K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

16 outputs 24 V DC, 0.5 A transistor

Estimated Shipping Size

Dimensions: 4.0" x 3.0" x 4.0"

(10.2 cm x 7.6 cm x 10.2 cm)

Weight: 0 lbs 6.1 oz (0.2kg )

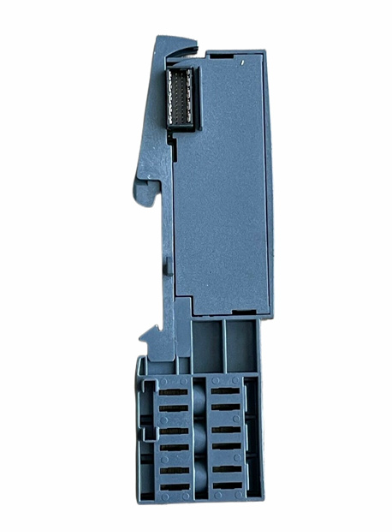

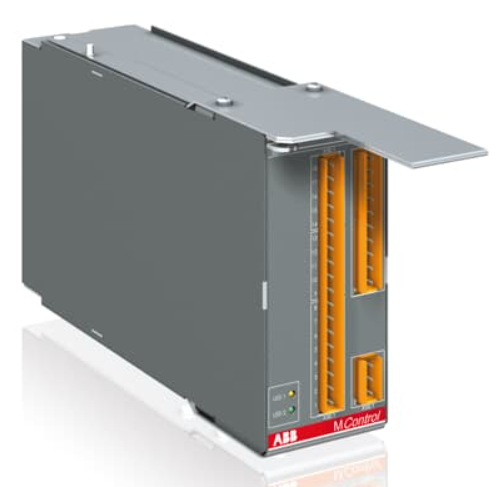

ABB 1SBP260105R1001 XO16N1 Digital Output Module

Basic introduction

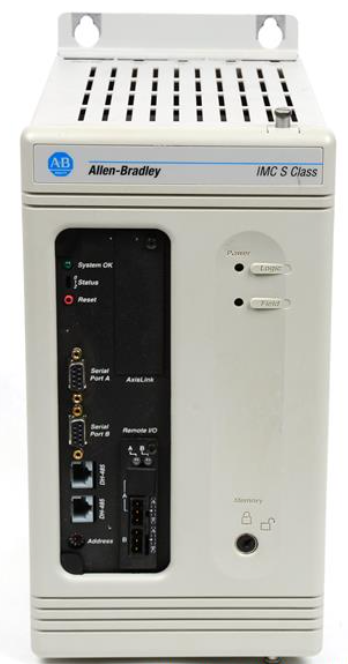

Product Overview:ABB 1SBP260105R1001 XO16N1 digital output module is an important component in industrial automation control system. It is mainly used to convert digital signals from the controller into actual physical outputs to drive external devices, such as relays, solenoid valves, indicator lights, etc., so as to achieve the control of industrial processes.

Module Design and Appearance: The module is usually designed in a compact structure for easy mounting on standard rails inside the control cabinet. Its casing is usually made of sturdy plastic or metal with good electromagnetic compatibility (EMC) and heat dissipation performance to ensure stable operation in complex industrial environments. There are several interfaces and indicator lights on the module. The interfaces are used to connect external devices and communication lines, while the indicator lights are used to display the working status of the module, signal output status and other information.

Functional Features

Output Function

Number and type of channels: There are 16 digital output channels, which can output high level or low level signals for controlling different external devices. For example, in an automated production line, one of the channels can be used to control the opening or closing of a solenoid valve for material conveying control.

Output Signal Characteristics: The output signals are typically at industry standard levels such as TTL (Transistor-Transistor Logic) levels or CMOS (Complementary Metal-Oxide-Semiconductor) levels and are capable of directly driving many common digital devices. The output current and voltage of each channel has a certain rating, for example, the output current may range from a few hundred milliamps to several amperes, and the output voltage is typically between 5V - 30V, depending on the design of the module, which makes it capable of meeting the driving requirements of most industrial equipment.

Control and Communication Features

Communication with controllers: It communicates with upper controllers (e.g. PLC, DCS, etc.) through standard communication interfaces. It can receive digital control commands from the controller and convert them into corresponding output signals. The communication interface may support a variety of protocols, such as industrial Ethernet protocols (Ethernet/IP, Profinet, etc.), fieldbus protocols (Profibus, CANopen, etc.) or serial communication protocols (RS-232, RS-485), ensuring compatibility with different types of control systems.

Configuration and Programming Flexibility: The module supports a variety of configuration methods, and users can configure the parameters, such as setting the initial state of the output channel, the delay time of the output signal, the pulse width, etc., through the programming software or the host computer interface. This flexibility makes it possible to adapt to a variety of complex control logic, for example, in an automated packaging system, the output pulse width can be programmed to accurately control the sealing time of the packaging machine.

Diagnostic and Protection Functions

Fault diagnosis: The built-in fault diagnosis function can monitor its own working status in real time, including power supply status, communication status and output channel status. When a fault occurs, such as output short circuit, open circuit, communication interruption, etc., the module is able to alarm by flashing status indicator, sending fault code to the controller, etc., which is convenient for maintenance personnel to quickly locate and solve the problem.

Protection mechanism: In order to protect the module and external equipment, there are a variety of protection mechanisms. For example, with output overcurrent protection, when the output current exceeds the rated value, it will automatically cut off the output channel to avoid damage to the module and the connected equipment; may also have electrostatic discharge (ESD) protection to prevent electrostatic damage to the internal circuit.

Technical Parameters

Electrical parameters

Operating voltage range: There is usually a wide operating voltage range, such as 18V - 30V DC, to adapt to different power supply conditions. This voltage range ensures that the module will function properly in the event of power fluctuations common in industrial sites.

Output Current Ratings: The rated output current for each output channel may range from 0.5A - 2A, depending on the module model. The total output current is also limited, e.g. the total output current of all 16 channels may not exceed a certain value, in order to ensure the overall performance and safety of the module.

Response Time: The response time of the output signals is short, typically in the millisecond range. For example, it may take only a few milliseconds from the time a command is received from the controller to the time the output signal changes, which is important for industrial control applications that require a fast response (e.g., high-speed packaging lines, rapid sorting systems, etc.).

Communication Parameters

Communication interface types: Common communication interfaces include Ethernet interface (RJ45), serial interface (DB9 or Phoenix terminal, etc.). The Ethernet interface supports high-speed data transmission and remote monitoring functions, while the serial interface can be used for simple local communication or connection to some specific devices.

Supported communication protocols: As mentioned earlier, a variety of communication protocols are supported. For example, it may support Ethernet/IP protocol, which is used to integrate with Rockwell Automation's control system; Profibus - DP protocol, which facilitates communication with Siemens and other brands of equipment; and Modbus RTU/TCP protocol, which is a common protocol widely used in industrial automation.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|