K-WANG

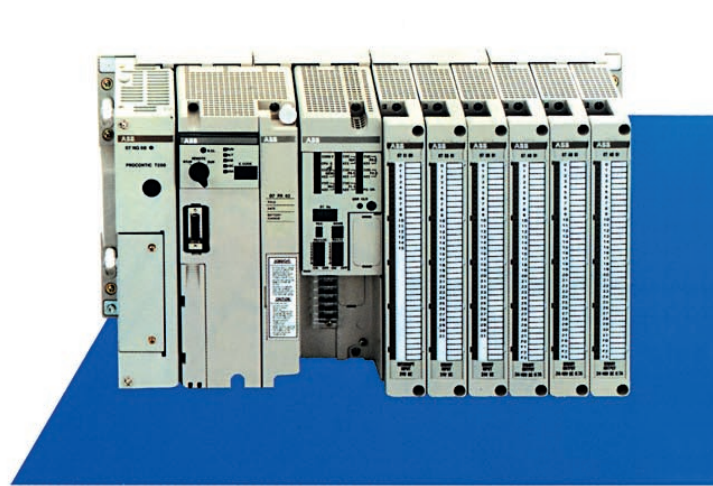

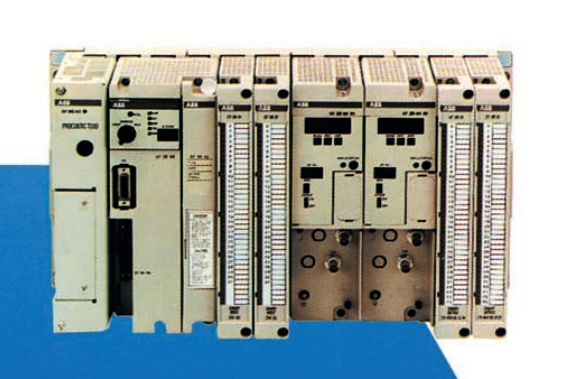

ABB Procontic T200 series programmable controller

ABB Procontic T200 series programmable controller

The ABB Procontic T200 automation system is

a modular control system that largely satisfies

the requirements of today and tomorrow.

Thanks to its rack based architecture and wide

range of modules, the ABB Procontic T200 can

be assembled to suit most any application.

The simple handling and planning of the

system saves time and money.

ABB Procontic T200 programming software is

IBM-compatible and provides efficient process

display,PLC operation,and connection to fieldbuses.

ABB Procontic systems are designed for heavy-

duty industrial operation and are distinguished

by their resistance to interference(EMC).

Extensive diagnostic functions of the ABB

Procontic T200 simplify commissioning and

troubleshooting of the system.

Efficient and easy-to-program serial bus

systems connect separately located stations

●The ABB Procontic field bus,ZB10,ex-

changes process data with the other ABB

Procontic systems.

An ABB Procontic T200 control consists, in its

simplest form, of a module rack, a central unit,

program memory, an input module,an output

module, and a power supply unit.

Expansion module racks provide ample room

for further input and output devices.Four

central units classified according to their ex-

pandability and a series of pre-processors and

interface equipment enable optimum adaptation

of the ABB Procontic T200 to the respective

control task. The T200 can be configured cen-

trally (in the immediate vicinity) or decentrally.

Equipment overview

●4 central units per rack,T200 offers a choice

of 4 central units graduated in performance

with the same instruction set

●RAM and EPROM memories with different

memory capacities

●3 basic module racks in 2, 5 and 8 slot

configurations

3 expansion module racks with 4, 7 or 10 I/O

slots

.Descrete input and output devices available

in common voltages

●Analog input and output devices for voltage

and current

Input devices for temperatures

●Interrupt input device,fast counter,

positioning device

●Modules for central and decentral coupling of

expansion module racks

●Interface equipment

.Couplers for theABB Procontic field bus

ZB10,ABB Procontic T200 bus ZB20,and

PROFIBUS

·High-performance industrial computer

The ABB Procontic T200 with a number of

subracks and its central unit can be suited to

any application within wide limits.

Smallest System

●Basic rack with central unit 07 ZE 60 and 2,

5 or 8 peripheral slots

Medium System

.Basic rack with central unit 07 ZE 61 and 2,

5 or 8 peripheral slots

●Expansion rack with 4, 7 or 10 peripheralslots

This makes a maximum of 18 peripheral slots

Maximum System

.Basic rack with central unit07 ZE 62

or 07 ZE 63 and 2, 5 or 8 peripheral slots

up to 5 racks for central I/O expansion with

4, 7 or 10 peripheral slots each

This makes a maximum of 58 peripheral

slots

Remote I/O-expansion systems overcome the

space restraints of a switchgear cabinet,and of

the data capacity of a central assembly.

Up to 4 coupling units may be located within

the basic rack, independent of the type of

central units and the centrally connected

expansion racks.

The coupling units connect 4 lines, thus increa-

sing the data scope of the ABB Procontic

T200.

Decentral expansion withABB Procontic T200

components allows up to 10 substations

(expansion module rack with I/Ounits per line).

The total line lenght may be up to 1,640 ft

(500 m) when using triax cables. If the spurious

radiation on the connecting lines is above the

usual level in industrial applications,fibre optic

cables with a lenght of up to 32,800 ft(10 km)

are used.

Decentral expansions via the ABB Procontic

CS31 bus is also possible in theABB Procontic

T200. The special advantage of the ABB Pro-

contic CS31 components is in the compact

design of the modules which find room even in

the smallest of onsite terminal boxes. Every CS31

line allows connection of up to 31 modules.

The CS31 two-wire system bus may reach a

maximum lenght of 1,640 ft(500 m).

Automatic control systems today require flexible

networks. ABB networks individual parts of a

production plant with each cell having their

own intelligent processing units. There is a

choice of two robust serial buses for networ-

king: the ZB20 bus and the ZB10 field bus.The

ZB20 bus supports the capabilities of the ABB

Procontic T200 system whereas the ZB10 field

bus connects other ABB Procontic systems.

The ZB20 bus connects up to 64 T200 stations

of the automatic control system. Each one of

these stations can be fully expanded centrally

and decentrally. The distance between the

stations may be up to 1,640 ft (500 m) when

using triax cables. Every station can include 2

couplers providing connectivity with two diffe-

rent bus systems for a total distance of 3,280 ft

(1000 m). Fiber optic media is also available for

industrial applications that require high noise

immunity. Maximum distance for fiber optic is

32,800 ft(10 km)

ZB20 bus offers high performance as well as

data integrity. Throughput can range from 50 ms

for small data volume and up to 400 ms for full

expansion (with 2,048 bytes).

The ZB20 station addresses are conveniently

set during creation of the user program.

The ABB Procontic T200 ZB20 bus features

program transfer with parameters in addition

to processing data. A programming

device,connected anywhere in the

automation system, offers insight into

the user programs of all central units,

with all the appropriate functions

(for example down line loading).

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

BENTLY NEVADA 3500/15 133292-01 Power Supply Module

-

ABB PM877 3BDH000777R1 Central_Unit Controller

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor