 5 (4 channels available) 2 channels 1-5V DC (1 channel can be changed to 4-20mA) 6 sizes compatible with YS80, terminal layout matching YS100

100 wire (YS100 terminal) compatible YS1700-x5x (/Ax) 5 (4 channels available) 2 channels 1-5V DC (1 channel can be changed to 4-20mA) 6 compatible with 100 wire pneumatic instrument replacement scenarios

Note: Some analog inputs can be changed to 4-20mA through parameter settings, and DI/DO terminals can be specified as input or output functions through parameters.

Core functions and technical features

1. Display and operation functions

High visibility display: using a 120 × 320 pixel full dot matrix TFT color LCD, supporting backlight brightness adjustment and off, even in direct sunlight in the morning and evening, it is still clearly visible; Provide multiple display modes such as dashboard, trend chart, bar chart, alarm, event, etc., which can be quickly switched through panel buttons.

Flexible data display: The tag number can display up to 12 characters, PV (process value) and SV (set value) can display up to 7 digits (including decimal point and symbol), and MV (operation value) can display up to 6 digits; The trend chart supports three types of variables (such as PV1/SV1/MV1), with a time span of 1.5 minutes to 45 hours, and can hide/display a single curve.

Convenient manual operation: The panel is equipped with SV/MV increase and decrease buttons, supporting FAST mode (MV adjustment speed 4 seconds/full range, normal mode 40 seconds/full range); When there is a malfunction, it automatically switches to FAIL display, and the hard manual wheel can adjust the output urgently.

2. Control mode and computing power

Dual control mode:

Programmable mode: Requires YSS1000 configuration software, supports basic control (BSC1/BSC2), cascade control (CSC), selector control (SSC) modules, and can freely combine control and calculation modules.

Function selection mode: No programming required, select commonly used functions (single loop, cascade, selector control) directly, and I/O functions are allocated through parameters.

Rich control types: Supports four control types: PID, PD, sample and hold PI, and batch PID. PID parameters (proportional range 0.1-999.9%, integration time 1-9999 seconds, differentiation time 0-9999 seconds) can be flexibly set, and additional functions such as self-tuning (STC), nonlinear PID, and output limitation can be added.

High precision calculation: using IEEE754 format 4-byte floating-point operation, supporting over 100 calculation modules such as exponential, logarithmic, temperature/pressure compensation, etc., to ensure data processing accuracy.

3. Programming and debugging skills

Dual programming mode:

Text programming: Program capacity of 1000 steps (main program+subroutines, subroutines can be reused), supporting logical operations, conditional judgments, jumps, and other instructions.

Function block programming: Based on GUI interface, with a program capacity of 400 modules, supporting online monitoring and testing operation, reducing programming barriers.

Online debugging: Through YSS1000 software, program testing, I/O signal simulation (up to 50 steps of simulation program), and functional block status monitoring can be achieved for easy troubleshooting and parameter optimization.

Data storage: Provides 30 P-parameter variables, 100 K-parameter constants, and 60 temporary data registers to meet the data storage needs of complex programs.

4. Communication function

Support multi protocol communication and adapt to different industrial control systems, with specific parameters as follows:

Key parameters of communication type interface/protocol applicable scenarios

RS-485 PC Link, Modbus RTU/ASCII, YS protocol, point-to-point communication connection PLC, PC or multiple YS1700 devices can be networked up to 32 devices, with a maximum communication distance of 1200 meters

Ethernet Modbus/TCP (basic type only) connection DCS/PLC, supports remote configuration and monitoring 10BASE-T/100BASE-TX, RJ45 interface, distance of 100 meters

DCS-LCS communication Yokogawa dedicated protocol connects up to 8 devices per LCS card in Yokogawa CENTUM CS 3000 and other DCS systems, with a communication distance of 100 meters

Programmer communication RS-232C (dedicated interface) downloads/uploads programs and parameters through YSS1000 software using a dedicated USB-RS232C cable, with a distance of approximately 2.7 meters

Host control mode: Supports DDC (direct control MV) and SPC (control SV) modes, and can automatically switch to manual (MAN) or automatic (AUT) backup mode when communication is interrupted.

Wiring cost optimization: Modbus multi station output supports 32 devices sharing one communication cable, reducing wiring workload.

5. Alarm and self diagnosis

Alarm function: Supports PV high and low limit/high and high limit/low and low limit alarms, deviation alarms, and rate alarms. The alarm threshold (-6.3-106.3%) and hysteresis (0.1-20.0%) can be set; When an alarm is triggered, the ALM yellow light will light up, the tag number will be displayed in reverse, and the event message can be stored and traced back on the ALARM interface (up to 5 messages).

Self diagnosis: It can detect hardware faults such as CPU failure, A/D/D/A conversion errors, memory errors, etc. When there is a fault, the FAIL red light will light up, the analog output will maintain the current value, the DO signal will be locked, and the hard manual function will be enabled.

Hardware specifications and environmental adaptability

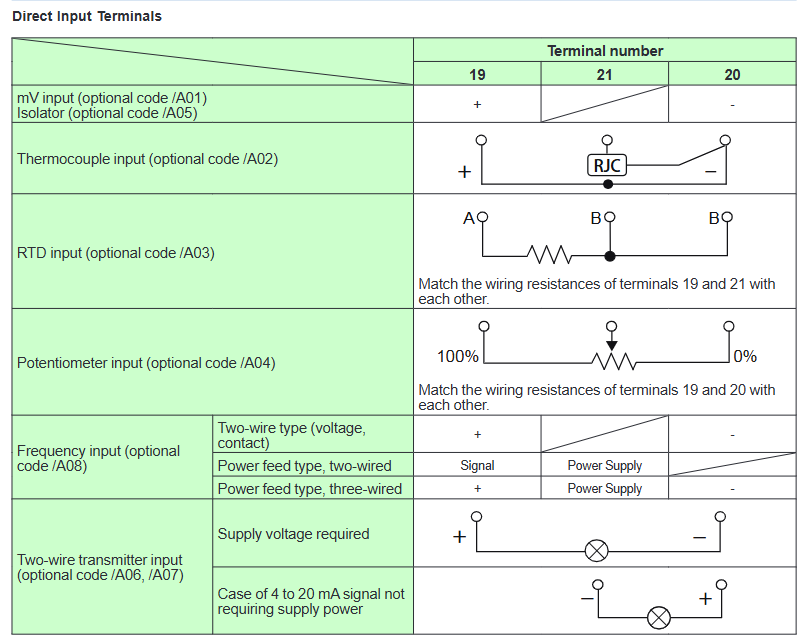

1. Input and output electrical parameters

Signal type specification parameter accuracy requirements

Analog input (1-5V) input resistance 1M Ω, range 0-5.5V, supports direct input (mV, thermocouple, RTD, etc.) ± 0.1% range (basic type), ± 0.2% range (extended I/O)

Analog output (4-20mA) load resistance 0-750 Ω, output range 0.8-21.0mA ± 0.2% range

Digital input with no voltage contacts (below 200 Ω/above 100k Ω), voltage contacts (low -0.5-1V/high 4.5-30V), minimum pulse width of 70-220ms (according to control cycle)

Digital output transistor contact, open circuit output in case of 30V DC/200mA (resistive load) fault

Transmitter power supply 25-25.5V DC, load below 60mA (including 30mA below direct input) short circuit protection 80 ± 10mA

2. Environmental and mechanical characteristics

Working conditions: temperature 0-50 ℃, humidity 5-90% (non condensing), altitude below 2000 meters, atmospheric pressure 86-106kPa; Anti vibration (5-14Hz amplitude 0.625mm, 14-150Hz acceleration 4.9m/s ²), anti impact (49m/s ², within 11ms).

Protection and material: Basic panel protection IP54, shell 316 stainless steel; Insulation resistance 100M Ω (500V DC), withstand voltage 1000-3000V AC (depending on model), in compliance with IEC/EN 61010 safety standards.

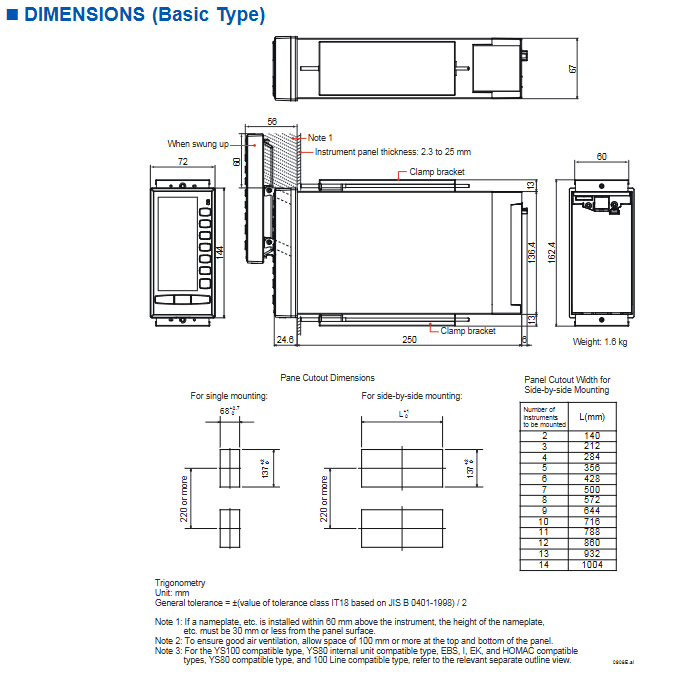

Size and Installation: The basic size is 144 × 72 × 250mm (H × W × D), with a panel opening of 137 × 68mm. It supports parallel installation, and the opening width needs to be adjusted according to the quantity when installing multiple devices (such as 2 units of 140mm and 3 units of 212mm).

Safety Compliance and Certification

General safety standards: comply with IEC/EN 61010-1/2-201/2-030, CAN/CSA-C22.2 No.61010 series standards, overvoltage category II, pollution level 2, measurement category O.

EMC standards: EN 61326 Class A, EN 55011 Class A Group 1, anti common mode noise 83dB, series mode noise 46dB (50/60Hz).

Hazardous Area Certification: Optional FM/CSA non flammable certification (Class I, Division 2, Groups A-D, Temperature Class T4), suitable for potentially explosive environments.

Environmental standards: Compliant with the EU RoHS directive (EN IEC 63000), with no harmful substances except for the A08 frequency input option.

Installation and Accessories

1. Installation requirements

Panel installation: The panel thickness is 2.3-25mm, with at least 60mm of space reserved at the top (to avoid obstruction during operation), and 100mm of ventilation space reserved above and below.

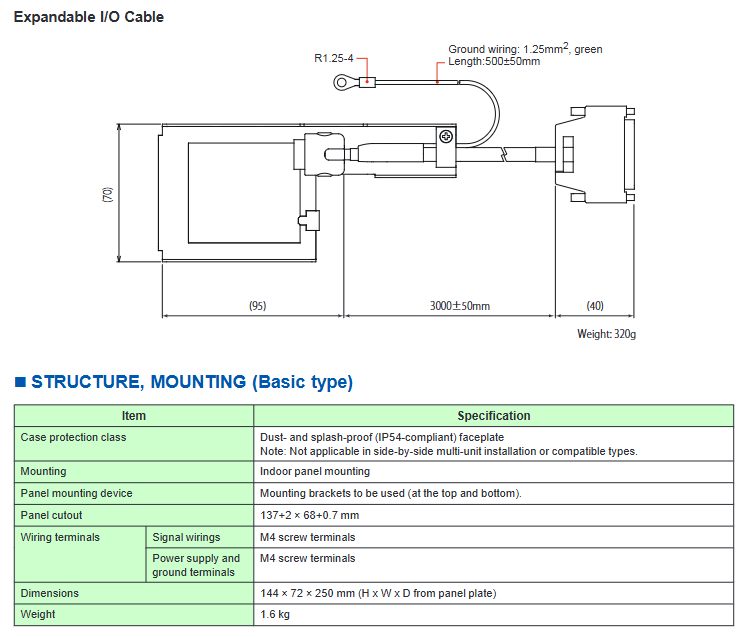

Expansion I/O installation: The expandable I/O type requires YS010 expansion terminals and YS011-03 expansion cables (3 meters), with a cable bending radius of ≥ 60mm.

Wiring specifications: The signal terminal and power terminal are both M4 screws. Shielded twisted pair cables are required for analog signals, and grounding must comply with Yokogawa grounding specifications.

2. Standard and optional accessories

Accessory type, model, purpose, and remarks

Install brackets L4041RA, E9760RJ, and other fixed controllers onto the panel to adapt to different compatible controllers of different models

Expansion I/O accessories YS010 (terminal), YS011-03 (cable) are only applicable for expandable I/O type signal expansion YS1700-x1x

Temperature compensation accessory L3501RA (RJC sensor) thermocouple input reference compensation only/A02 option applicable

YS020 (120 Ω terminal resistor) and YS021 (250 Ω shunt resistor) resistor accessories are suitable for RS-485 communication matching and signal conversion. The terminal resistors can be enabled or not by parameter selection

Replace the shell SHUP-000/SHUP-100/SHUP-420, YS006 to adapt to the installation of old equipment, such as YS80 and 100 line instruments, and select the corresponding shell according to the compatible model

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923