K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

PURPOSE The purpose of this document is to describe the features of the Advanced Micro Controller 2, providing basic information in a datasheet form.

GE FANUC T1693EN Liquid Cooled DELTA

AEM

Active Energy Management

CDC

Common Drive Controller

CDM

Complete Drive Module

DDM

Drive Data ManagerTM

DELTA

Generic term for the transistor module or rectifier unit in the DELTA modular drive

DFE

Diode Front End

DIB

DELTA Interface Board

Drive

Cubiclised DELTA components (CDM)

DNV

Det Norske Veritas

I/O

Input /Output

IEC

International Electro-technical Committee

IGBT

Insulated Gate Bipolar Transistor

Machine Bridge

The machine bridge controls the bi-directional power flow between the d.c. link and

the motor or generator

MVM

Mains Voltage Monitor

Network Bridge

The network bridge controls the power flow from the mains supply into the d.c. link.

In the case of an AEM system, bi-directional power flow between the supply and the

d.c. link is controlled.

PDS

Power Drive System

PWM

Pulse Width Modulation

SFE

Sinusoidal Front End

SMPS

Switch Mode Power Supply

System

General term for the PDS

UNITS COVERED

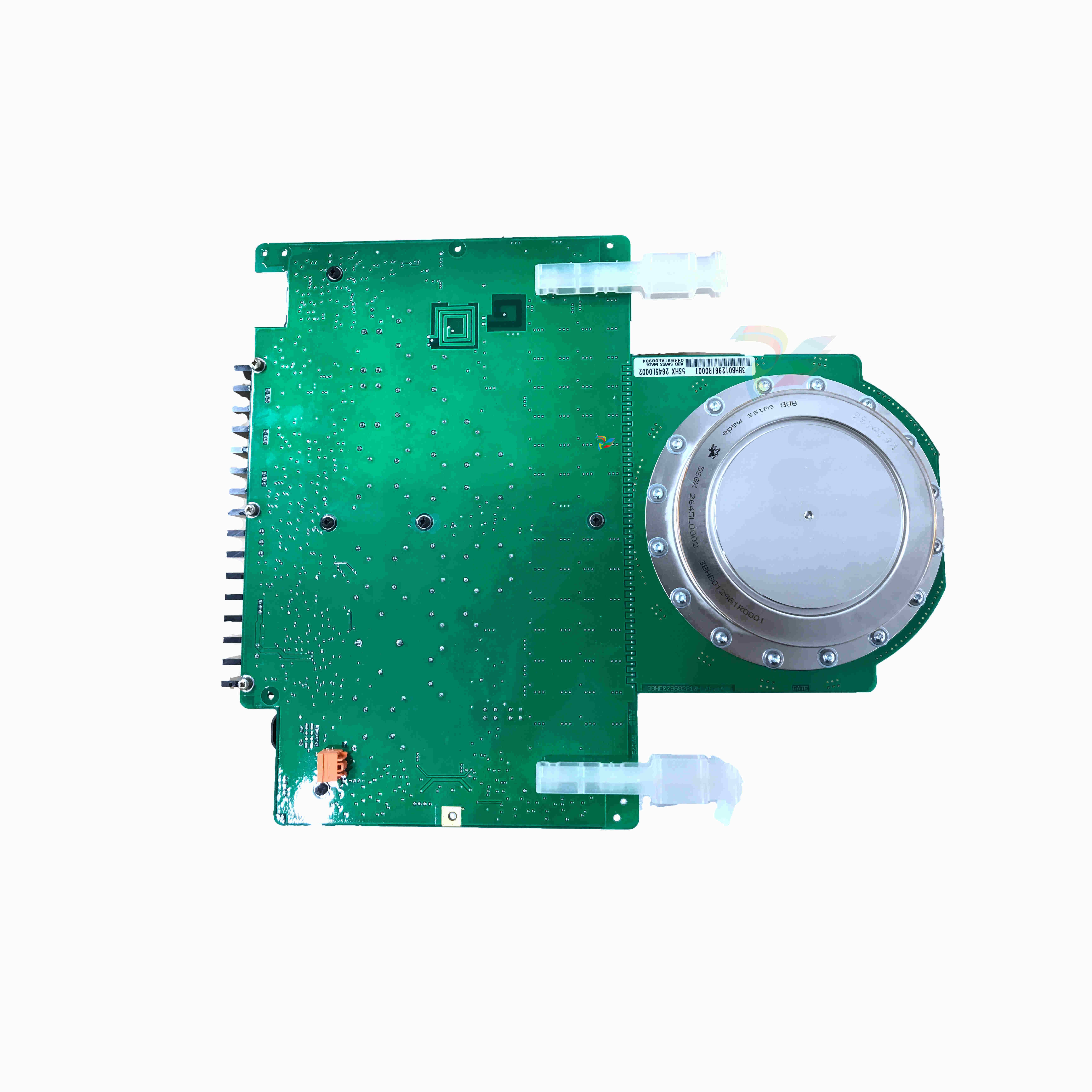

LIQUID COOLED DELTA POWER MODULES

MVDL643-4702

Transistor Module 643 A, 690V a.c. 1200Vd.c.

MVDL800-47xx

Transistor Module 800 A, 690 Va.c. 1250Vd.c.

MVDL800-XXxxXXX

Transistor Module 800 A, 690 Va.c. 1250Vd.c

MVDL1000-47xx

Transistor Module 1000 A,690Va.c.1250Vd.c.

MVDL1000-xxxxxxx

Transistor Module 1000 A, 690Va.c. 1250Vd.c

MVRL2100-4601

Rectifier Module 2100 A,690Va.c.

MVRL2100-4602

Rectifier Module 2100 A, 690V a.c.Hosetail connection.

DFE NETWORK BRIDGE SHARING REACTORS

50Z0081/01

3 phase, 986 A, 690Va.c.

AEM AND MACHINE BRIDGE SHARING REACTORS

50Z0126/01

3 phase, 645 A, 690Va.c.

5020126/02

3 phase, 800 A, 690Va.c.

50Z0126/03

3 phase, 1000 A, 690Va.c.

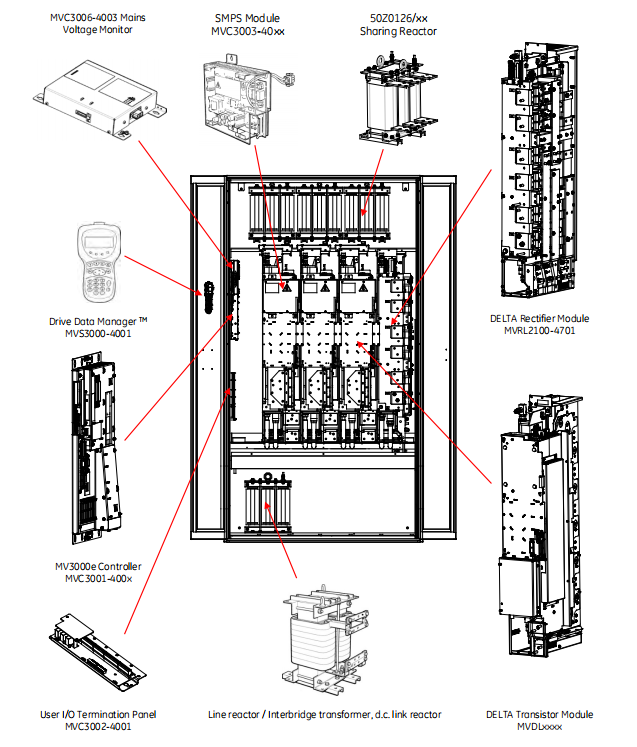

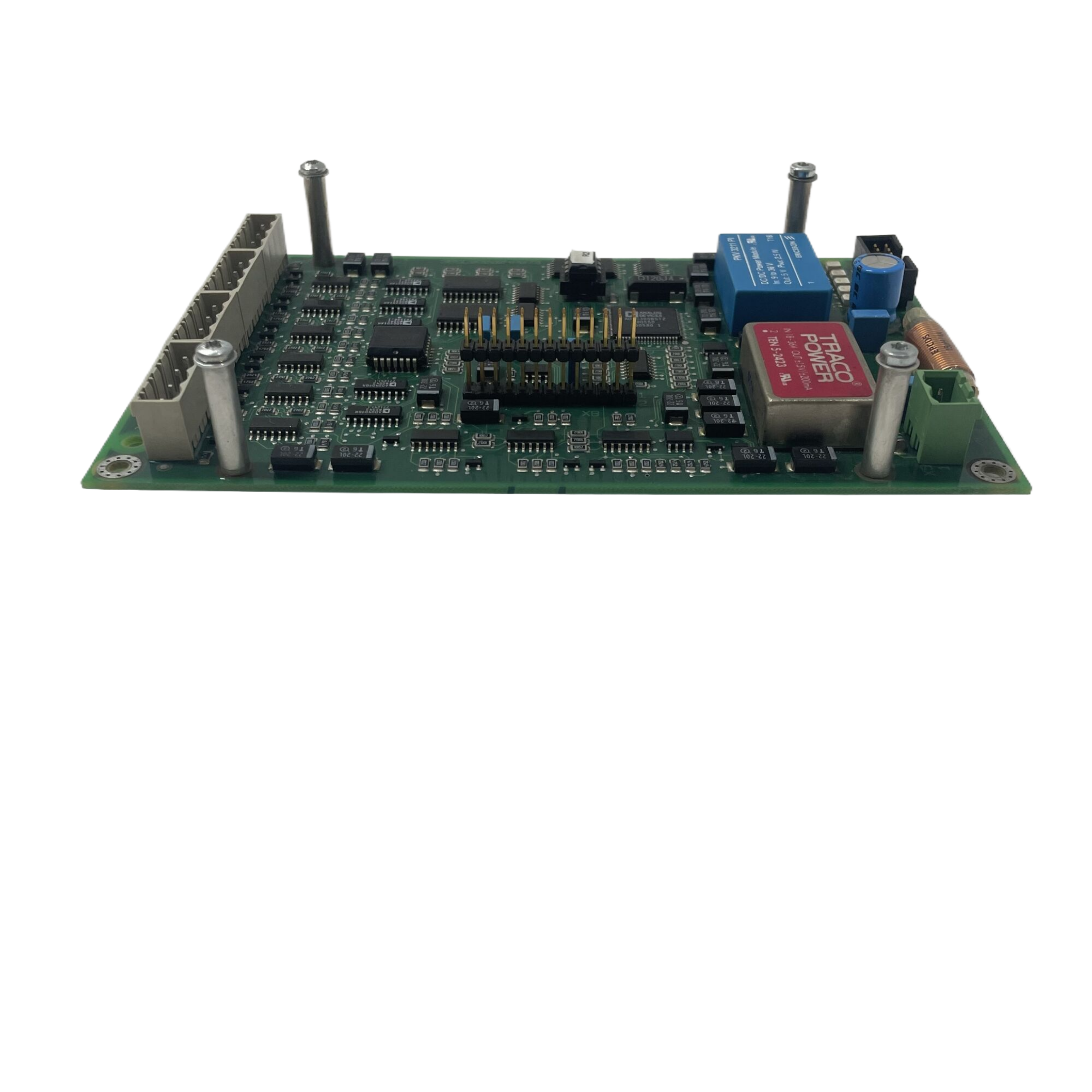

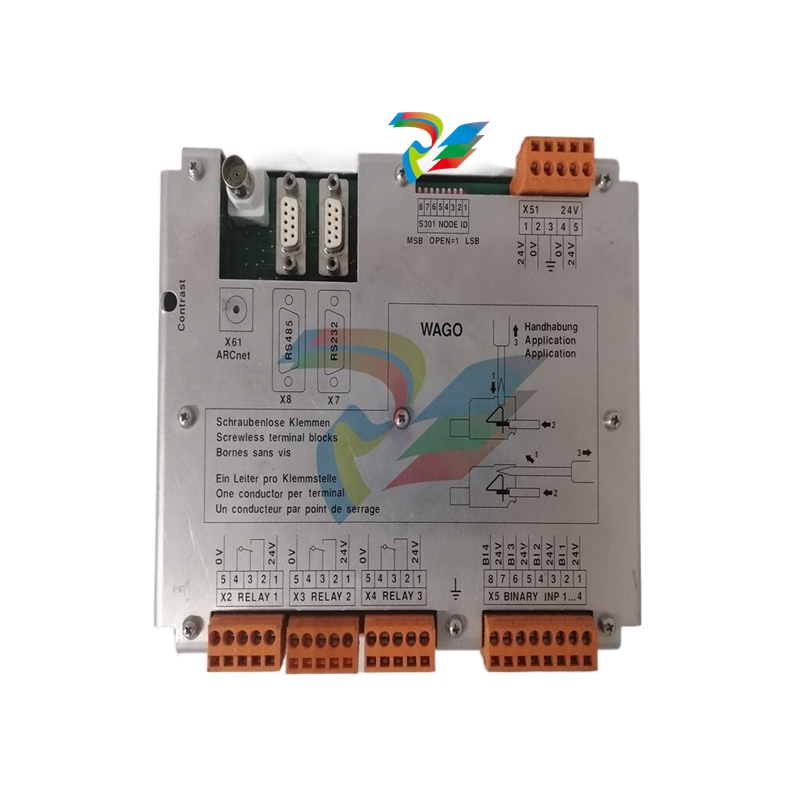

DELTA CONTROL COMPONENTS

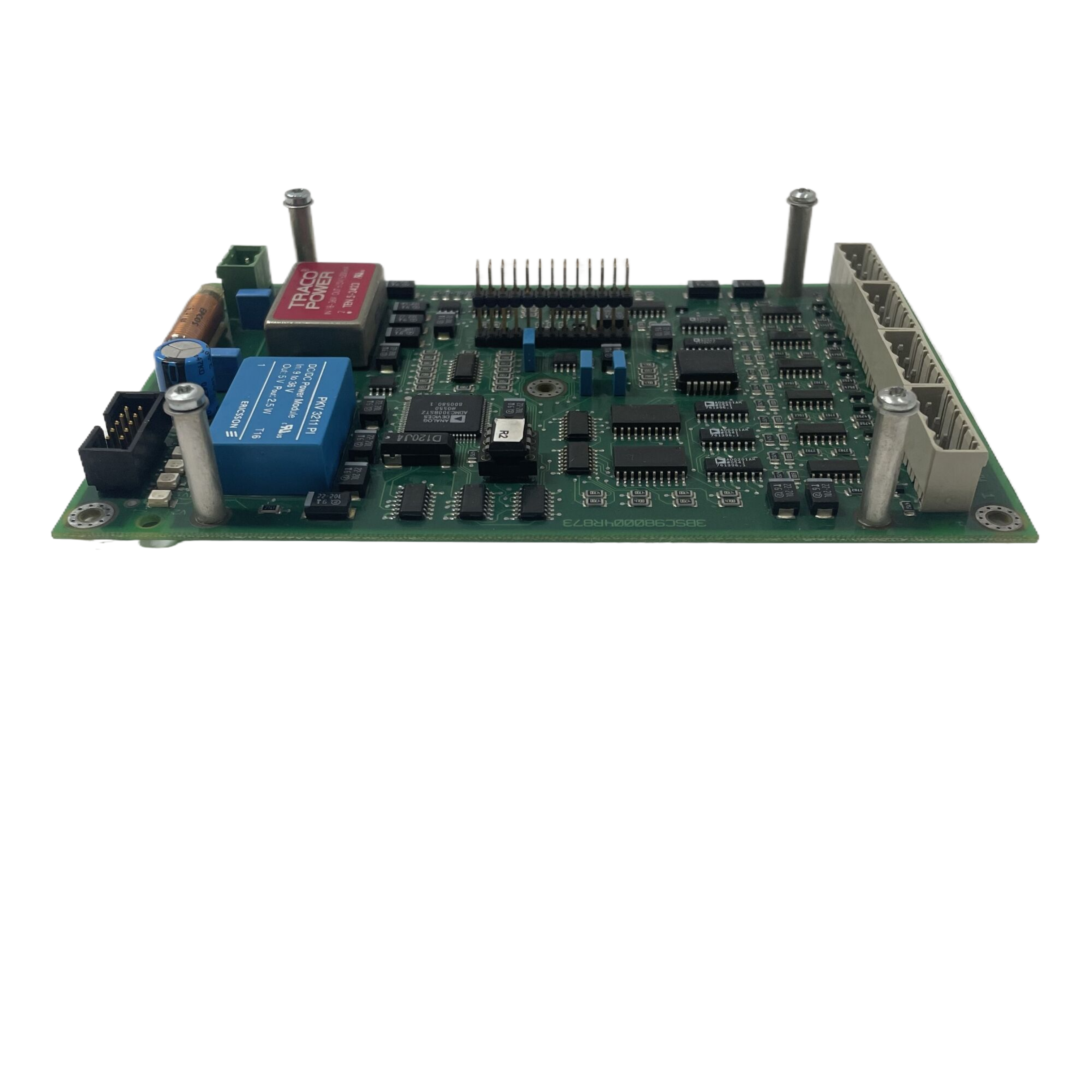

MVC3001-400x

MV3000e Controller

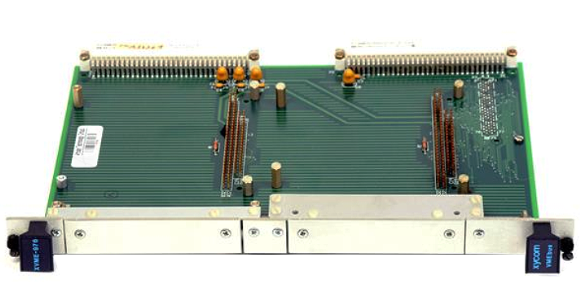

MVC3002-4001

User I/O Termination Panel

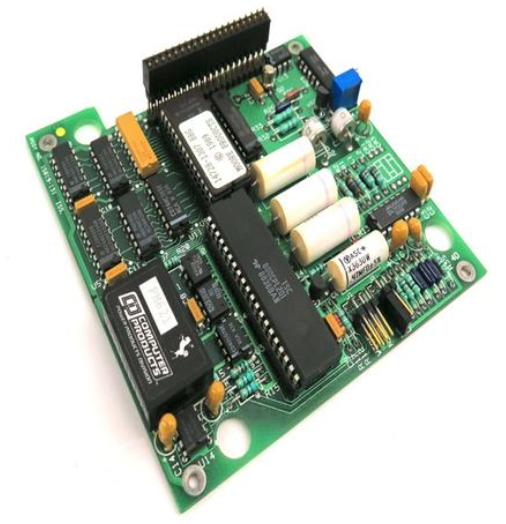

MVC3003-40xx

Switched Mode Power Supply

MVC3006-400x

Mains Voltage Monitor

MVS3000-4001

Drive Data ManagerT™(Keypad)

MVS3001-4001

Drive Data Manager T™(Keypad) Mounting Kit

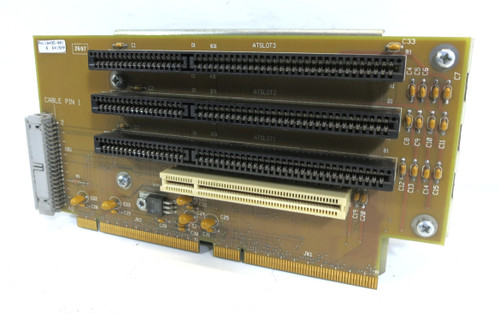

DELTA RIBBON CABLES +ACCESSORIES

MVS3017-4001

16way Ribbon Cable Earthing Clamp

MVS3018-400x

40way Ribbon Cable Earthing Clamp

MVS3019-4001

50way Ribbon Cable Earthing Clamp

MVS3020-40xx

40way Screened Ribbon Cable

LIQUID COOLED DELTA MOUNTING FRAMES FOR RITTAL TS8 ENCLOSURE

MVDL-TS-4001

Liquid Cooled DELTA Mounting Kit 800Dx600W

MVDL-TS-4002

Liquid Cooled DELTA Mounting Kit 800Dx800W

MVDL-TS-4003

Liquid Cooled DELTA Mounting Kit 800Dx 1000W

MVDL-TS-4004

Liquid Cooled DELTA Mounting Kit 800Dx1200W

MVDL-TS-4005

Liquid Cooled DELTA Mounting Kit 600Dx 600W

MVDL-TS-4006

Liquid Cooled DELTA Mounting Kit 600Dx800W

MVDL-TS-4007

Liquid Cooled DELTA Mounting Kit 600Dx1000W

MVDL-TS-4008

Liquid Cooled DELTA Mounting Kit 600Dx 1200W

1.

INTRODUCTION

1.1

GENERAL DESCRIPTION

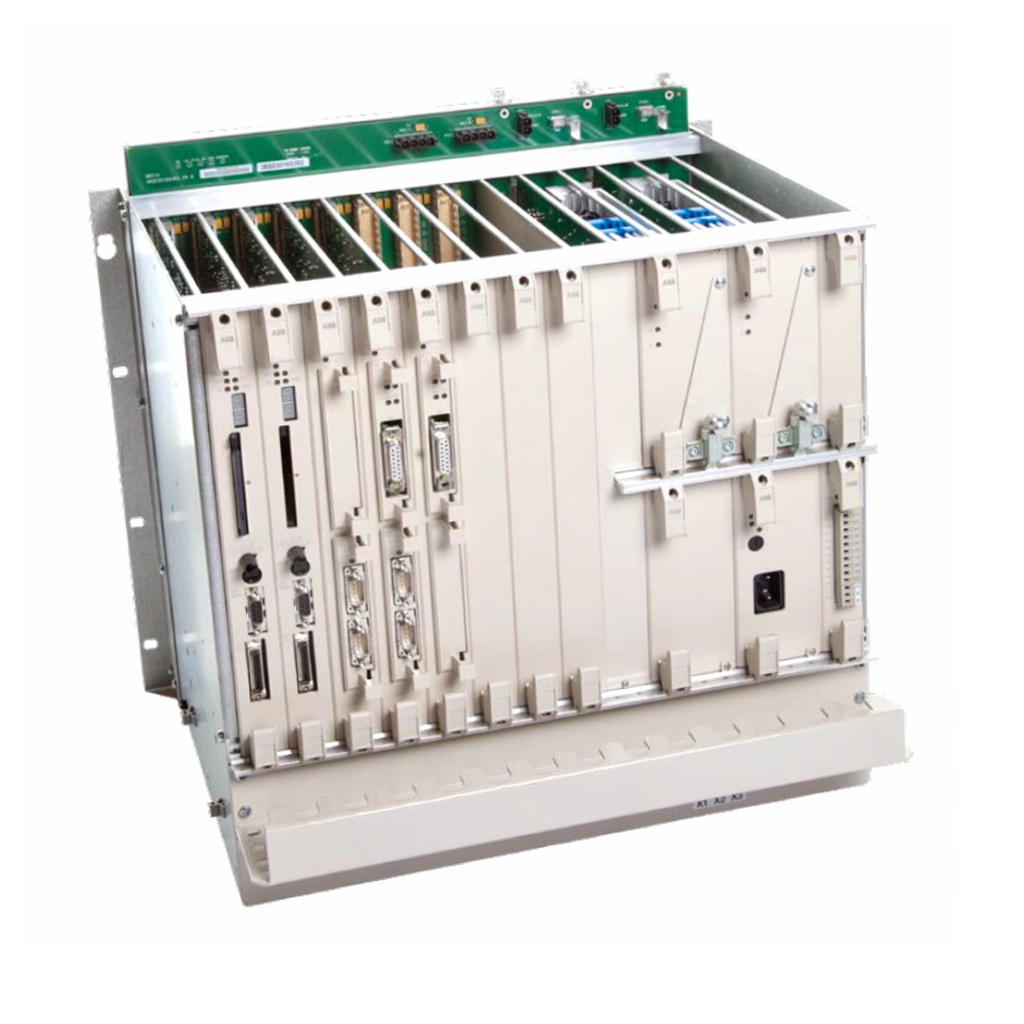

An MV3000e DELTA a.c. drive is used to control a motor, generator, or power conditioning application.

It uses a modular approoch which allows the use of a small number of common components to create a

large number of system variants.

1.1.1 Advantages Of The Modular System

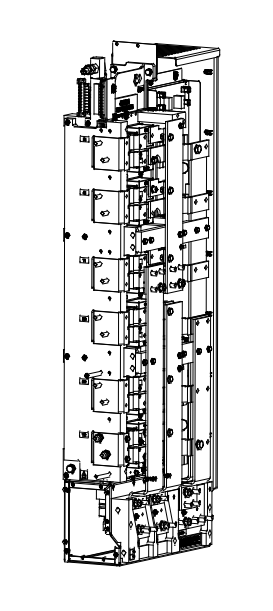

The DELTA transistor and rectifier modules are of a standard mechanical design, using the

same mounting method and dimensions:

DELTA rectifier and transistor modules can be connected in parallel to provide a wide range of

power levels;

Modular construction makes maintenance and repair work simple, and enables rapid module

replacement;

.

DELTA transistor and rectifier modules can be withdrawn on a simple slide system for ease of

assembly and maintenance.

Ease of handling - smaller, lighter modules are assembled to form large drives.

1.1.2

DELTA Product Range

Rectifer module:

Transistor modules;

MV3000e Controller

SMPS (Switch Mode Power Supply) units;

User I/O termination panel;

MVM (Mains Voltage Monitor;

DDM (Drive Data Manager™- Keypad;

Reactors and transformers;

Installation accessories (mounting kits and control cables).

1.2

ASSOCIATED MANUALS

T1676-MV3000e Getting Started Manual (for rectifier fed systems);

T1679-MV3000e Software Manual (and Firmware SupplementT21541;

T2002-MV3000e Getting Started Manual (for AEM systems).

The T1676 and T2002 manuals include commissioning and operating details for the complete MV3000e

DELTA drive.

The T1676,T1679 and T2002 manuals should be regarded as part of the DELTA product.Individual DELTA

component instructions sheets that may also be required are shown below.

T1694

MVS3007-4002-Profibus Field Coupler 12 Mb/s;

T1915

MVS3000-4001-Drive Data Manager ™(keypod);

T1916

MVS3001-4001-Keypad mounting kit;

T1930

MVC3006-4003- Mains Voltoge Monitor (MVM);

T1968

MVS3011-4001-CANbus communications module,

T1973

MVC3003-40xx - Switch Mode Power Supply (SMPS) Module;

T2034

MVS3012-400x-Ethernet interfoce;

T2100

MVDL800 DELTA Transistor Module;

T2101

MVDL1000 DELTA Transistor Module,

T2112

MVC3001-400x-DELTA Controller.

2.

SPECIFICATION

2.1

INTRODUCTION

The specifications provided in this section are for the individual DELTA components.These components are

the transistor and rectifier modules, the MV3000e Controller,the Switched Mode Power Supply (SMPS), the

User I/O Termination Panel, associated reactors and transformers and the installation occessories (for use

in endosures).Consideration should be given to the rating of individual components when they are

indluded in a CDM as derating for parallel applications may apply.

2.2

DELTA COMPONENTS (GENERAL ENVIRONMENT)

All DELTA components are designed to comply with the common specifications in Table 2-1 to Table 2-6

unless otherwise detailed in the individual component specification.Drive performance data for an

MV3000e based DELTA drive is indluded in Table 2-7.

2.2.1

Electrical Supply

DELTA modules are intended to be used in a drive connected to an electrical supply with the following

characteristics:

FUNCTION

SPECIFICATION

Electrical Supply

TN or TT (i.e. earthed/grounded neutrall.

Network Type

Can also be connected to IT network (i.e. isolated or high impedance neutral) if IT network

separated from public mains supply by an isolating transformer

Isee Section 4.5.1: Protection Against Transients).

Voltoge Range

575 V-690V(600V nominal)

Voltage Variation

(on voltage range)

±10% long term,±15% for 0.5 to 30 cycles with loss of performance but no trip

Voltage Unbalance

Negative sequence voltage not to exceed 3%

Frequency loptimised)

50Hz,60 Hz

Operational Frequency

45 Hz to 63 Hz.With frequencies outside the optimised values, extra d.c. link ripple may

Range

be apparent and may impair motor control performance.

Insulation Coordination

EN 50178,IEC 61800-5-1,UL 840,CSA C22.2 No.0.2

TN or TT network

: Overvoltage Category Ill

Overvoltage Category

IT network

: Overvoltoge Category ll

(line to earth)

For full compliance with UL 508C, transient suppressers complying with UL 1449 must be

fitted between line and earth. These must be fitted as close as possible to the point

where the electrical supply enters the drive enclosure.

Table 2-1.-Electrical Specification

2.2.2

Switching Frequency

The switching frequency is set by parameter P35.00 in the MV3000e controller (see MV3000e Software

Manual T16791.The range of possible switching frequencies is given in Table 2-2.

Default

Alternatives Available

Network Bridge(AEM only)

2.5kHz

5kHz

Machine Bridge

1.25kHz

2.5kHz,5kHz

Notes:

1.If one of the alternative switching frequencies is selected, it may be necessary to reduce the power rating

of the drive, particularly at higher ambient temperatures.

2. lf the switching frequency of the network bridge is altered, the effects on the PWM filter must be

assessed.The change of PWM frequency will affect the power dissipation in the filter and will also affect

the emissions onto the electricity supply.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)