K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

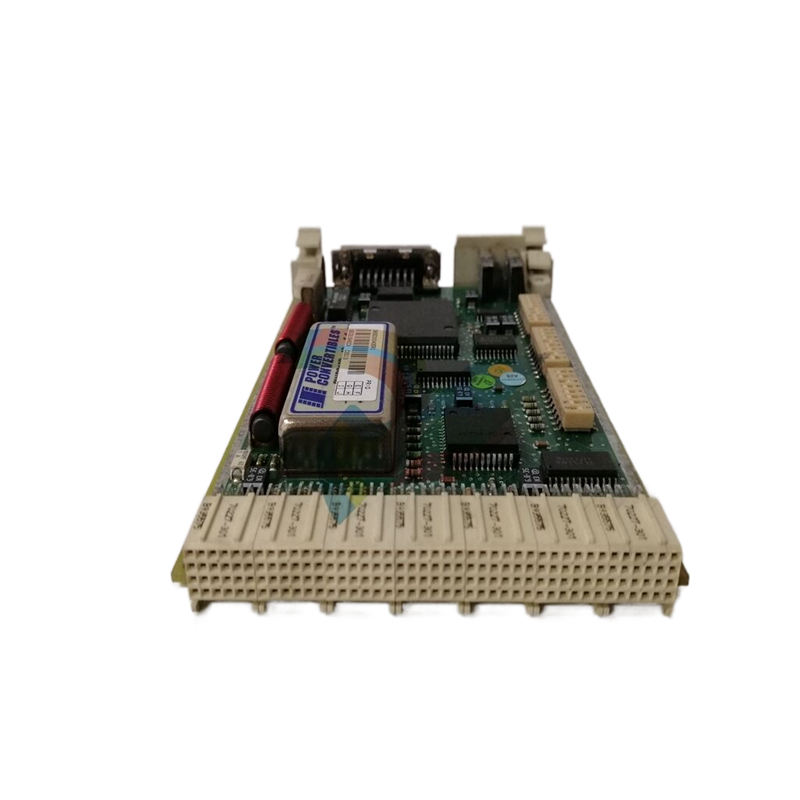

ABB Display Panel TA 144 H&B Contronic

Basic Information

Appearance Features:

The ABB Display Panel TA144 typically has an intuitive display interface. The screen is of a medium size to clearly display a wide range of data and information. The enclosure is typically made of robust materials such as engineering plastics or metal alloys to protect the internal components and to suit the industrial environment. The casing colour is usually an industry-standard colour, such as grey or black, and the surface may be specially treated to provide some resistance to scratching, abrasion and corrosion.

On the front of the panel, in addition to the display, there will be some buttons or operation areas to facilitate the user's operations such as parameter setting and function selection. These buttons are well laid out, clearly labelled and easy to operate.

Size and Installation:

The exact size will vary according to the design, but it is generally a compact rectangular shape, which is convenient to be installed in the front panel of the control cabinet or other suitable locations. It can be fixed by screw fixing, snap mounting or rail mounting to ensure that it can be firmly placed during the operation of industrial equipment.

Functional features

Display Functions:

Capable of displaying a wealth of information, including but not limited to equipment operating status (e.g., running, stopped, fault, etc.), process parameters (e.g., temperature, pressure, flow rate, etc., numerical values), and alarm information (expressed in text or specific symbols). The resolution of the display can meet the clear display requirements in industrial environments, and the text and graphics are displayed clearly and accurately, making it easy for users to read the information quickly from a certain distance.

Supports a variety of display modes, such as digital display, graphic display (such as trend charts, bar charts, etc.) and character display. It can be flexibly switched according to the specific needs of users and different application scenarios, providing users with an intuitive way of data analysis and monitoring.

Interactive function:

Through the keys on the panel, users can perform various operations on the device. For example, setting the upper and lower limits of parameters, switching the display page, confirming alarm messages, starting or stopping the related equipment, etc. The buttons have good tactile feedback, and the operation will have clear pressing and popping sensation to prevent misoperation.

It may also support some advanced interactive functions, such as password protection function, which is used to restrict certain key operations, and only authorised users can carry out operations such as setting modification to improve the security of the system.

Communication functions:

Usually equipped with a communication interface that enables data communication with other devices (e.g. PLCs, controllers, sensors, etc.). It supports common industrial communication protocols, such as Modbus, Profibus, etc., to achieve real-time data transmission and sharing. Through the communication function, it can receive data from other devices for display, and can also send the parameters set by the user on the panel to other devices to achieve collaborative work.

Application Areas

Industrial automation control:

In various industrial production processes, such as chemical, electric power, metallurgy, pharmaceutical and other industries, it is used as the human-machine interface (HMI) of the equipment to monitor the operation status and process parameters of the production equipment. Operators can use the TA144 panel to keep abreast of whether the equipment is running normally and whether various key parameters are within normal limits, and to be able to react quickly in the event of an abnormal situation.

For example, in chemical production, it can display the temperature, pressure and stirring speed of the reaction kettle, helping operators to accurately control the reaction process to ensure product quality and production safety.

Equipment monitoring and management:

It is used to monitor and manage various industrial equipments, such as motors, pumps, compressors and so on. It can display the running time, fault code and other information of the equipment, which is convenient for maintenance personnel to carry out equipment maintenance and troubleshooting. By communicating with the control system of the equipment, it can also achieve remote monitoring and improve the efficiency of equipment management.

Intelligent building system:

It is also used in the heating, ventilation and air conditioning (HVAC) system and lift control system of intelligent buildings. For example, in the HVAC system, the indoor temperature, humidity, and operating status of air conditioning equipment can be displayed, and users can perform operations such as temperature setting through the panel to achieve comfortable control of the indoor environment.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923