K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

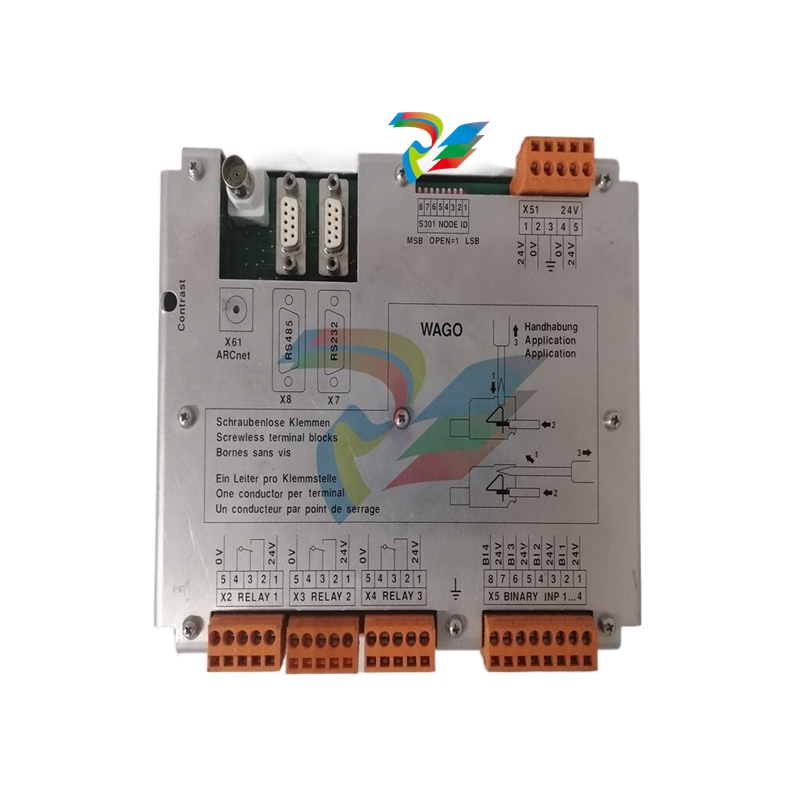

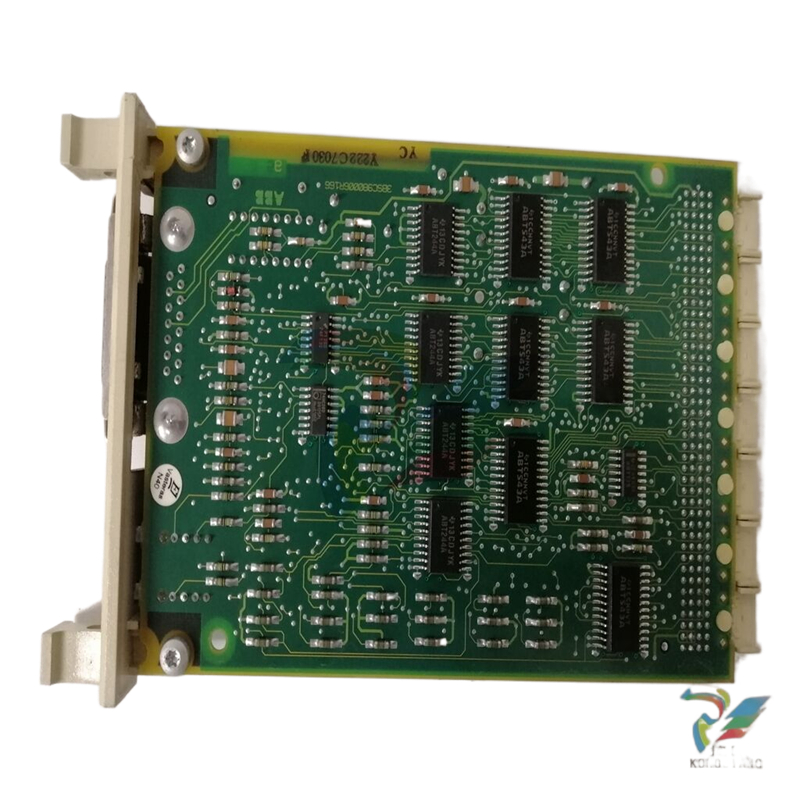

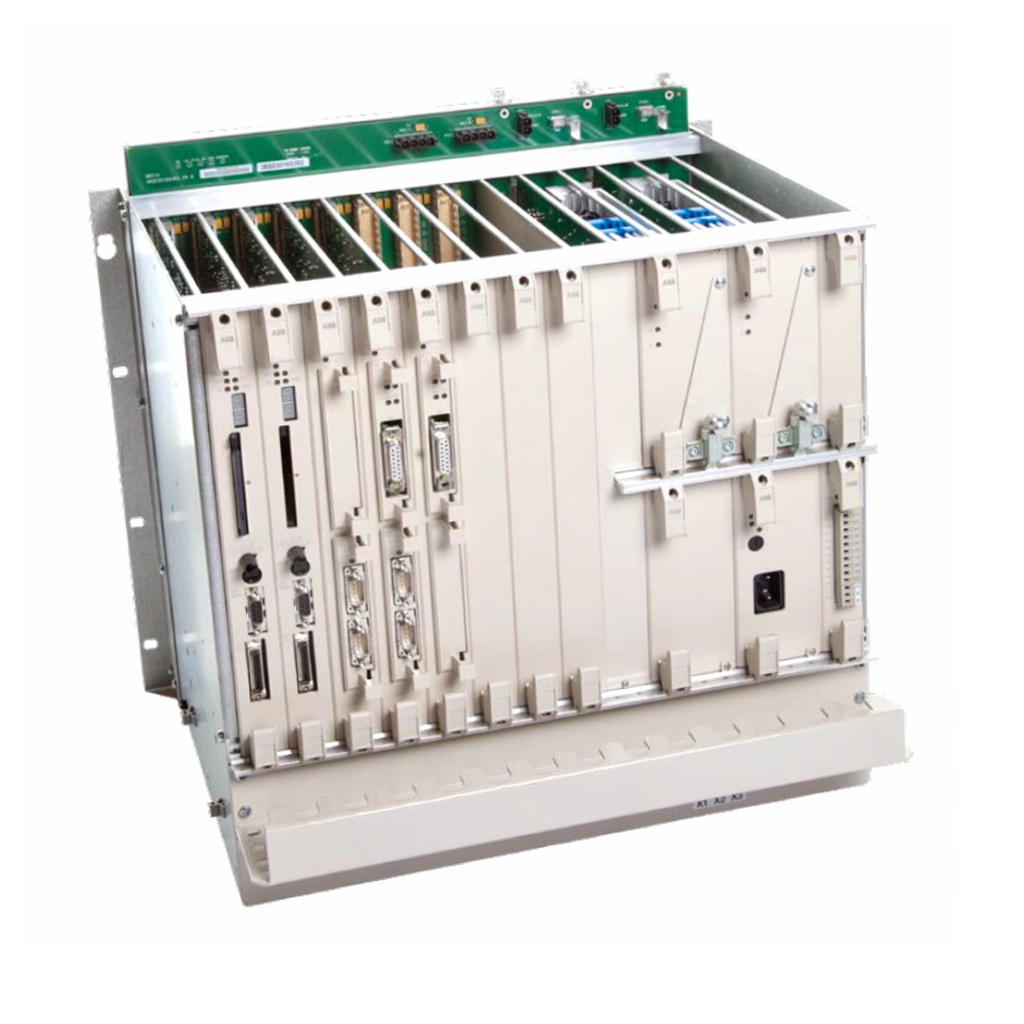

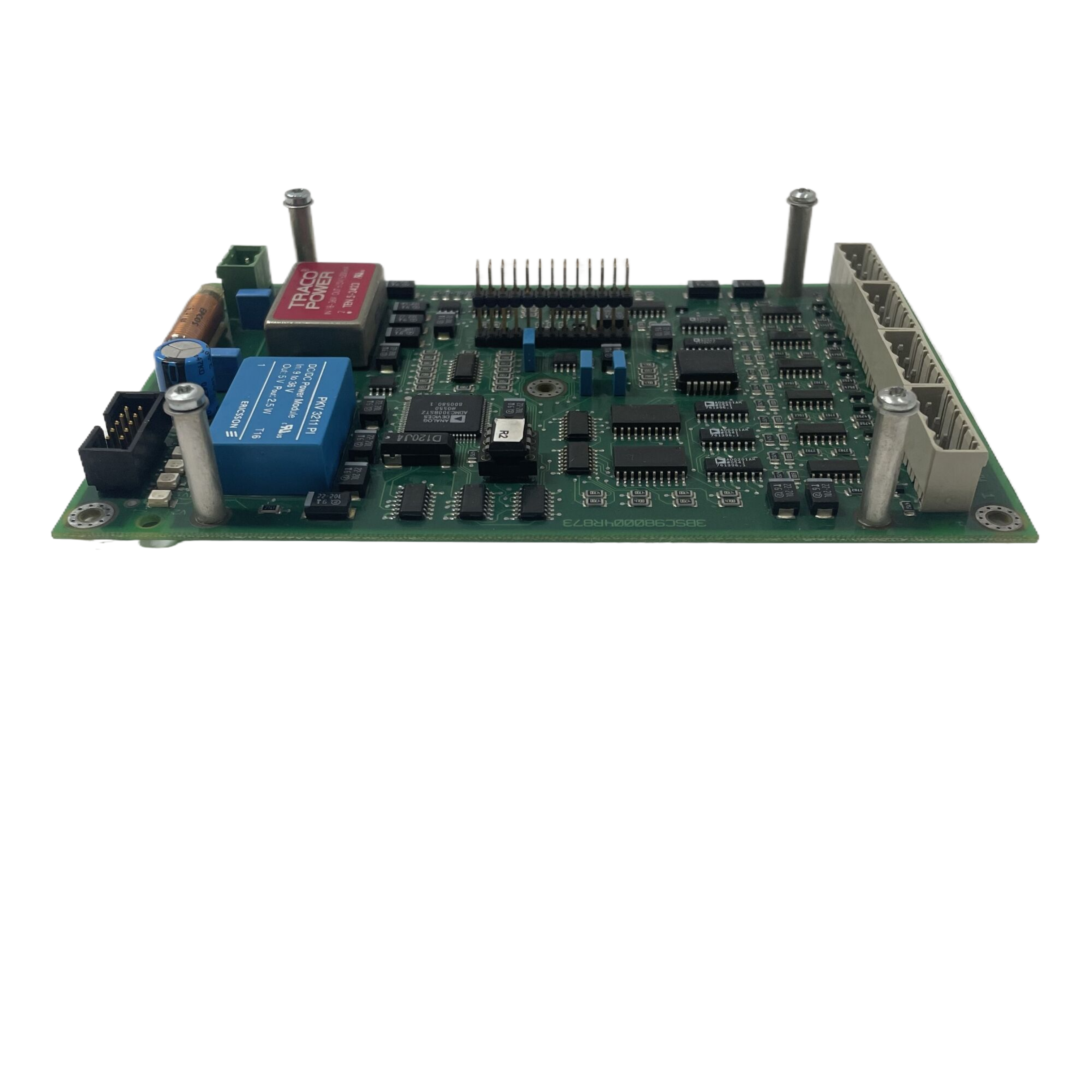

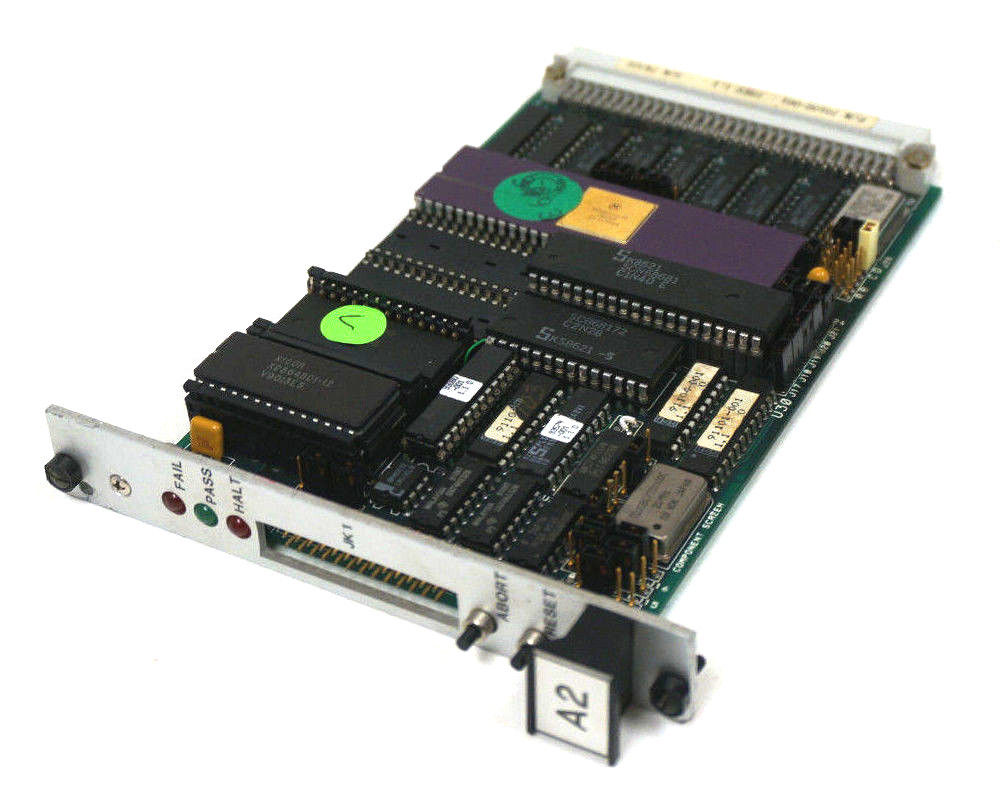

RCU501 is a high performance, general purpose, real-time process control computer for use in a wide variety of system applications in both on- and offshore installations. The processor core is an embedded Power PC™ architecture and the module is approved for Ex Zone 2 applications

KOLLMORGEN-RCU501Remote Controller Unit

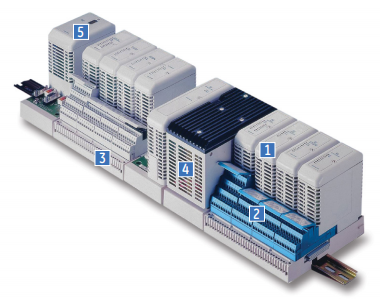

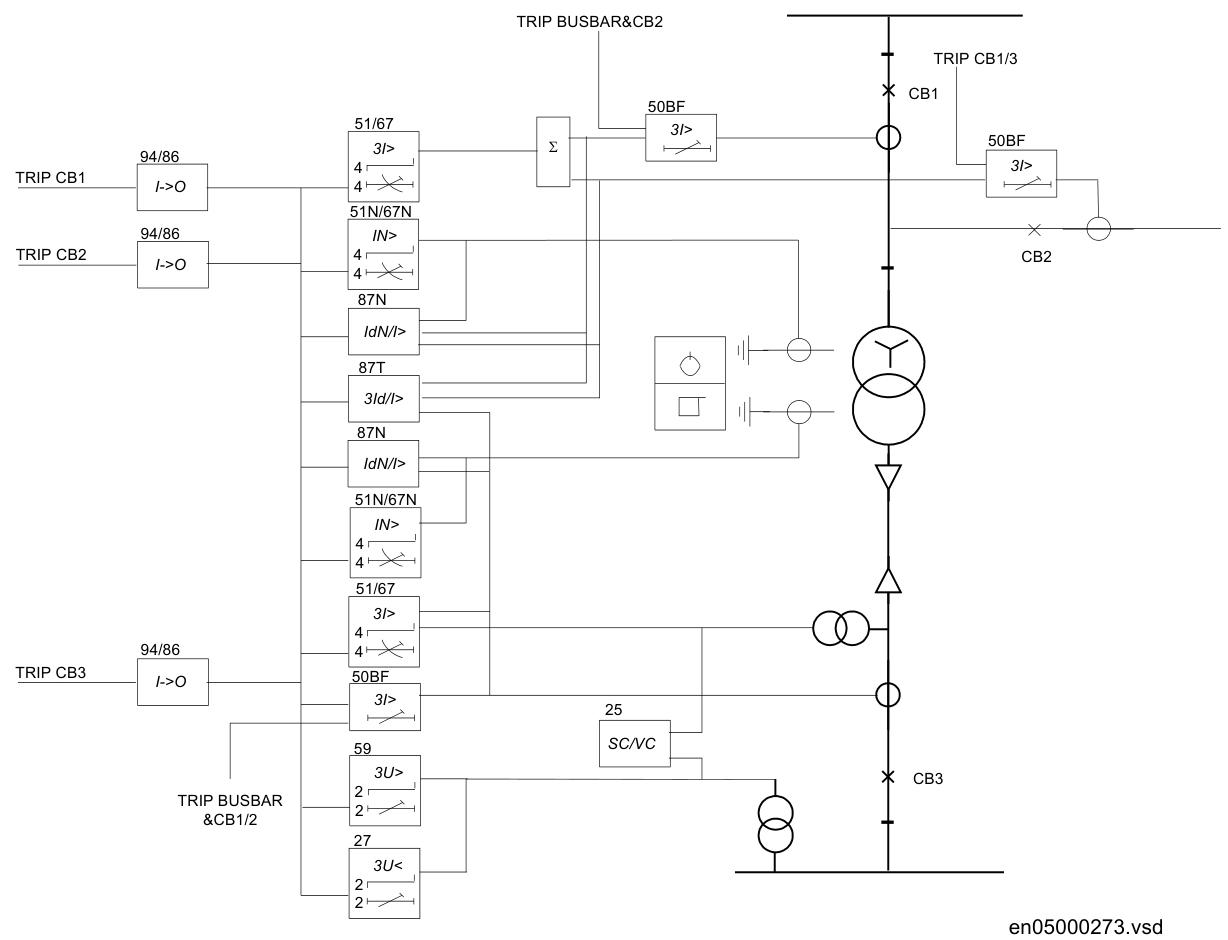

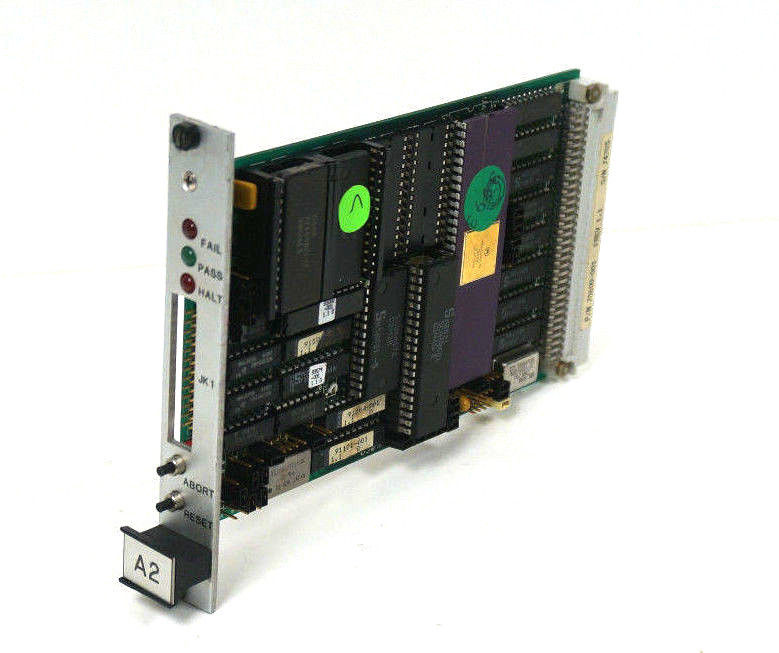

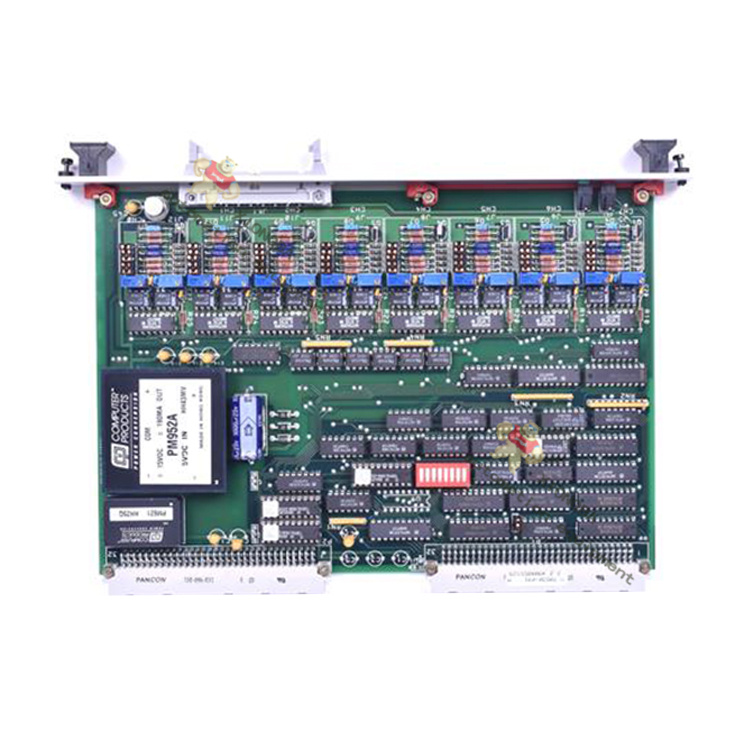

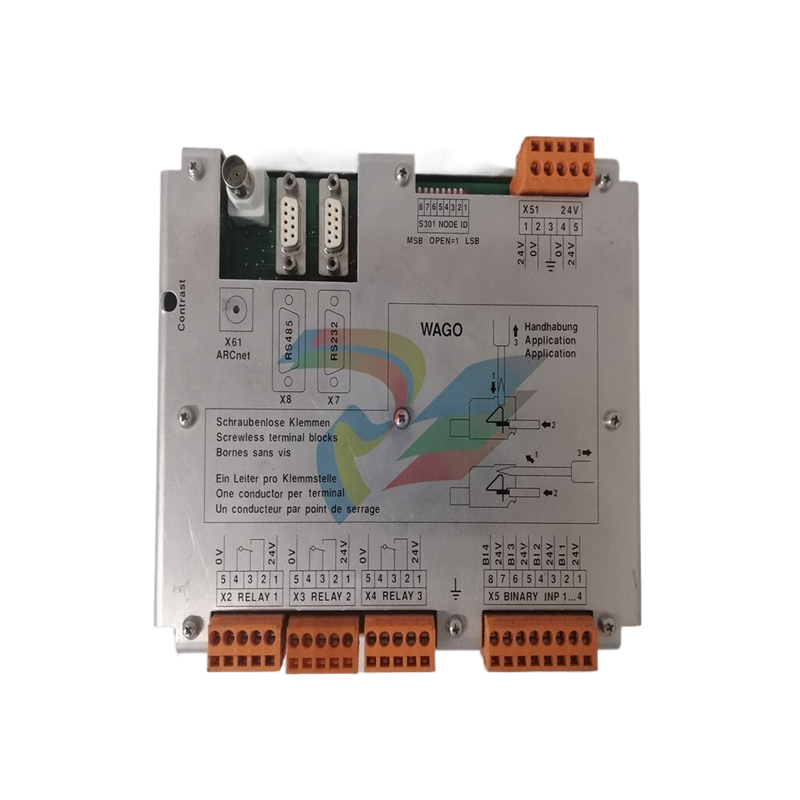

Application types • Dynamic Positioning Systems • Thruster Control / Steering Systems • Navigation Sensor Integrator • Integrated Process Control Systems • Alarm and monitoring Systems • Safety Systems Function • Dual ethernet LAN process networks • Dual RedundancyNet interface for redundant RCU confi guration • Dual Remote IO process BUS (RBUS) • 4 general purpose Digital Input channels • 4 general purpose Digital Output channels • 32 serial lines for 3rd party interface • 2 PROFIBUS channels for 3rd party interface • 2 CANBUS channels for 3rd party interface Feature • Single unit topology: SIL 1 compliant • Dual unit topology: SIL 2 and SIL 3 compliant • Triple unit topology • Ex Zone 2 approved • Compliant to the following protocols: 1. Modbus (Serial and TCP) 2. NMEA 0183 3. PROFIBUS/PROFIsafe 4. CAN/DeviceNet • 3rd party vendor specifi c protocols are available upon request • Power: 1. Redundant power input with power alarm monitoring 2. Inrush current and over-voltage protection • Enhanced watchdog with fail-safe function and system status output Benefi ts The following built-in functions minimize system downtime: • Extended Built-in Self- Test (BIST) for computer diagnostics and fault identifi cation during start-up and runtime • Prepared for online remote diagnostics • Prepared for online fi rmware upgrade • Bootable from fi le server or local fl ash memory • Easy installation and replacement 1. DIN Rail mounting 2. All connections are pluggable 3. 3 digit address switches • Hot swap in redundant applications, dual and triple Hot-Standby redundancy, 1oo2 redundancy • Status LED indication (Normal/Error) • RoHS compliant Computer performance • RCU501 performance is application dependant and governed by process complexity, updating frequency and number of interfaced I/O. Maximum updating frequency is 50 Hz. • Confi guration guidelines: 1. ESD/PSD: max. 800 I/O, F&G: max. 700 I/O both at scan rate: 1 Hz 2. Process/ Automation: max. 2000 I/O, design advice: 1280 I/O both at scan rate: 1 Hz 3. Anti-surge: 3 loops, Scan rate: 50 Hz 4. Dynamic Positioning: Triple redundant DP system combined with Position Mooring. (Scan rate is adapted to signal processing and varies from 1 to 10 Hz).

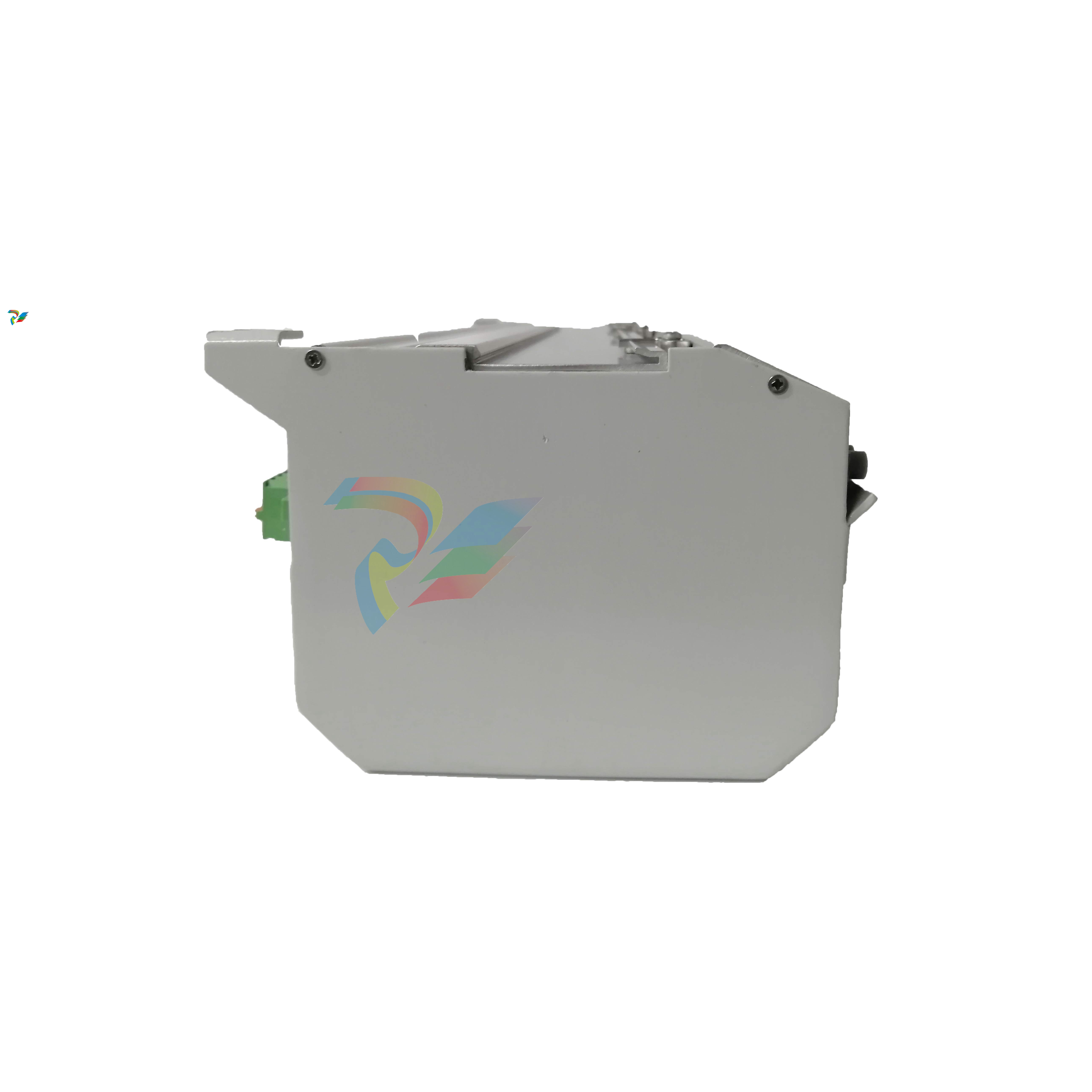

KM article number RCU501: 603439 Standards RCU501 complies with the following: • IACS E10 • IEC 60533 • IEC 60945 • IEC 61508 • IEC 62061 Type approval RCU501 is type approved by: • Det Norske Veritas (DNV) • The American Bureau of Shipping (ABS) • TÜV Rheinland • Wurldtech™; Achilles level 1 certifi ed CE marking CE mark compliant, confi rm to: • 2004/108/EC (EMC directive) • 94/9/EC (Atex directive) Ex certifi cation Ex nA II T4 (Zone 2) Environmental specifi cations Ambient temperatures and humidity: • Temp. Operation: -15˚C to 70˚C • Temp. Storage: -25˚C to 70˚C • Humidity Operation: Up to 98% RH • Humidity Storage: Up to 98% RH Protection Standards: IP 20 Dimensions Height: 355 mm Width: 158 mm Depth: 87 mm Weight: 1.35 kg Cross point screw lock on DIN Rail T35 7.5/15 according to EN 50022 Electrical Input supply voltage: 24 VDC (+30%, -25%) Nominal current consumption: ≈ 0.8 A Start-up current: Max. 2.7 A Power consumption: Max. 20 W Heat dissipation: Max. 20 W Power connectors: • Screw terminals (slotted) • Cable cross section: 2.5 mm² Processor and memory Processor: • Type: Power PCTM host processor MPC8245 • Clock frequency: 400 MHz Memory: • RAM size and speed: 64 MB @ 133 MHz • PROM: 16 MB application fl ash-fi le Serial line Channels: 32 insulated serial lines, distributed on 8 RJ45 connectors Physical layer: RS232. RS422 and RS485 Multidrop via RSER200 Bit rate: Max. 115 kb/s General purpose I/O channels Digital Output (DO): • 4 x opto-isolated outputs • 1 x opto-isolated watchdog (for external interface) Digital Input (DI): 4 x opto-isolated inputs I/O connectors: • Cage clamps • Cable cross section: 1 mm² LAN interface Process network & RedundancyNet: 2 x RJ45 Ethernet IEEE 802.3 type 10BASE-T/100BASE-TX RBUS interface Connector: 2 x RJ45 Bit-rate: 2 Mb/s Signal code: Manchester encoded (Self-clocked) Copper wire topology: • Insulation: 500 V (Optocoupler) • Physical layer: RS485 Multidrop • Cable attenuation: < 6.5 db/100m @ 10 MHz (CAT 5) • Cable length: Max. 200 m between repeaters. Max. 3 repeaters Fibre optical topology (w/ additional fi bre media converter): • Fibre cable: 62.5/125 μm. Multimodus • Connector: ST • Cable length: Max. 1000 m (point to point). 500 m if used in patch-panel topology Field interface CAN interface: • 2 x CANopen/DeviceNet @ 5 pole cage clamp terminals. 2.5 mm² cable • Bit rate: Max. 1 Mb/s. (DeviceNet not defi ned above 500 kb/s) PROFIBUS interface: • 2 x opto-isolated 9 Pin female D-Sub connectors • Bit rate: Max. 12 Mb/s Life cycle prediction Predicted failure rate @ GB 25˚C (60% confi dent, based on chip suppliers data): 24.2 Years Predicted failure rate @ NS 35˚C (Environmental de-rating based on Rome Laboratory toolkit): 6.5 Years

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)