K-WANG

YOKOGAWA WT1801R series precision power analyzer communication interface

YOKOGAWA WT1801R series precision power analyzer communication interface

Overview

The communication interface user guide for YOKOGAWA WT1801R, WT1802R, WT1803R, WT1804R, WT1805R, and WT1806R series precision power analyzers was first released in October 2024. The core of the document revolves around the three communication interfaces of the instrument (Ethernet, USB, GP-IB), providing detailed explanations of interface functions, configuration methods, programming instructions, and status reporting mechanisms. It also provides a document system, terminology conventions, and global contact information, aiming to help users achieve remote control and data exchange of the instrument through PC.

Core Communication Interface Functions and Configuration

1. Ethernet interface

(1) Core Features and Specifications

Compatibility: Compliant with IEEE 802.3 standard and supports TCP/IP (VXI-11) communication protocol.

Connection capability: Supports connection with PC through hub/router, does not support cross line direct connection; The maximum number of simultaneous connections is limited by network devices.

Remote control switch: Receive: Communicate: REMote ON/OFF command to switch between remote/local mode. In remote mode, only the LOCAL key is available (disabled when local is locked).

Timeout setting: The network connection timeout time can be set (1-3600 seconds or "infinite"), and the connection will be automatically disconnected after timeout. The default is "infinite".

(2) Configuration steps

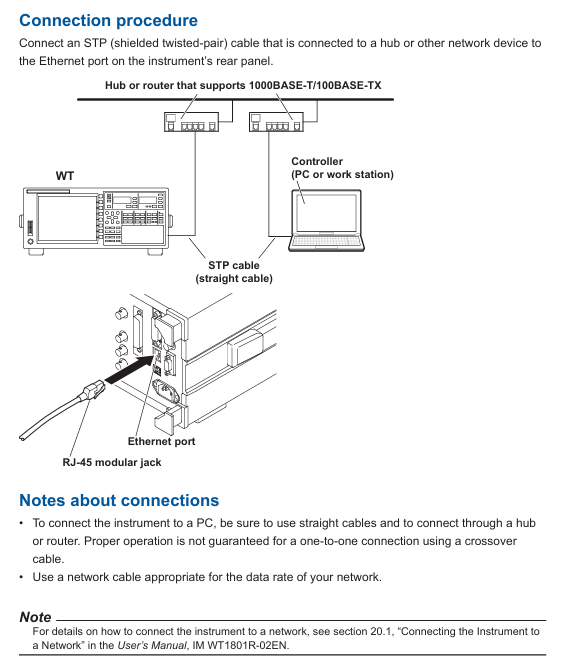

Hardware connection: Use shielded twisted pair (STP) to connect the Ethernet port of the instrument Rear panel to the hub/router.

Enter the configuration menu: Press the UTIL key on the panel → click the Remote Control soft key → select the Network soft key to enter the network settings interface.

TCP/IP settings: IP address, subnet mask, and default gateway need to be configured (refer to section 20.2 of the IM WT1801R-02EN user manual for detailed steps).

Timeout setting: In the network settings interface, adjust the timeout time (Infinite or 1-3600s) through the cursor keys.

2. USB interface (USB-TMC)

(1) Core Features and Specifications

Compatibility: Compliant with USB 3.0 standard, supports USB-TMC (Test Measurement Class) protocol, requires installation of Yokogawa dedicated USB driver.

System requirements: Only supports Windows 10/11 system, PC needs to install communication library (TMCTL) and USB device driver (official website) https://tmi.yokogawa.com/ Downloadable).

Remote mode switching: Consistent with the Ethernet interface logic, it can be switched using the COMMunicate command or LOCAL key, and supports local locking.

Uniqueness: Only one USB device connection is supported at a time and cannot be used simultaneously with Ethernet or GP-IB interfaces.

(2) Configuration steps

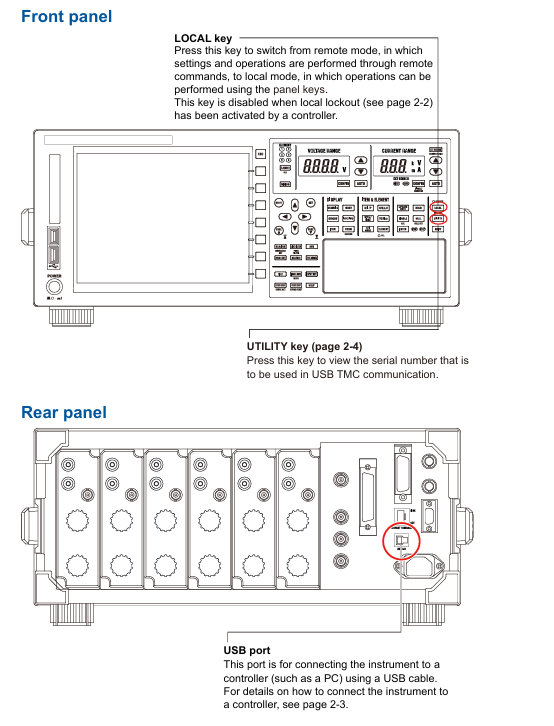

Hardware connection: Connect the USB port of the instrument Rear panel to the PC using a USB Type B cable, and wait for 20-30 seconds after booting up before operating (to avoid damaging the device).

Driver installation: Download and install the Yokogawa USB TMC driver from the official website, and prohibit the use of third-party drivers.

View device serial number: Press the UTIL key → click on the Remote Control soft key → select the USB soft key to view the device serial number required for USB-TMC communication.

3. GP-IB interface (IEEE 488)

(1) Core Features and Specifications

Compatibility: Compliant with IEEE 488-1978 (Mechanical/Electrical) and IEEE 488.2-1992 (Protocol) standards, supports National Instruments GP-IB cards (such as PCIe GPIB, GPIB-UB-HS+).

Functional subset: Supports SH1 (source handshake), AH1 (receive handshake), T6 (basic talker), L4 (basic listener), SR1 (service request) and other functional subsets, without controller capability.

Address setting: The address range is 0-30, and each device on the bus needs to be assigned a unique address to avoid conflicts.

Connection restriction: The bus can connect up to 15 devices (including controllers), with a single cable length of ≤ 2 meters and a total length of ≤ 20 meters.

(2) Configuration steps

Hardware connection: In the shutdown state, use a 24 pin GP-IB cable to connect the GP-IB port of the instrument Rear panel to the GP-IB board of the PC, and tighten the connector screws.

Address configuration: Press the UTIL key → click the Remote Control soft key → select the GP-IB soft key, and set the address (0-30).

Interface response: Supports interface messages such as IFC (interface clearing), REN (remote enable), SDC (selected device clearing), etc. Please refer to section 3.5 of the document for specific response logic.

Fundamentals of Programming and Instruction System

1. Core programming concepts

Message types: divided into "program messages" (instructions sent by the PC to the instrument, such as configuration instructions and query instructions) and "response messages" (data returned by the instrument to the PC, such as measurement results and status information).

Instruction structure:

Common instruction: IEEE 488.2 standard instruction, starting with * (such as * CLS clearing status register, * IDN?)? Check the instrument model).

Composite instruction: Instrument specific hierarchical instruction, separated by: (e.g. DISPlay: MODE NUMeric to set display mode to numerical display).

Simple instruction: Non hierarchical independent instruction (such as HOLD to set data hold).

Data format: Supports decimal (NR1/NR2/NR3), physical quantities (with units, such as 100V), registers (binary/octal/hexadecimal), strings (user-defined, such as file names), and other formats.

2. Core instruction grouping and functions

Chapter 5 of the document provides a detailed list of 23 instruction groups, covering scenarios such as interface control, display settings, data storage, measurement and calculation. The key instruction groups are as follows:

Instruction group core instruction example function description

COMMunicate Group :COMMunicate:REMote ON

: Communicate: READer OFF controls remote/local mode, sets response with header information

DISPlay Group :DISPlay:MODE WAVE

DISPlay: WAVE: TDIV 5MS Set display mode (waveform/value/trend), adjust waveform timeline scale

FILE Group :FILE:SAVE:NUMeric "DATA1"

: FILE: LOAD: SETup "SET1" saves numerical data to a file, loads instrument settings file

MEASure Group :MEASure:AVERaging:STATE ON

MEASure: FUNCtion1: EXPResolution "URMS (E1)" Enable data averaging function and define user-defined measurement functions

NUMeric Group :NUMeric[:NORMal]:VALue?

NUMeric: FORM ASCII queries numerical measurement data, sets data output format (ASCII/FLOAT)

STORe Group :STORe:START

: STORe: FILE: CONVert: EXECUTE "STR1" Start storing data and convert stored data to CSV format

Common Command *IDN?

*OPC? Query instrument identification (model/serial number), query operation completion status

3. Synchronization and status reporting

Synchronization mechanism: through * WAI (waiting for operation completion),: Communicate: WAIT (waiting for specified event), * OPC? (Operation completion query) Avoid instruction execution conflicts and ensure data consistency.

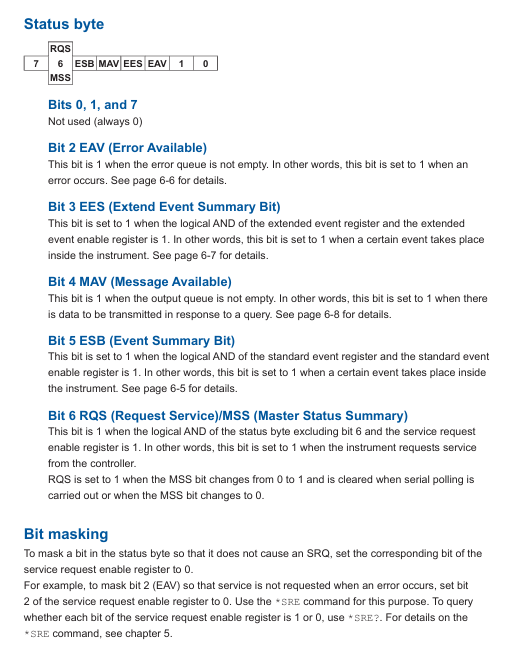

Status report: includes status bytes, standard event registers, extended event registers, and error queues, supported through: Status: ERRor? Query error codes and messages through * STB? Query status bytes to help locate communication or operational anomalies.

Modbus/TCP communication (extended functionality)

Function Overview: Supports Modbus/TCP protocol, can communicate with client devices (such as PLC, SCADA systems), and achieve register read/write and data interaction.

Register configuration: Chapter 7 of the document provides detailed definitions of register addresses and functions, covering measurement data, instrument status, configuration parameters, etc. It supports reading real-time data such as voltage, current, power, etc. through Modbus commands.

Communication process: The client needs to connect to the instrument's IP address and port (default 502) through TCP, and send Modbus function codes (such as 03H read hold registers) to achieve data exchange.

Precautions and Compatibility

Interface exclusivity: Ethernet, USB, and GP-IB interfaces cannot be used simultaneously and need to be manually switched or specified as a unique active interface through commands to avoid command conflicts.

Driver and library dependencies: USB and Ethernet interfaces require the installation of Yokogawa Communication Library (TMCTL) and drivers, and only support Windows systems, not compatible with third-party drivers.

Cable and Connection: GP-IB requires cables that comply with IEEE standards, Ethernet needs to be connected through a hub/router (cross wiring is not supported), and USB needs to be plugged in and unplugged after the instrument is turned on and stabilized.

Legacy compatibility: Chapter 8 of the document provides instructions for compatibility with WT1600, WT1800, and WT1800E series legacy instruments, facilitating smooth migration for existing users.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

-

BENTLY NEVADA 3500/15 133292-01 Power Supply Module

-

ABB PM877 3BDH000777R1 Central_Unit Controller

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor