K-WANG

Westinghouse WPX3000e/WPX3400e electric high-pressure cleaning machine

Westinghouse WPX3000e/WPX3400e electric high-pressure cleaning machine

Overview

The comprehensive guidance document for the Westinghouse WPX3000e (3000 PSI maximum pressure/1.76 GPM maximum flow) and WPX3400e (3400 PSI maximum pressure/2.0 GPM maximum flow) electric high-pressure cleaning machines covers product safety specifications (such as prohibiting direct spraying of human/electrical objects, anti electric shock/anti freezing measures), detailed parameters, assembly steps (including installation of wheels, handles and other components), operating procedures (preparation before start-up, power on/off, nozzle selection and use), maintenance (cleaning, storage, replacement of vulnerable parts) and troubleshooting, while emphasizing the need for product registration to protect warranty rights.

Core parameters and configuration of the product

1. Comparison Table of Model Parameters

Parameter category WPX3000e WPX3400e

Water temperature requirement: Cold Water Only

Maximum pressure (PSI) 3000 3400

Rated pressure (PSI) 2600 3000

Maximum Flow Rate (GPM) 1.76 (6.7 LPM) 2.0 (7.57 LPM)

Rated flow rate (GPM) 1.1 (4.16 LPM) 1.1 (4.16 LPM)

Power parameters 120V AC/60Hz/13A 120V AC/60Hz/14A

Core protection double insulation structure, GFCI leakage protection double insulation structure, GFCI leakage protection

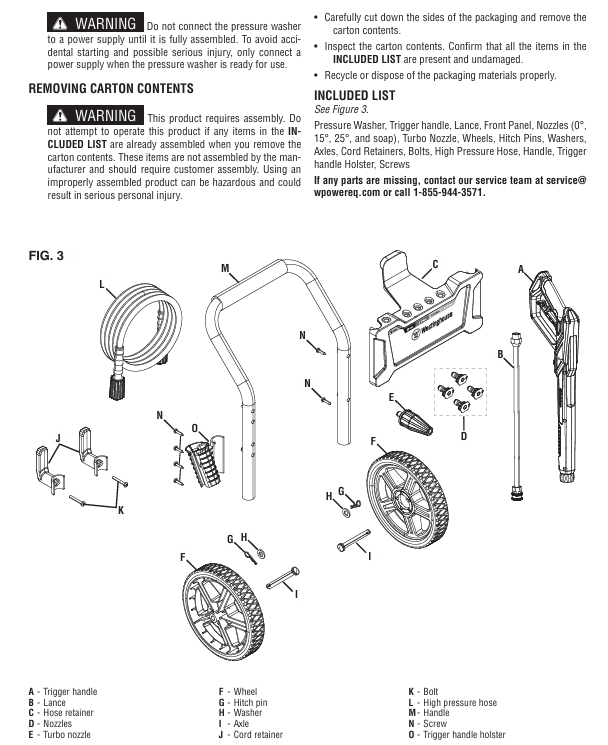

2. Standard accessory list

Main components: high-pressure cleaning machine body, spray gun handle, spray long gun, front panel

Nozzle group: 0 ° turbine nozzle (high pressure), 15 ° nozzle (medium pressure), 25 ° nozzle (medium pressure), soap nozzle (low pressure)

Auxiliary accessories: 2 wheels, axle pins, washers, wire clamps, high-pressure hoses, handles, nozzle storage racks, screws/bolts

Safety Operation Standards (Key)

1. Environment and usage restrictions

Prohibited scenarios: indoor/enclosed spaces (carbon monoxide free, this is electric, mainly to prevent electric shock), rainy/snowy/damp floors, near electrical appliances/combustibles (≥ 6 feet distance), using hot water (only cold water, hot water will damage pump seals).

Water source requirements: Only tap water is allowed, and the use of lake water, pool water, and swimming pool water (which can clog the filter) is prohibited. The inlet pressure should be ≤ 150 PSI.

2. Electrical safety

GFCI protection: The plug has built-in GFCI and needs to be tested monthly (press the TEST button to hear a "click" sound, then press RESET to reset). To replace the plug/wire, accessories with GFCI of the same specifications are required.

Extension cable restrictions (not recommended, use only when absolutely necessary):

WPX3000e: wire diameter ≥ 16 AWG, length ≤ 50 feet;

WPX3400e: wire diameter ≥ 14 AWG, length ≤ 25 feet;

Do not use damaged extension cords to avoid voltage drop causing motor overheating.

3. Operation taboos

It is prohibited to directly spray human bodies, animals, glass, and electrical appliances (which are prone to injury/damage/electric shock);

The pump body should not idle for more than 1 minute (after cutting off water), otherwise the motor/pump will overheat and be damaged;

Before disassembling the nozzle, it is necessary to stop the machine, release pressure (press the spray gun to release pressure), and lock the trigger;

Children are not allowed to operate it, and adults should avoid using it under the influence of alcohol/drugs.

Assembly steps

1. Key assembly process (tools required: screwdriver, wrench)

Wheel installation: Place the body on the side, pass the shaft through the wheel and washer → insert into the body bracket → fix with the shaft pin;

Install the handle: slide the handle into the slot of the body, press the buckle until it makes a "click" sound to ensure stability;

Wire clamp and nozzle holder: Align the holes of the wire clamp/nozzle holder and fix them on the side of the machine with screws;

Connect the spray gun and hose: One end of the high-pressure hose is connected to the threaded interface of the machine body (tighten the locking nut), and the other end is connected to the spray gun (insert after pulling the collar and tighten the locking nut).

Complete operational process

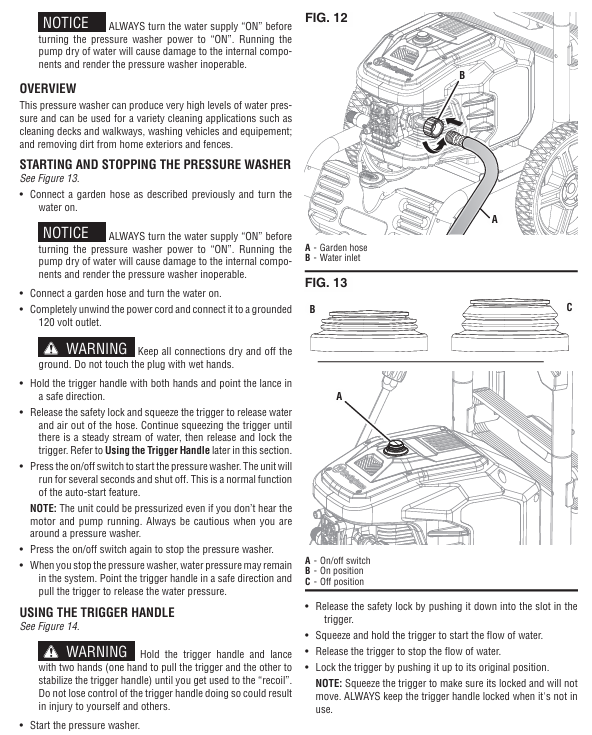

1. Preparation before startup

Water source connection: Connect the garden hose to the machine's water inlet. First, rinse the hose for a few seconds to remove impurities and check the inlet filter screen (no damage/blockage);

Oil/Consumables: For the new machine, add 10W30 4-stroke engine oil (to the H-L range of the dipstick), and add a special high-pressure cleaning machine to the soap tank using a remover (dilute according to the instructions, do not use detergent/laundry detergent, as it may clog the nozzle);

Load check: Disconnect all nozzles, ensure trigger lock, and reset circuit breaker.

2. Startup and operation

Step operation details

1. Open the water source, press the trigger of the spray gun to release air until the water flow is stable (without bubbles), and then lock the trigger

Plug in the GFCI plug and press the power switch to "ON". The device will run for 1-2 seconds before shutting down (automatic start stop function, normal)

3 nozzle options: Install nozzle after shutdown and pressure relief (0 ° turbine for paint removal/concrete washing, 15 °/25 ° brick and stone washing, soap spray detergent)

Unlock the trigger, hold the gun with both hands (anti recoil), aim at the cleaning face, press the trigger to start spraying, and move from bottom to top to clean

3. Shutdown and Storage

Normal shutdown: Disconnect the nozzle → Run without load for 3-5 minutes to cool down → Press the power switch to "OFF" → Unplug the plug → Drain the water from the hose/pump;

Long term storage (over 30 days): Empty soap tank and rinse with clean water → Change engine oil → Remove spark plug and add 1 tablespoon of engine oil (lubricate cylinder) → Store in a dry and constant temperature place (anti icing/overheating, optional pump protector).

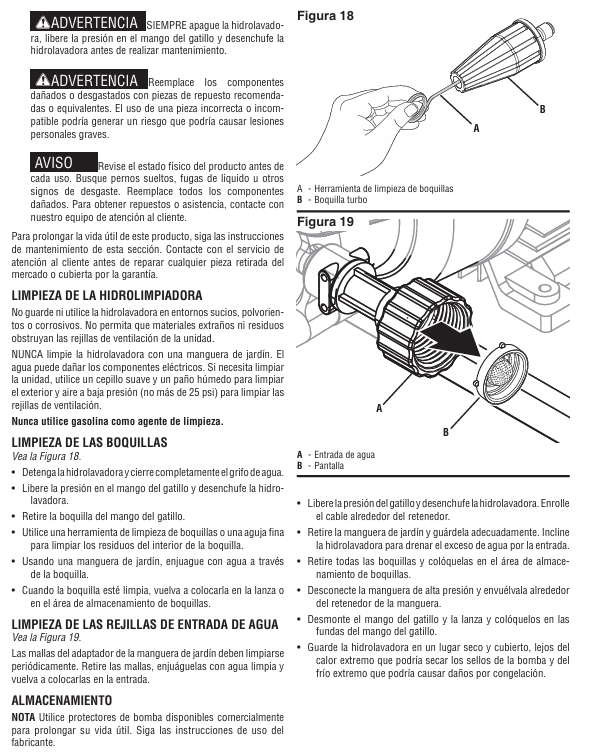

Maintenance and upkeep

1. Maintenance cycle and content table

Maintenance project maintenance frequency operation details

Before each use, remove the inlet filter and rinse it with clean water. If there is no damage, reinstall it

Spray nozzle cleaning every 50 hours/when clogged, use a nozzle cleaning tool/fine needle to pass through the nozzle hole and rinse with clean water in reverse

Clean the body with a soft cloth after each use, blow the vents with low-pressure air (≤ 25 PSI), and prohibit water flushing of electrical components

Lubricate the O-ring of the hose and clean it every 100 hours before applying Vaseline (non water soluble grease)

Replacement of vulnerable parts every 300 hours/replacement of nozzle, inlet filter screen, hose O-ring when damaged, recommended original accessories (such as turbine nozzle PWTN, filter screen 04000267-0)

2. Precautions

Waste engine oil/detergent cannot be dumped and must be disposed of according to EPA regulations;

Do not use flammable solvents such as gasoline to clean components and avoid corrosion;

Before maintenance, the power must be cut off, the pressure must be relieved, and the standby body must be cooled to room temperature.

Troubleshooting

Common troubleshooting solutions table

Possible causes and solutions for the fault phenomenon

The body is not powered on. 1. It is not grounded to a power source; 2. GFCI trips; 3. Damaged power cord. 1. Connect to a 120V grounded socket; 2. Press the GFCI reset button; 3. Contact after-sales service to replace the power cord

Running without water flow: 1. Wrong water source (not tap water); 2. nozzle blockage; 3. Spray gun malfunction 1. Replace with tap water; 2. Clean the nozzle; 3. Replace the spray gun

The connection between the hose and the spray gun is leaking, and the O-ring is missing/damaged. After stopping the machine and releasing pressure, replace the O-ring with the same specification

Stop the machine after 2 seconds of startup, unable to restart the automatic start stop function (pump pre pressure). Press the spray gun trigger to release pressure, and the machine will automatically start (normal phenomenon, not a fault)

Key questions and answers

Question 1: What are the differences in the use of extension cords between WPX3000e and WPX3400e? Why is there such a restriction?

Answer: The difference lies in the different specifications of the extension cord - WPX3000e requires the use of extension cords with a wire diameter of ≥ 16 AWG (American Wire Gauge) and a length of ≤ 50 feet; WPX3400e requires the use of extension cords with a wire diameter of ≥ 14 AWG and a length of ≤ 25 feet. The reason is that the rated current of the two models is different (WPX3000e is 13A, WPX3400e is 14A). The thinner and longer the wire diameter, the greater the resistance, which can easily lead to voltage drop, resulting in a decrease in motor power and overheating damage; WPX3400e has a higher current, so a thicker wire diameter and shorter length are required to reduce losses.

Question 2: What are the applicable scenarios for different nozzles when using a high-pressure cleaning machine? What are the consequences of making a wrong choice?

Answer: Different nozzles are suitable for the following scenarios:

0 ° Turbine Nozzle: High pressure mode, suitable for cleaning concrete, removing stubborn stains, and peeling paint (requires close range use, strong force);

15 °/25 ° nozzle: medium pressure mode, suitable for cleaning masonry tiles, exterior walls, and vehicles (moderate force to avoid scratches);

Soap nozzle: Low pressure mode, only used for spraying detergent (unable to suck soap under high pressure and easily causing detergent splashing and waste).

The consequences of choosing the wrong option: Cleaning the vehicle/wood with a 0 ° nozzle can cause surface scratches; The efficiency of using a medium pressure nozzle to treat stubborn stains is extremely low; Spraying Detergent in high-pressure mode can cause blockage of the soap circuit and even damage to the soap tank.

Question 3: What are the key steps to complete before storing a high-pressure cleaning machine for a long time? What is the purpose?

Answer: Long term storage (over 30 days) requires completing 5 key steps, with the following objectives and details:

Empty and rinse soap tank: Start the machine with clean water and spray it out with soap nozzle to prevent residual detergent from solidifying and blocking the soap path;

Change engine oil: Drain the old oil and add new 10W30 oil to prevent impurities in the old oil from corroding the crankcase components;

Lubricate the cylinder: Remove the spark plug, inject 1 tablespoon of engine oil, and pull the recoil handle several times to form an oil film on the cylinder wall and prevent long-term storage rust;

Drain water: Disconnect the water source and use the spray gun to drain the water from the hose/pump. The purpose is to prevent water from freezing and expanding in low-temperature environments, which may cause the pump body/hose to crack;

Constant temperature and dry storage: stored at ≥ 0 ℃ in a dry and ventilated place, with the purpose of preventing electrical components from being affected by moisture and short circuiting, as well as avoiding aging of pump seals caused by high temperatures.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923