K-WANG

TOSBERT VF-AS3 Industrial Inverter Quick Start Manual

TOSBERT VF-AS3 Industrial Inverter Quick Start Manual

The fast start manual for Toshiba TOSBERT VF-AS3 series industrial frequency converters covers three voltage levels of 500V/600V (575V)/690V and a power range of 1.5kW-75kW/2HP-100HP. The core content includes safety specifications, installation wiring, standard compliance measures, peripheral equipment selection, parameter settings, product specifications, and warranty terms. It emphasizes the need for professional operation, clarifies the compliance requirements for multi rating settings (HD/ND), EMC/UL/CSA, and safety taboos such as high voltage operation and capacitor discharge, and is suitable for controlling the speed of three-phase induction motors, IPMSM, and SPMSM.

1. Basic information

Product positioning: Used for controlling the speed of three-phase induction motors, built-in permanent magnet synchronous motors (IPMSM), and surface permanent magnet synchronous motors (SPMSM) in industrial scenarios, and cannot drive single-phase motors

Voltage and power range:

500V level: 1.5kW-55kW

600V (575V) level: 2HP-75HP (HD)/3HP-100HP (ND)

690V level: 2.2kW-75kW (HD)/3kW-90kW (ND)

Core features: Supports multiple ratings (HD/ND), V/f control, vector control, PID control, built-in EMC filter and DC reactor

2. Core security standards

2.1 Personnel and Protection Requirements

Qualification requirements for homework types require necessary protective equipment

All qualified installation/maintenance personnel shall wear protective gloves and safety work clothes

Electrical work requires the qualification of insulated gloves, insulated shoes, and anti electric shock clothing

High altitude operations (≥ 50cm) require industrial safety helmets with high-altitude operation qualifications and ladders that comply with ISO14122 standards

Shoes for heavy object transportation (≥ 20kg) without special qualifications but requiring training on anti smashing toe caps

Qualified maintenance personnel with electrician specific protective gloves for maintenance operations

2.2 Key safety taboos

High voltage operation: After power failure, wait for 15 minutes (capacitor discharge), confirm that the charging light is off and the DC voltage is ≤ 45V before operation

Prohibited behavior:

Do not disassemble the front cover/small front cover (including high-voltage components inside) while it is live

Do not connect the power supply to the output terminals [U/T1] [V/T2] [W/T3]

Do not modify equipment or use non specified accessories

Prohibit the use of welding machines in enclosed spaces (to prevent carbon monoxide poisoning)

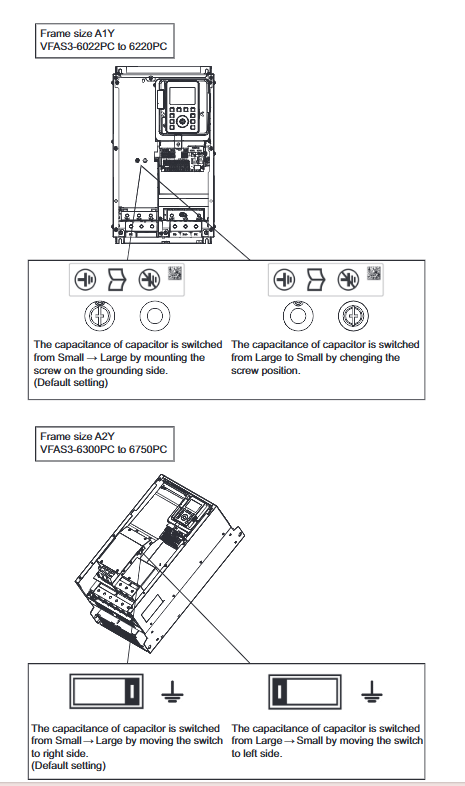

Power requirement: Do not connect the corner grounding system, IT system needs to disconnect the grounding capacitor

3. Installation and wiring

3.1 Installation environment and conditions

Remarks on the Range of Environmental Parameter Requirements

If the ambient temperature is between -15 ℃ and+60 ℃ and exceeds 50 ℃, it is necessary to reduce the capacity for operation

Relative humidity 5%~95%, no condensation

Altitude ≤ 2000m>1000m, capacity reduction of 1% per 100m

Vibration ≤ 5.9m/s ² (10-55Hz) Avoid installation in locations with high vibration

Installation location: Indoor, no direct sunlight, no corrosive gas/oil mist, ventilation space needs to be reserved

3.2 Installation and wiring specifications

Installation method:

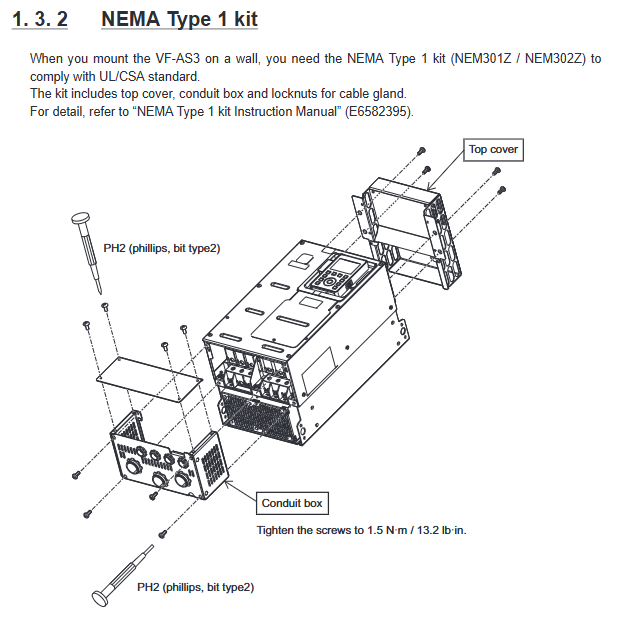

Wall mounted installation: NEMA Type 1 kit is required (NEM301Z for A1Y, NEM302Z for A2Y)

Multiple parallel devices: A1Y spacing ≥ 11mm, A2Y spacing ≥ 11mm, with a ventilation space of ≥ 10cm reserved above and below

Wiring requirements:

Power terminal: [R/L1] [S/L2] [T/L3] (three-phase input)

Motor terminals: [U/T1] [V/T2] [W/T3] (three-phase output)

Grounding terminal: [PE], wire diameter needs to be matched (such as 600V HD type 12AWG corresponding to grounding 12AWG)

Terminal torque: A1Y 12AWG is 26.5lb · in, A2Y output terminal is 363lb · in

4. Parameter settings

4.1 Core Parameters (Basic Settings)

Parameter Name Function Adjustment Range Default Settings

CMOd (Command Selection) Select the control mode terminal/operation panel/communication, etc. 0 (terminal)

FMOd (frequency command selection) Select frequency control source terminal/touch screen/communication, etc. 1 (terminal RR)

ACC (Acceleration Time 1) Acceleration Time from 0Hz to FH 0.0~6000s 10.0s

Deceleration time from FH to 0Hz for dEC (deceleration time 1) is 0.0~6000s 10.0s

FH (maximum frequency) output frequency upper limit 30.0~590.0Hz 80.0Hz

AUL (Multiple Rating Selection): Select HD/ND and voltage levels 2 (ND-600V), 3 (HD-600V), etc. 3 (HD-600V -60Hz)

4.2 Differences in Multiple Rated Values (HD/ND)

Rated Value Type Overload Capacity Applicable Scenario Parameter Setting (AUL)

HD (Heavy Duty) 150% -60s constant torque load (conveyor, crane, etc.) 3 (600V), 15 (500V), 17 (690V)

ND (Normal Duty) 120% -60s variable torque load (fan, pump, blower, etc.) 2 (600V), 14 (500V), 16 (690V)

5. Standard compliance measures

5.1 Main Compliance Standards

Key measures for compliance requirements of standard types

The EMC directive complies with IEC61800-3, CISPR11 with built-in EMC filters, shielded cables, and separate wiring

Low voltage instructions comply with IEC61800-5-1 for installation in cabinets, standardized grounding, and installation of protective devices

UL/CSA standards comply with UL61800-5-1, using UL certified cables and installing specified fuses/circuit breakers

ATEX directive not applied for and cannot be used in explosion-proof scenarios

5.2 Short circuit protection configuration (UL/CSA standard)

Inverter Model Maximum Voltage (V) Branch Circuit Protection (Fuse) Power Wire Specification (AWG) Grounding Wire Specification (AWG)

VFAS3-6022PC 600 Class J,10A 12 12

VFAS3-6110PC 600 Class J,25A 10 10

VFAS3-6300PC 600 Class J,60A 4 2

VFAS3-6750PC 600 Class J,150A 1/0 2

6. Product specifications and warranty

6.1 Core specifications (taking 600V HD type as an example)

Model Applicable Motor (HP) Output Capacity (kVA) Output Current (A) Cooling Method Weight (kg)

VFAS3-6022PC 2 3.1 3.1 Forced Air Cooling 21.6

VFAS3-6110PC 10 13 13.5 Forced Air Cooling 21.6

VFAS3-6300PC 30 34 34 forced air cooling 51.9

VFAS3-6750PC 75 83 83 Forced air cooling 52.5

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923