K-WANG

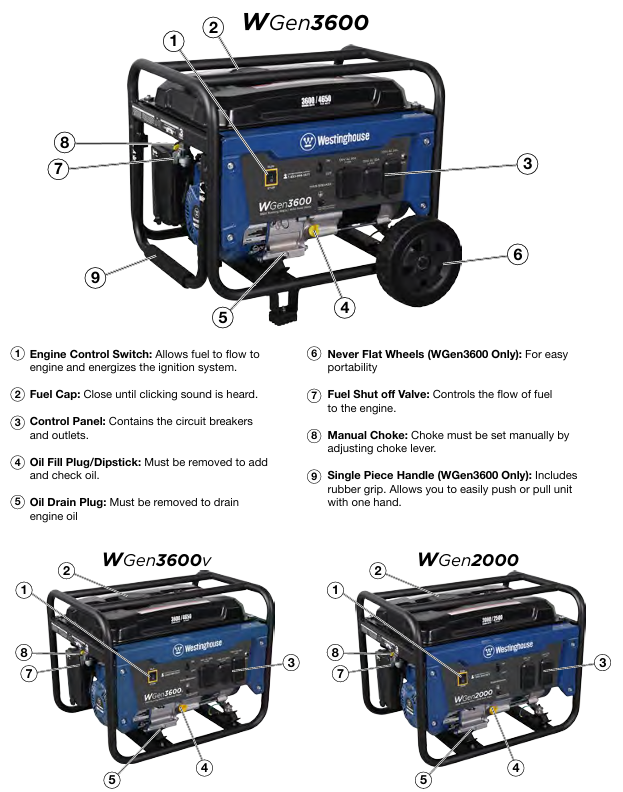

Westinghouse WGen2000, WGen3600, and WGen3600V portable generators

Westinghouse WGen2000, WGen3600, and WGen3600V portable generators

Core parameters and configuration of the product

1. Basic parameters (common/difference comparison among three models)

Parameter category WGen2000 WGen3600 WGen3600V

Operating power 2000 Watts 3600 Watts 3600 Watts

Peak power 2500 Watts 4650 Watts 4650 Watts

Fuel tank capacity 15L/4.0 gallons 15L/4.0 gallons 15L/4.0 gallons

Rated speed 3600 RPM 3600 RPM 3600 RPM

Ignition type TCI (transistor ignition) TCI (transistor ignition) TCI (transistor ignition)

Spark plug model F7TC F7TC F7TC

Engine displacement 212 cc 212 cc 212 cc

Cylinder diameter x stroke 55 x 70 55 x 70 55 x 70 55 x 70

Oil capacity 0.60 L 0.60 L 0.60 L

Recommended engine oil 10W30 (4-stroke engine oil) 10W30 (4-stroke engine oil) 10W30 (4-stroke engine oil)

Total Harmonic Distortion (THD) < 23% < 23% < 23% < 23%

Special configuration - non inflatable wheels, integrated rubber handle-

California compliance configuration optional CARB carbon canister optional CARB carbon canister standard CARB carbon canister

2. Core components and functions

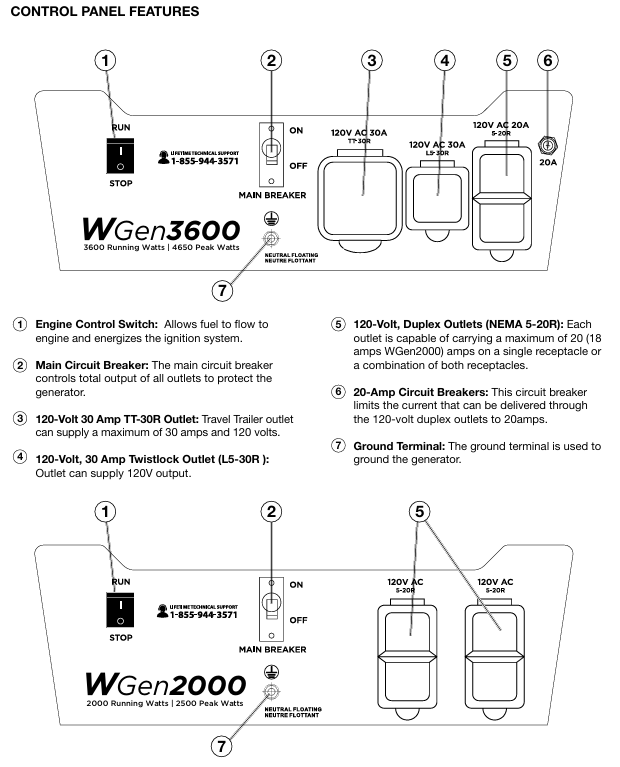

Control panel: including main circuit breaker, multiple power sockets (120V 20A dual socket, 120V 30A trailer specific socket, 120V 30A twist lock socket), grounding terminals, WGen2000 dual socket maximum load of 18A, other models are 20A.

Engine components: including fuel tank (with oil level gauge), muffler and spark arrester (fireproof flower leakage), ignition coil assembly, throttle return spring, governor linkage device, etc.

Safety components: low oil level automatic shutdown switch (cutting off the engine when there is insufficient oil), circuit breaker (overload protection), GFCI socket (some models, anti leakage).

Safety operation standards (top priority)

1. Environmental safety requirements

Only operate in outdoor ventilated areas, away from doors, windows, ventilation openings, and flammable materials. The minimum safe distance is 6 feet (1.8 meters). It is strictly prohibited to use indoors, in garages, or in enclosed spaces (engine exhaust contains carbon monoxide, colorless, odorless, and highly toxic).

It should be placed on a flat and hard surface, avoiding loose environments such as sand and grass (to prevent debris from blocking the air intake or cooling system); Do not use in rainy, snowy, humid environments or areas with accumulated water (to prevent short circuit and electric shock).

Avoid high temperature and high conductivity areas (such as metal decks, steel construction sites), and operate without open flames or sparks (such as cigarettes, matches, static power sources) around.

2. Fuel safety operation

Only use unleaded gasoline grade 87 and above, with an ethanol content not exceeding 10%. It is strictly prohibited to use 2-stroke engine oil, diesel, or other fuels.

Before refueling, the machine must be stopped and cooled to a surface that is not hot to the touch. Clean the surrounding area before opening the fuel tank cap and slowly refuel, not exceeding the neck of the refueling port (leaving space for fuel expansion).

If there is a fuel leak, immediately wipe it clean with a cloth and dispose of the cloth properly. Wait for the leaking area to dry before starting the generator; Wear goggles when refueling to avoid prolonged skin contact with fuel or inhalation of vapor.

Fuel containers should be stored in a well ventilated area, away from sources of ignition, and the use of gasoline as a cleaning agent is strictly prohibited.

3. Electrical safety operation

Before starting, it must be properly grounded: if used as a backup power source to connect to household circuits, a certified electrician must install a transfer switch and set up a grounding rod (in accordance with the national electrical code NEC and local regulations); Use grounding extension cords and three core/double insulated electrical appliances.

Do not touch the live terminals or exposed wires of the running generator, and do not operate with wet hands or when the generator is damp; Do not use damaged or aged power cords, and the plug should be fully inserted into the socket (the 240V socket should be fixed by rotating 1/4 turn clockwise).

Do not use generators to supply power to medical support equipment to avoid loads exceeding the rated power of sockets or circuit breakers.

4. Safety check before operation

Confirm that all loads have been disconnected (unplug external appliances and extension cords).

Check the engine oil level (new engines need to be filled with oil first, starting without oil will damage the engine).

Check the fuel quantity, whether the fuel pipeline leaks, and whether the air filter is clean.

Remove tools, cloths, and other debris placed during maintenance to ensure there are no obstacles around.

Complete operation process (start run stop)

1. Preparation before startup

Site selection: Outdoor ventilation, flat and hard, dry, away from combustibles and ventilation openings.

Grounding: Connect the grounding terminal as required (operated by an electrician when a grounding rod is required).

Oil inspection:

Engine oil: After cooling down the machine for a few minutes, clean the area around the oil filling port, take out the dipstick and wipe it clean, completely unscrew it, and then take it out again. The oil level should be between the H (high) and L (low) marks. If it is insufficient, add 10W30 4-stroke engine oil (to avoid excess).

Fuel: Ensure that the fuel tank has sufficient qualified gasoline and check if the fuel valve is closed (before starting).

Load disconnection: Disconnect all external electrical appliances and extension cords, and confirm that the circuit breaker is in the reset state.

2. Manual startup steps (applicable to all three models)

Reset circuit breaker: Set the main circuit breaker and branch circuit breaker to the "ON" position (reset if tripped previously).

Open the fuel valve: Switch the fuel shut-off valve to "ON" (ensure that fuel flows to the engine).

Adjust the air door: Turn the air door handle to the "ON" position (necessary for cold engine start-up, can be omitted for hot engine).

Start switch: Push the engine control switch to the "RUN" position.

Pull the recoil starter: Slowly pull the recoil handle until you feel an increase in resistance (compression stroke), then quickly pull upwards and slightly away from the generator direction, repeating until the engine starts.

Stable engine: After starting the engine, wait for the speed to stabilize and gradually turn the throttle handle back to the "OFF" position (to avoid unstable operation caused by excessive mixture).

Connect the load: After confirming that the generator is running smoothly, connect the electrical appliances one by one (the total load does not exceed the rated power).

3. Precautions during operation

Real time observation of operating status: If there is abnormal noise, excessive vibration, smoking, sparks, or overheating of the socket, immediately stop the machine for inspection.

Avoid overload: It is forbidden to connect multiple high-power electrical appliances at the same time. If the circuit breaker trips, disconnect the load first, cool down, and then reset to investigate the cause of overload.

Fuel replenishment: When there is insufficient fuel during operation, it is necessary to first shut down for cooling, and then refuel according to the requirements of fuel safety operation.

Altitude adaptation: For every 300 meters (1000 feet) increase in altitude, the engine power decreases by about 3.5%, and the power decrease is even more significant when the carburetor is not modified. High altitude use requires early modification of the carburetor.

4. Shutdown steps

Normal shutdown

Disconnect the load: First unplug all external appliances and extension cords.

No load cooling: Run the generator without load for 3-5 minutes to reduce the temperature of the engine and generator.

Turn off the engine: Set the engine control switch to the "STOP" position; If stored for a long time, first close the fuel valve and let the engine run until the fuel runs out before automatically stopping (clearing the carburetor to prevent fuel deterioration).

Emergency shutdown

When encountering risks of fire, leakage, electric shock, or engine abnormalities, simply turn the engine control switch to the "STOP" position without the need for idle cooling.

Maintenance and upkeep (extend lifespan+ensure safety)

1. Maintain safety prerequisites

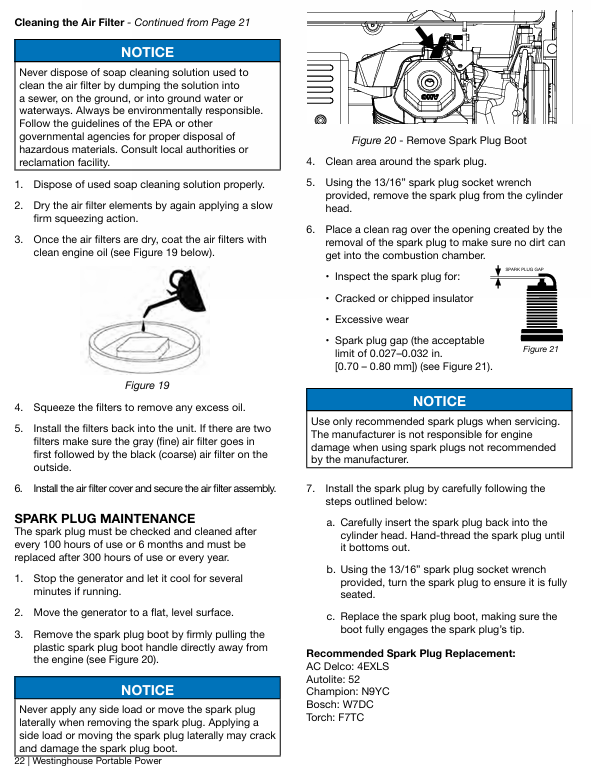

Stop the machine and cool it down until the surface is not hot to the touch, then remove the spark plug cap (to prevent accidental start-up); The electric starter model requires disconnecting the negative cable of the battery.

Maintain good ventilation in the area, keep away from sources of fire, avoid skin contact with engine oil and fuel, and wear gloves and goggles.

Do not use gasoline or flammable solvents to clean components. Waste engine oil and cleaning fluids must be disposed of properly in accordance with EPA or local regulations and cannot be dumped.

2. Long term storage and maintenance (not used for more than 30 days)

Cleaning the body: Clean dust, debris, and oil stains according to daily cleaning requirements.

Handling fuel:

Method 1: Drain the fuel tank, open the fuel valve, start the engine until the fuel runs out, and automatically stop (empty the carburetor).

Method 2: Add fuel stabilizer, fill the fuel tank (reduce air contact), run for 10 minutes to circulate stabilizer to the carburetor, and close the fuel valve.

Change engine oil: Follow the oil change steps to replace the new engine oil to avoid the old oil from deteriorating and corroding the engine.

Protect the cylinder: Remove the spark plug, inject 1 tablespoon of clean engine oil, pull the recoil handle several times by hand (to evenly apply the oil to the cylinder wall), and reinstall the spark plug.

Storage environment: dry, ventilated, cool, away from sources of fire and corrosive substances. WGen3600 needs to remove the wheels or cushion the body to avoid tire deformation under pressure.

Regular inspection: Pull the recoil handle several times a month (without starting) to keep the components moving.

Common troubleshooting (problem cause solution)

1. Engine running but no power output

Potential cause solutions

The main circuit breaker or branch circuit breaker trips and disconnects all loads. Press the circuit breaker reset button and check if the load exceeds the rated power to avoid overload

The power cord plug is not fully inserted into the socket and needs to be unplugged again. The 240V socket needs to be rotated clockwise by 1/4 turn to ensure locking

Replace the damaged or faulty power cord with a new qualified power cord (matching the load power)

External electrical malfunction: Disconnect the faulty electrical appliance and connect it to a known normal low-power appliance (such as a desk lamp) for testing

GFCI socket trip (some models) Press the "reset" button on the GFCI socket

Internal circuit failure of generator: Contact Westinghouse authorized service dealer for repair

2. The engine cannot start or immediately stalls after starting

Potential cause solutions

If the fuel tank is empty or the fuel has deteriorated, add qualified gasoline. If the deteriorated fuel needs to be drained and the fuel tank and carburetor need to be cleaned

The fuel valve is not open. Switch the fuel valve to the "ON" position

Improper adjustment of the air door (too tight or too loose): Set the air door to "ON" when starting the cold engine and to "OFF" when starting the hot engine. Adjust it slightly according to the operating status after starting

Air filter blockage. Clean or replace the air filter according to maintenance steps

Insufficient engine oil triggers low oil level shutdown to replenish oil to the qualified level, restart the engine

Spark plug malfunction (carbon buildup, improper clearance, damage) Clean, adjust clearance or replace spark plug

The spark plug cap is not locked tightly. Press the spark plug cap firmly to ensure that it fully covers the top of the spark plug

Spark eliminator blockage, remove and clean. Spark eliminator carbon buildup

Electric starter models have insufficient battery power. Charge or replace the battery

3. Sudden engine shutdown during operation

Potential cause solutions

After running out of fuel and shutting down for cooling, add gasoline

If the oil level is too low, replenish the oil to the qualified range and check for any oil leaks

Overloading caused overload tripping and partial load disconnection. After cooling down, reset the circuit breaker and restart

Clean the debris in the cooling system after the engine overheats, ensure good ventilation, stop and cool down before restarting

Check the fuel pipeline and filter for blockage, and clean impurities

4. Unstable engine speed (shaking, fluctuating fast and slow)

Potential cause solutions

The air door is not closed (not adjusted after the refrigeration machine is started), gradually move the air door to the "OFF" position

Clean or replace the dirty air filter

Poor fuel supply (blocked pipelines, dirty filters) Clean the fuel pipelines and filters

Frequent switching of loads to avoid frequent starting and stopping of high-power electrical appliances, maintaining load stability (slight fluctuations are normal phenomena)

Check for looseness of the governor linkage and tighten the governor linkage. If necessary, contact the dealer for adjustment

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923