K-WANG

Toshiba Integrated Control System V Series Selection Manual

Toshiba Integrated Control System V Series Selection Manual

The Toshiba V series integrated control system covers three models: Model 3000 (large), Model 2000 (medium/small), and Model 1000 (ultra small). It can be freely combined through sequential control (S module), loop control (L module), and computer control (C module), and is equipped with multi-layer networks such as Ethernet/TC net/DeviceNet. It supports 20000 tag points, 22 human-machine interface stations, and 32 control stations, and has advantages such as 40ns high-speed data processing and super PID algorithm. It is widely used in multiple industries such as petroleum, chemical, and power, providing high-performance and scalable distributed control solutions.

Core advantages

Hardware: Adopting the DCS template from Japanese company CONTEC, with high reliability; 40ns high-speed data processing

Software: Chinese character operation interface, suitable for domestic operators; Support simulation and remote management

Function: Super PID algorithm, suitable for high-precision control (boiler, combustion control, etc.); 100Mbps industrial control network

Applicable industries: petroleum, chemical, machinery, electricity, textile, metallurgy, pharmaceuticals, building materials, food, water treatment, environmental protection, etc

System architecture

2.1 Network Layering

Network hierarchy core role support type key parameters

Monitoring and management network connection monitors, operating devices, and V-series station Ethernet (single/dual network) support remote access and OPC data sharing

TC net supports 254 nodes for high-speed data transmission between control network stations, including TC net100 (100Mbps) and TOSLINE-S20/S20LP (2Mbps), with a transmission distance of 100m (cable)/2km (optical cable)

Fieldbus network connects field devices (sensors, drivers, etc.) such as DeviceNet and Profibus. The transmission rate of DeviceNet is 125kbps-500kbps, with a maximum of 64 points

2.2 Station Configuration Structure

Main Unit Configuration Bus Type I/O Expansion Capability Core Features

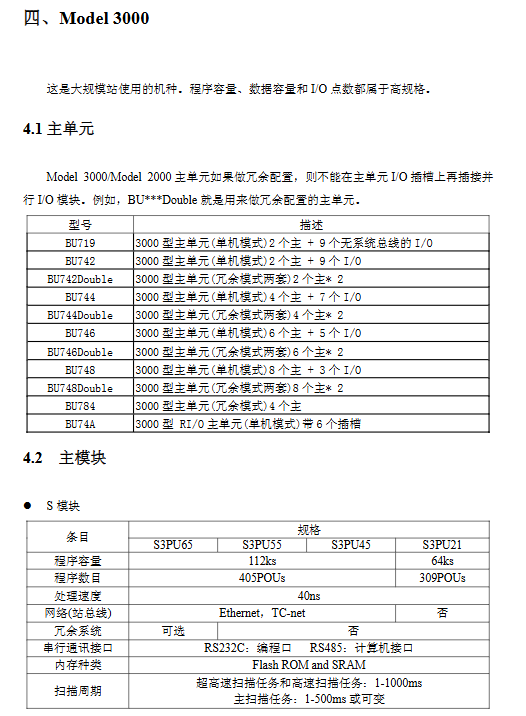

Model 3000 (large) 2-8 main slots+3-9 I/O slots Parallel bus (G3Bus), serial bus Each parallel bus extends 7 I/O units Support redundant configuration, suitable for large factory control

Model 2000 (medium/small) 1-5 main slots+3-8 I/O slots Parallel bus (G2Bus), serial bus Each serial bus connects 15 communication modules to balance expansion and cost, suitable for medium scale scenarios

Model 1000 (ultra small) integrated main module slot I/O bus (I/OBus) can connect up to 16 serial I/O modules. The structure is simple and suitable for small-scale control

Core hardware module

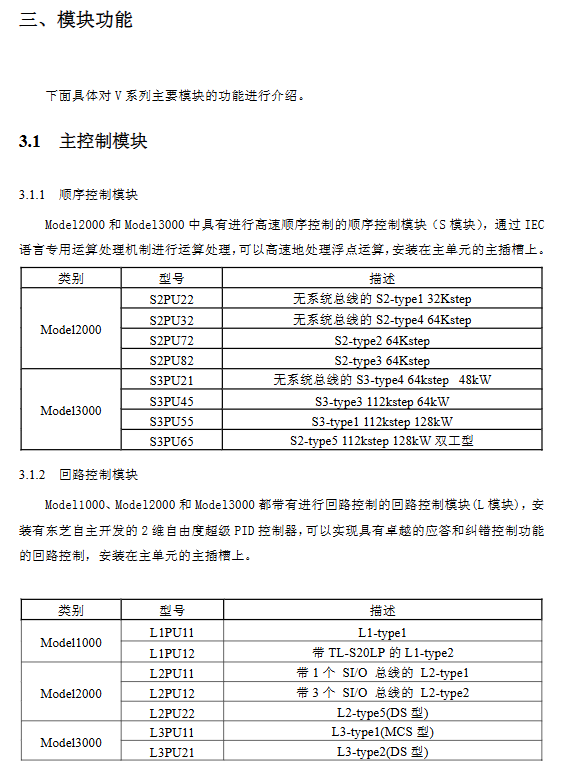

3.1 Main control module

Module type, core function, model adaptation, key specifications

S module (sequential control) high-speed sequential control, floating-point operation processing Model 2000/3000 Model 3000 maximum 112kstep program capacity, 40ns processing speed

L module (loop control) super PID algorithm, high-precision loop control. The entire Model 3000 supports 256 control loops, with a scanning rate of 32 loops/100ms

C module (computer control) Web/OPC server, data processing Model 2000/3000 with Windows system, maximum 512MB memory, 30GB hard drive

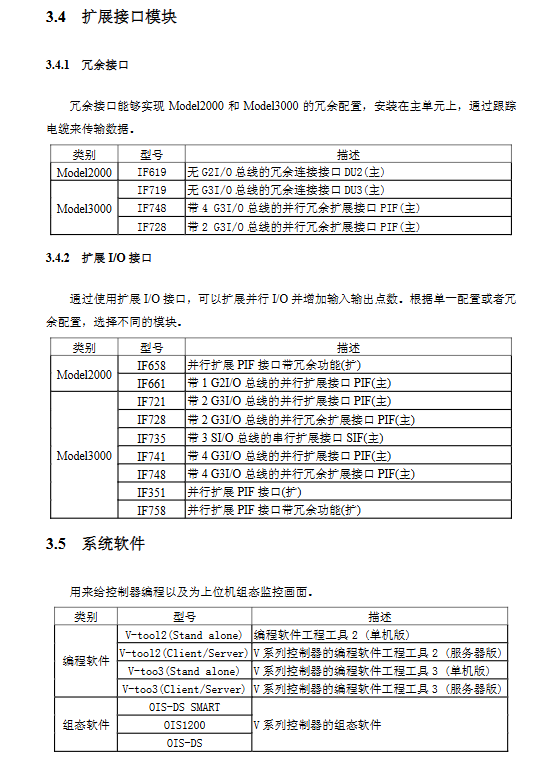

3.2 Communication module

Module Name Adaptation Network Model Adaptation Key Parameters

Ethernet module monitoring and management network supports 10BASE-T/100BASE-TX for all models, with a transmission rate of 10/100Mbps

TC net100 module control network Model 3000 dual network redundancy, scanning transmission capacity of 128kW/system

DeviceNet module fieldbus network model 2000/3000, with a maximum of 64 main stations, supporting interconnection of devices from multiple vendors

Profibus module fieldbus network model 2000/3000 transmission rate 9.6kbps-12Mbps, maximum 122 points for the main station

3.3 I/O module

Module type subdivision category key specifications (taking Model 3000 as an example)

Parallel I/O digital input (DI) DI335: 64 points, DC24V, 0.1A/point

Digital output (DO) DO333: 16 points, DC24V, 2.0A/point

Analog input (AI) AD368: 8 points, supports ± 10V/4-20mA, 12 bit resolution

Analog output (AO) DA374: 4 points, supports 4-20mA, 16 bit resolution

Serial I/O Analog Input (SAI) SAI06: 8 points, ± 10mV - ± 5V/4-20mA, 0.1% accuracy

Thermocouple input (STC) STC01: 8 points, supports J/K/T and other types, 0.2% accuracy

Digital Input (SDI) SDI01: 32 points, DC24V, 5mA, 10ms update cycle

Software system

4.1 Programming software

Software name, version type, core function

V-tool2/V-tool3 standalone/client/server version supports IEC61131-3 standard, including configuration editing, symbol assignment, and online debugging

Tag editor integrated tool for managing loop control tag database, including tag signatures, PID parameters, etc

System log auxiliary tool displays error logs, event logs, and I/O error information

4.2 Human Computer Interface Software

Software type represents the key specifications of the product

The OIS-DS large-scale system supports 20000 tag points, 22 human-machine interface stations, and 32 control stations

The OIS-DS SMART small system supports 4000 tag points, 8 human-machine interface stations, and 8 control stations

Core functions - real-time data display, trend monitoring, alarm management, remote access, redundant backup

Core differences among the three models

Comparison Dimension Model 3000 (Large) Model 2000 (Medium/Small) Model 1000 (Ultra Small)

Applicable scenarios: DCS control for large factories, medium/small-scale process control, single point control for small equipment

Maximum program capacity: 112kstep, 64kstep, 6kstep

256 control circuits, maximum 96, 8/500ms

The network supports Ethernet/TC net and other (redundant) Ethernet/TOSLINE and other Ethernet/TOSLINE-S20LP

Main module configuration S/L/C module fully supports S/L/C module only supports L module

Tag points support 20000, 8000, and 4000

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923