K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

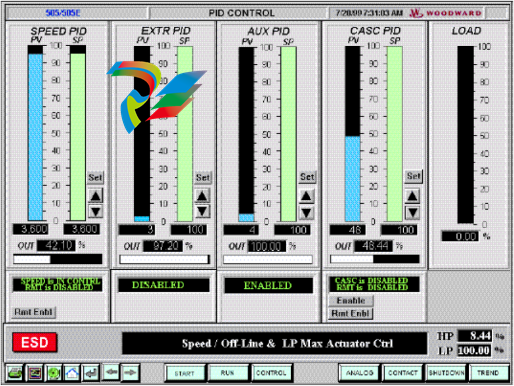

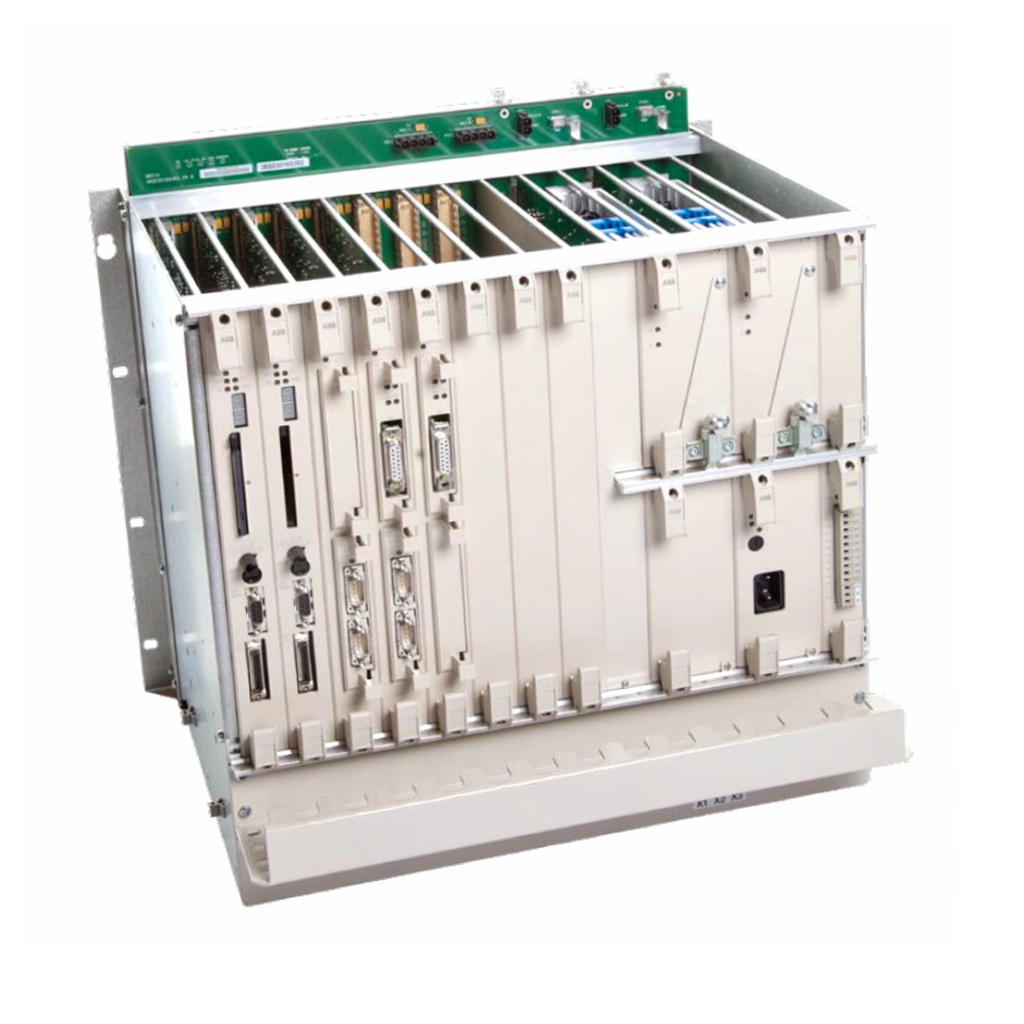

Woodward offers two different HMI software packages - OpView and 505View - to enable operation

Operators can remotely browse operational inputs, adjust controller settings, issue operating mode commands, and

And monitor/troubleshoot the turbine controller. Both HMI software packages can be automatically configured to reduce

Small on-site workload - able to automatically set its screen display according to the programming configuration of 505E.

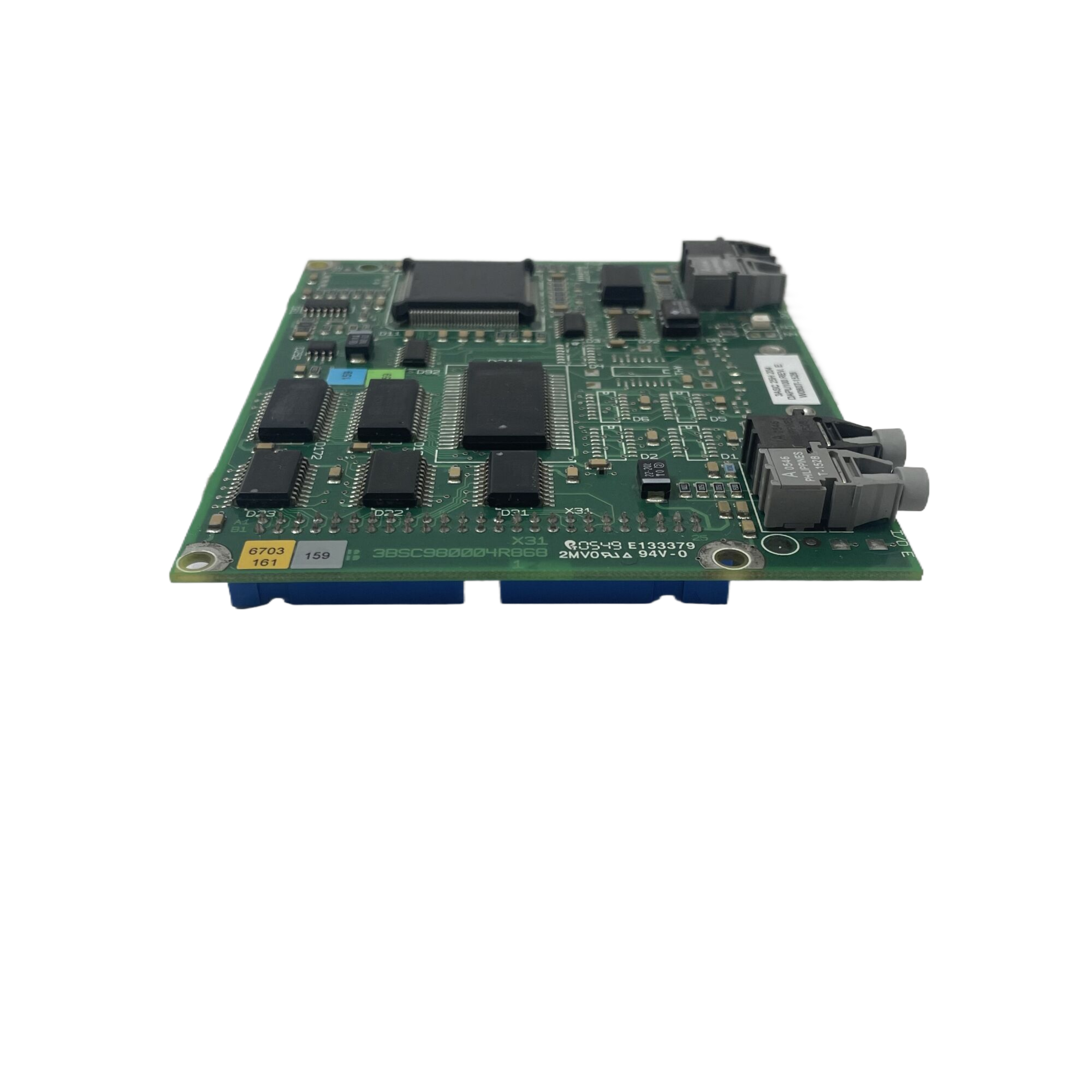

Woodward-505E 8200-1302-digital controller

1-1. 505 human-machine interface software

By connecting OpView or 505View to any Modbus of 505E Interface connection, it comes from

Configure its screen display to match the programming application of the 505E. If 505E is not available

The HMI is configured to accept Modbus commands and can only be used as a system monitor. If 505E

If configured to accept Modbus commands, the 505E operating mode can be monitored and executed through HMI

All operations under the formula (start, stop, mode input/output, given value rise/fall). For safety reasons

Consider that the overspeed test function cannot be performed through HMI. Further information on Modbus interface programming

Please refer to Chapter 7 of Volume 1 for information.

The user-friendly touch screen allows operators to browse and control multiple screens from a single display screen

Operation mode and given value. Featuring 10 different screen displays for users to browse flexibly

Look. These screens will display the following information:

• Control parameter information

• Complete startup program

• Turbine and/or generator information

• Speed, extraction/replenishment, auxiliary, cascade, and limiter information

• Simulate input and output values

• Contact input/relay output status

• Alarm and shutdown records

OpView or 505View is connected to 505E through serial RS232. RS422. or RS485 communication

Take it. Using RS422 and RS485 communication, the HMI can be located as far away as the 505E digital controller

4000 feet (1220 meters) away.

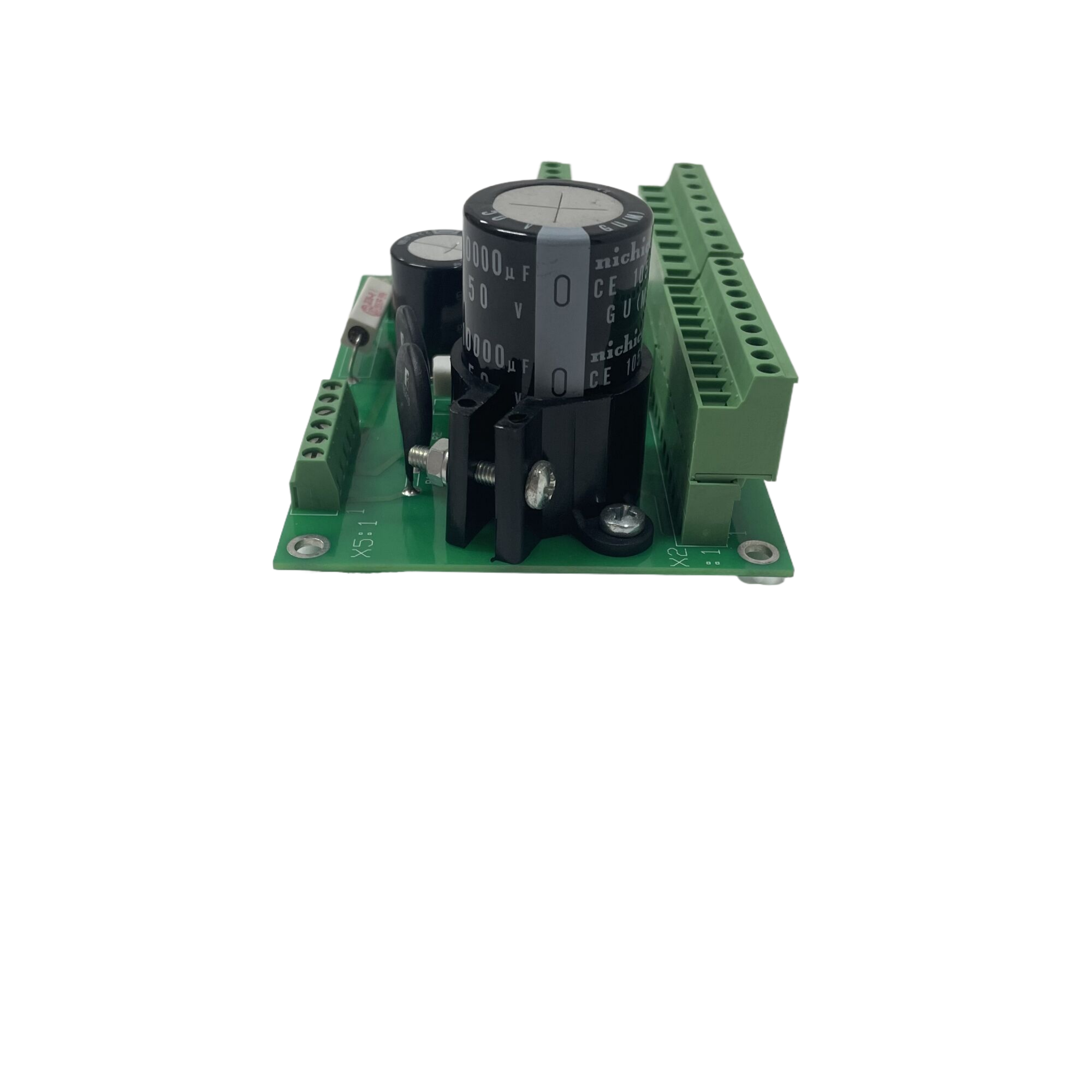

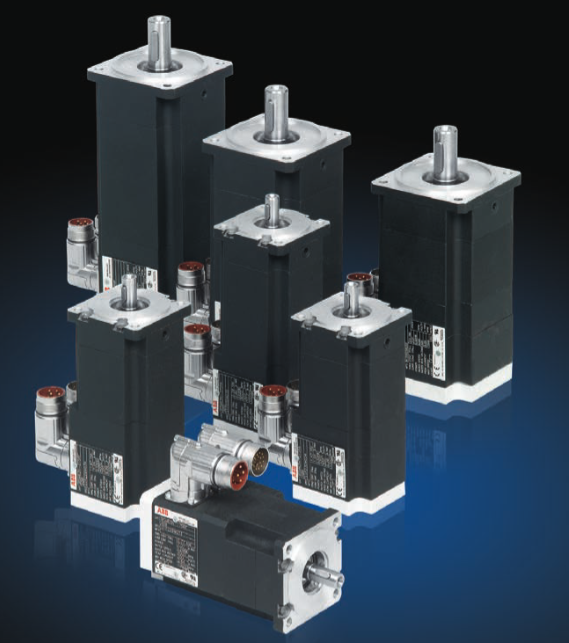

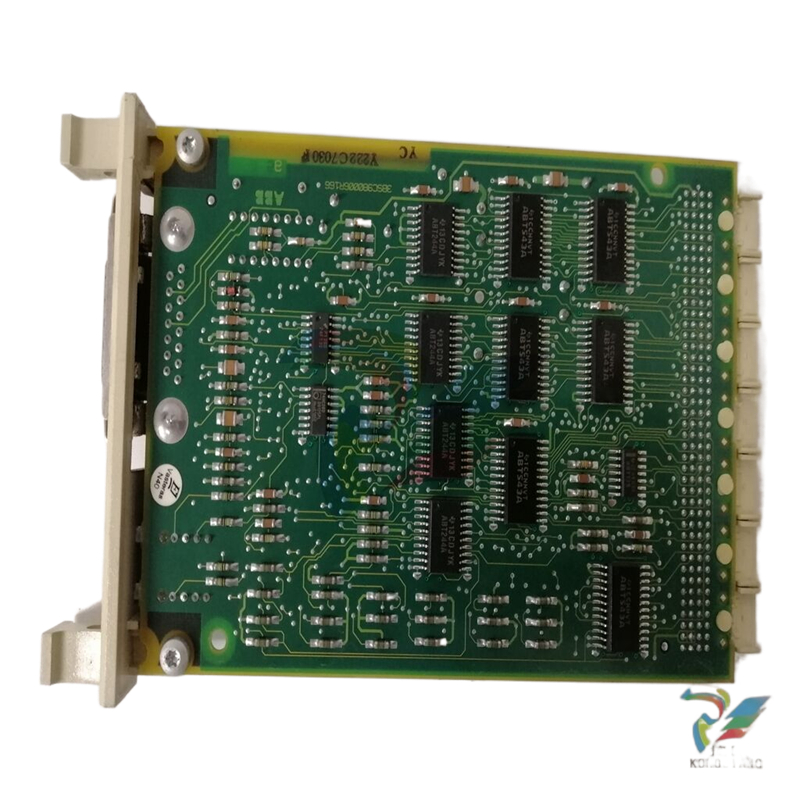

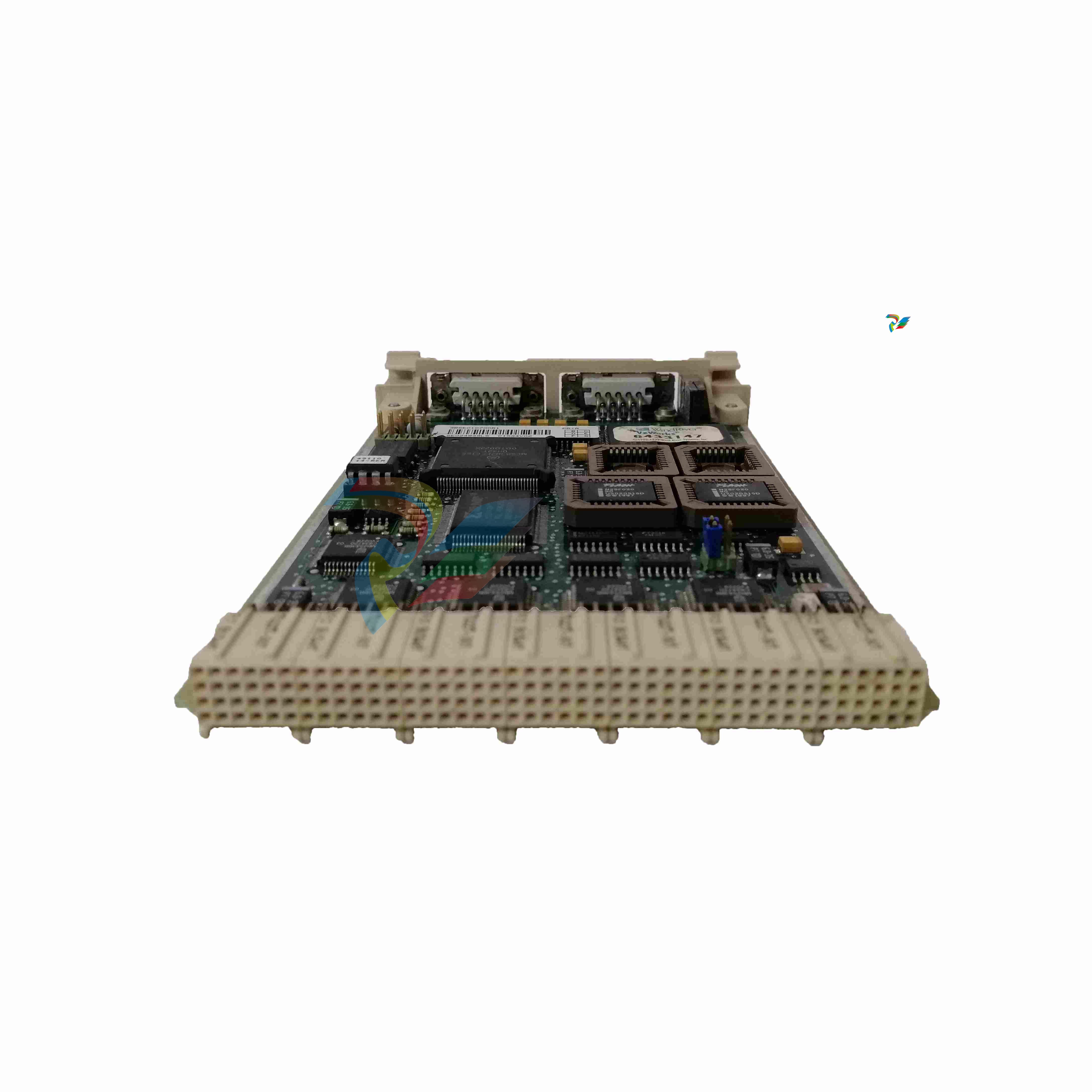

Digital remote terminal driver

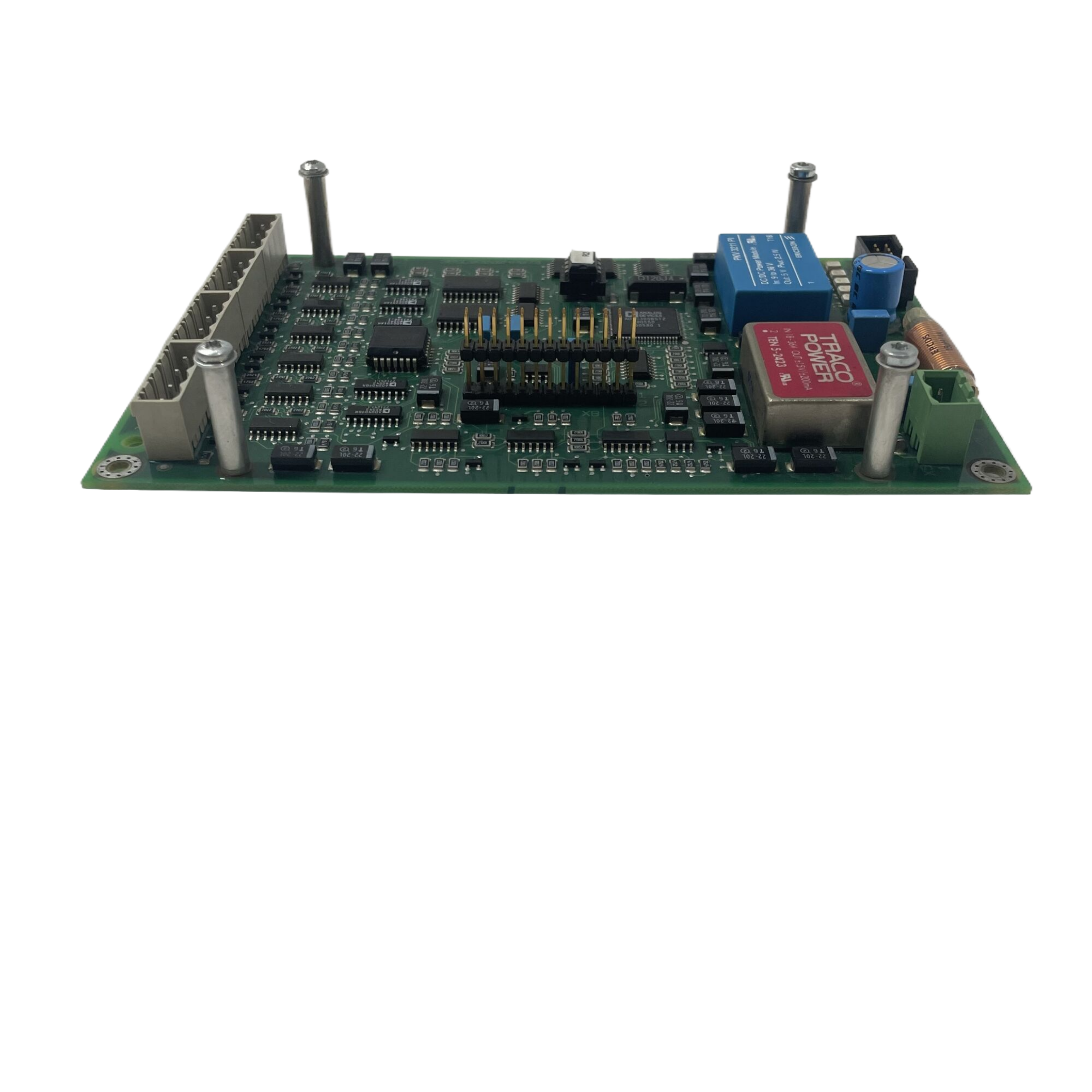

Digital Remote Terminal Driver (DRFD) is used for 505E digital controllers with integral

The connection of existing valve control mechanisms or Woodward actuators that do not match the 505E function.

The output channel of the 505E controller's actuator can output one for the actuator coil

A proportional signal of 4~20mA or 20~160mA (maximum 200mA). These 505E actuators lose

The output signal represents the command signal (proportional) equivalent to the required valve position. If the executing agency used

If different driving signals or control actions are required for servo components (combined with zero adjustment devices), then it is necessary

Digital remote terminal drivers or similar devices must be used.

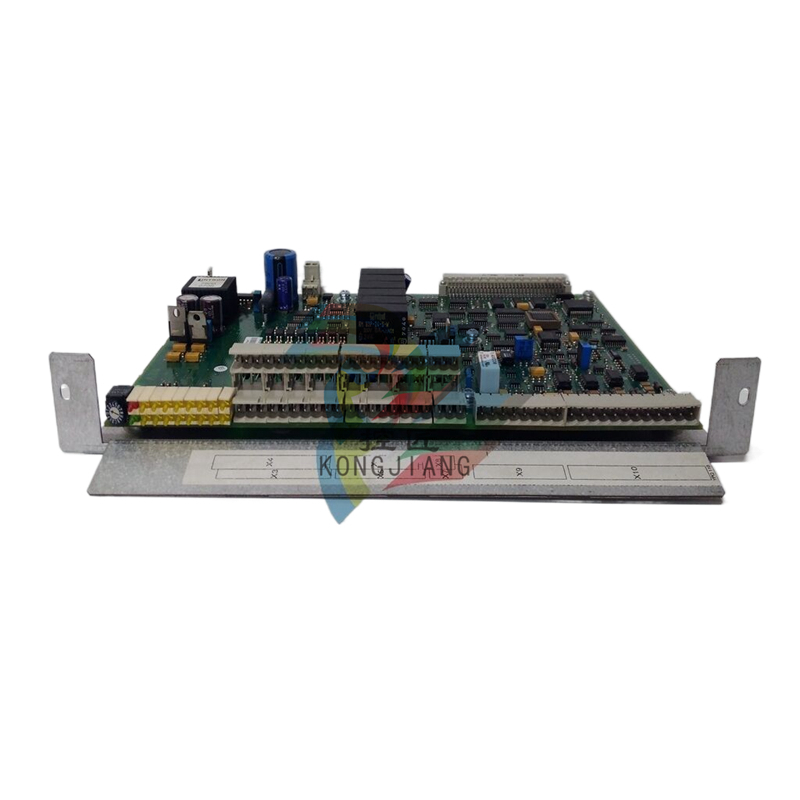

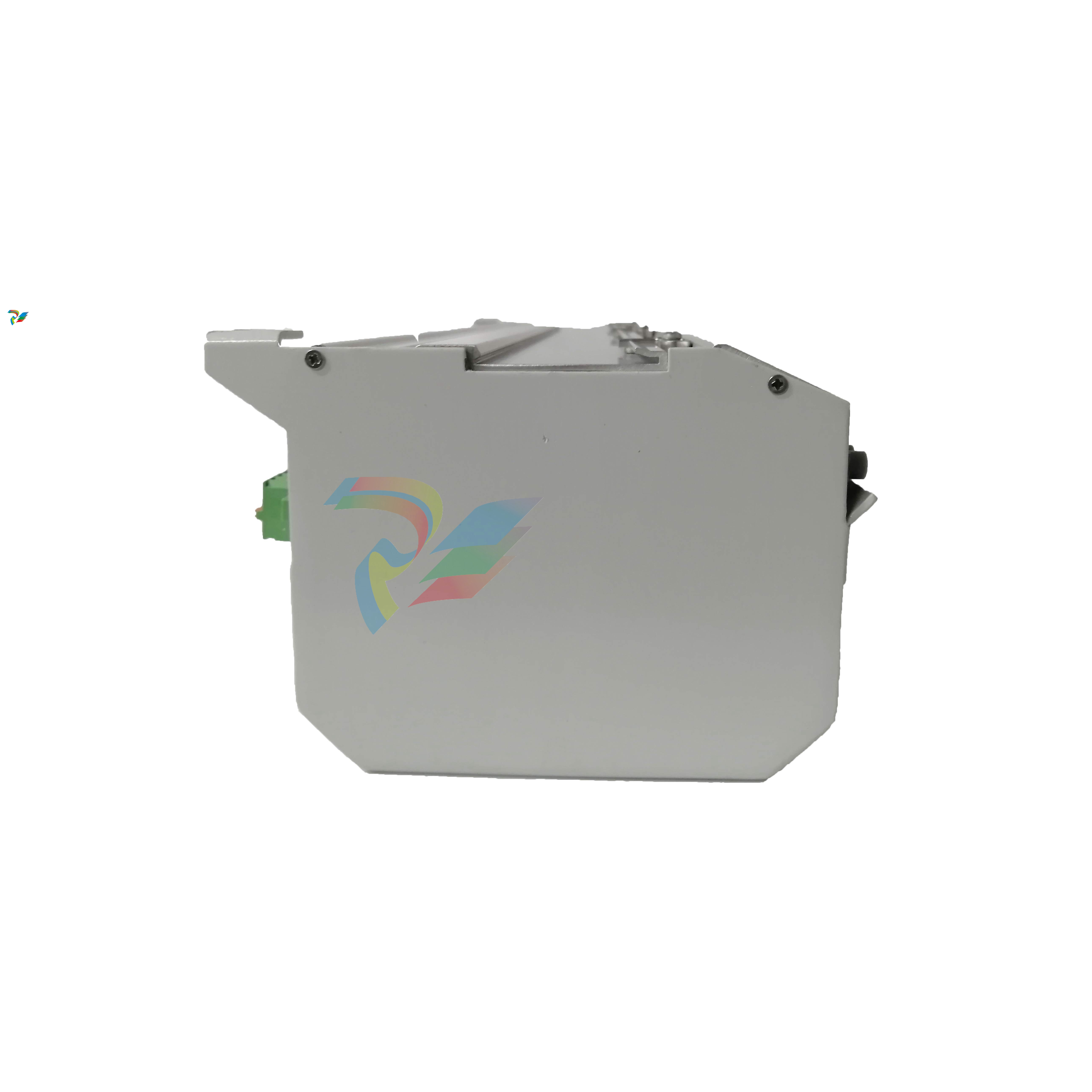

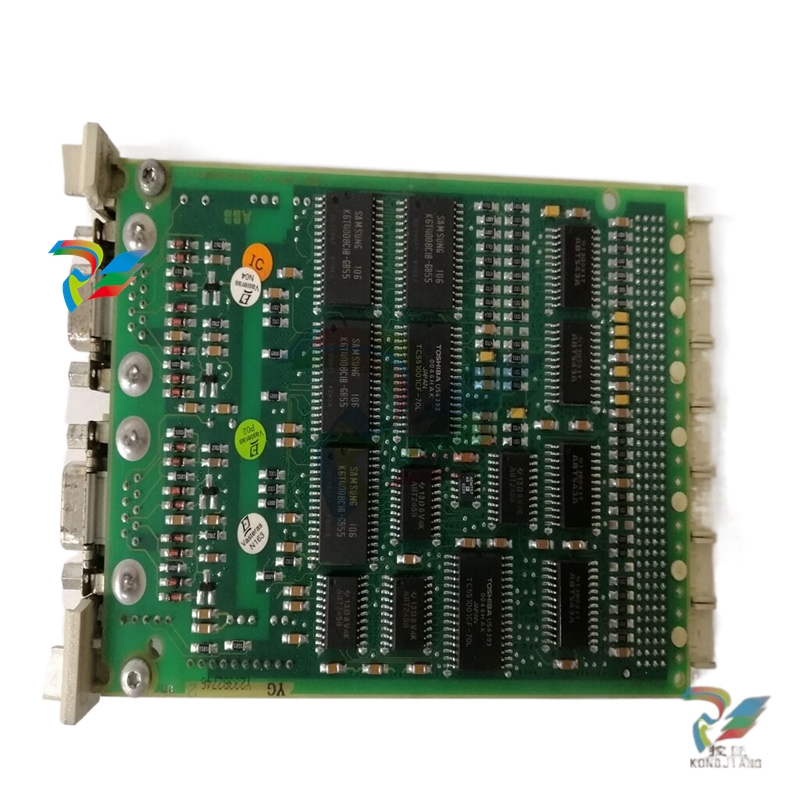

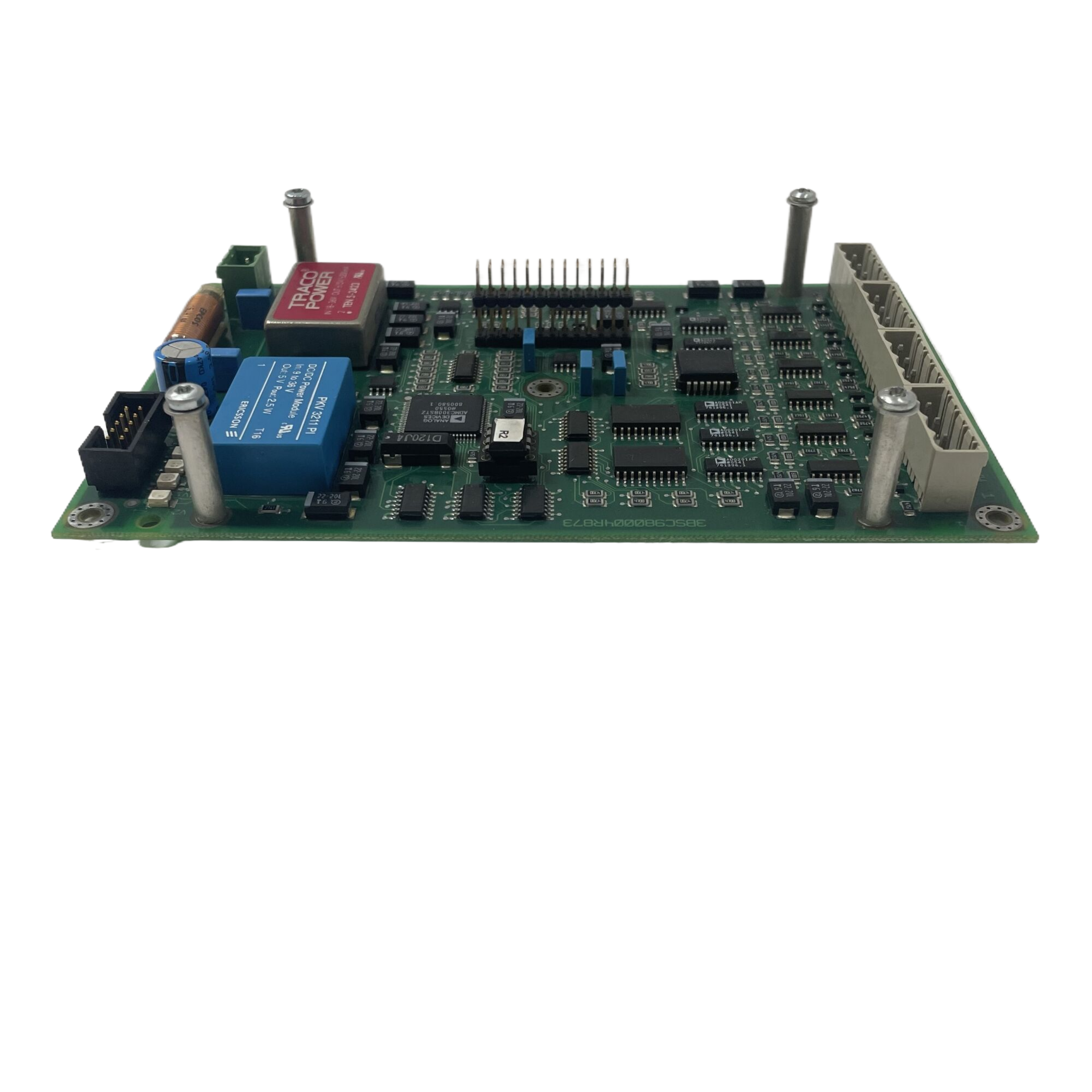

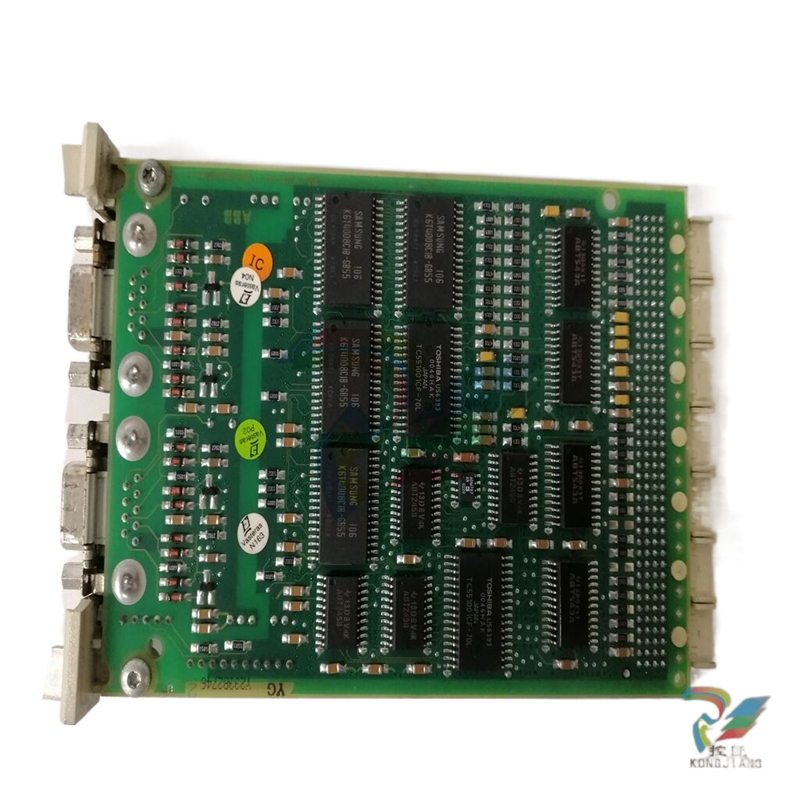

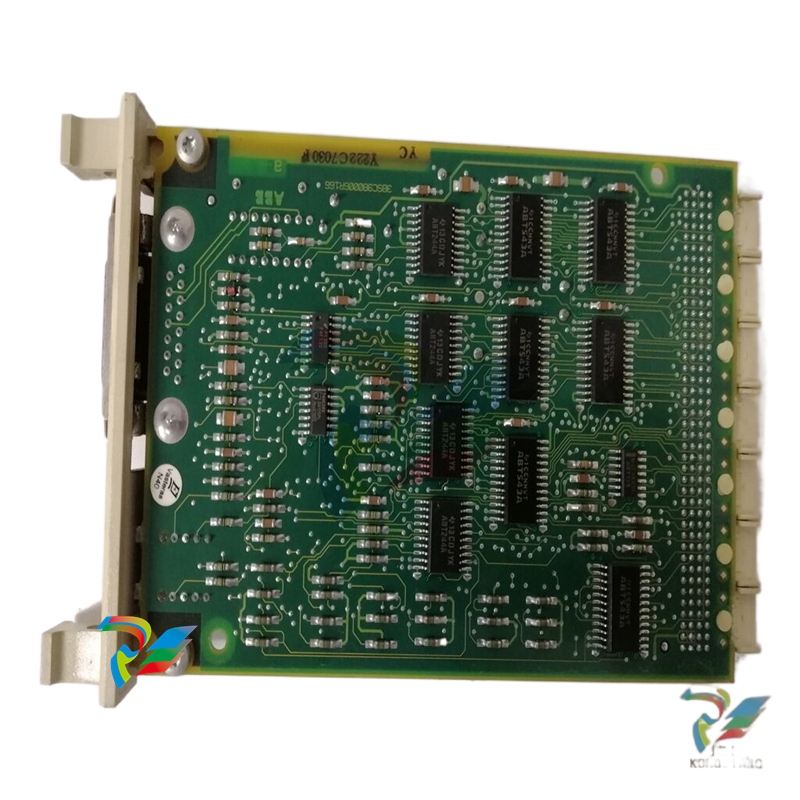

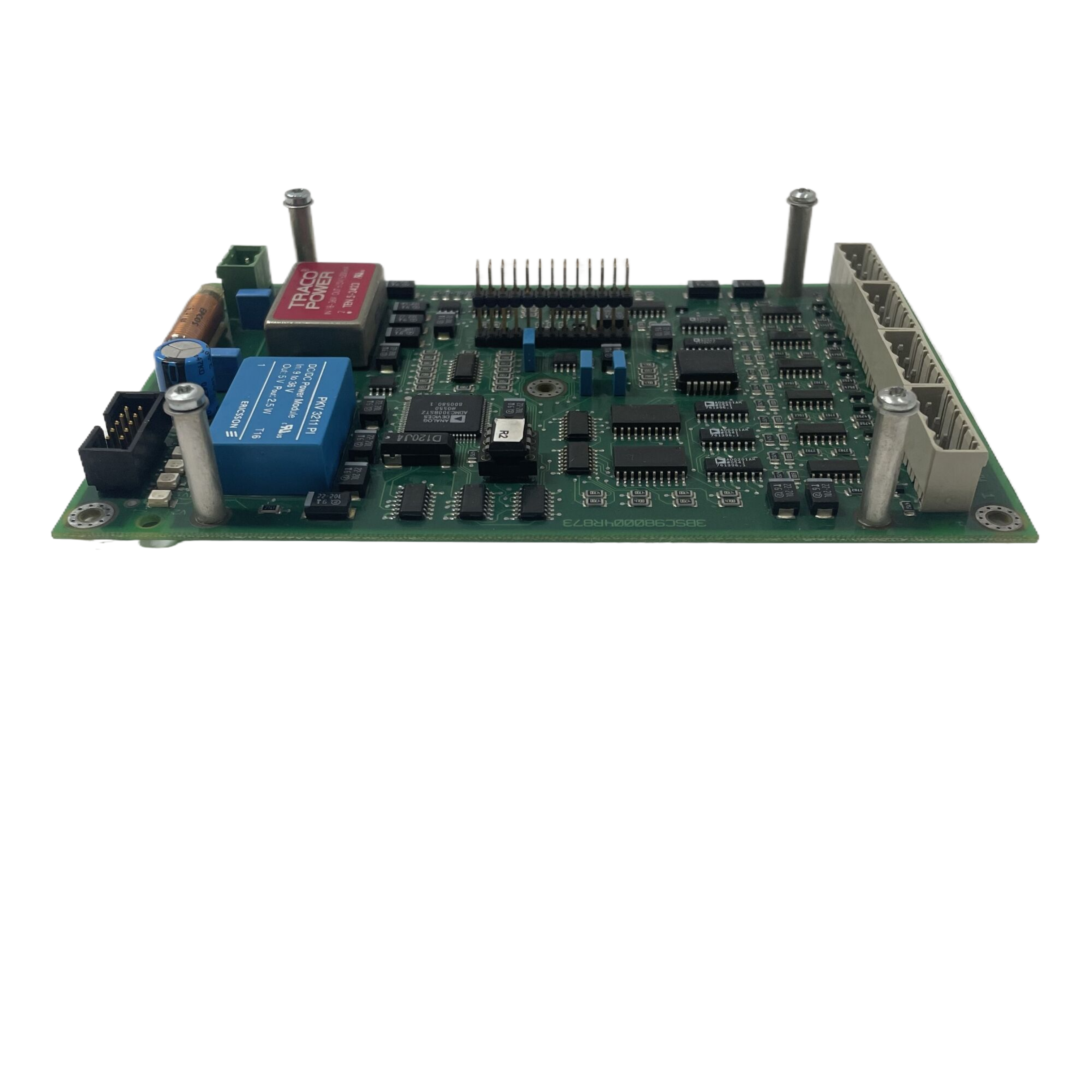

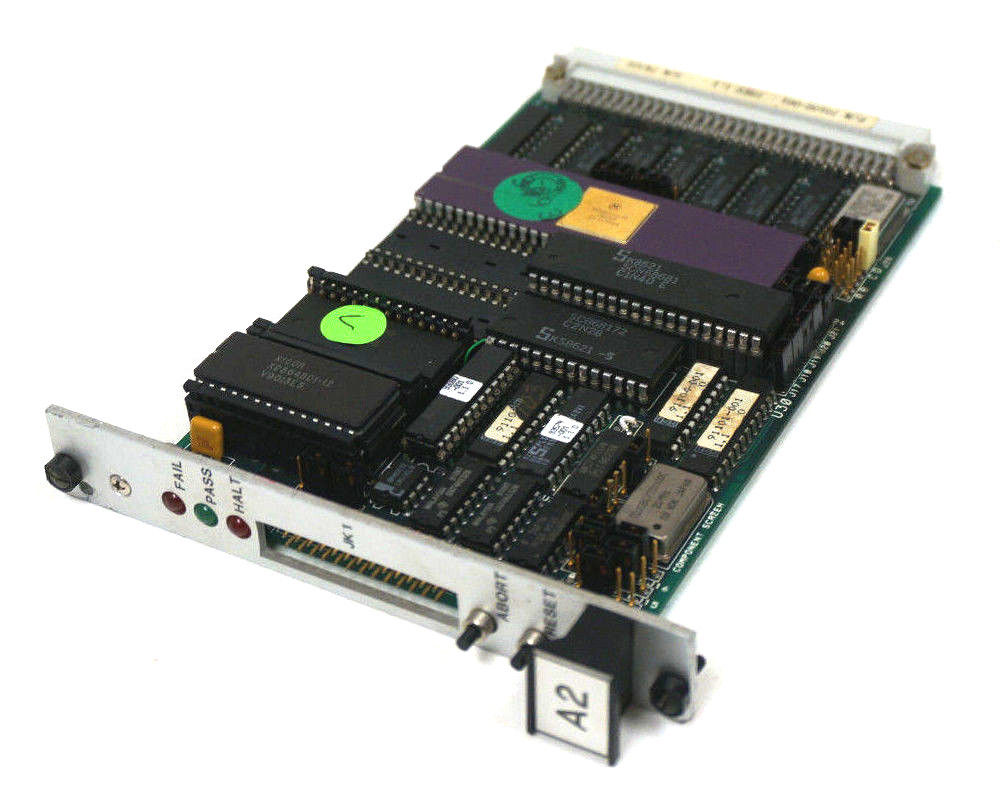

Figure 1-2 Digital remote terminal driver

Woodward digital remote terminal driver accepts a valve position proportional to the required valve position

4~20mA actuator drive signal, and correspondingly control a servo component. According to the connected

The type of servo component can adopt integral or proportional DRFD. Woodward's DRFD is capable of

Drive unipolar or bipolar actuator command signals, with a maximum of 0-400mA or

+400mA.

The digital remote terminal driver is assembled in a NEMA-4X housing with a hinged cover

Internally, it consists of driver components and power components. The driver components use plug-in jumpers and letters

Digital display for easy on-site configuration and calibration.

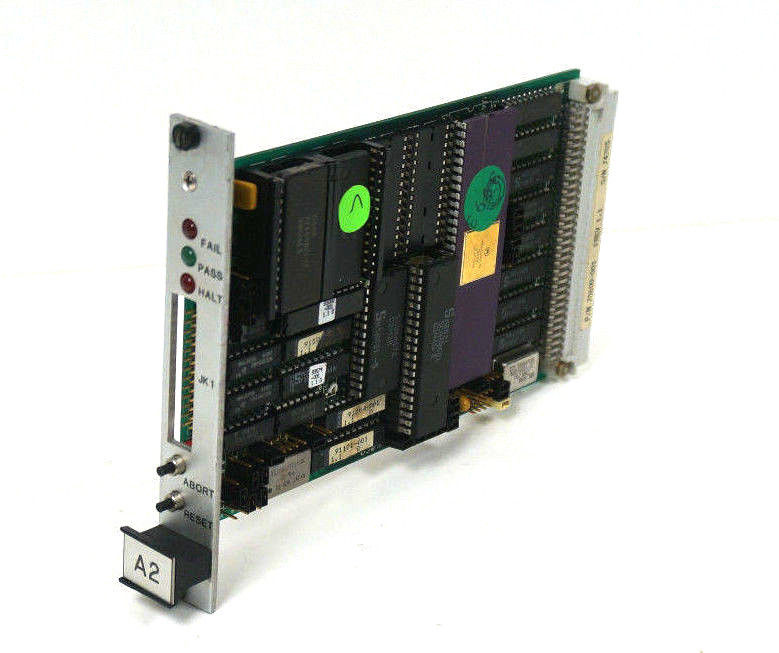

The proportional DRFD can provide a maximum output drive signal of 400mA to match the existing servo group

Match the item. This drive signal is proportional to the 4-20mA input from the 505E digital controller.

Integral DRFD detects the actual valve position (via LVDT, RVDT, MLDT, or DC position)

The feedback device compares the signal with the input position command signal from 505E and responds accordingly

Output a driving signal to control the servo mechanism components. Refer to Figure 1-2.

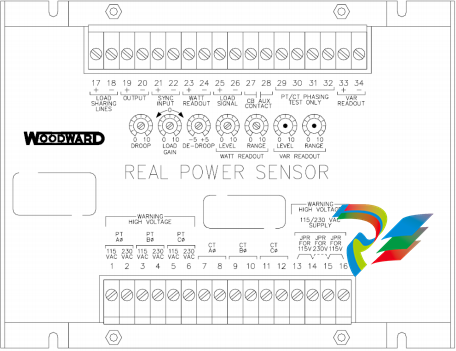

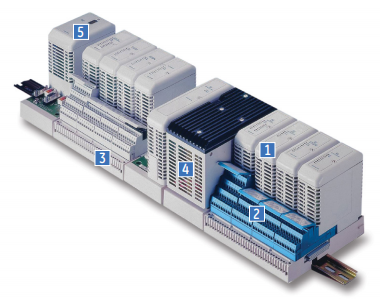

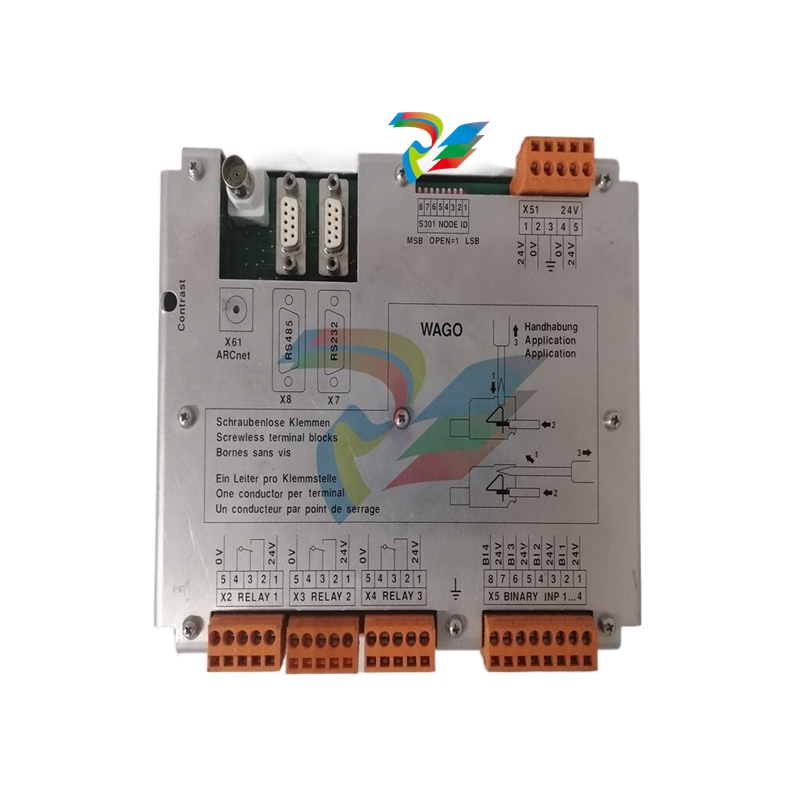

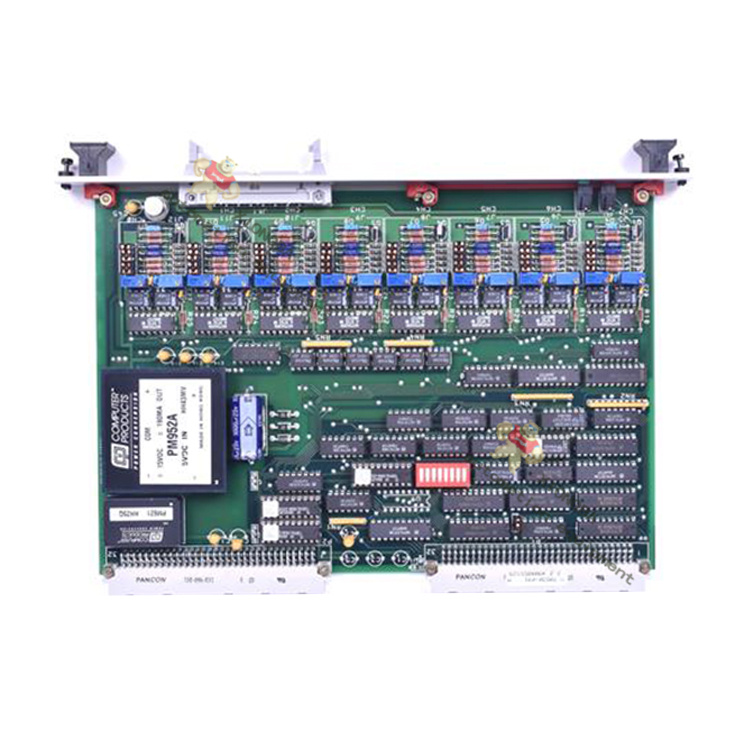

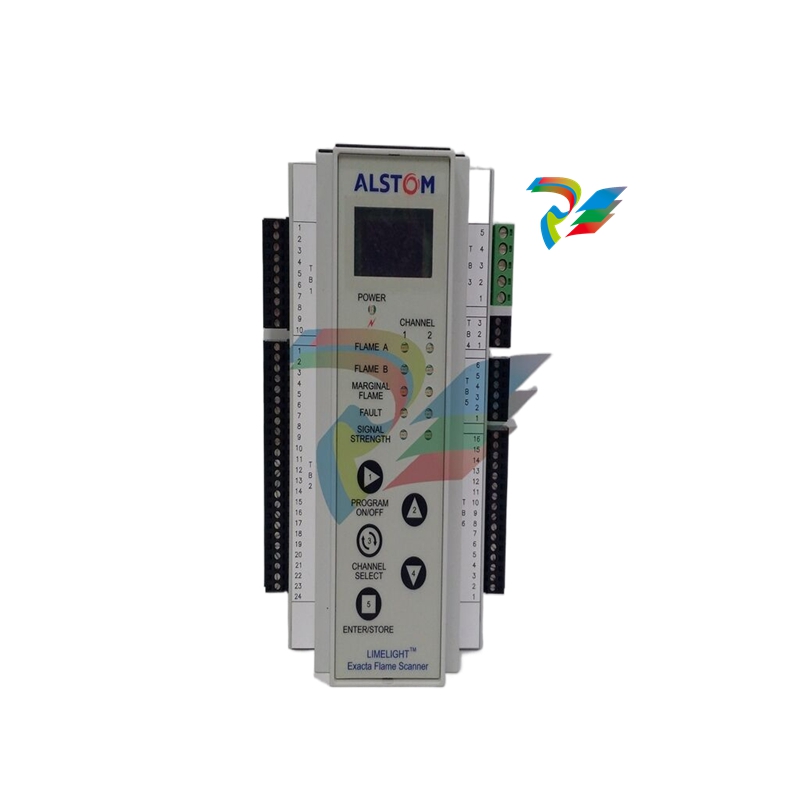

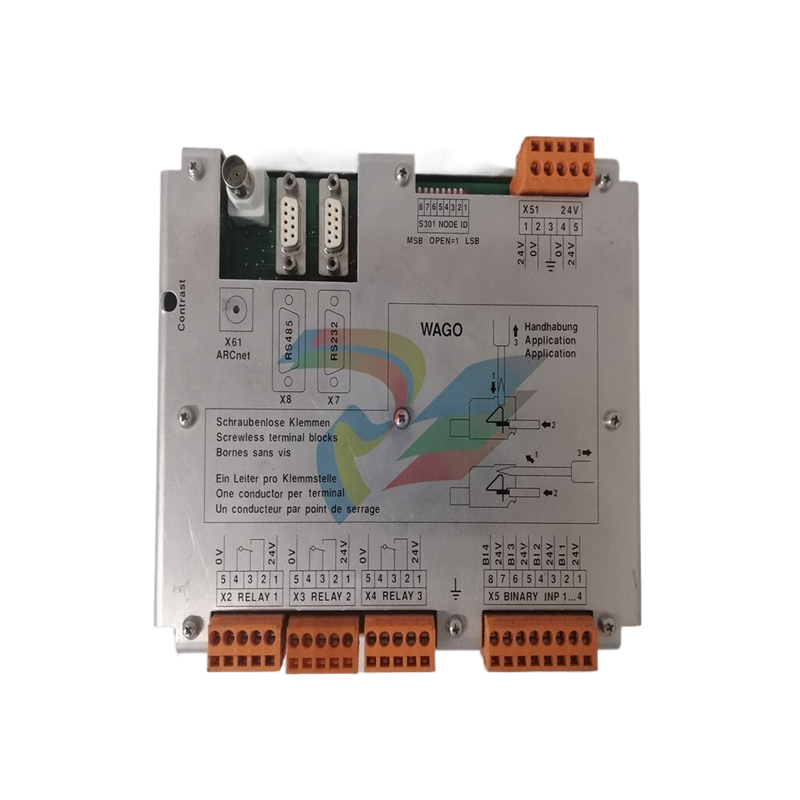

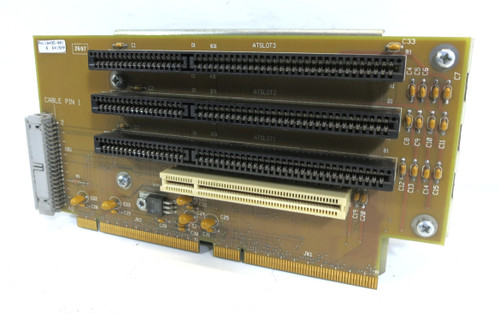

Active power sensor

Active power sensor (RPS) is used to detect the power generated by the generator or flowing through the grid connection line

The active power. Woodward's active power sensor detects three-phase voltage and three-phase current

Compare the voltage and current relationship of each phase and generate a 4-20mA proportional to the active power

Output.

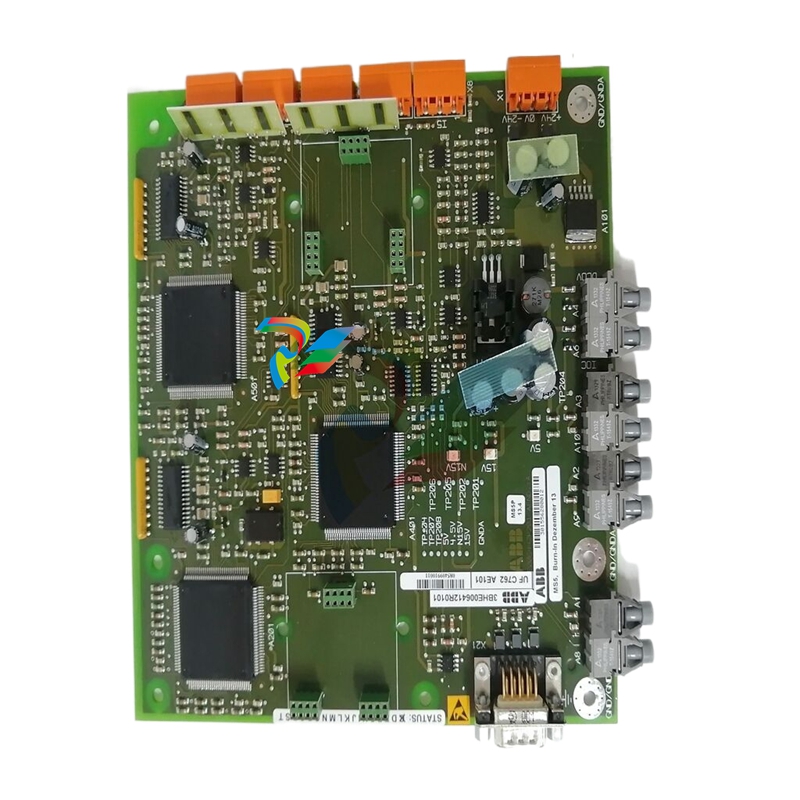

Figure 1-3 Active power sensor

Woodward produces two types of active power sensors. The first type of RPS is only used for detection

Unidirectional power flux (only 0~+5A center tap current), and output a proportional

4-20mA signal. This type of RPS is used to detect the power output of a generator. At present, the market

There are many different types of active power sensors available. Optional RPS features include reactive power

VAR detection, load distribution, 0-1A center tap current detection, and combinations of these characteristics.

For specific applications, please consult Woodward authorized distributors or Woodward factories for recommendations

Recommended RPS for use.

The second RPS produced by Woodward is used to detect power flux between power grids. such

RPS (8272-726) detects the center tap current of -5A~+5A to ensure that its output represents two directions

Upward power flux. RPS provides a 4-20mA power indication output signal. Here, 12

MA represents zero power flux. It is recommended to use this RPS to detect the power flux passing through the grid. about

The input or output power detection of power plants requires the use of this RPS or equivalent equipment

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.jpg)

.jpg)

.jpg)

.jpg)