K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

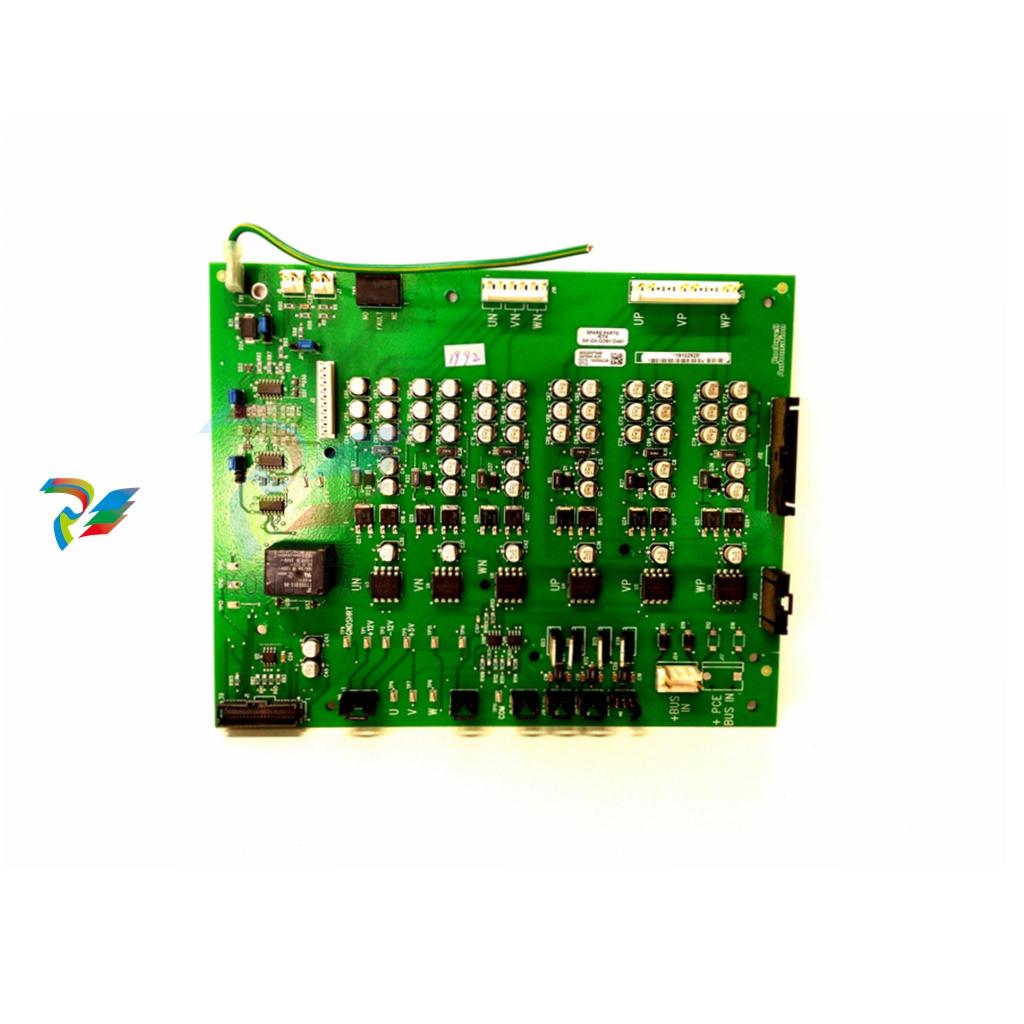

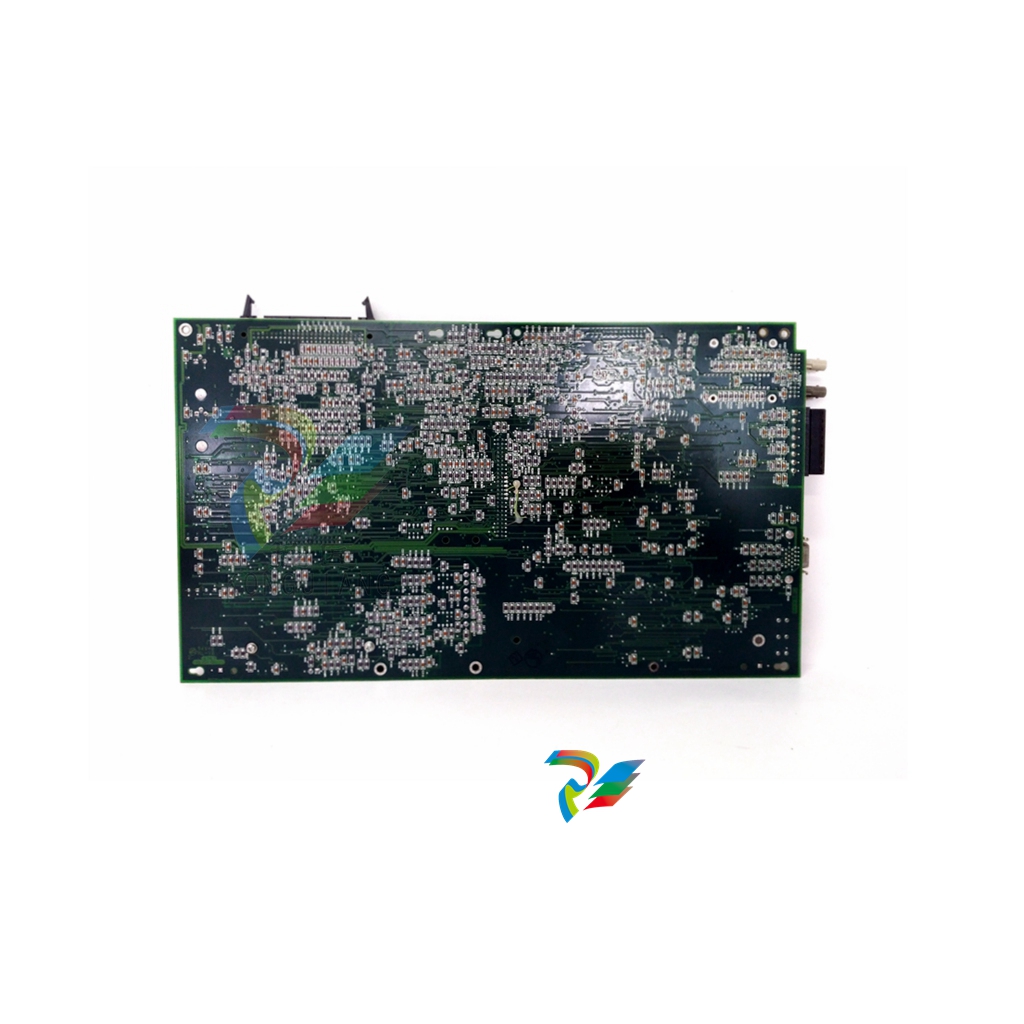

GE AL129A CD101152 | ALSTOM MARTEK POWER Module

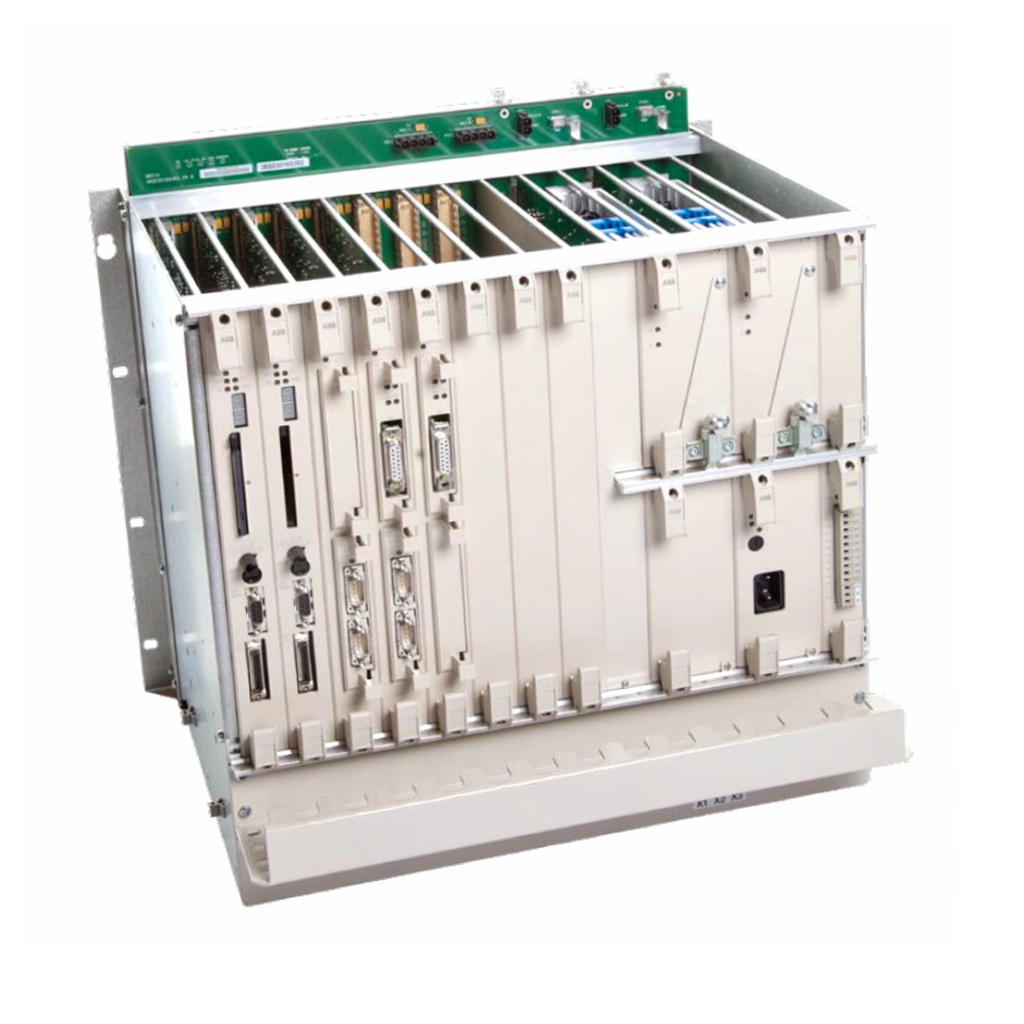

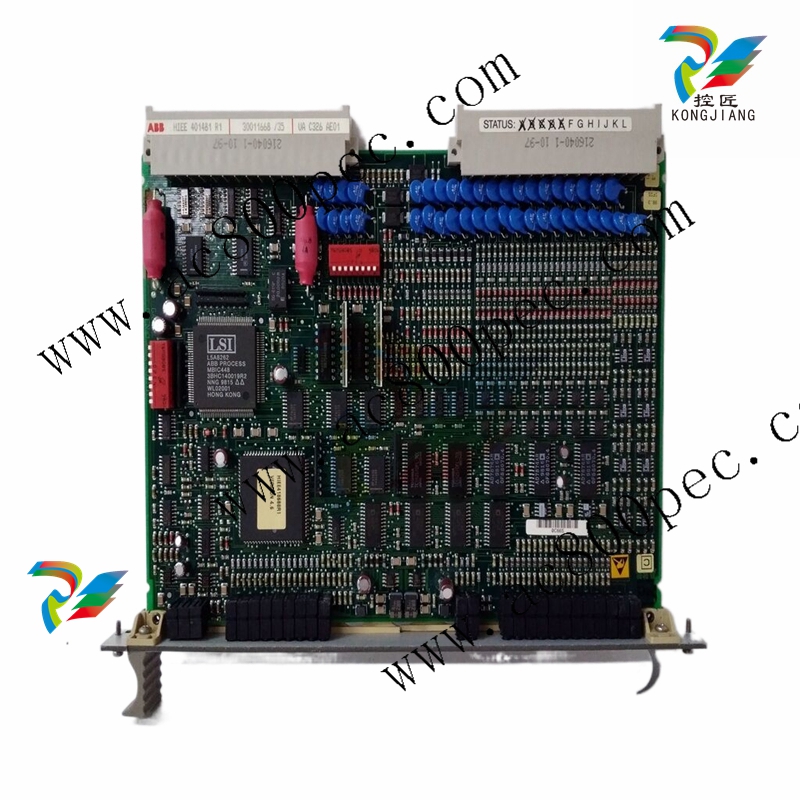

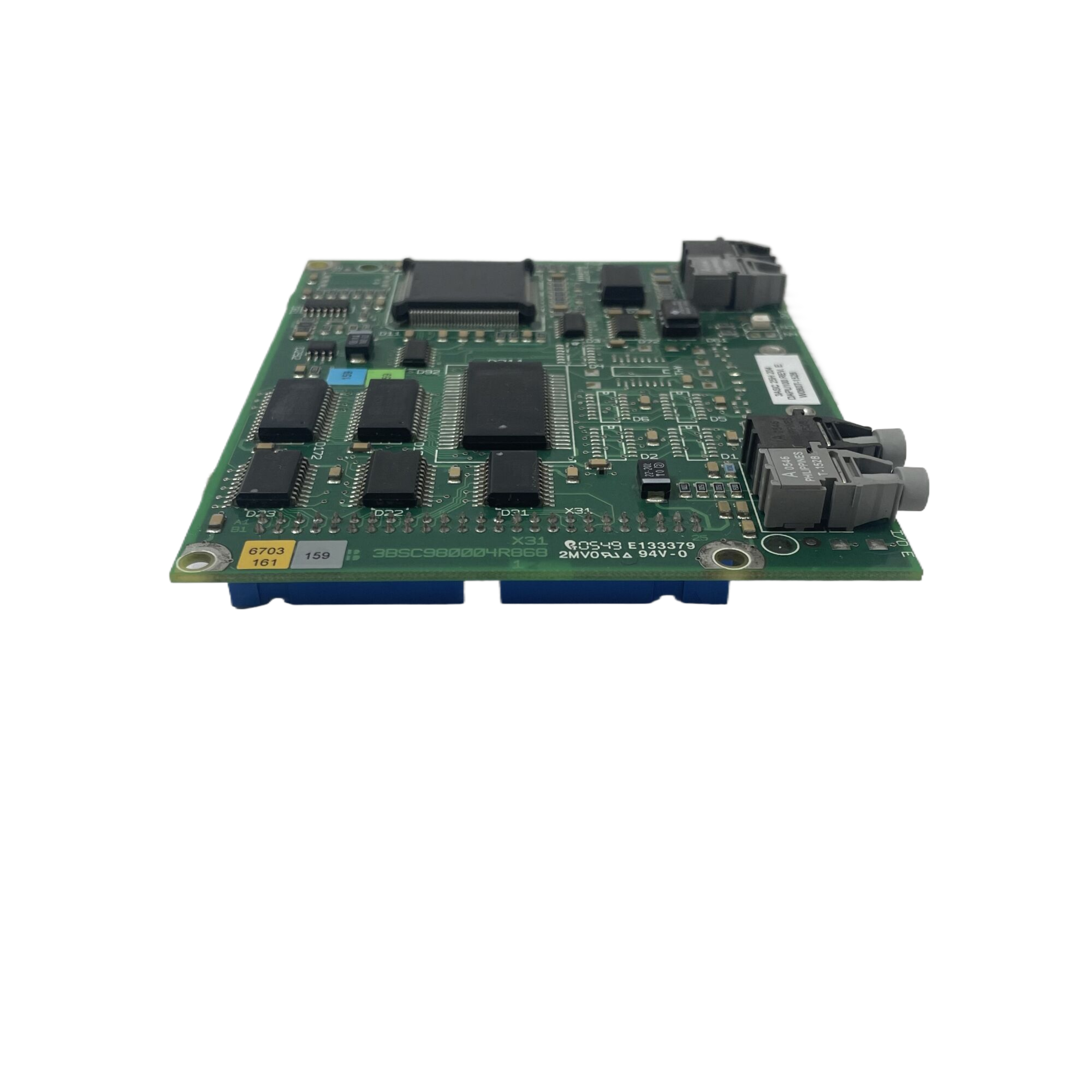

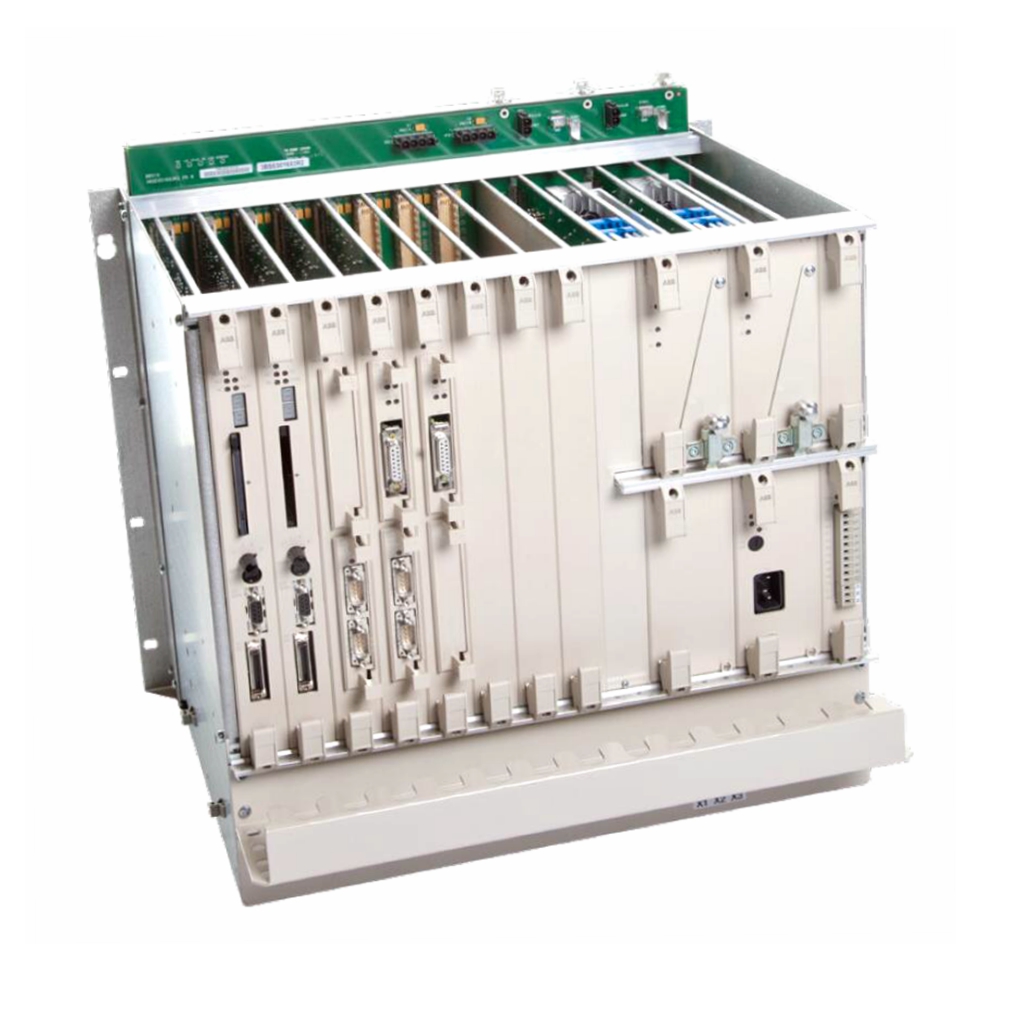

Operating Voltage:110V to 240V AC Input Frequency:50Hz or 60Hz Output Power:1000W Dimensions:200mm x 100mm x 50mm Weight:1kg Operating Temperature Range:-20"C to +55"C Storage Temperature Range:-40"C to +70"C The GE AL129A CD101152 ALSTOM MARTEK POWER Control Module is engineered for seamless integration into complex industrial systems. It features an innovative microprocessor design that enhances operational efficiency and reduces downtime.

Crafted from high-grade aluminum alloy, this module ensures durability and resistance to harsh conditions. Its compact size facilitates easy installation in various industrial settings. Equipped with a variety of input/output configurations, it offers flexibility in connecting with different devices and systems, making it suitable for a wide range of applications from manufacturing to power generation. With its robust communication capabilities, the module supports seamless data exchange and control over industrial processes, enhancing productivity and operational insights.

Compliant with international safety standards, this control module ensures user safety and compliance with global regulations, offering peace of mind for industrial operators. The GE AL129A CD101152 ALSTOM MARTEK POWER Control Module is a sophisticated component designed for high-efficiency control systems in industrial applications. This module ensures precise operation, enhancing system reliability and performance.

Features

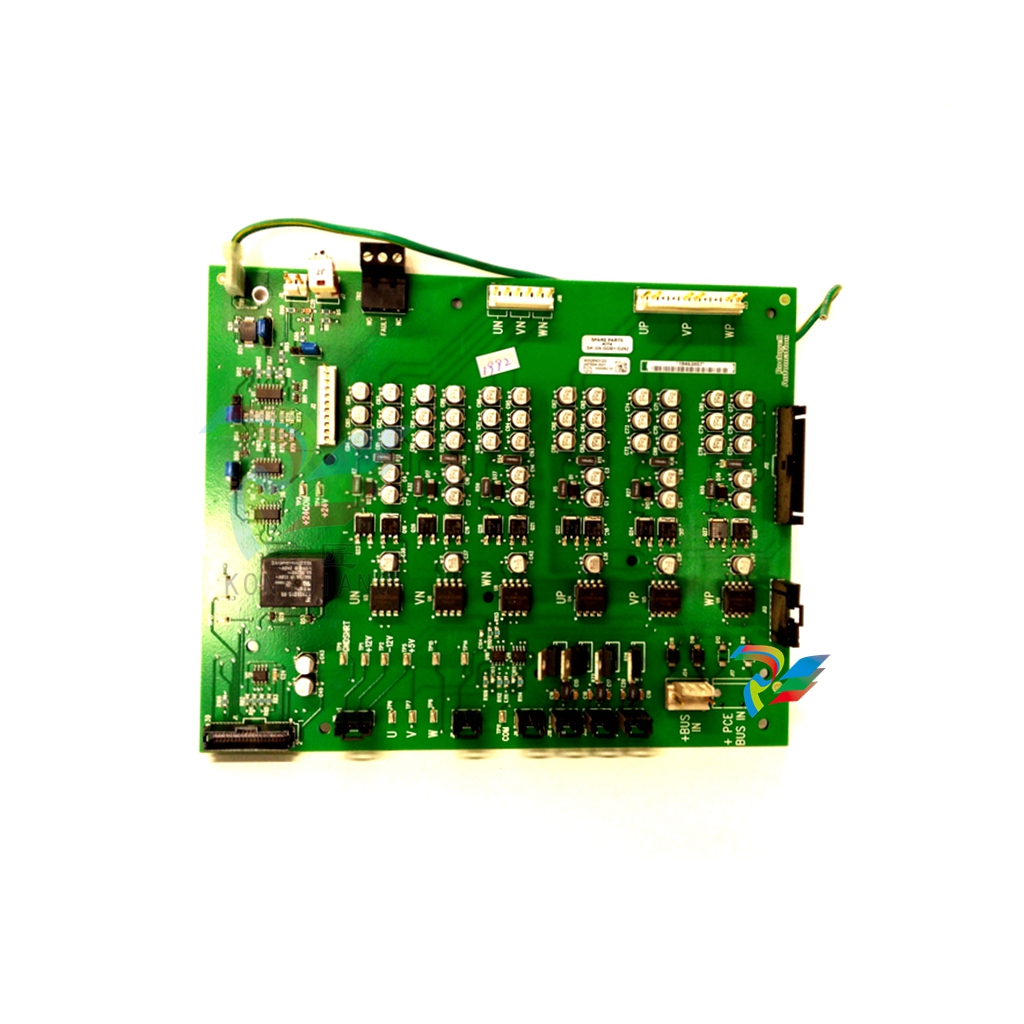

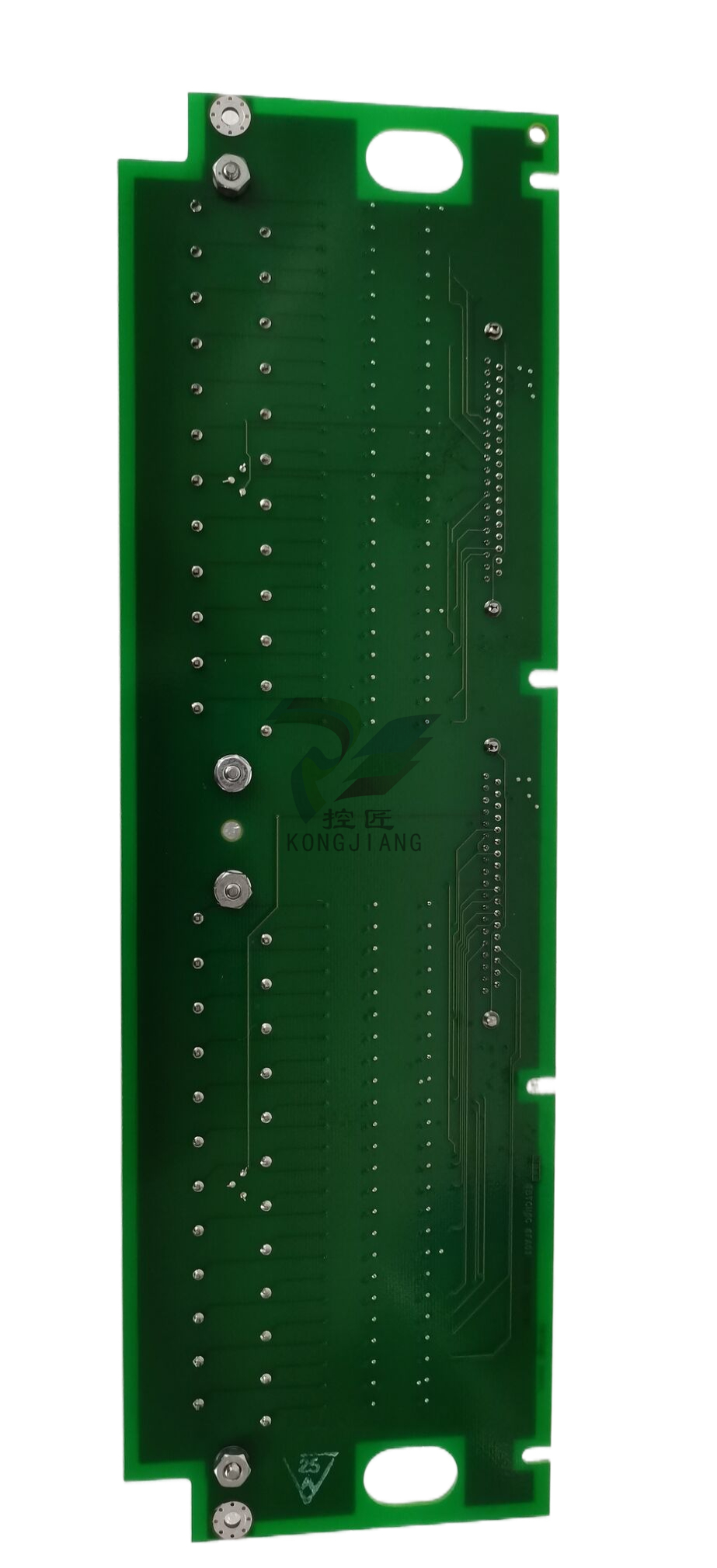

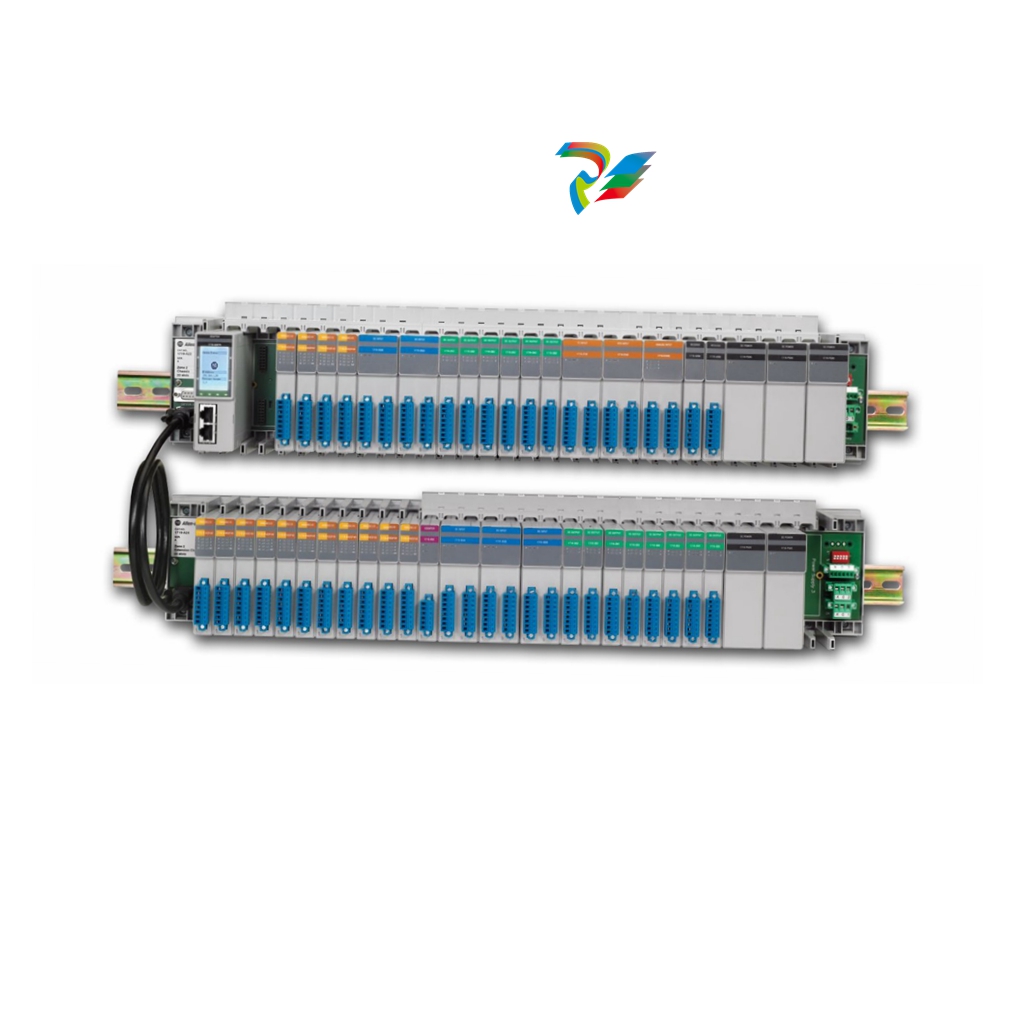

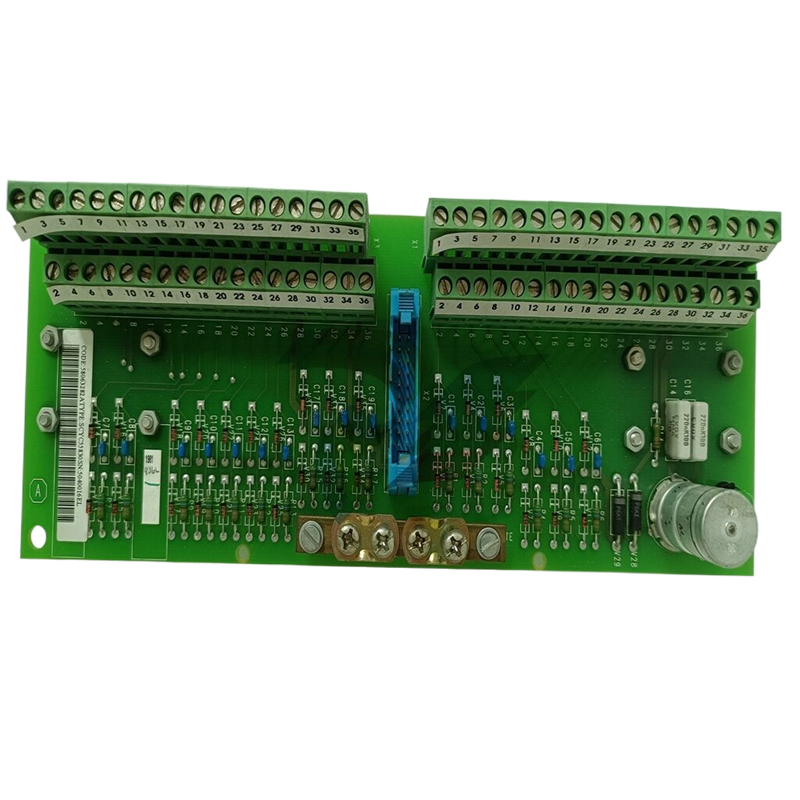

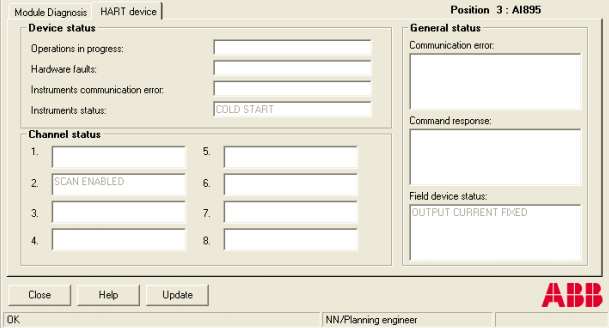

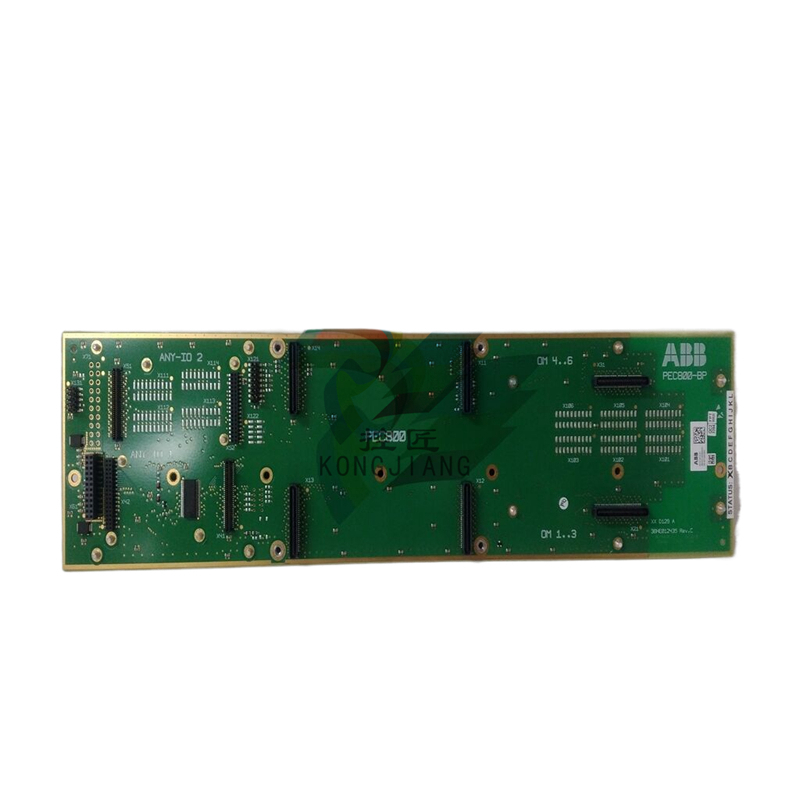

Complete Analog subsystem includes Base Converter and Expander modules

Base Converter module has eight differential inputs individually configurable for voltage or current

Accepts unipolar or bipolar Analog Inputs up to " 10 volts full scale

Accepts 4 to 20 milliamp current loop signals

Individual user scaling on each input channel on Base Converter module; scaling on a per module basis for Expander modules

Fast update rate for Base Converter module

Voltage and current Expander modules, each with 16 inputs, provides for additional inputs at a lower cost per point

Complete subsystem can accept up to 120 inputs

No jumpers or DIP switches to configure

Easy configuration with MS-DOS

or Windows

programming software configuration function.

APPLICATIONS

• Simulation

• Instrumentation

• Industrial control

• Process control and monitoring

• Factory automation

• Intelligent networked PLC controllers

• Automated test

• Data acquisition

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)