K-WANG

Foxboro Evo FDSI Triconex integrator driver product

Brand Foxboro (formerly Invensys, under Schneider Electric)

Document version PSS 31S-3A9 B3

The core positioning is an integrated driver based on the TSAA protocol, which enables data exchange and unified management between the Triconex security controller and the Foxboro system

The core protocol Triconex System Access Application (TSAA) protocol is designed specifically for secure applications

Core carrier FBM232 (single module, non redundant), FBM233 (dual module, redundant)

Foxboro Evo FDSI Triconex integrator driver product

Product basic information

Key content of the project

Product Name Foxboro Evo FDSI Triconex Integrated Driver

Brand Foxboro (formerly Invensys, under Schneider Electric)

Document version PSS 31S-3A9 B3

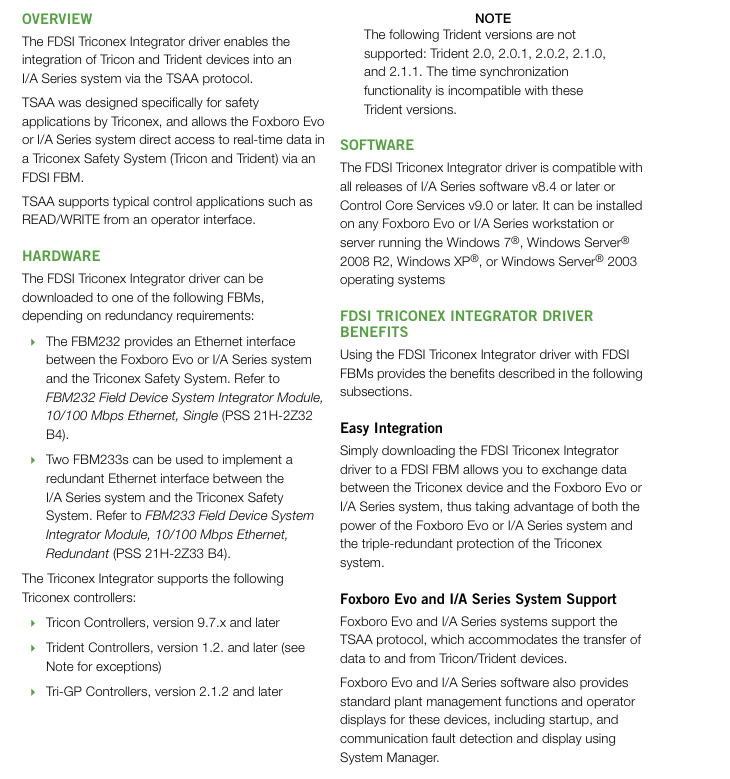

The core positioning is an integrated driver based on the TSAA protocol, which enables data exchange and unified management between the Triconex security controller and the Foxboro system

The core protocol Triconex System Access Application (TSAA) protocol is designed specifically for secure applications

Core carrier FBM232 (single module, non redundant), FBM233 (dual module, redundant)

Core functions and advantages

(1) System integration and data interaction

Bidirectional data read and write: Supports real-time data exchange between Foxboro system and Triconex controller, including input and output of analog (integer/IEEE single precision floating-point) and digital quantities.

Efficient access method: The I/O points of the Triconex controller can be directly accessed through the TriStation tag name or Modbus alias without additional adaptation.

Batch operation support: A single write command can achieve multi-point writing, improving data transmission efficiency.

System Function Reuse: Directly supports the standard factory management functions (such as startup and fault detection) and operator display interface of Foxboro Evo/I/A Series, without the need for separate development.

(2) Redundancy and reliability design

Redundant configuration: FBM233 dual modules can form a redundant architecture, which is divided into a master module and a tracker module. The modules monitor the health status and share device information through communication links.

Fault switching: When the main module fails, it automatically switches to the tracking module without data loss during the switching process, and can also be manually triggered through System Manager.

Fault maintenance: When FBM or network faults occur, replacing modules or repairing the network will not affect the normal transmission of on-site I/O signals.

(3) Diagnostic and monitoring capabilities

Enhanced Diagnostic Monitoring (EnDM): Supports the integration of Triconex Enhanced Diagnostic Monitor software, which can be directly launched from Foxboro System Manager to monitor the hardware, communication, and application status of the Triconex controller.

Diagnostic data output: All diagnostic data of Triconex devices are provided through DCI input blocks, which can quickly develop FoxView process graphics to display diagnostic information and status.

Connection detection: System Monitor can detect the real-time connection status of devices. When a device fails, the FDSI ECB201 object will enter a warning state and trigger a system alarm.

(4) SOE event logging function

Event Collection: Sequence of Events (SOE) messages generated by the Triconex system can be collected and recorded to the AIM * Historian or Alarm Provider application through the Aprint mechanism.

Configuration management: SOE configuration information (device IP, event destination, alarm block, time zone, SOE point list) is stored in an XML file, independent of the control application configuration.

Capacity support: The TSAA workstation driver supports up to 10000 Triconex tags for SOE data collection.

Software and hardware compatibility and requirements

(1) Hardware compatibility

Hardware type, supported models, and requirements

FBM module FBM232 (single module, 10/100 Mbps Ethernet), FBM233 (redundant module, 10/100 Mbps Ethernet)

Triconex controllers Tricon v9.7. x and above, Trident v1.2 and above (excluding v2.0-2.1.1), Tri GP v2.1.2 and above

The communication module Tricon requires installation of NCM/TCM module, while Trident requires installation of CM module

Network devices support switches; Trident v3.0 CIM module does not support hubs

(2) Software and System Requirements

Category specific requirements

Foxboro system version I/A Series software v8.4 and above, Control Core Services v9.0 and above

Operating System Windows XP ®、 Windows 7 ®、 Windows Server ® In 2003 Windows Server ® 2008 R2

Configure software FDSI Configurator (to configure Ethernet ports), TriStation (to configure Triconex devices)

Diagnostic software Triconex EnDM v2.8.0+(requires System Manager v2.5+for direct startup)

Key technical parameters

Parameter category specific specifications

Single FBM supports up to 10 Triconex devices (actual quantity depends on performance and configuration)

DCI connection capacity up to 2000 (used for reading and writing Triconex controller data)

Data point capacity of up to 32000 digital I/O points, or up to 2000 analog systems/I/O values (can be mixed configured)

The fastest data scanning rate is 50 milliseconds per time (not exceeding the Triconex controller's own scanning rate, default is 200 milliseconds per time)

Communication timeout setting: If the controller does not receive a data request for 2 minutes, it will stop sending data

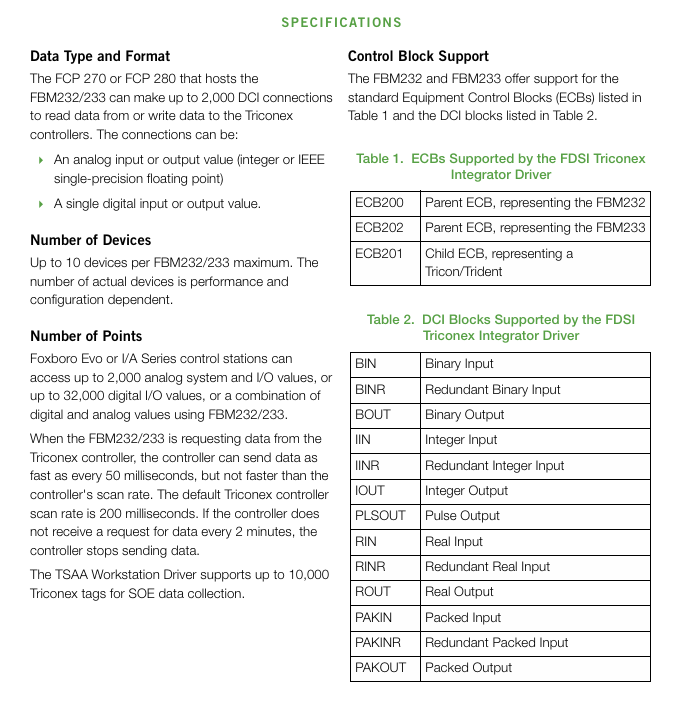

Support control block ECB block (ECB200/FBM232, ECB202/FBM233, ECB201/Triconex devices); DCI block (13 types including BIN, BOUT, IIN, IOUT, etc., including redundancy types)

Supports 13 core commands of TSAA (such as data request/response, clock read/write/adjust, SOE data request, etc.)

Installation and Configuration

Installation feature: Driver installation does not require shutting down system software or restarting workstations/servers; When updating the driver, it can be directly downloaded to FBM232/FBM233 without affecting the operation of other parts of the Foxboro system.

Configuration tool:

Driver configuration: Use FDSI Configurator (to be installed on a compatible workstation/server);

Device configuration: Use the TriStation Configurator to configure the Triconex controller;

SOE configuration: Maintain SOE point and device configuration information through XML files, independent of control applications.

Network configuration:

The Triconex controller needs to be connected to the FBM through a primary/backup hub/switch;

The Trident V3.0 CIM module only supports switches and does not support hubs.

Key issues

Question 1: What is the core integration value of FDSI Triconex Integrated Driver? How to achieve efficient interconnection between Triconex safety controller and Foxboro system?

Answer: The core integration value lies in the deep integration of Triconex security system and Foxboro automation system without the need for separate interface development. It directly reuses the factory management functions, operating interface, and diagnostic tools of Foxboro system, reducing integration costs and improving system consistency. Efficient interconnection implementation method: ① Based on the TSAA protocol designed by Triconex for secure applications, establish a 10/100 Mbps Ethernet connection through FBM232 (single module) or FBM233 (redundant module); ② Support direct access to device I/O points using TriStation tag names or Modbus aliases, and enable multi-point writing with a single command; ③ Driver installation and updates do not require downtime, the configuration process is simple, and a single FBM can connect up to 10 Triconex devices, meeting the integration requirements of medium and large-scale projects.

Question 2: What are the redundant configuration and fault handling designs of this driver? How to ensure the reliability of data transmission?

Answer: Redundancy and fault handling design: ① Hardware redundancy: FBM233 dual modules are used to form a master-slave architecture, with real-time monitoring of health status and sharing of device information between modules; ② Fault switching: When the main module fails, it automatically switches to the tracking module without data loss, and also supports manual switching; ③ Maintenance convenience: In case of FBM or network failure, replacing modules or repairing the network will not affect on-site I/O signals. Data transmission reliability guarantee: ① Communication link redundancy: Build dual links through primary/backup hubs/switches; ② Data scanning mechanism: a scanning rate of up to 50 milliseconds per scan (adapted to controller capabilities) to ensure real-time performance; ③ Timeout protection: If the controller does not receive a request within 2 minutes, it will stop sending to avoid invalid transmission; ④ Diagnostic warning: System Monitor detects connection status in real-time, DCI block outputs diagnostic data, EnDM tool monitors equipment status, and detects potential faults in advance.

Question 3: What Triconex controller models and system environments does the driver support? How can data processing capabilities match project requirements of different scales?

Answer: Compatibility between controller and system environment: ① Supported Triconex controllers: Tricon v9.7. x and above, Trident v1.2 and above (excluding v2.0-2.1.1), Tri GP v2.1.2 and above; ② Compatible Foxboro systems: I/A Series v8.4 and above, Control Core Services v9.0 and above; ③ Supported operating systems: Windows XP/7/Server 2003/2008 R2. Data processing capability adaptation: ① Equipment capacity: A single FBM can support up to 10 Triconex devices, which can be expanded through multiple FBMs; ② Data point capacity: Supports up to 32000 digital I/O points or 2000 analog values, meeting the signal acquisition needs of small (single device) to medium to large (multi device cluster) projects; ③ Connection capacity: 2000 DCI connections can cover the data exchange needs of multiple devices, SOE logs support the collection of 10000 tags, and are suitable for high demand security event tracing scenarios.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923