K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

8 24VDC Configurable I/O, 8 Inputs 0-24V DC 5mA, 8 Outputs 24V DC 0.5A.

Estimated Shipping Size

Dimensions: 4.0" x 3.0" x 4.0"

(10.2 cm x 7.6 cm x 10.2 cm)

Weight: 0 lbs 6.1 oz (0.2kg )

Tariff Code: 8538907080

Country of Origin: Sweden

Ships from Webster NY, USA

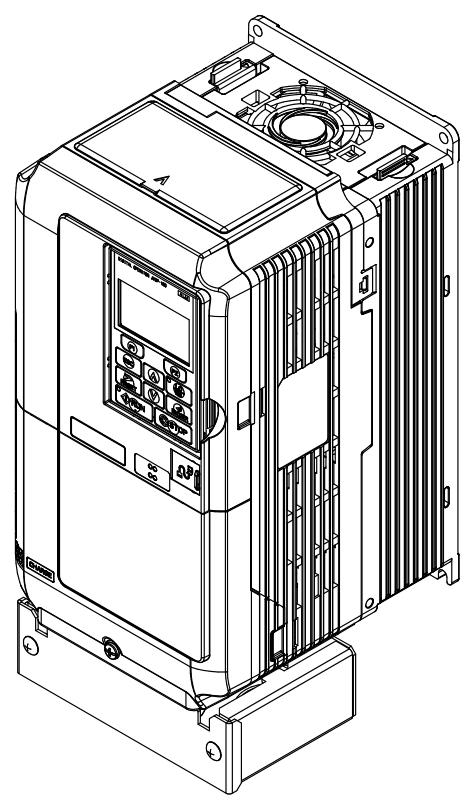

ABB 1SBP260102R1001 XC08L1 Digital I/O Extension Unit

Basic Information

Product Overview:The ABB 1SBP260102R1001 XC08L1 Digital I/O Extension Unit is a digital input/output (I/O) extension unit for expanding the number of digital I/O points in ABB automation control systems. It is used in industrial automation to enhance the input and output capabilities of a system, enabling it to connect more external digital devices such as sensors and actuators.

Physical Characteristics: Usually in a compact design for easy mounting on control cabinet rails. The enclosure is made of robust materials with good electromagnetic compatibility (EMC), which can effectively resist electromagnetic interference in industrial environments. Compact size and light weight help layout and installation in limited space.

Functional Features

Digital I/O Functions

Number of I/O channels: 8 digital I/O channels, which can be flexibly configured as digital inputs or digital outputs, and the specific configurations can be set through programming or configuration software according to the actual application requirements. For example, in a simple automated production line monitoring system, some of the channels can be configured as input channels for connecting limit switches, photoelectric sensors and other devices to obtain information such as equipment position, material availability, etc. At the same time, the other channels can be configured as output channels for controlling actuators such as indicator lights, small relays, etc., to realise status indication or simple equipment control.

Signal Processing Capability: For the digital input channel, it can receive digital signals of various level standards, such as 24V DC, 110V AC and other common industrial control signal levels. Moreover, the input channel usually has a certain filtering function, which is used to remove the noise interference in the signal and improve the stability and reliability of the signal. For the digital output channel, it is capable of outputting enough drive current to directly drive some small industrial devices, such as small relays, indicator lights, etc. The output current is generally between several hundred milliamps to several amps, depending on the channel design and load requirements.

Communication and Compatibility

Communication interface support: Equipped with standard communication interfaces, such as RS-485, RS-232 or Ethernet interface, etc., through which it communicates with the main controller (such as PLC, DCS, etc.). The communication interfaces support a variety of communication protocols, such as Modbus RTU, Modbus TCP and other common industrial communication protocols, ensuring compatibility with different brands and types of host controllers, and facilitating integration and expansion in existing automation systems.

Strong system compatibility: Designed to have good compatibility with other ABB automation products (e.g. controllers, HMIs, etc.), it can be seamlessly integrated into ABB's automation control system architecture. Parameter setting, programming and other operations can be carried out using the unified programming environment and configuration tools provided by ABB, reducing the complexity and workload of system integration.

Flexible configuration and programming

Rich Configurable Parameters: It supports flexible configuration of various parameters, for example, users can set the signal filtering time constant of the digital input channel, the output mode of the digital output channel (e.g., normally open, normally closed), and the scanning period of the I/O channel. This flexibility allows the expansion unit to adapt to a variety of control requirements in different industrial environments, for example, in an application scenario that requires high signal response speed, the filter time constant of the input channel can be appropriately shortened to speed up the signal response.

Various programming methods: It supports a variety of programming languages and programming methods, such as ladder diagrams, statement tables, function block diagrams and so on. Users can choose the appropriate programming method according to their programming habits and specific control logic. For example, for engineers who are familiar with relay control logic, ladder programming method can quickly realise the writing of control logic for digital I/O channels, such as realising simple motor start/stop control, material conveying control and other logic.

Technical Parameters

Electrical Parameters

Operating voltage range: Generally has a wide operating voltage range, for example, may support 18 - 30V DC or 85 - 264V AC operating voltage, so that can adapt to different power supply conditions in the industrial field, to ensure that the power supply voltage fluctuations can still work normally.

Input/Output Electrical Characteristics: The input voltage range of the digital input channels can be a variety of level standards depending on the specific configuration, e.g., the input voltage range of the 24V DC input channel may be 18 - 30V DC, and the input current is usually between a few milliamps and tens of milliamps. The digital output channels typically have output current ratings between 0.5 - 2A, and output voltages are available in a variety of levels depending on the load and configuration to meet the drive requirements of most small industrial equipment.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|