K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

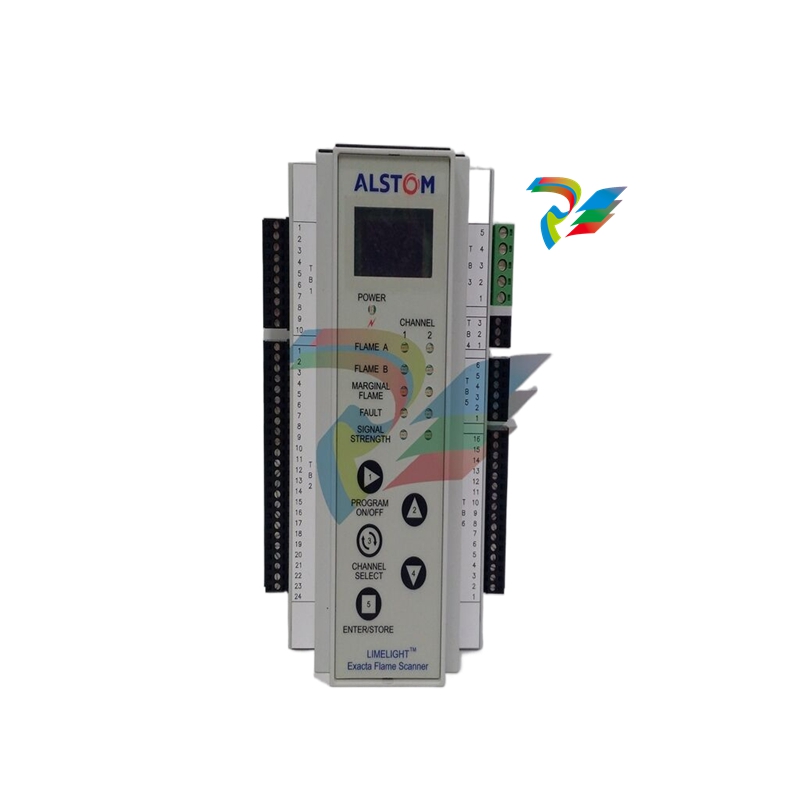

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

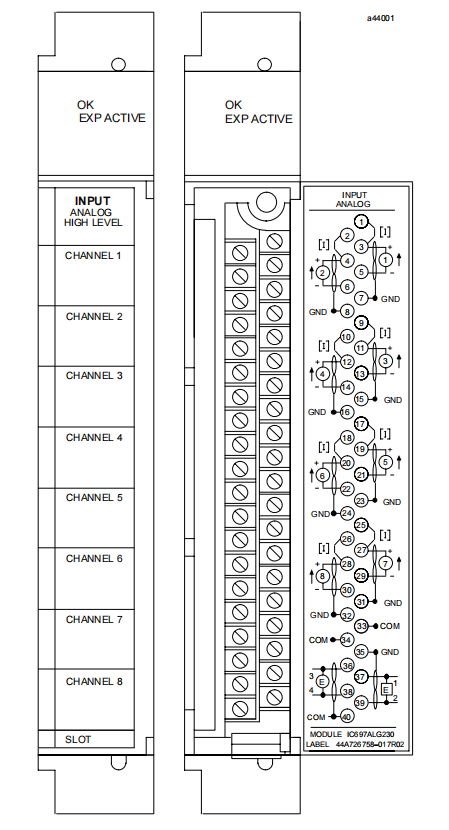

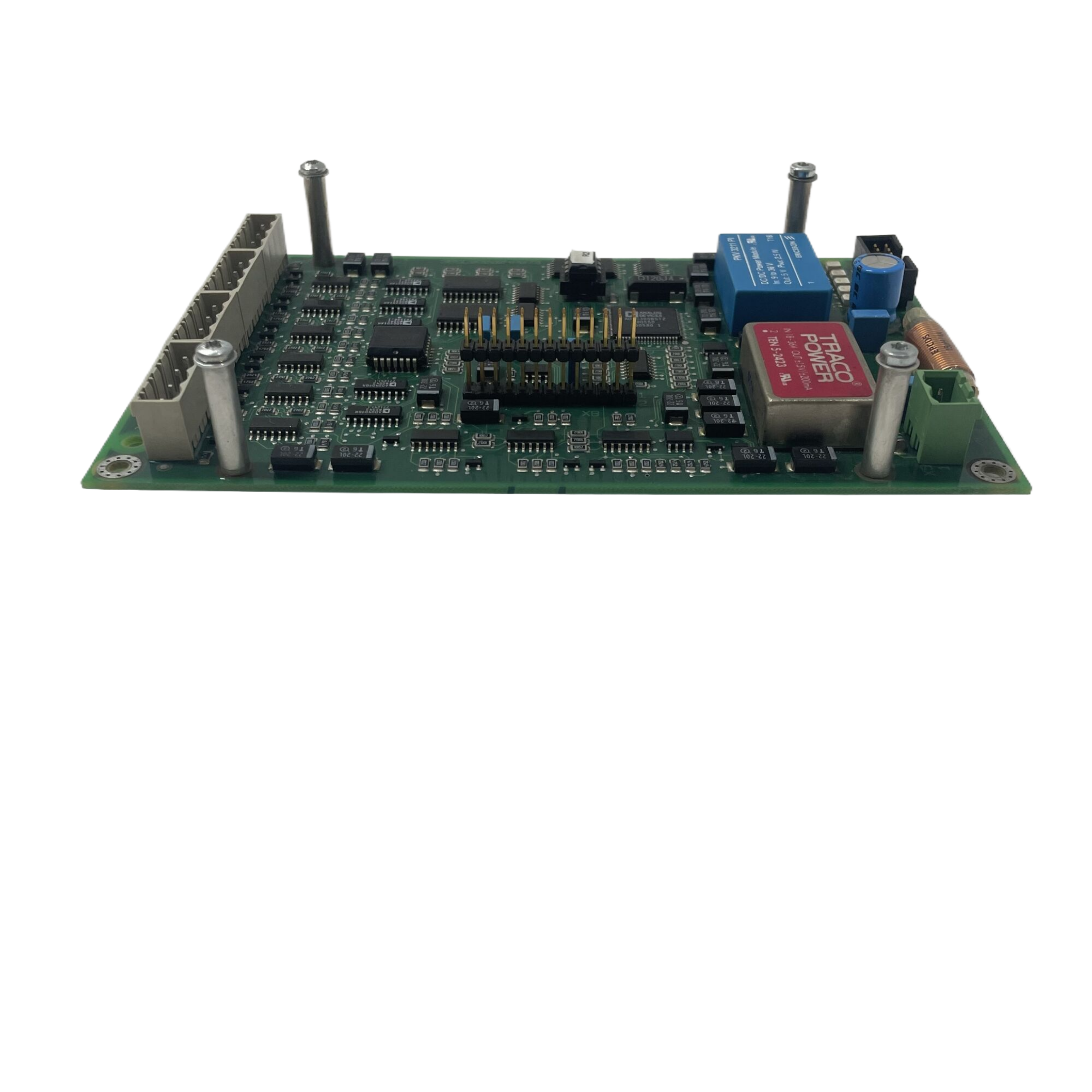

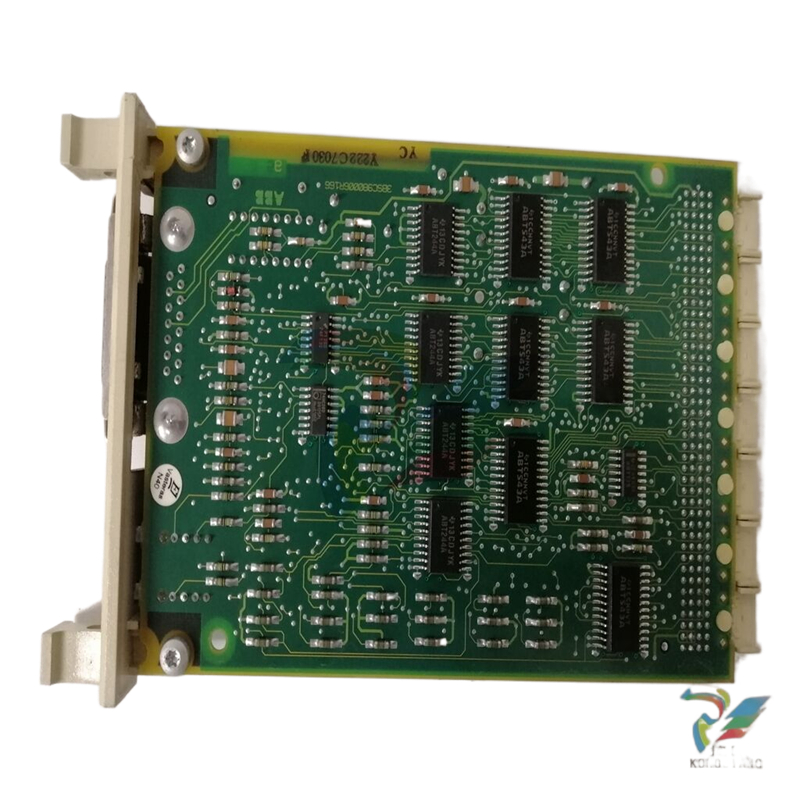

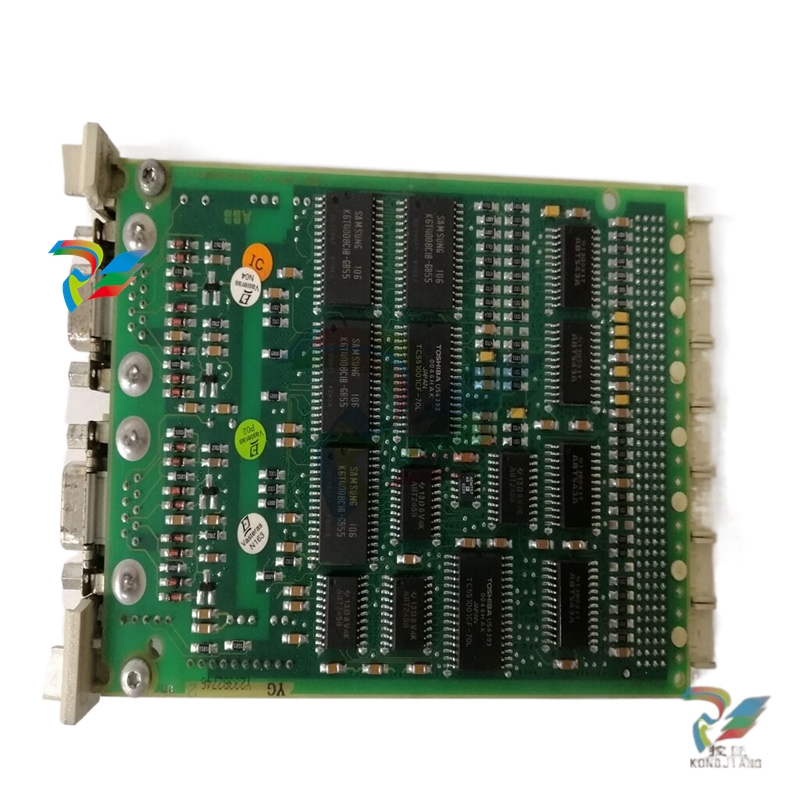

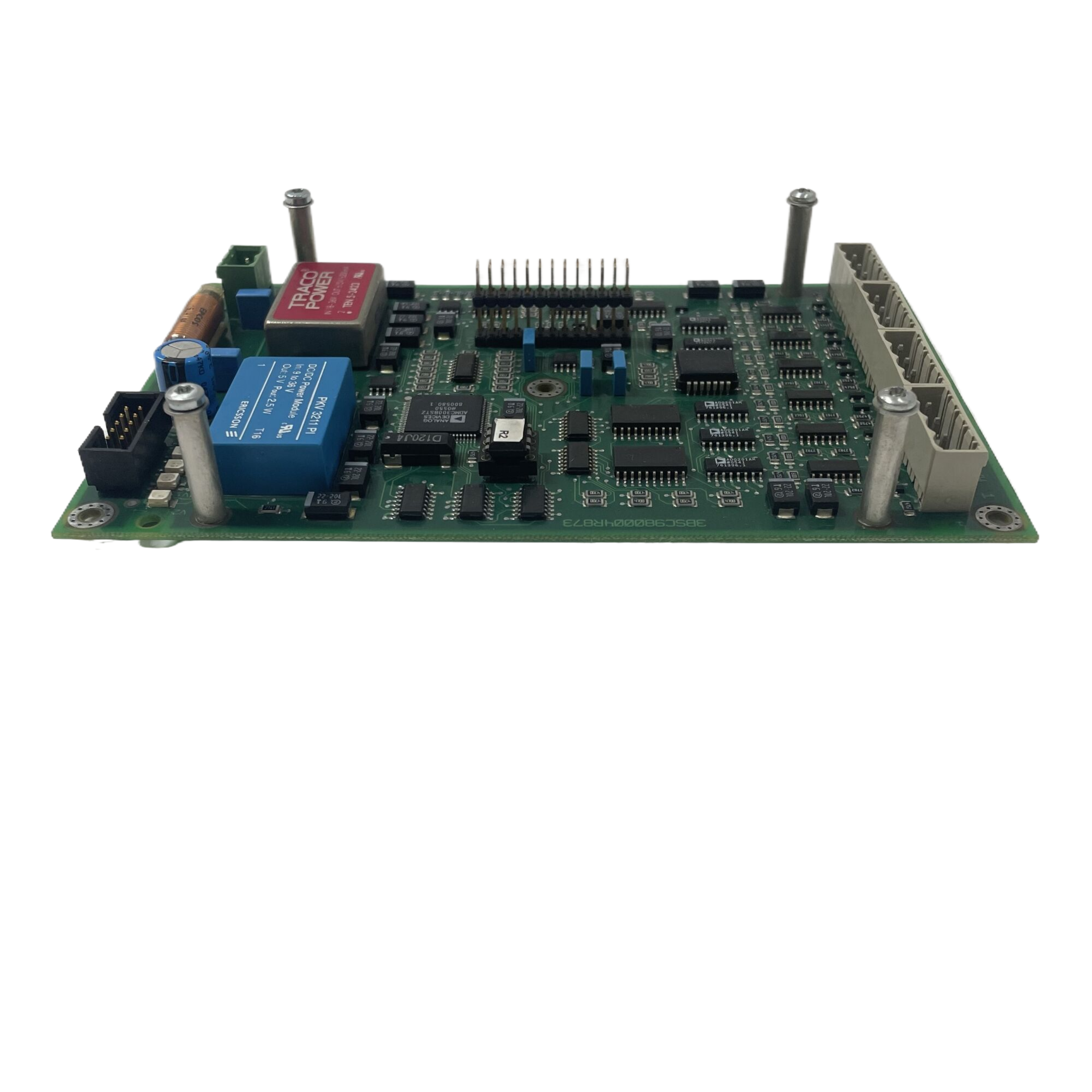

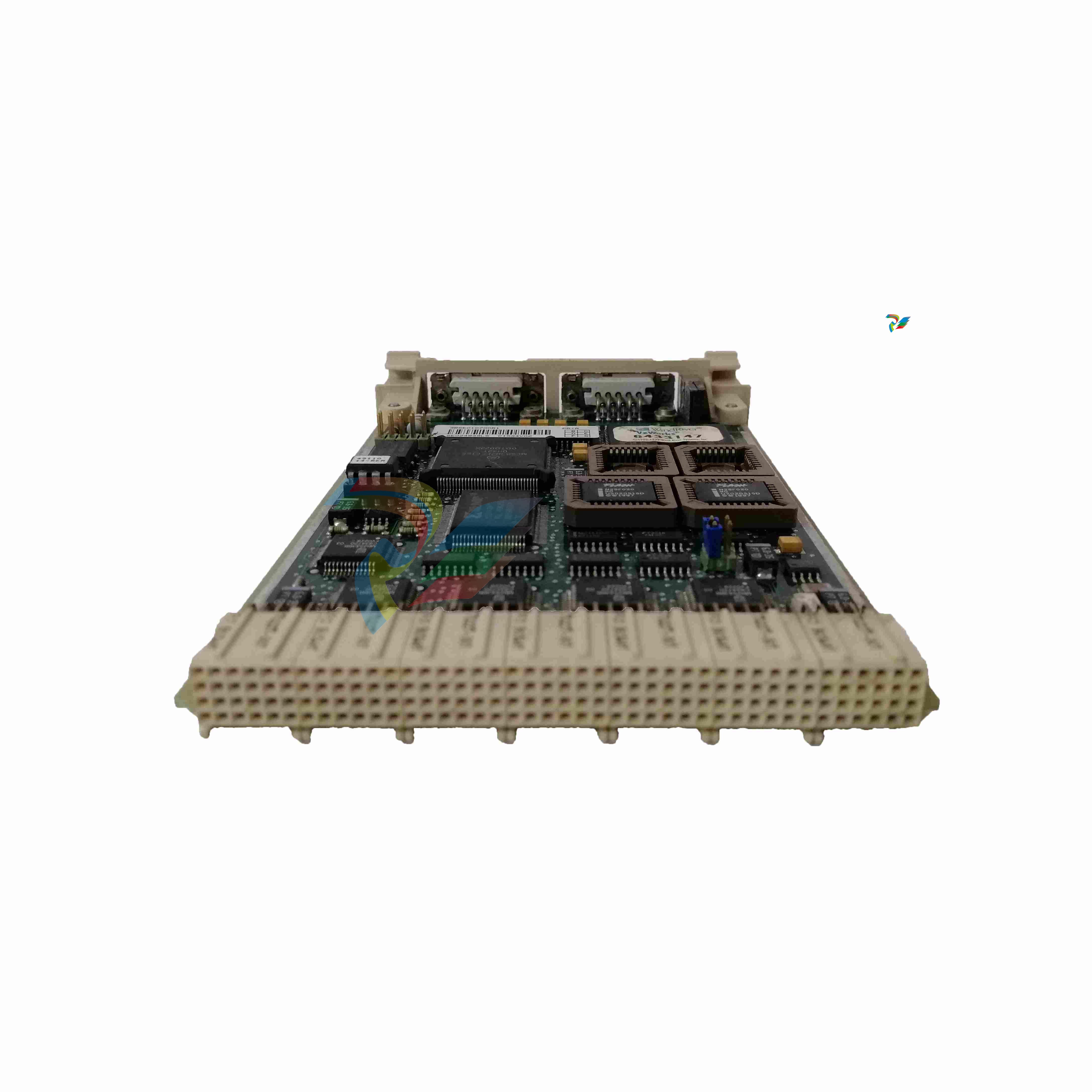

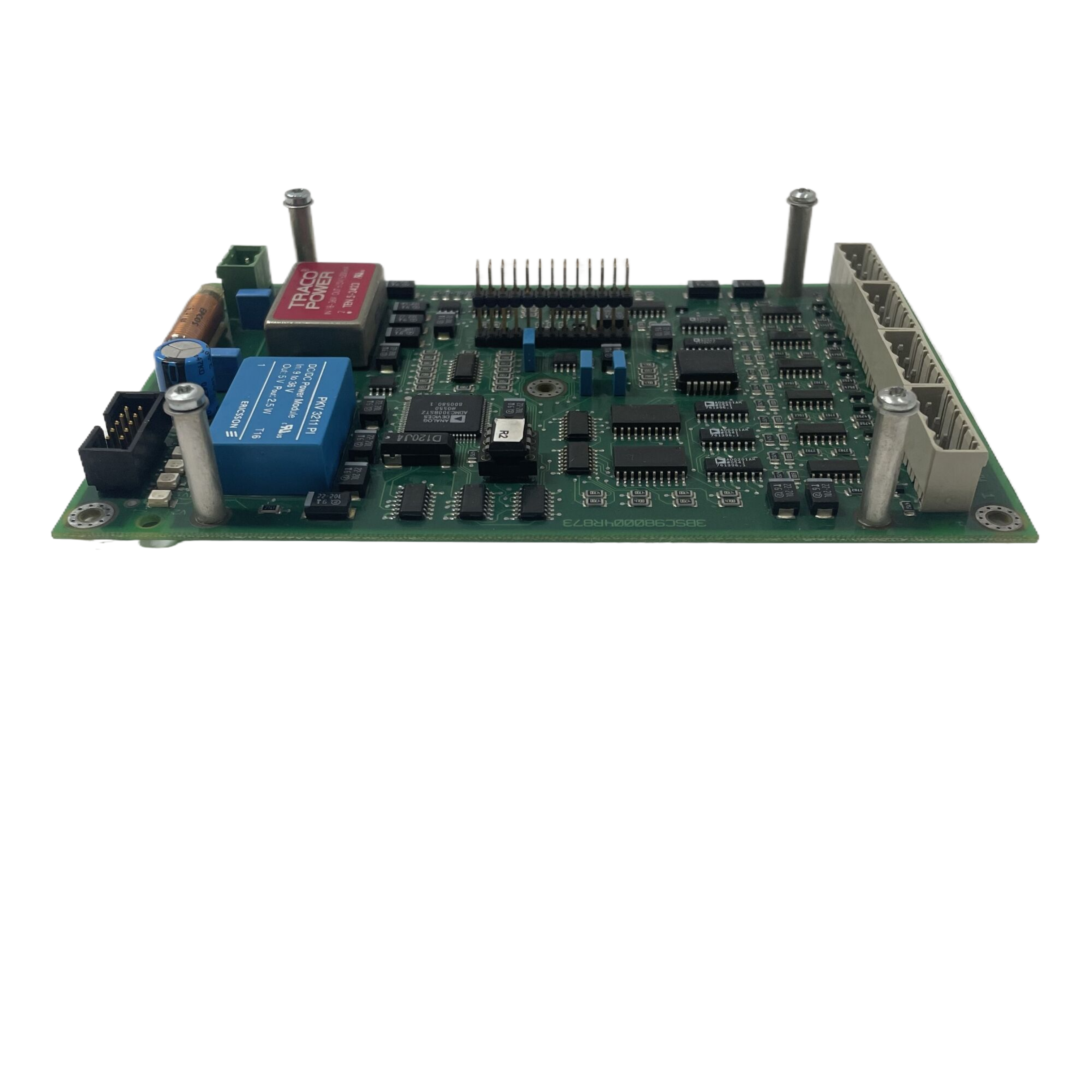

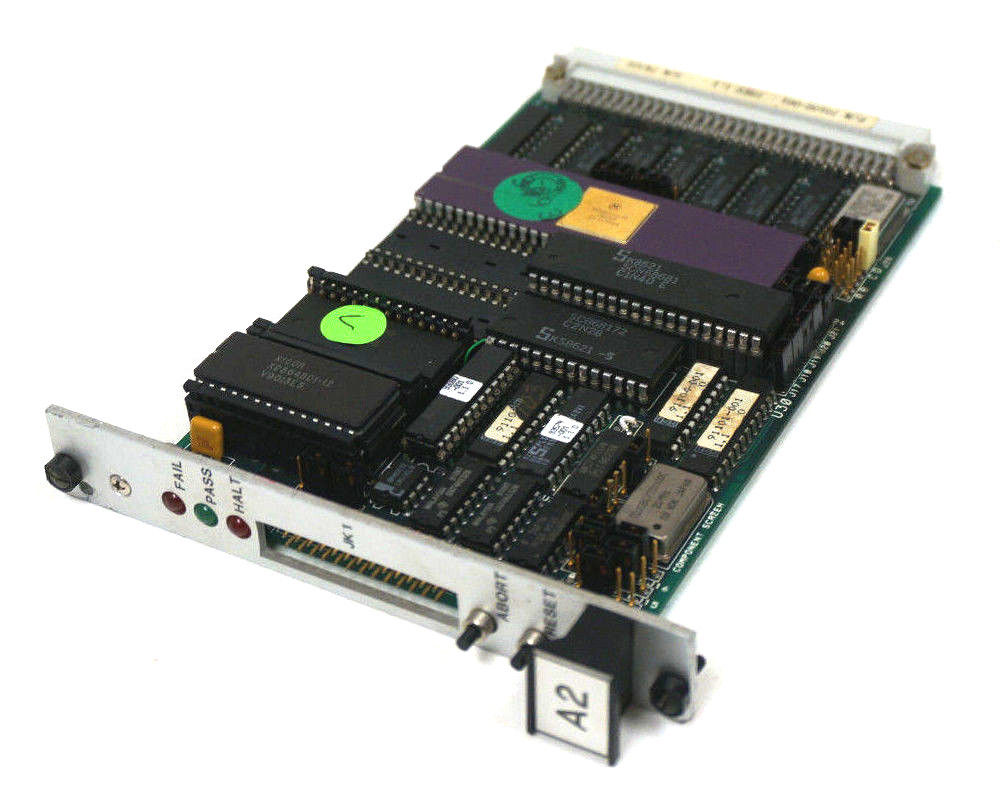

Analog Modules

Base Converter Module - IC697ALG230, Current Expander Module - IC697ALG440

Voltage Expander Module - IC697ALG441

Analog Input System, High Level, 16 Channels

GE IC697ALG230 Analog Input, Voltage/Current, 8 Channels.

Features

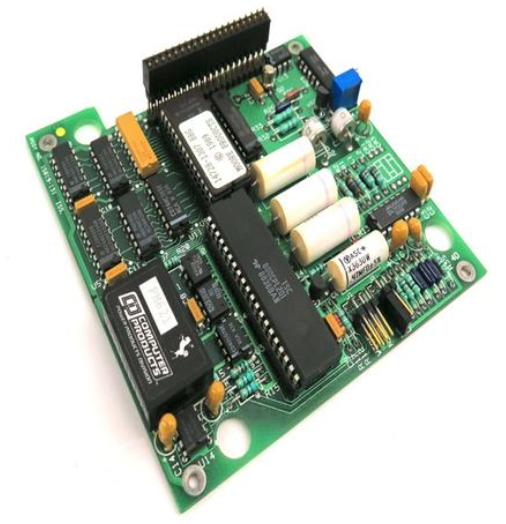

Complete Analog subsystem includes Base Converter

and Expander modules

Base Converter module has eight differential inputs

individually configurable for voltage or current

Accepts unipolar or bipolar Analog Inputs up to " 10

volts full scale

Accepts 4 to 20 milliamp current loop signals

Individual user scaling on each input channel on Base

Converter module; scaling on a per module basis for

Expander modules

Fast update rate for Base Converter module

Voltage and current Expander modules, each with 16

inputs, provides for additional inputs at a lower cost

per point

Complete subsystem can accept up to 120 inputs

No jumpers or DIP switches to configure

Easy configuration with MS-DOSor Windows

programming software configuration function.

Functions

The High Level Analog Input subsystem for the Programmable Logic Controller (PLC) accepts analog inputs of up to Ç 10 volts full scale, or 4 to 20 milliamp

current loop signals. These inputs are converted to

digital form for use by the CPU or other controllers

accessing analog inputs via the VME backplane.

Converted data is presented as 2’s complement (sign

+ 15 bits). The basic converter is 14 bits resolution (1

part in 16384); an oversampling and averaging technique further enhances this resolution. Inputs are

protected against transient and steady-state overvoltage conditions.

Analog inputs use %AI references in the programmable controller. A maximum of 8K words of %AI

memory is currently available in the programmable

controller. Each input channel uses one word (16 bits)

of %AI memory.

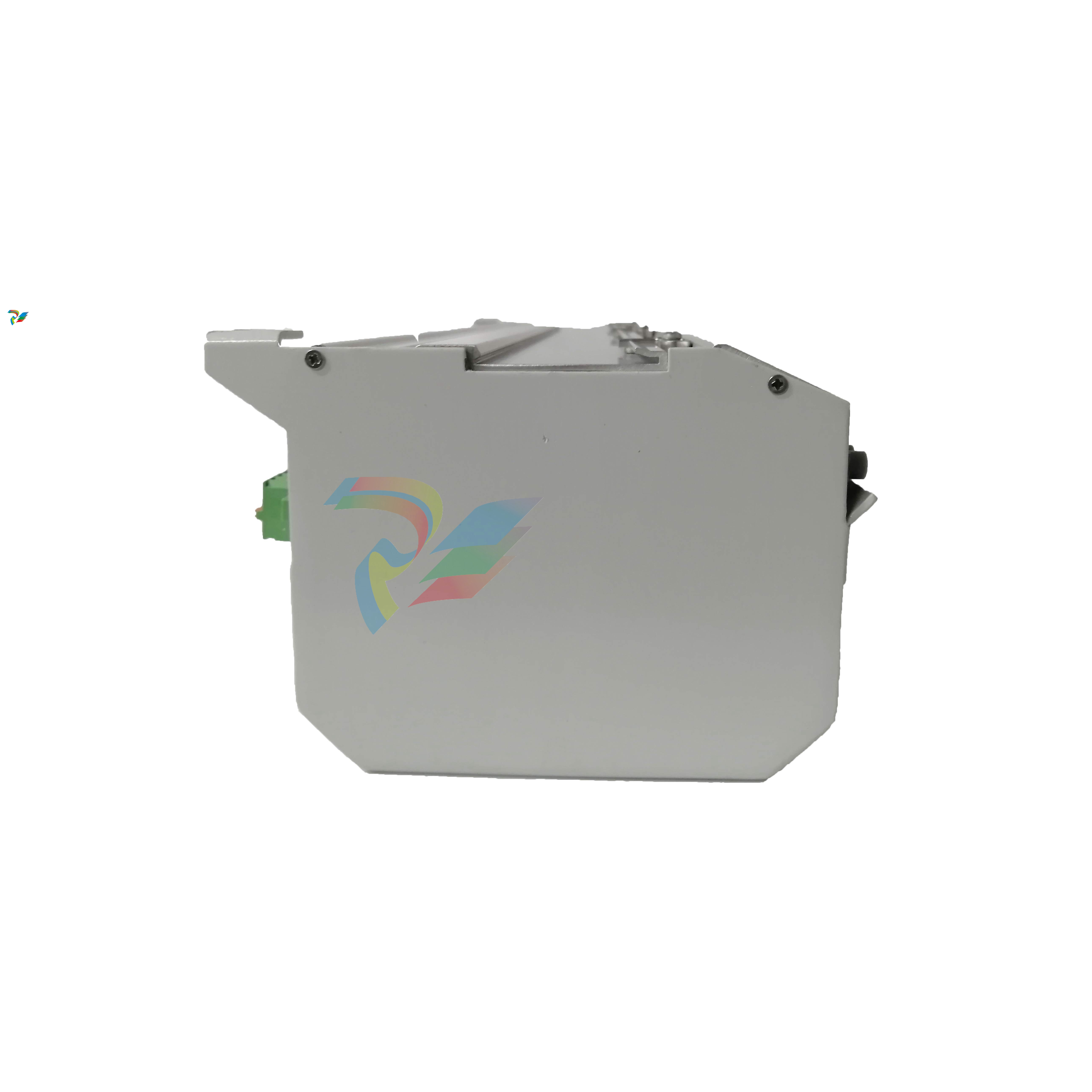

Field wiring is made to a removable terminal board

and the module is mechanically keyed to ensure correct replacement with a similar module type in the

field. I/O references are user configurable without the

use of jumpers or DIP switches on the module.

Configuration is done using the configuration function of the MS-DOS or Windowsprogramming software running on Windows 95 or Windows NT over

Ethernet TCP/IP or through the SNP port. The Programming Software configuration function is installed

on the programming device. The programming device can be an IBM XT, AT, PS/2 or compatible Personal Computer.

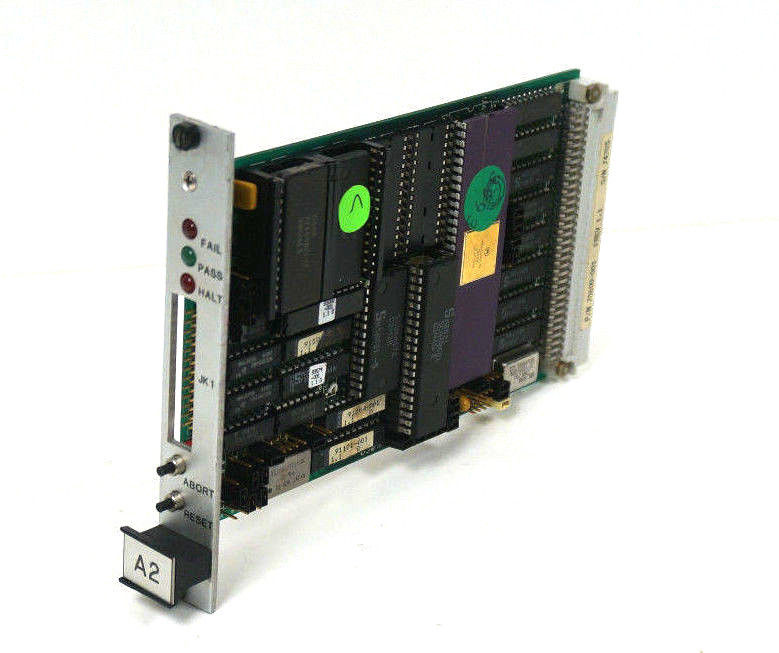

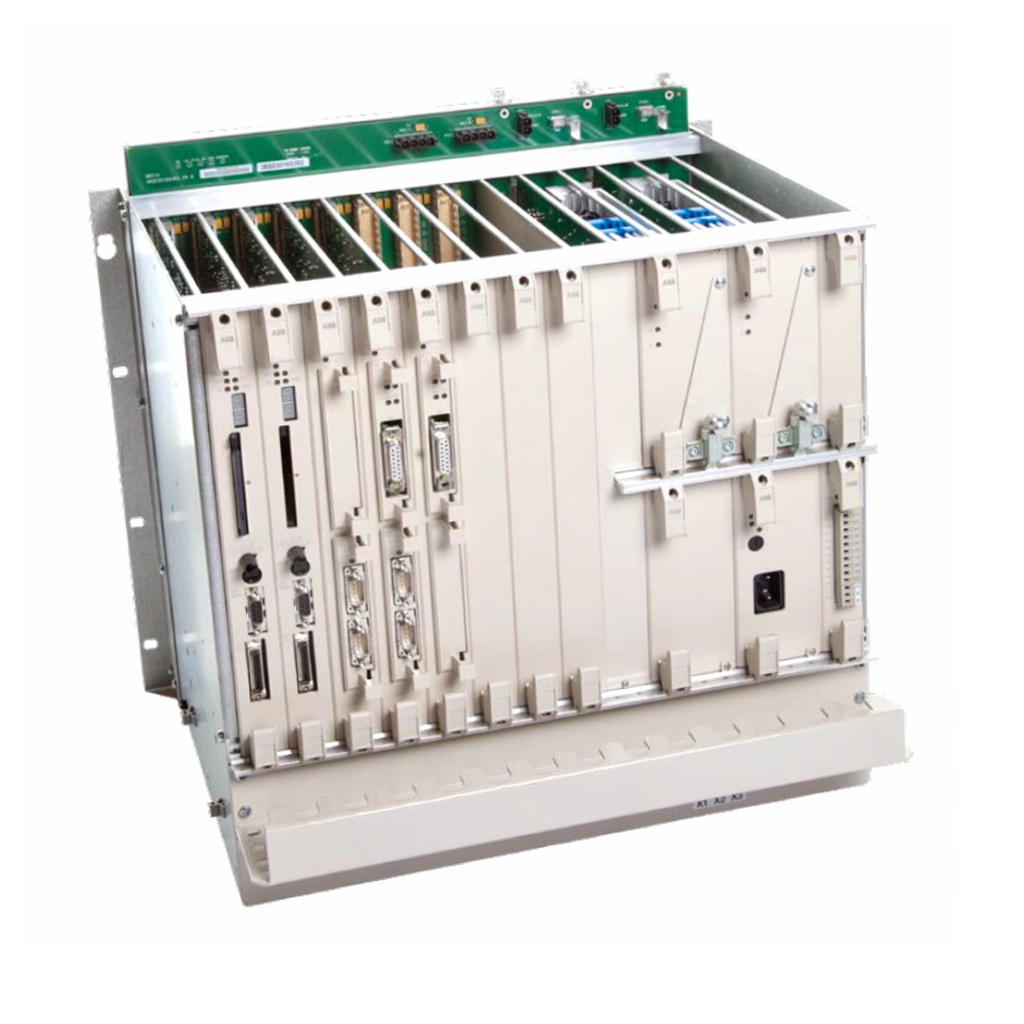

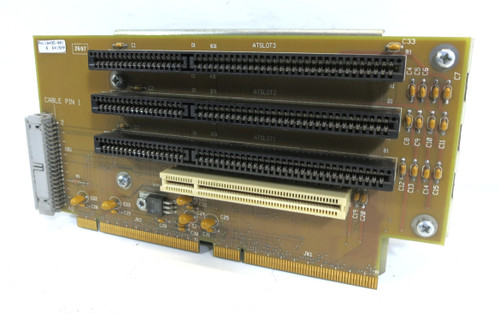

High Level Analog Input System Modules

Three module types are included in the High Level

Analog Input subsystem: a Base Converter module, a

Current Expander module, and a Voltage Expander

module. A typical subsystem will use a Base Convert er module and (if required) one or more expander

modules.

Base Converter module - catalog number

IC697ALG230

This module has eight differential inputs and

an expansion port. Each input can be individu ally configured for either voltage or current.

Each of the input channels also has individual

user scaling.

On-board load resistors are included for normal

input current ranges up to Ç 40 mA. If other

current ranges or different resolution is re quired, external resistors may be used.

Standard system configurations for Ç 10 volts

and 4 to 20 mA are available. These, and other

lower input ranges, can be scaled to engineer ing units with the user scaling feature.

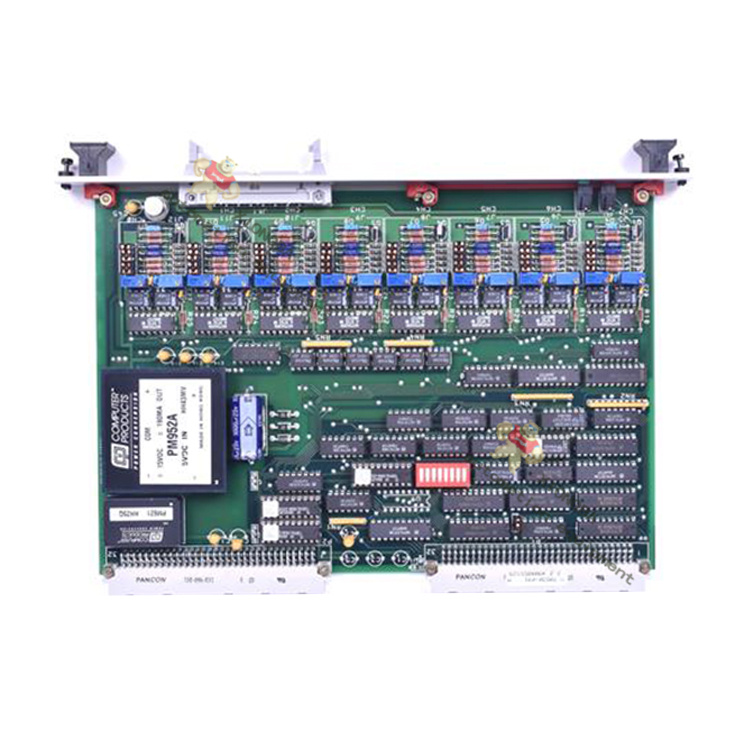

Expander Modules

Up to seven Expander modules can be daisy chained off the Base Converter module to in crease the number of inputs of the total subsys tem up to a maximum of 120.

The Base Converter module accepts any mix of

the two Expander module types.

A common user scaling factor applies to all in puts on each Expander module, however each

Expander module may be individually scaled as

required.

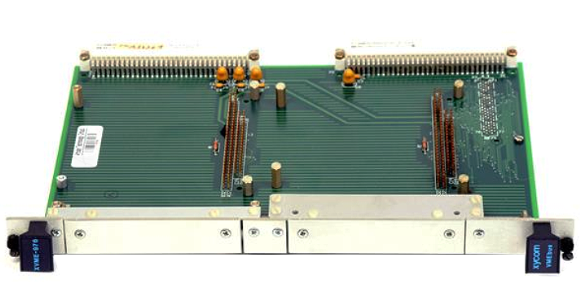

Current Input Expander module - catalog number

IC697ALG440

The Current Expander module has 16 current

inputs each accepting up to Ç 20 mA.

Voltage Input Expander module - catalog number

IC697ALG441

The Voltage Expander module has 16 differen tial voltage inputs each accepting up to Ç 10V

signals.

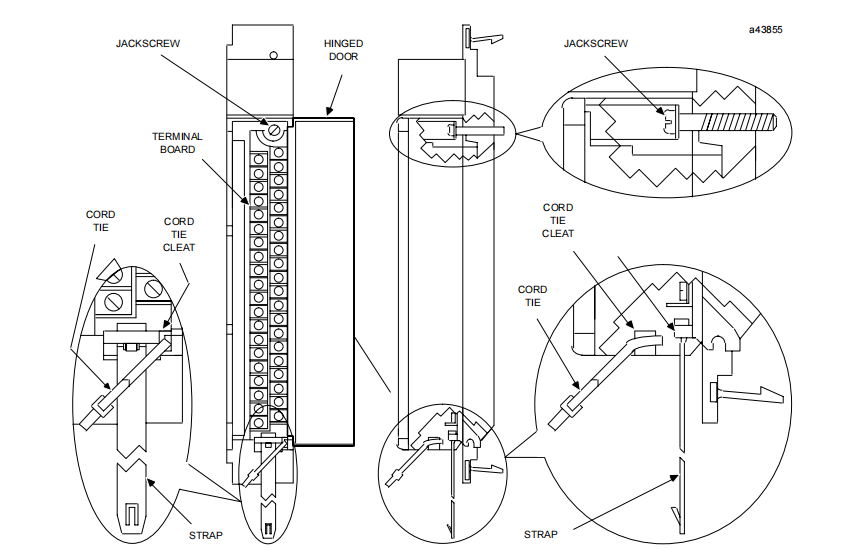

Recommended Field Wiring Procedures

The following procedures are recommended when

connecting field wiring to the detachable terminal

board on an Analog Input Base Converter or Expander module. Module features referenced in the following procedures which are common to all IC697 I/O

modules are illustrated in the following figure.

Figure 8. Removal of I/O Terminal Board

5. After completing connections to all modules in a

rack, the wire bundle must be secured. To ensure

that the wire bundle is secured properly, it is recommended that a cable tie be wrapped around the

wire bundle and tightly secured through the cable

tie cleat located at the lower right corner of the

terminal board. For extremely large wire bundles,

additional cable ties should be used.

6. A door label insert is included with each module to

indicate circuit wiring information and provide

space to record user circuit wiring identification.

A slot is provided on the hinged door to allow for

insertion of this label. If the label is difficult to insert, crease the scored edge before insertion. The

outside label has a color coded stripe to allow

quick identification of the module voltage type

(blue: low voltage; red: high voltage).

7. After field wiring is completed, the terminal board

should be securely fastened to the rack by inserting the terminal board strap (attached to each

module) into the small rectangular slots in the bottom card guide grill on the rack. This strap not

only secures the terminal board to the rack, it also

provides a way of identifying the wired terminal

board with its correct mating rack slot location.

8. For adequate module ventilation, it is recommended that at least a 5 inch (127mm) clearance be

allowed above and below the rack grill. Wire

bundles should not obstruct the rack grill work.

Removing an I/O Module

The instructions below should be followed when removing an I/O module from its slot in a rack.

Grasp the board firmly at the top and bottom of

the board cover with your thumbs on the front of

the cover and your fingers on the plastic clips on

the back of the cover.

Squeeze the rack clips on the back of the cover

with your fingers to disengage the clip from the

rack rail and pull the board firmly to remove it

from the backplane connector.

Slide the board along the card guide and remove it

from the rack.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)