K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Move your platform applications into the future with the new Allen-Bradley PanelView Plus from Rockwell Automation. PanelView Plus is ideal for applications with a need to monitor, control, and display information graphically, allowing operators to quickly understand the status of their application. A cornerstone of the ViewAnyWare strategy, PanelView Plus is programmed with RSView Studio Machine Edition. It combines the best features from the popular Allen-Bradley PanelView Standard and PanelView “e” operator interface products and adds new functionality

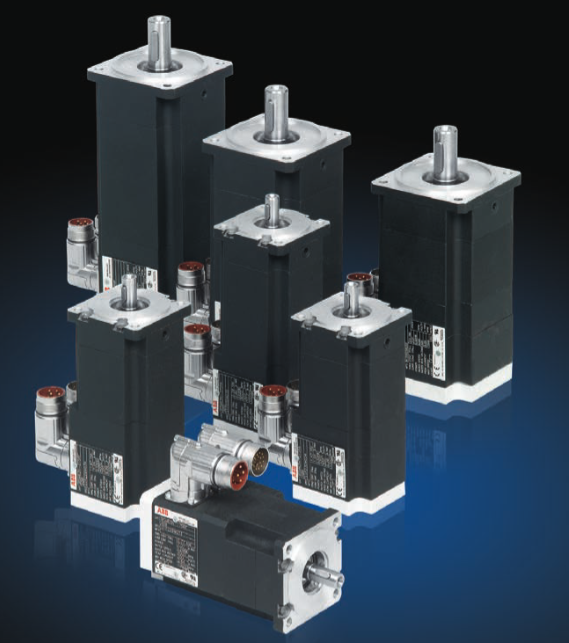

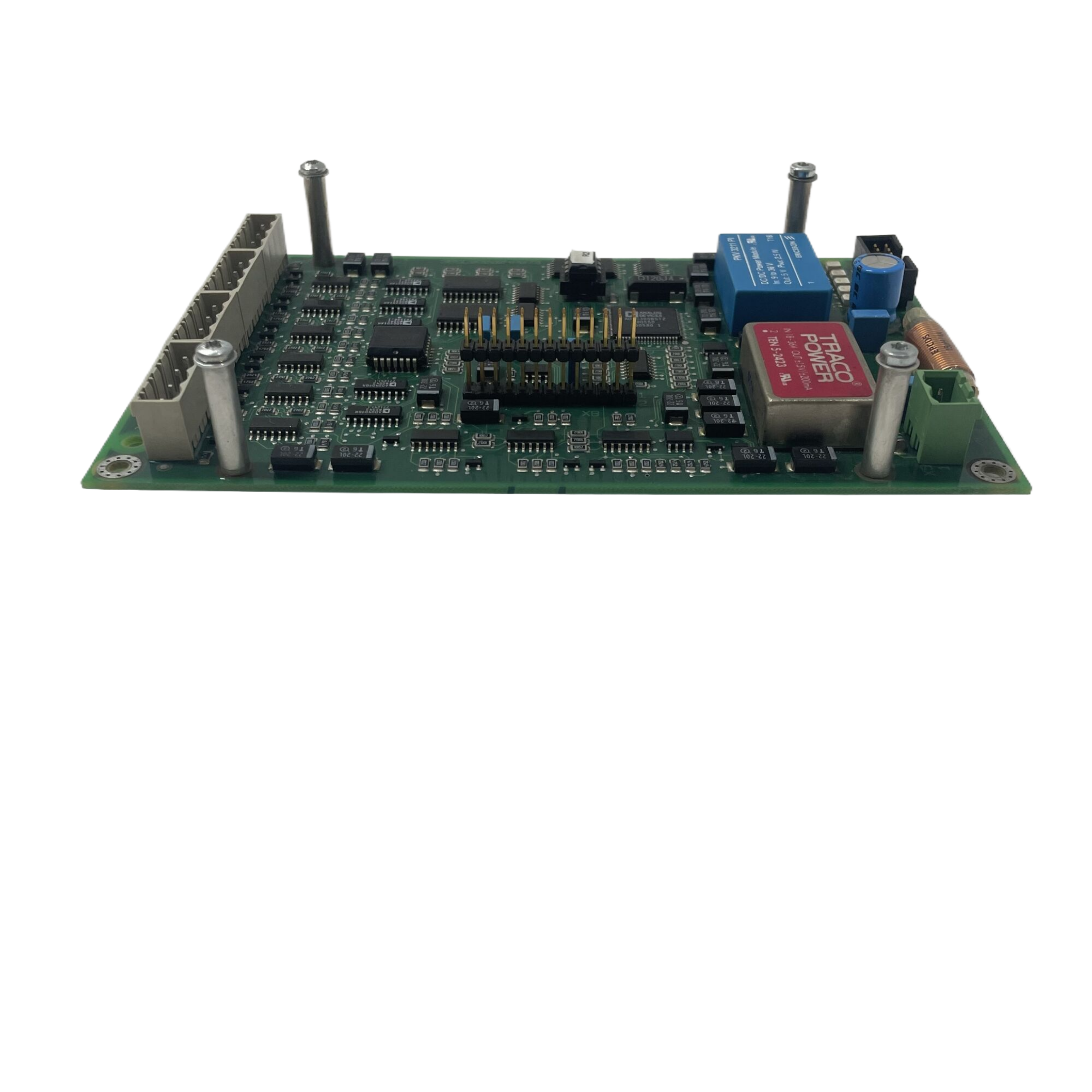

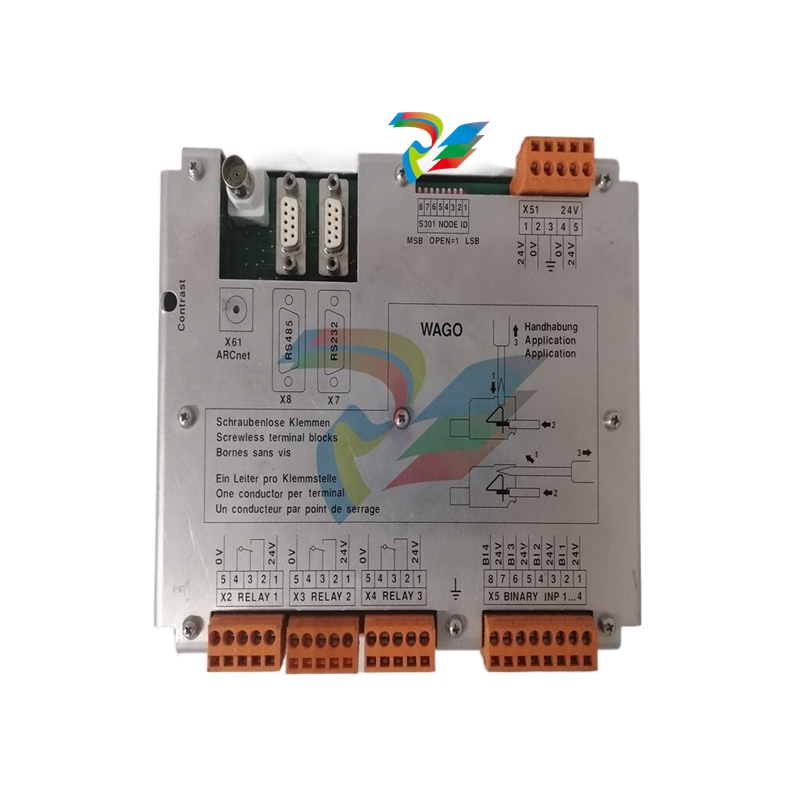

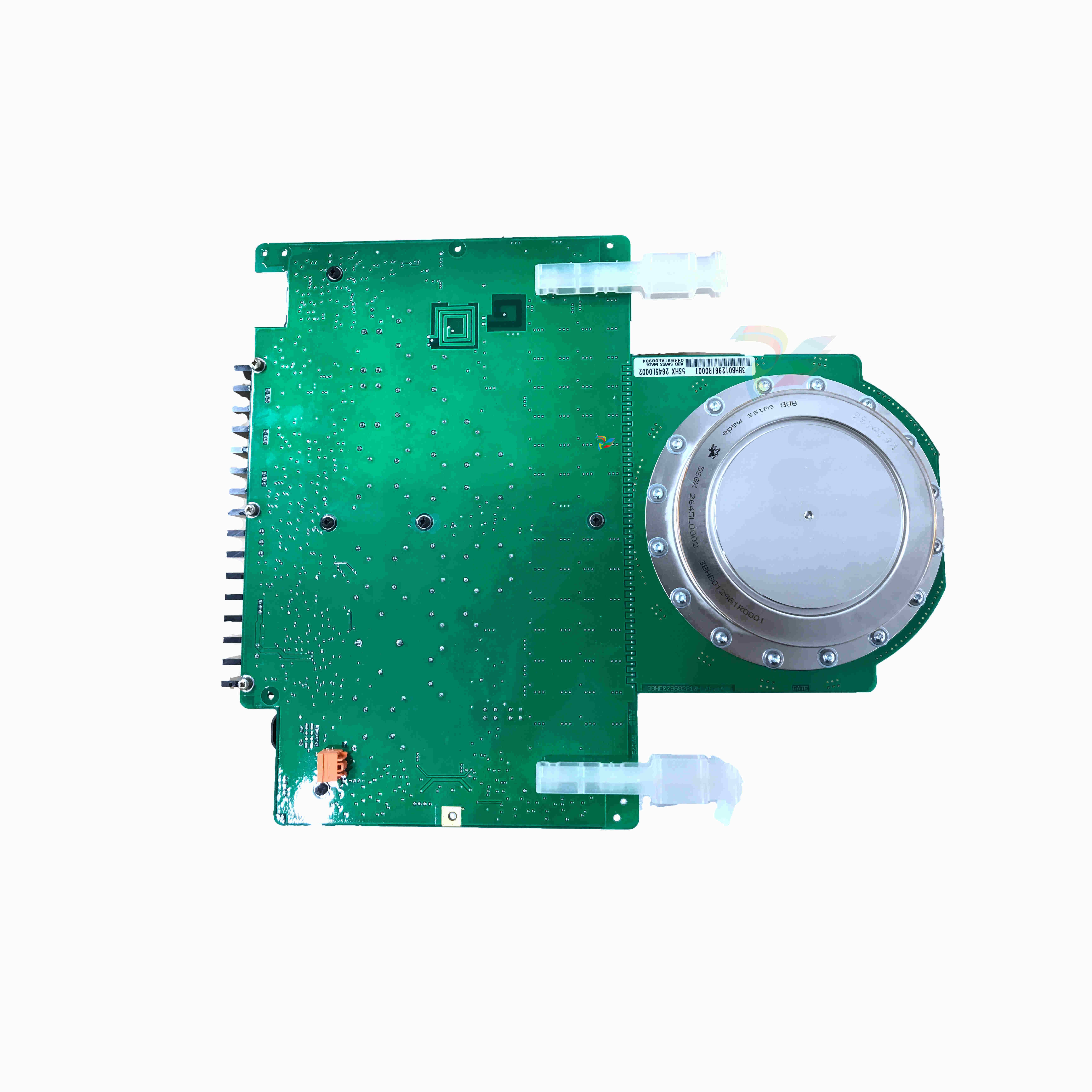

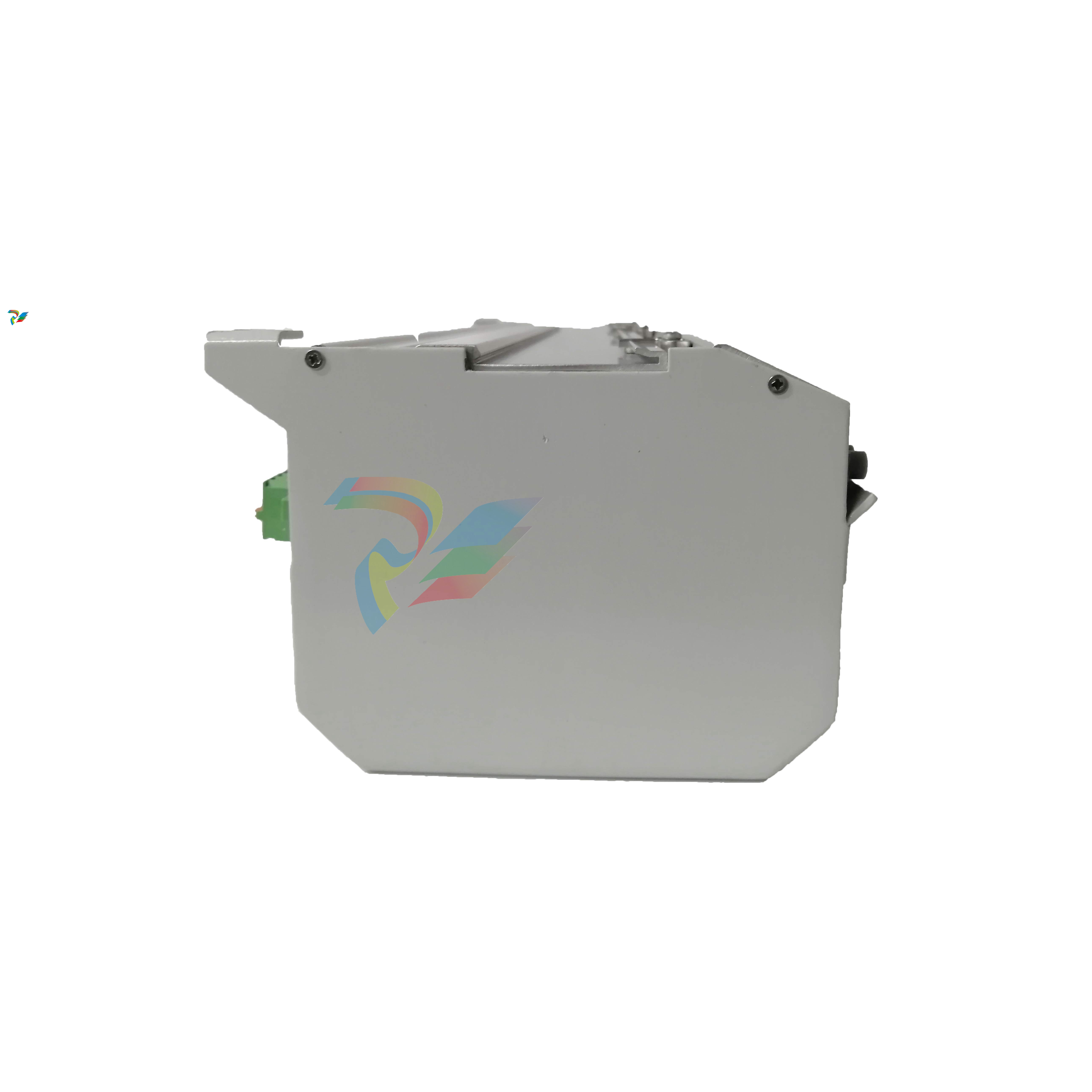

KOLLMORGEN-903-200003-06 AKD Digital Driver Driver

Use according to instructions

AKD drivers are specifically designed to drive suitable synchronous servo motors and can provide closed-loop control of torque, speed, and/or position

Control. AKD is a component built into electrical equipment or machines, and can only be used as an integrated component of these devices or machines

Operate on it. Manufacturers of machines using drivers must conduct risk assessments on the machines. When in a machine or device

When there is a built-in driver, unless it has been determined that the machine or device meets the requirements of the following area instructions, it shall not

Use a driver.

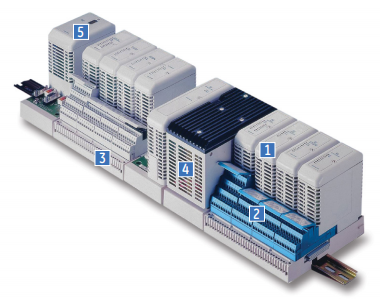

Cabinet and wiring

Drivers can only be operated in enclosed cabinets under suitable environmental conditions (➜ # 33). To ensure low temperature inside the cabinet

At 40 ° C, ventilation or cooling may be required.

Only copper wires can be used for wiring. The cross-section of the wire can comply with the IEC 60204 standard (which also applies to

AWG cross-section: NEC Table 310-16. column 75 ° C.

Power Supply

The driver can be powered by a single-phase or three-phase industrial power network.

Drivers from the AKD series can be provided, with specific details as follows:

Models with hardware revisions F, FA, or FB

AKD-xzzz06:1 or 3-phase industrial power network (at 100-240 V).

Models with hardware versions A, C, D, E, DB, DA, EB, or EA

AKD-xzzz06:1 or 3-phase industrial power network (at 120 V/240 V).

AKD xzzz07: 3-phase industrial power network (at 240 V, 400 V, and 480 V).

If there are additional isolation transformers, they can be connected to power networks of other voltage types (➜ # 104).

AKD-x04807: When the power supply voltage asymmetry is greater than 3%, the power supply choke coil 3L0. 24-50-2 must be used.

The periodic overvoltage between each phase (L1. L2. L3) and the driver housing shall not exceed 1000 V. According to IEC

61800. the voltage spike (<50 µ s) between each phase shall not exceed 1000 V. Voltage spike between phase and shell

The peak (<50 µ s) shall not exceed 2000 V.

The user must perform EMC filter measurement for AKD-xzzz06.

For group devices and DC powered drivers

AKD has not been evaluated by Kollmorgen, UL, or T Ü V's group devices, nor has it specified the amount of DC input voltage

Fixed value.

It is necessary to check and evaluate the branch protection *, wire size, wire voltage rating, fuse protection, and system of the group device

Dielectric requirements, overvoltage, and rated input current.

If it is a DC powered driver, the built-in EMC filter will not work. The user is responsible for keeping the drive within the specified range

Conducted emissions and immunity within the noise level range.

*Special attention must be paid to the branch design with rated hybrid drives to avoid more compact drives becoming effective "fuses"

Circuit breakers, not circuit protection fuses.

**The power system design must ensure that the input current is limited during power on in order to provide surge current protection. Must be correct

Connect the polarity of the DC power supply. If the polarity connection of the DC power supply is improper, it will damage the driver, making it unable to operate

Enjoy warranty.

Rated voltage of the motor

The rated voltage of the motor must be at least equal to the DC bus voltage of the driver divided by √ 2 (UnMotor>=UDC/√ 2).

Safe torque off.

Before using this safety feature (compliant with ISO 13849 Class 3), please read the "Use as directed" section in the STO chapter

Model - Packaging size (mm) HxWxL - Total weight AKD-B. - P. - T (kg) - Total weight AKD-M (kg)

AKD-x00306 . -x00606 113 x 250 x 222 1.7 1.9

AKD-x01206 158 x 394 x 292 3.4 3.6

AKD-x02406 158 x 394 x 292 5 5.2

AKD-x00307. -x00607. -

x01207

158 x 394 x 292 4.3 4.5

AKD-x02407 158 x 394 x 292 6.7 6.9

AKD-x04807 390 x 600 x 400 15.3 15.5

5.2.1 European directives and standards of machine manufacturers

Drivers are built-in components in industrial electrical equipment and machines. When a machine or device has a built-in driver,

Drivers shall not be used unless it has been determined that the machine or equipment meets the requirements of the following standards

EC Machine Directive (2006/42/EU)

EC EMC Directive (2004/108/EU)

EC Low Voltage Directive (2006/95/EU)

The standards required to comply with the EC Machinery Directive (2006/42/EU)

IEC 60204-1 (Safety and Electrical Equipment in Machines)

ISO 12100 (Safety of Machines)

Machine manufacturers must conduct risk assessments on their machines and take appropriate measures to ensure that unexpected movements do not cause harm

Personal injury or property damage.

Standards required to comply with the EC Low Voltage Directive (2006/95/EU)

IEC 60204-1 (Safety and Electrical Equipment in Machines)

IEC 60439-1 (Low voltage switchgear and control gear)

Standards required to comply with the EC EMC Directive (2004/108/EU)

IEC 61000-6-1/2 (Immunity in residential and industrial areas)

IEC 61000-6-3/4 (Interference Generation in Residential and Industrial Areas)

Machine/equipment manufacturers are responsible for ensuring that machines/equipment comply with the limitations required by EMC specifications. This manual provides information on

Suggestions for proper installation of EMC, such as shielding, grounding, handling of terminal blocks, and cable layout.

Machine/equipment manufacturers must check whether other standards or EC directives should be applied to the machine/equipment.

Kollmorgen only guarantees that the servo system meets the standards mentioned in this chapter, provided that the corresponding components (motor, electrical)

Cables, chokes, etc. are all provided by Kollmorgen.

5.2.2 Compliance with RoHS

The manufacturing of this device complies with RoHS Directive 2011/65/EC and has been commissioned to be installed on the machine according to Directive 2015/863/EC

In the middle.

5.2.3 Compliance with REACH

EU Regulation No. 1907/2006 specifies the registration, evaluation, authorization, and restriction of Chemical 1 (abbreviated as

REACH ").

AKD does not include any substances (CMR substances) listed in the candidate product list that exceed 0.1 mass percentage per product

Quality, PBT substances, vPvB substances, and similar hazardous substances specified based on scientific standards for various situations.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)