K-WANG

Watlow plug-in heater

FIREROD ® Universal plug-in heater 1400 ° F (760 ° C) (Alloy 800 sheath) 400 W/in ² (62 W/cm ²) 60 years of industry validation, high thermal conductivity efficiency, supports multi scenario customization

High temperature FIREROD high-temperature working condition specific 1800 ° F (982 ° C) 100 W/in ² (15.5 W/cm ²) sealing design reduces oxidation, high emissivity sheath enhances heat transfer

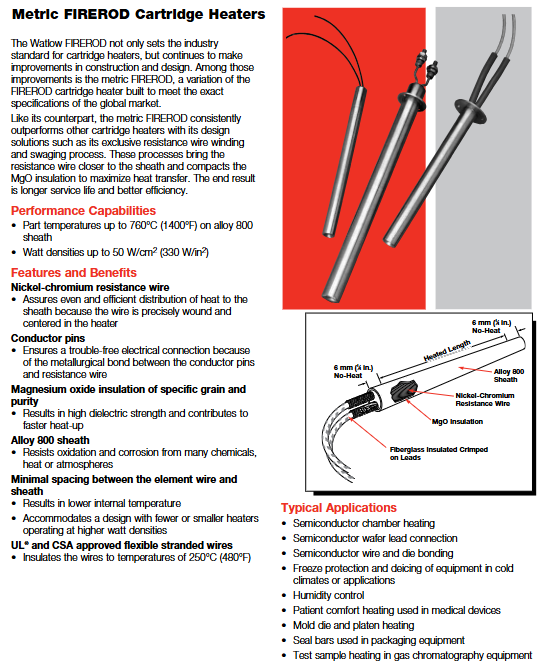

Metric FIREROD global adaptation 1400 ° F (760 ° C) 330 W/in ² (50 W/cm ²) meets metric standards, has high dimensional accuracy, and is compatible with international equipment

MULTICELL ™ Multi zone precise temperature control 2050 ° F (1120 ° C) 30 W/in ² (4.6 W/cm ²) up to 6 independent temperature control zones, loose assembly design for easy disassembly and assembly

Watlow plug-in heater

Product Family and Core Features

1. Product Line Overview

Core positioning of product series: Maximum operating temperature, maximum power density, key advantages

FIREROD ® Universal plug-in heater 1400 ° F (760 ° C) (Alloy 800 sheath) 400 W/in ² (62 W/cm ²) 60 years of industry validation, high thermal conductivity efficiency, supports multi scenario customization

High temperature FIREROD high-temperature working condition specific 1800 ° F (982 ° C) 100 W/in ² (15.5 W/cm ²) sealing design reduces oxidation, high emissivity sheath enhances heat transfer

Metric FIREROD global adaptation 1400 ° F (760 ° C) 330 W/in ² (50 W/cm ²) meets metric standards, has high dimensional accuracy, and is compatible with international equipment

MULTICELL ™ Multi zone precise temperature control 2050 ° F (1120 ° C) 30 W/in ² (4.6 W/cm ²) up to 6 independent temperature control zones, loose assembly design for easy disassembly and assembly

2. Core common advantages

Material and Structure: Made of nickel chromium resistance wire (uniform heating), magnesium oxide (MgO) insulation layer with specific grain purity (high dielectric strength, rapid heating), Alloy 800 or stainless steel sheath (anti-oxidation, corrosion-resistant).

Process design: Minimize the distance between the resistance wire and the sheath, reduce internal temperature, and support high power density operation; UL ®/ CSA certified leads, with insulation levels ranging from 250 ° C to 842 ° C.

Safety and reliability: non-volatile design, strong high-temperature stability; Some models support low leakage construction and are suitable for sensitive scenarios such as healthcare.

Detailed explanation of key technical specifications

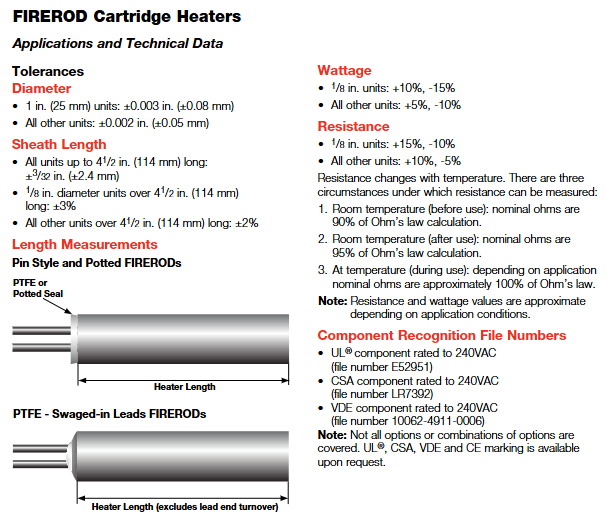

1. Dimensions and tolerances

(1)FIREROD ® standard size

Nominal diameter (in) Actual diameter (in/mm) Minimum sheath length (in/mm) Maximum sheath length (in/mm) Diameter tolerance

1/8 0.122(3.1) 7/8(22.2) 12(305) ±0.002 in(±0.05 mm)

1/4 0.246(6.3) 7/8(22.2) 36(915) ±0.002 in(±0.05 mm)

1/2 0.496(12.6) 7/8(22.2) 60(1520) ±0.002 in(±0.05 mm)

1 0.996(25.3) 1 1/4(32.0) 72(1830) ±0.003 in(±0.08 mm)

(2) Tolerance requirements

Length tolerance: The sheath with a length tolerance of ≤ 4.5 in (114 mm) is ± 3/32 in (± 2.4 mm); The sheath with a diameter greater than 4.5 inches is ± 2% (1/8 inch diameter is ± 3%).

Power tolerance: 1/8 inch diameter is+10%/-15%, other diameters are+5%/-10%.

Resistance tolerance: 1/8 inch diameter is+15%/-10%, other diameters are+10%/-5%; Resistance varies with temperature, with room temperature (before use) being 90% of the value calculated by Ohm's Law, and after use being 95%.

2. Electrical performance

(1)FIREROD ® Voltage and power range

Diameter (in) Maximum voltage (V) Maximum current (A) 120V Minimum power (W) 240V Maximum power (W)

1/8 240 3.1 - 720

1/4 240 4.4 100 1050

3/4 480 23.0 30 5520

1 480 23.0 - 5520

(2) Metric FIREROD Electrical Parameters (Example)

Diameter (mm) Maximum voltage (V) 230V Maximum power (W) 400V Maximum power (W) Maximum current (A)

6.5 250 1650 - 7.2

16 480 4830 8400 21

20 480 4830 8400 21

3. Power density and application adaptation

Power density directly affects heating efficiency and heater lifespan, and should be selected based on the heating medium and operating conditions

Metal heating: The maximum allowable power density varies with the aperture fit gap and temperature (for example, at 1400 ° F, a fit gap of 0.005 in corresponds to a power density of approximately 80 W/in ²).

Air/gas heating: At an ambient temperature of 70 ° F, the maximum allowable power density for a single heater is approximately 60 W/in ²; When multiple devices are parallel, they need to be multiplied by a correction factor of 0.95, and when equipped with a reflector, they need to be multiplied by 0.85.

Mobile air heating: The higher the wind speed, the greater the allowed power density (for example, at a wind speed of 100 FPM, the power density can reach 1000 W/in ²).

Installation and Wiring Guide

1. Installation preparation

Aperture matching: It is recommended that the aperture be 0.001-0.006 inches larger than the actual diameter of the heater (for metal heating). A gap that is too large can reduce thermal efficiency, while a gap that is too small may make disassembly difficult.

Installation location: The sensor should be installed in a temperature uniform area, away from the edge of the heat source; The sheath should be in full contact with the heating medium to avoid local overheating.

Environmental requirements: Avoid installing in close proximity to noise sources such as motors and relays; In humid environments, models with sealing (PTFE/silicone) should be selected.

2. Wiring specifications

(1) Lead type and specifications

Lead type, maximum temperature, applicable scenarios, wire diameter specifications (example)

GGS fiberglass 482 ° F (250 ° C) universal scenario 18 AWG (1/2 inch diameter heater)

MGT 842 ° F (450 ° C) high temperature scenario 18 AWG (3/4 inch diameter heater)

PTFE 392 ° F (200 ° C) corrosion-resistant scenario 20 AWG (3/8 in diameter heater)

Mineral Insulation (MI) 1500 ° F (815 ° C) Extreme High Temperature/Vibration Scenarios Conductor Diameter 0.044 in (3/8 in diameter heater)

(2) Wiring precautions

Lead length: Standard length of 12 inches (305 mm), customizable extension, extra long leads need to consider voltage drop (recommended wire diameter not less than 22 AWG).

Grounding requirements: Models with grounding leads must be reliably grounded to avoid the risk of electrical leakage; In high temperature scenarios, the lead wire should be kept away from the sheath (with a minimum length of 1 inch without thermal zone).

Multi zone control: MULTICELL ™ The heater needs to be wired separately for each temperature control zone to ensure independent adjustment.

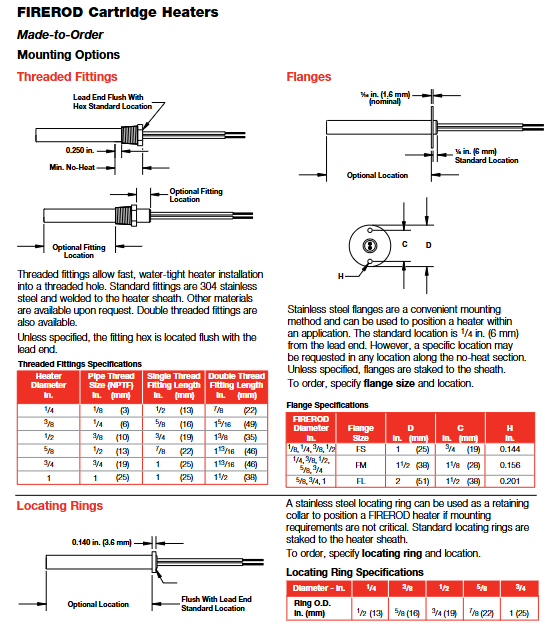

3. Fixed method

Flange fixing: Stainless steel flange (FS/FM/FL type), suitable for panel installation, flange position can be customized (standard distance from lead end 1/4 in).

Threaded fixation: 304 stainless steel or brass threaded joints (NPT/DIN specifications), waterproof installation, suitable for pipeline or threaded hole scenarios.

Positioning ring: Stainless steel positioning ring, used for non precision fixed scenarios, installed at the end of the no heat zone.

Customized Options and Selection Guide

1. Core customization options

(1) End and sealing options

Option Type Function Applicable Temperature Minimum No Hot Zone Length

PTFE seal and lead anti moisture, oil, solvent 392 ° F (200 ° C) 1 in (25 mm)

Silicone sealing and lead anti moisture, mild corrosion 302 ° F (150 ° C) 1 in (25 mm)

Epoxy resin sealing high temperature sealing (up to 260 ° C) 260 ° F (500 ° C) 1 in (25 mm)

Mineral Insulated (MI) Seal for Extreme High Temperature, Vibration, Corrosion 1500 ° F (815 ° C) 6 in (152 mm)

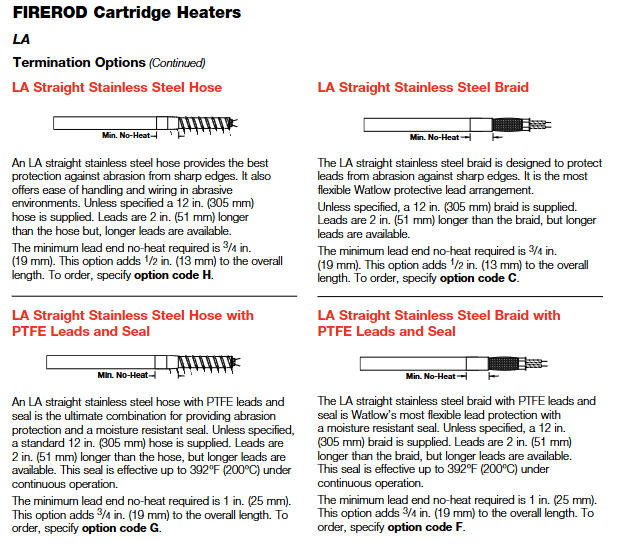

(2) Lead protection options

Stainless steel hose: wear-resistant, suitable for harsh environments, standard length of 12 inches, lead wire 2 inches longer than hose.

Stainless steel woven mesh: high flexibility, wear-resistant, standard length of 12 inches, supports right angle wire output.

Galvanized conduit: Abrasion protection, with 90 ° bend, standard length 8 inches.

(3) Function extension options

Built in thermocouples: Style A (monitoring the internal temperature of the heater), Style B (approximate workpiece temperature), Style C (end temperature, suitable for plastic molding), supporting J/K type.

Distributed power: Set different power densities in segments along the length of the heater to compensate for edge heat loss (suitable for scenarios such as sealing strips).

Dual voltage design: supports switching between two voltages and is suitable for multi scenario power supply (only available for metric models with diameters of 12.5 mm and above).

Extension without hot zone: The lead end or terminal without hot zone can be extended (up to 2.5 inches) to avoid the influence of high temperature on the lead.

2. Selection steps

Determine operating parameters: maximum working temperature, heating medium (metal/air/liquid), aperture and installation method.

Calculate power demand: Determine the required power based on the heating area, heating rate, and heat loss (recommended power density not exceeding the maximum allowable value of the corresponding medium).

Select product series: FIREROD for general scenarios ®, Choose high-temperature FIREROD for high temperature scenarios, metric models for international equipment, and MULTICELL for multi zone temperature control ™。

Customized function options: Select the sealing type according to the environment, choose the lead protection and fixing method according to the installation space, and select the built-in thermocouple according to the temperature control accuracy.

Maintenance and troubleshooting

1. Daily maintenance

Regular inspection: Check the insulation layer of the lead wires and the sheath for oxidation and discoloration every month, and replace them promptly if any problems are found.

Cleaning and maintenance: Remove dust and oil stains from the surface of the sheath to avoid affecting heat transfer; WATLUBE can be used for disassembly ™ Lubricant, easy to disassemble and does not affect thermal conductivity.

Life management: Under high temperature conditions (such as above 1400 ° F), it is recommended to regularly check the resistance value and replace the heater when the resistance changes by more than 10%.

2. Common faults and solutions

Possible causes and solutions for the fault phenomenon

Slow heating, insufficient power density, loose aperture fit, excessive lead voltage drop, replacement with higher power model, adjustment of aperture gap, and thickening of lead wire diameter

Improper installation position due to local overheating, poor medium contact, adjust installation position, and ensure that the protective cover is fully attached to the heating surface

Damaged leads, high temperature baking, wear, corrosion, extended no heat zone, replacement of protected lead options (hose/braided mesh), selection of corrosion-resistant seals

Excessive leakage, insulation layer affected by moisture or damage, replacement of sealing model, drying environment, and inspection of reliable grounding

High power density due to heater burnout, reduced power density due to dry burning of medium, ensuring sufficient heating medium, and installing temperature protection devices

Typical application scenarios

Semiconductor manufacturing: wafer bonding, chamber heating (using high cleanliness, low leakage FIREROD) ®, With PTFE seal).

Plastic molding: mold heating, sealing strip heating (using models with distributed power and built-in thermocouples).

Medical equipment: patient insulation, instrument heating (using low leakage, small-sized FIREROD) ®)。

Freezing protection: Anti icing of equipment in low-temperature environments (using high-power density, waterproof sealing models).

High temperature process: Superplastic forming of titanium alloy, diffusion welding (using high-temperature FIREROD or MULTICELL) ™)。

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923