K-WANG

Westinghouse WGen20000 Generator

Electrical specifications: Rated voltage: 120/240V; Frequency: 60Hz (3600RPM); Phase: single-phase; Total harmonic distortion ≤ 5%

Engine configuration displacement: 999cc; ignition type: TCI; Starting method: Electric start

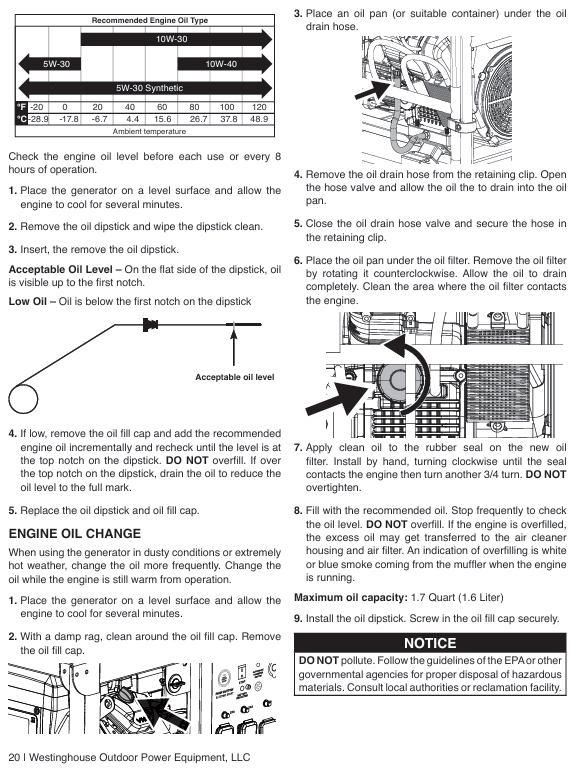

Fuel and engine oil fuel type: unleaded gasoline (87-93 octane, ethanol content ≤ 10%, E15/E85 prohibited); Fuel tank capacity: 64L (17 gallons); Oil capacity: 2.3L (2.4 US quarts); Recommended engine oil: SAE 10W-30 (can be replaced with 5W-30/10W-40/5W-30 synthetic oil at extreme temperatures)

Key component spark plug model: 97108 (F7TC); Gap: 0.024-0.032 inches (0.60-0.80mm); Voltage regulator: AVR; AC generator type: brushed

Maximum ambient temperature for environmental adaptation: 40 ℃ (104 ° F); Certification: EPA, CARB, CSA; Altitude impact: Power decreases by 3.5% for every 1000 feet increase

Westinghouse WGen20000 Generator

Core technical specifications of the product

1. Basic performance parameters

Category specific parameters

Power output operating power: 20000 watts; Peak power: 28000 watts

Electrical specifications: Rated voltage: 120/240V; Frequency: 60Hz (3600RPM); Phase: single-phase; Total harmonic distortion ≤ 5%

Engine configuration displacement: 999cc; ignition type: TCI; Starting method: Electric start

Fuel and engine oil fuel type: unleaded gasoline (87-93 octane, ethanol content ≤ 10%, E15/E85 prohibited); Fuel tank capacity: 64L (17 gallons); Oil capacity: 2.3L (2.4 US quarts); Recommended engine oil: SAE 10W-30 (can be replaced with 5W-30/10W-40/5W-30 synthetic oil at extreme temperatures)

Key component spark plug model: 97108 (F7TC); Gap: 0.024-0.032 inches (0.60-0.80mm); Voltage regulator: AVR; AC generator type: brushed

Maximum ambient temperature for environmental adaptation: 40 ℃ (104 ° F); Certification: EPA, CARB, CSA; Altitude impact: Power decreases by 3.5% for every 1000 feet increase

2. Control panel and output interface

Core functions: Data center (displaying voltage, frequency, cumulative operating time, maintenance reminders), 83A main circuit breaker, low idle switch (reducing fuel consumption and noise during intermittent loads, disabled for sensitive electronic devices).

Output interfaces: 120V 20A GFCI dual socket (2), 120V 30A twist lock socket (1), 120/240V 30A twist lock socket (2), 120/240V 50A socket (2), grounding terminal.

Safety operation standards (core focus)

1. High risk warning and contraindications

Risk of carbon monoxide poisoning: It is strictly prohibited to use it in enclosed/semi enclosed spaces such as indoors, garages, and basements. It can only be operated in outdoor ventilated areas and kept away from doors, windows, ventilation openings, and air conditioning inlets. It is recommended to install carbon monoxide detectors.

Fire and explosion risks: The vehicle must be shut down and cooled down for at least 2 minutes before refueling; Do not overfill (the oil level should not exceed the red filling ring in the fuel tank); Keep away from sources of fire, sparks (cigarettes, static electricity); When there is a fuel leak, it is necessary to wipe it clean immediately and wait for the area to dry before starting.

Electric shock risk: Do not use in damp environments, rainy or snowy weather; Do not touch live terminals and exposed wires during equipment operation; Use grounded three core extension cables and prohibit the use of damaged or aged cables; The connection to the building power grid must be installed by a certified electrician to ensure isolation from the mains.

Other taboos: Not suitable for powering medical equipment; Prohibition of modifying equipment; Overloading operation is prohibited; Do not move or tilt the device while it is running.

2. General safety requirements

Maintain a clearance of at least 5 feet (1.5 meters) around the device during operation, including above; Avoid touching high-temperature components such as mufflers and engines (after cooling).

Wear protective equipment (gloves, goggles) to avoid direct skin contact with engine oil and gasoline; Wash hands promptly after operation.

Cool down for 30 minutes before transportation, keep it level, and if necessary, empty the fuel to prevent leakage; Keep away from sources of fire and heat (such as water heaters, stoves, etc.) during storage.

Battery maintenance: The battery contains sulfuric acid electrolyte (corrosive) and lead compounds, and protective equipment should be worn during operation; No smoking or proximity to fire sources; Prohibit wires and tools from crossing the two poles of the battery; If the acidic solution comes into contact with the skin, immediately rinse with water and apply baking soda to neutralize it.

Assembly and start-up process

1. Open box inspection and assembly

(1) List of unboxing items

Core components: generator host, wheel assembly (2 pieces), lifting hook, battery (36AH), battery charger.

Tools and consumables: spark plug socket wrench, assembly wrench, funnel, M8 flange bolts (4 pieces), split pins (4 pieces), washers (4 pieces), SAE 10W-30 engine oil (1 bottle).

Documents: User Manual, Quick Launch Guide, Product Registration Card.

(2) Assembly steps (requiring collaboration between two people to avoid single person handling)

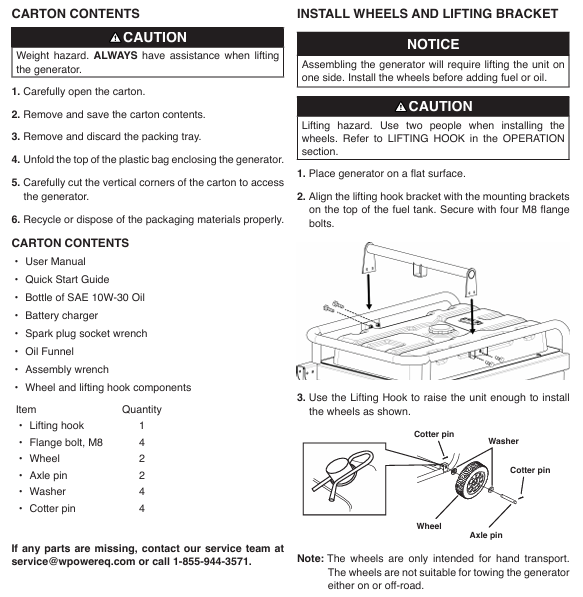

Wheel installation: Place the generator on a horizontal surface, insert the axle pin through the washer and wheel, insert it into the frame axle bracket, fix it with an open pin, and repeat the operation on the other side (the wheel is only used for manual handling and dragging is prohibited).

Installation of lifting hook: Align the top fuel tank bracket with the lifting hook and tighten it with 4 M8 flange bolts (only used for lifting or fixing the binding strap, do not grip other components for handling).

Battery installation: First, connect the red positive cable to the positive pole of the battery and cover it with a protective sleeve, then connect the black negative cable; Use insulated tools to avoid short circuits between the positive and negative poles.

2. Preparation before startup

Location selection: Outdoor ventilated area, at least 5 feet away from buildings and combustibles, on a horizontal dry surface, avoiding loose materials (such as sand and grass debris) to prevent blockage of air vents.

Oil inspection:

Engine oil: The new machine has no engine oil and needs to be added to the "MAX" mark on the dipstick (place the cold machine horizontally, wipe the dipstick dry, fully screw it in, and then remove it for inspection).

Fuel: Add unleaded 87-93 gasoline with ethanol content ≤ 10%; Clean the fuel tank after refueling and check for leaks.

Load and grounding: Disconnect all electrical equipment connections; Grounding must comply with local regulations. If connecting to building systems, an electrician must confirm whether a grounding rod (copper wire ≥ 10 AWG) is required.

3. Startup and shutdown operations

(1) Start the process

Turn the fuel valve to the "ON" position.

Cold machine: fully pull out the air damper; Heat engine: Set the choke to the middle or "RUN" position.

Press the start switch to "START" and hold for up to 5 seconds (to avoid overheating of the starter motor); After successful startup, release and warm up for 3-5 minutes.

After the engine runs steadily, slowly push back the choke to the "RUN" position.

(2) Shutdown process

Normal shutdown: Disconnect all loads → Run without load for 3-5 minutes → Turn the switch to "OFF"; Long term non use requires closing the fuel valve and allowing the engine to run until it shuts down on its own (running out of carburetor fuel).

Emergency stop: Simply turn the switch to "OFF" (only for use in case of malfunction or danger).

Key maintenance operation details

(1) Oil change

Place the refrigeration unit horizontally, clean the area around the oil filling port, and place the oil pan.

Remove the oil drain hose, open the valve to drain the oil, close the valve and secure the hose.

Disassemble the old oil filter counterclockwise and clean the installation surface; Apply a small amount of engine oil to the rubber sealing ring of the new filter, manually tighten it until it fits snugly, and then tighten it 3/4 turn (do not overtighten).

Add recommended engine oil to the "MAX" mark on the dipstick, install the dipstick and filler cap, start the engine and check for leaks.

(2) Battery maintenance

Charging: The generator can recharge the battery after running for 30-60 minutes; Long term use of the included trickle charger (connected to the control panel charging port), red light charging in progress, green light fully charged.

Replacement: First disconnect the negative cable, then disconnect the positive cable; The installation sequence of new batteries is reversed (connect the positive electrode first), part number 511075 (36AH), and used batteries need to be disposed of according to local regulations.

(3) Storage maintenance

Key points for storage duration operation

No special treatment is required within one month to maintain normal oil and fuel levels

Add fresh fuel and fuel stabilizer every 2-6 months, and empty the carburetor float

Drain the fuel tank and carburetor fuel after more than 6 months; Change the engine oil; Inject 1 tablespoon of engine oil into the spark plug hole, pull the starting rope to make the piston run (protect the cylinder wall); After cleaning the equipment, store it in a dry and ventilated place, and do not cover it with plastic sheeting (which is prone to moisture and rust)

Common troubleshooting

Possible causes and solutions for the fault phenomenon

The engine cannot start. 1. The battery switch is turned off or running low; 2. Insufficient/deteriorated fuel; 3. Air filter blockage; 4. Low oil level (low oil protection); 5. Spark plugs are damp/faulty/have improper clearances; 6. Fuel filter blockage 1. Turn on the battery switch or charge; 2. Add fresh fuel; 3. Clean/replace the filter; 4. Add engine oil; 5. Dry/replace spark plugs and adjust clearances; 6. Replace the fuel filter

Immediately turn off the engine after starting. 1. Fuel is depleted; 2. Abnormal oil level; 3. The air filter is dirty; 4. Fuel pollution; 5. Low oil level switch fault: 1. Add oil; 2. Check the oil level; 3. Clean the filter; 4. Drain the deteriorated fuel; 5. Contact customer service

No power output 1. Circuit breaker tripped; 2. Load overload; 3. Power cord/electrical equipment malfunction; 4. Internal fault of the generator: 1. Reset the circuit breaker to reduce the load; 2. Disconnect some equipment; 3. Replace the power cord or test the normal equipment; 4. Send to authorized service points

Insufficient engine power/unstable operation 1. Air filter blockage; 2. Fuel deterioration/filter blockage; 3. Overloading; 4. Aging of spark plugs; 5. Abnormal valve clearance: 1. Clean/replace the filter; 2. Replace the fuel and filter; 3. Reduce load; 4. Replace the spark plug; 5. Adjust the valve clearance

Remote start failure (if supported): 1. Remote control battery runs low; 2. Exceeding the remote control distance (≤ 100 feet); 3. Not paired. 1. Replace the remote control battery; 2. Get close to the generator; 3. Re pair (long press the panel pairing button+remote control start/stop button)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923