K-WANG

YASKAWA VARISPEED-626M/656MR5 series vector control frequency converter

YASKAWA VARISPEED-626M/656MR5 series vector control frequency converter

Document Fundamentals and Product Overview

Document positioning: Yaskawa VARISPEED-626M5656MR5 series user manual, mainly used for vector control inverters/converters with power regeneration function for machine tools, guiding installation, maintenance, troubleshooting, and specification inquiry.

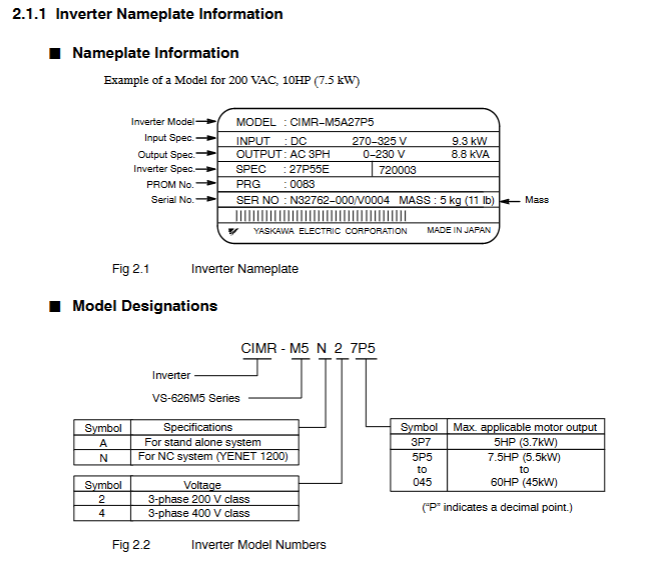

Product model and specifications:

Product Type Model Voltage Level Power Range (kW) Power Range (HP) Remarks

Variable frequency drive (VS-626M5) CIMR-M5 200V level 3.7/2.2-37/30 5/3-50/40 including M5A (independent drive), M5N (NC system)

Variable frequency drive (VS-626M5) CIMR-M5 400V level 5.5/3.7-45/37 7.5/5-60/50 including M5A (independent drive), M5N (NC system)

Converter (VS-656MR5) CIMR-MR5 200V class 3.7/2.2-37/30 5/3-50/40, including MR5A (without 24V control power supply) and MR5N (with 24V control power supply)

Converter (VS-656MR5) CIMR-MR5 400V class 5.5/3.7-45/37 7.5/5-60/50 including MR5A (without 24V control power supply), MR5N (with 24V control power supply)

Warranty information:

Warranty period: 12 months after delivery to the customer or 18 months from the date of shipment from the Yaskawa factory, whichever comes first.

Warranty scope: Only covers faults caused by defects in Yaskawa craftsmanship or materials, excluding improper maintenance, modification, and use beyond specifications.

Regional restrictions: Warranty services are only free within Japan and require payment overseas.

Safety regulations and operating taboos

Definition of Security Level:

Warning: Potential hazardous situation that, if not avoided, may result in death or serious personal injury (such as opening the cover with electricity, not grounded).

CAUTION: Potential hazardous situation that, if not avoided, may result in minor/moderate personal injury or equipment damage (such as grabbing the front cover during transportation or installing on flammable materials).

Core security precautions:

Power off operation: Before wiring or disassembling the digital operator (JVOP-132), the power must be turned off and the capacitor must be discharged (refer to the warning label time, usually 5 minutes).

Grounding requirements: 200V level grounding resistance ≤ 100 Ω, 400V level grounding resistance ≤ 10 Ω. It is strictly prohibited to share the ground with welding machines and high current equipment.

Temperature control: The ambient temperature of the frequency converter/inverter should be ≤ 55 ℃ (131 ° F), and the inlet temperature of the heat sink should be ≤ 45 ℃ (113 ° F). A fan or cooling device should be installed.

Operation taboos:

Do not connect the power supply to the output terminals of the frequency converter (U/T1, V/T2, W/T3), otherwise it will damage the internal components.

Do not connect phase-shifting capacitors, LC/RC noise filters, or electromagnetic switches in the output circuit, as it may cause damage or overcurrent to the frequency converter.

Do not modify the product, otherwise the warranty will expire and may cause electric shock/injury.

Equipment installation and wiring

Delivery Confirmation (CAUTION):

Check if the model is consistent with the order (verify the nameplate), if there is no transportation damage to the appearance, if screws or other components are loose, and if damaged/missing equipment is not allowed to be installed.

Installation requirements:

Environment: Indoor, no corrosive/explosive gases, no dust/metal particles, avoid direct sunlight, vibration acceleration ≤ 2.5G (10-60Hz).

Installation material: It must be installed on non combustible materials such as metal.

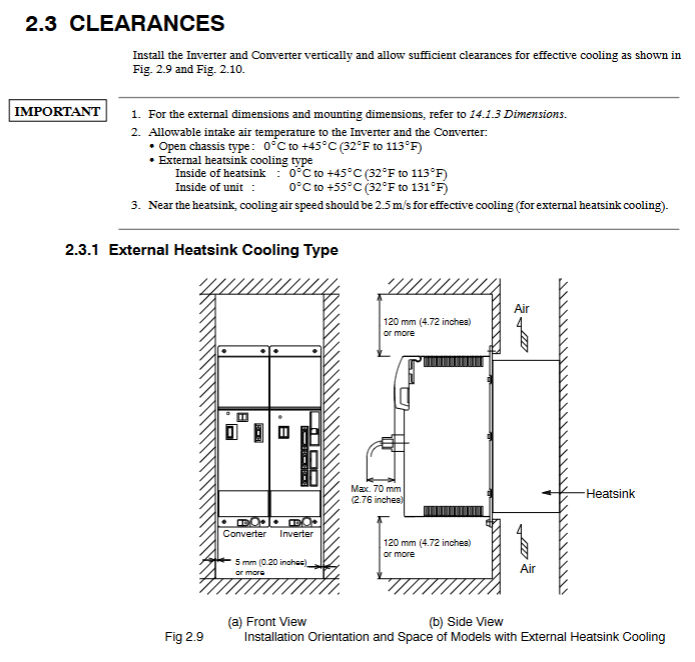

Distance requirement (to ensure heat dissipation):

Equipment type, left and right spacing, up and down spacing, note

External heat dissipation type ≥ 120mm ≥ 120mm Side spacing ≥ 5mm

Open chassis type ≥ 150mm ≥ 150mm Side spacing ≥ 5mm

Wiring specifications:

Main circuit wiring: Use the specified wire diameter (such as 200V level frequency converter CIMR-M5A23P7, main circuit wire diameter ≥ 2mm ²), and the terminal screw torque meets the requirements (such as M5 screw 2.35N · m).

Control circuit wiring: Separate the control signal line from the power line, with a length of ≤ 20m, and use shielded twisted pair to avoid wiring in the same conduit.

Core functions and operations

Digital Operator (JVOP-132):

Function: Display operating status (motor speed U1-01, torque reference U1-04), set control constants, fault reset, single machine trial run.

Operation mode: Set from positions 1 to 37, with 11 being the digital operator operation mode, which can achieve jog (5% rated speed) and forward/reverse control.

Trial operation process:

Check the power supply voltage (200V level 3-phase 200-230V, 400V level 3-phase 400-460V).

(NC system) Set YENET1200 node address (rotary switch SW1).

Connect the control power supply and confirm that the frequency converter displays "-" and the inverter displays "- U".

Connect the main circuit power supply, the inverter display changes to "- b", and the CHARGE light is on.

Check the direction of the motor cooling fan (standard intake from the load side).

Send RUN signal to confirm the motor direction (counterclockwise when viewed from the load end during forward rotation) and no abnormal vibration/noise.

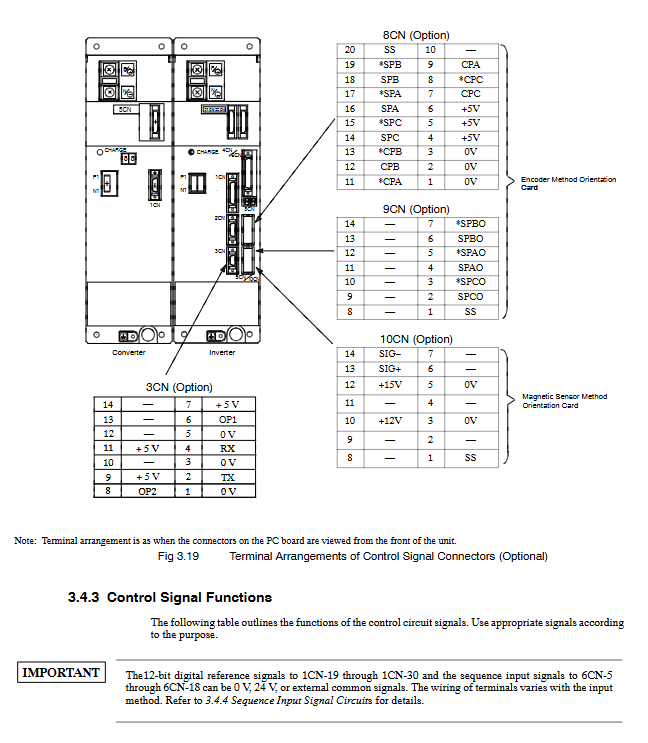

Directional control:

Encoder directional control:

Resolution: 360 °/4096=0.088 °, repeatability accuracy ± 0.2 °.

Applicable scenario: The load shaft is connected 1:1 to the motor shaft and requires a load shaft encoder (such as NE-1024-2MDF-068).

Magnetic sensor directional control:

Repetition accuracy ± 0.2 °, using magnet (MG-1378BS) and magnetic sensor (FS-1378C), detection range ± 15mm.

Troubleshooting and Maintenance

Common faults and solutions:

Fault code, fault type, cause, and handling measures

AL-01 inverter overcurrent output short circuit, ground fault check wiring, confirm no short circuit

AL-11 main circuit overvoltage input voltage is too high, load inertia is large. Check the power supply and adjust the acceleration time from C1 to 10

AL-20 winding switching fault switching was not completed within the specified time. Check the contactor wiring and confirm the C1-25 motor code

Maintenance cycle:

Daily inspection: motor abnormal noise, vibration, ambient temperature, display screen values.

Regular inspection:

Remarks on component replacement cycle

Cooling fan has accumulated 20000 hours of operation over 2-3 years

Filter capacitor for 5 years at an ambient temperature of 30 ℃

Motor bearings disassembled and inspected for wear after 12000 hours/2 years

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923