K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

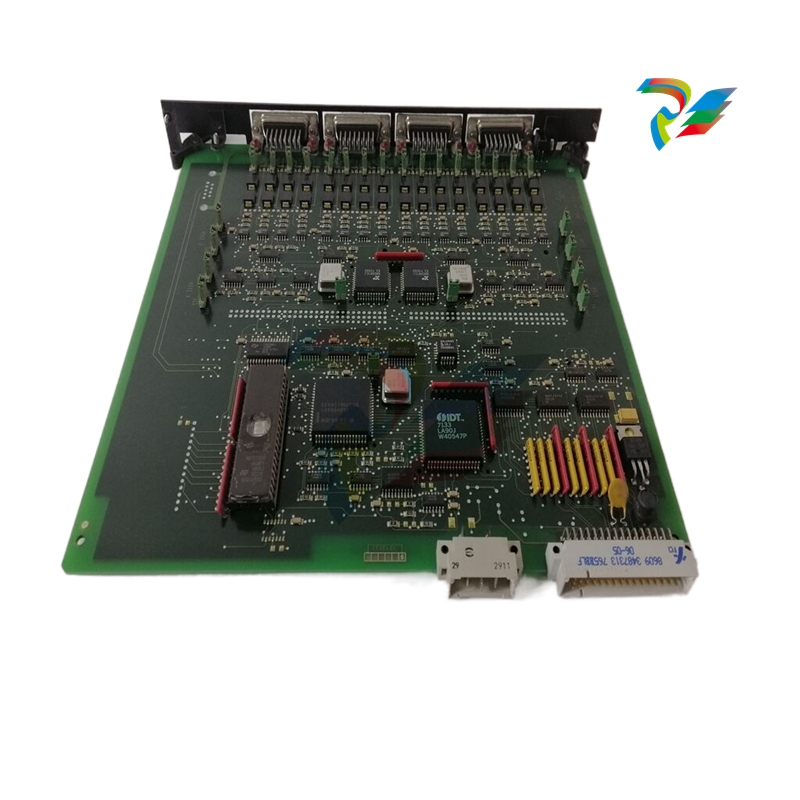

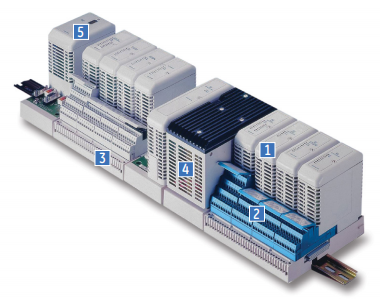

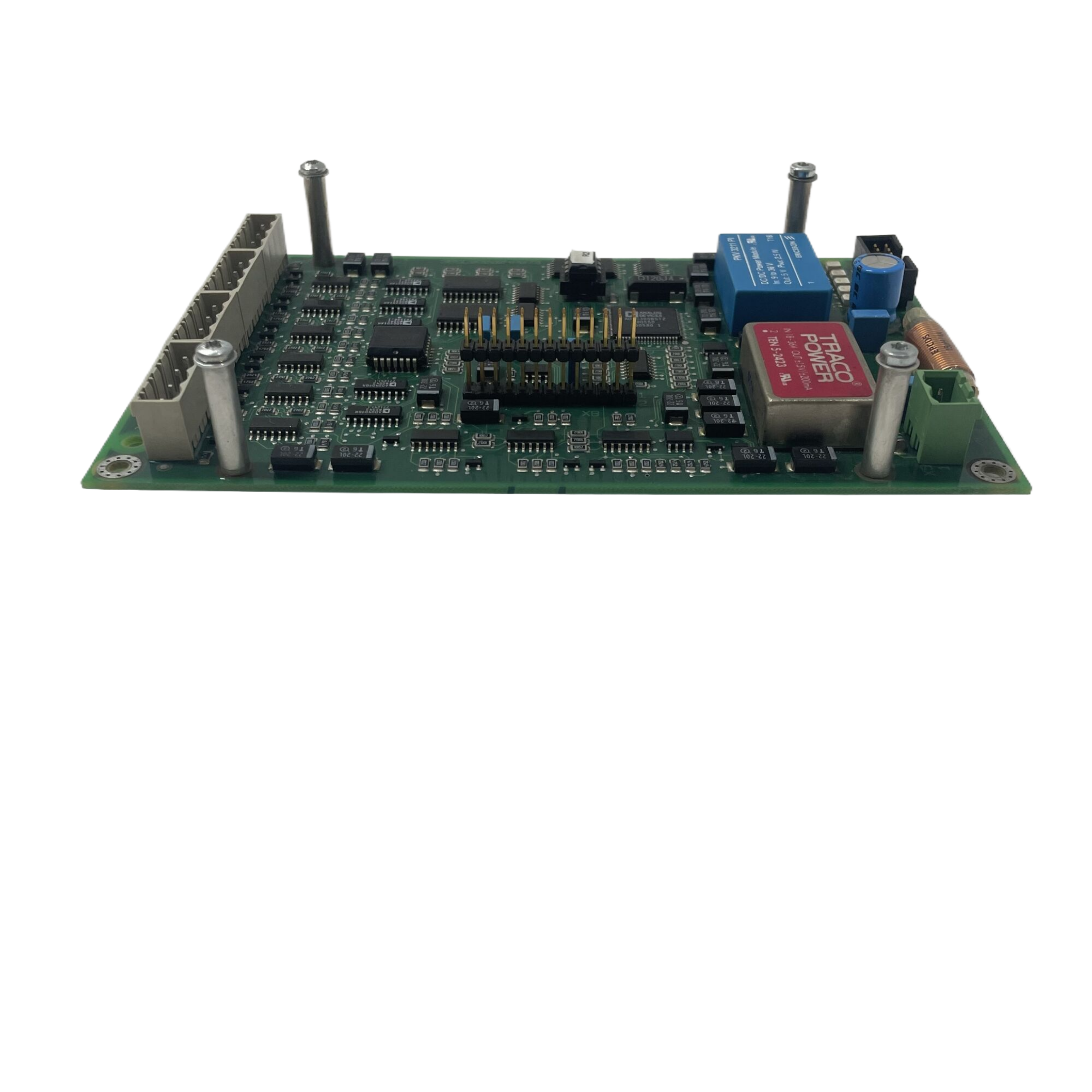

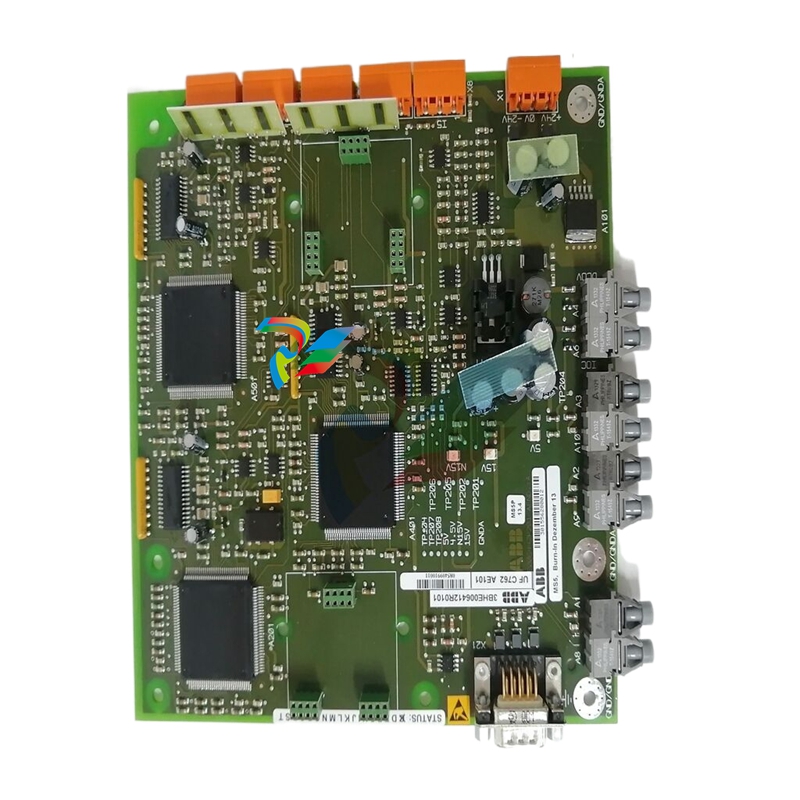

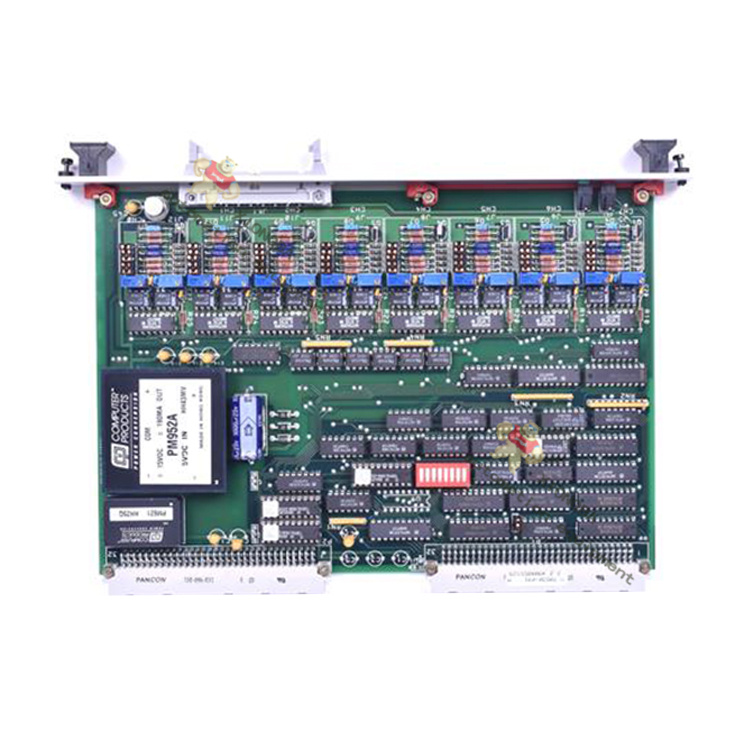

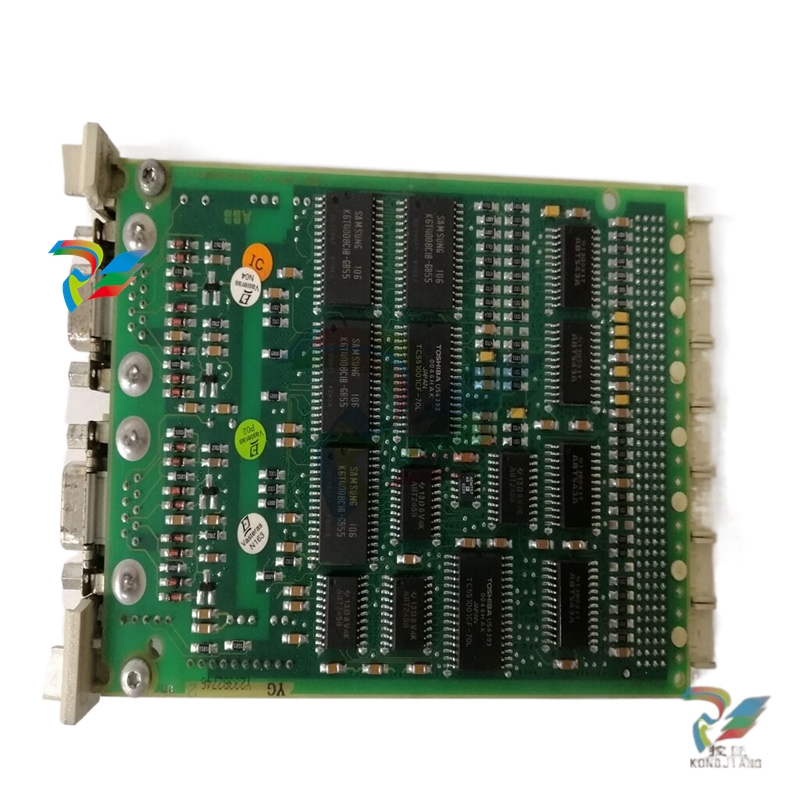

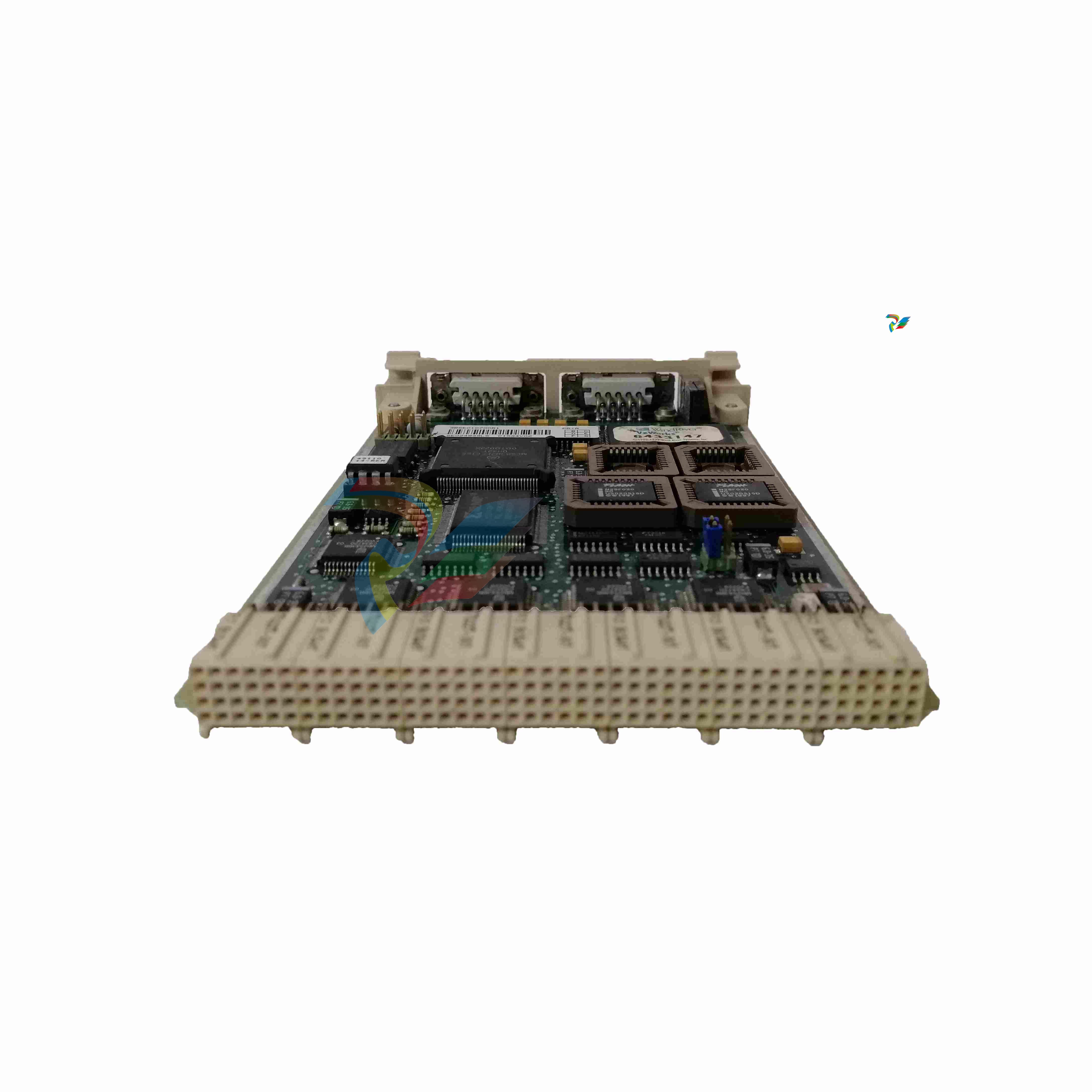

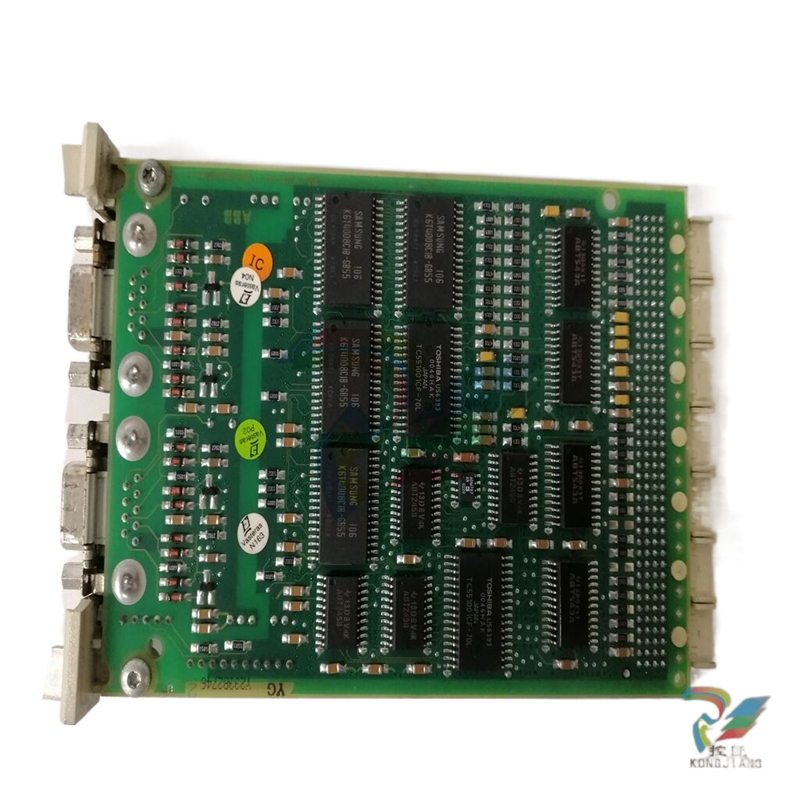

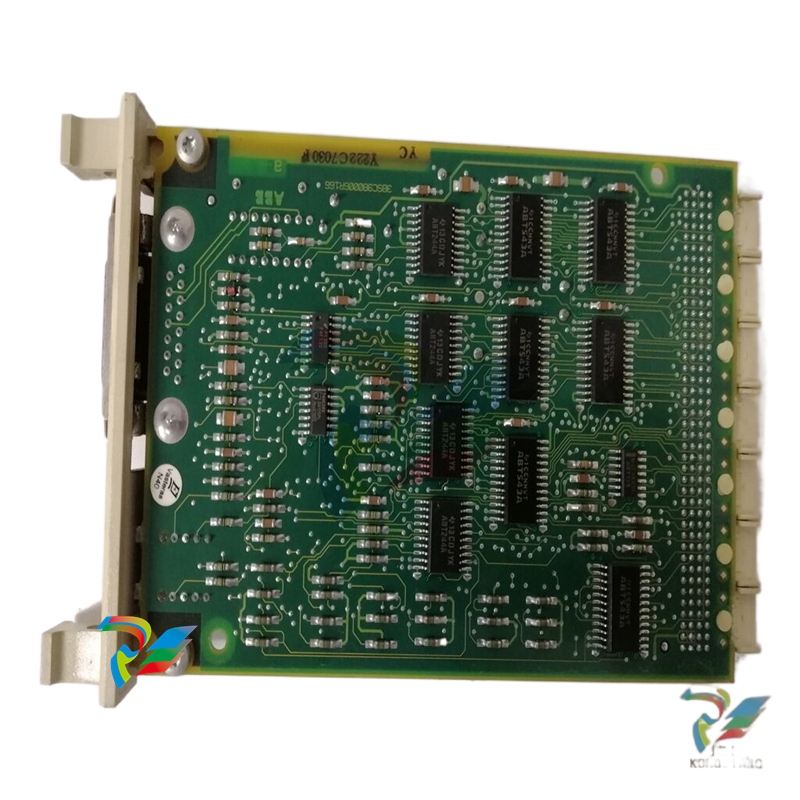

The Profibus Master Module (HE693PBM101/HE693PBM101-12) functions as a Profibus DP network master and is capable of controlling up to 64 slave devices. The Profibus DP application allows for the connection of I/O devices and simple field devices to an automation system via a Profibus network. Emphasis is on fast transmission of small data volumes. The PBM101/ PBM101-12 operates as Profibus DP module only and does not support other types of Profibus (FMS, PA).

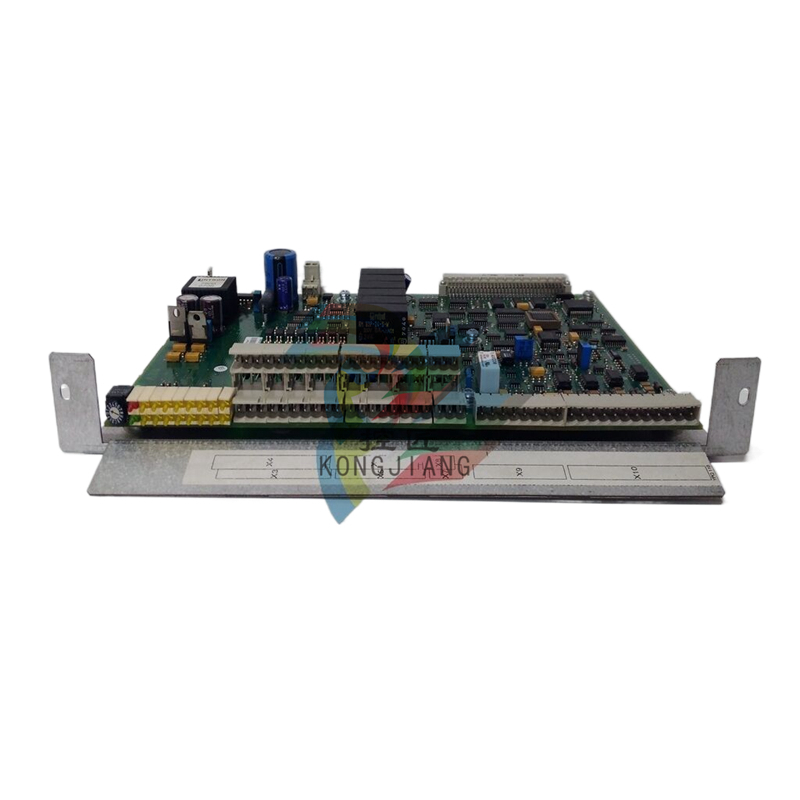

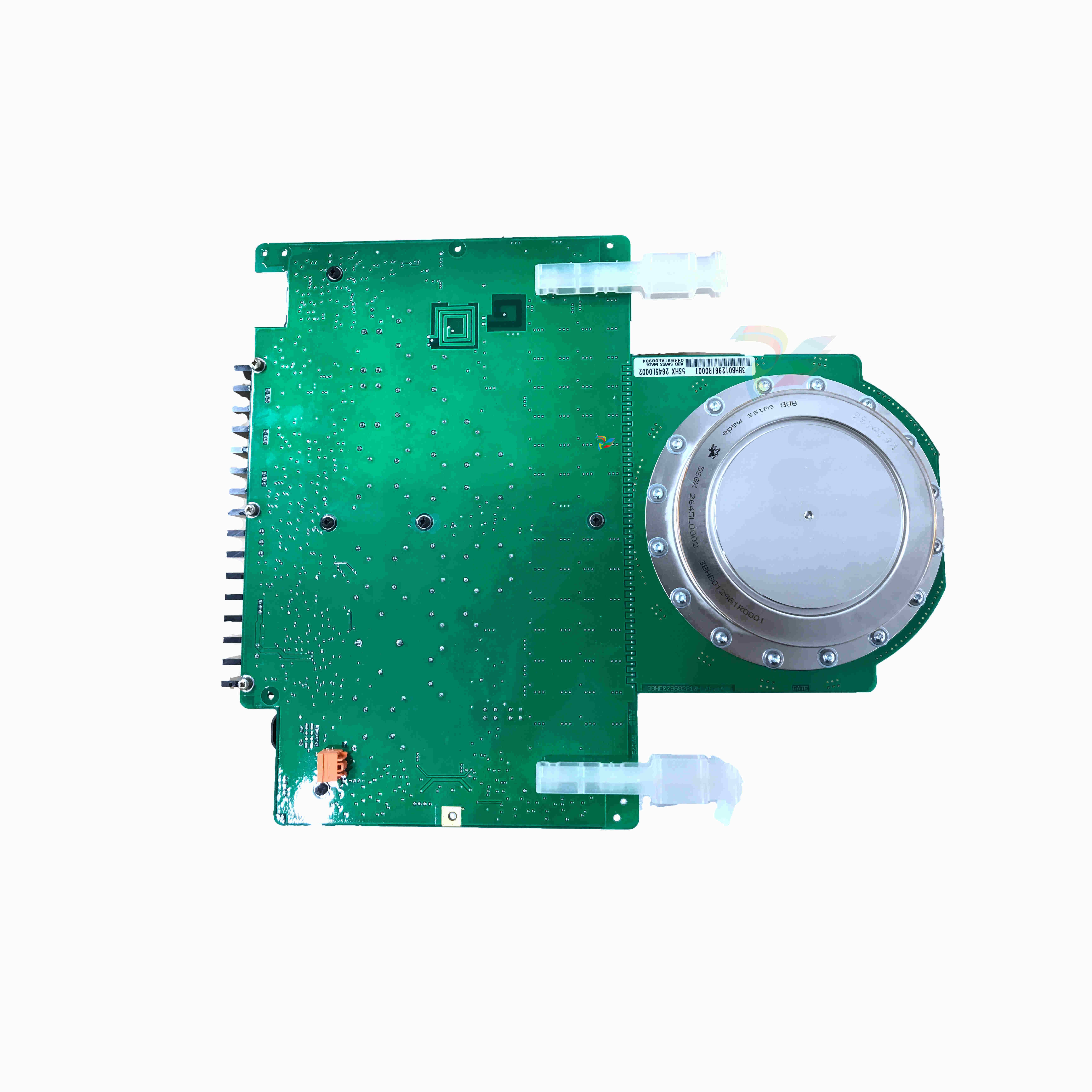

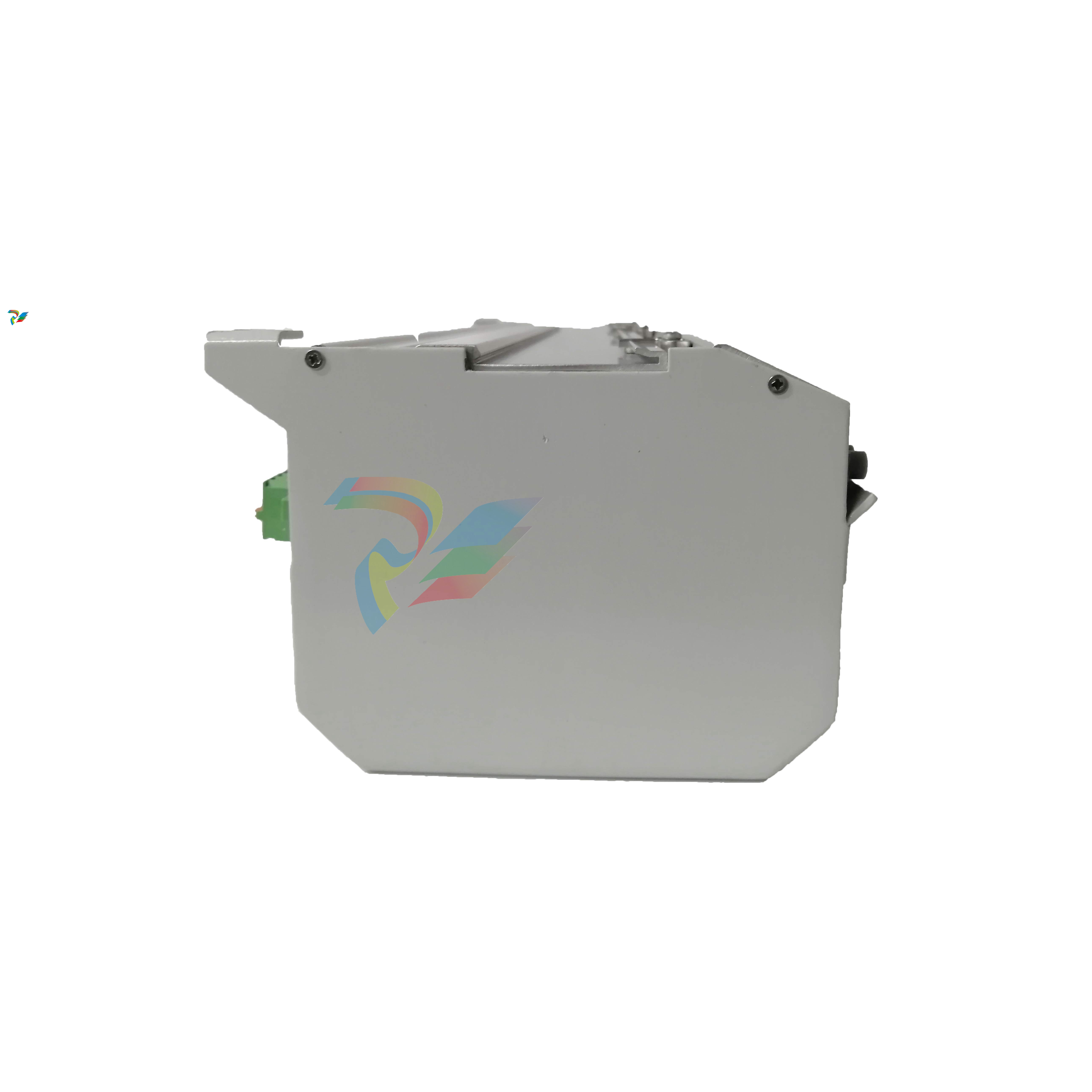

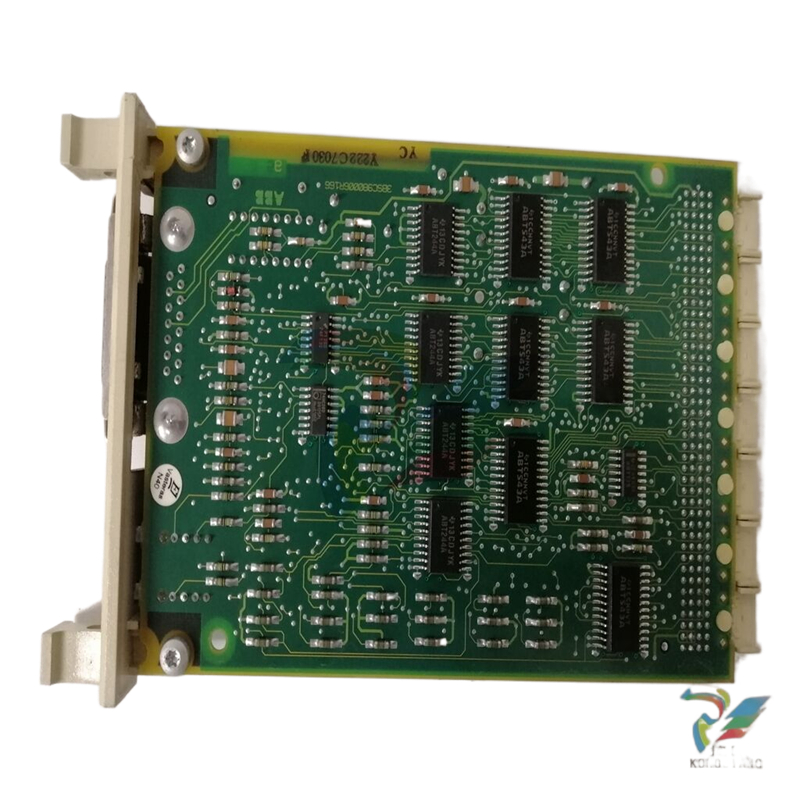

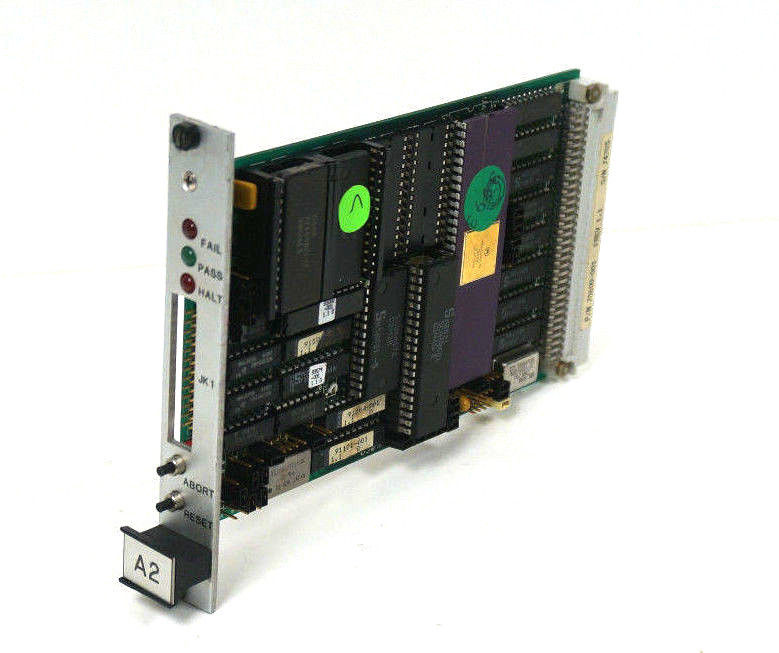

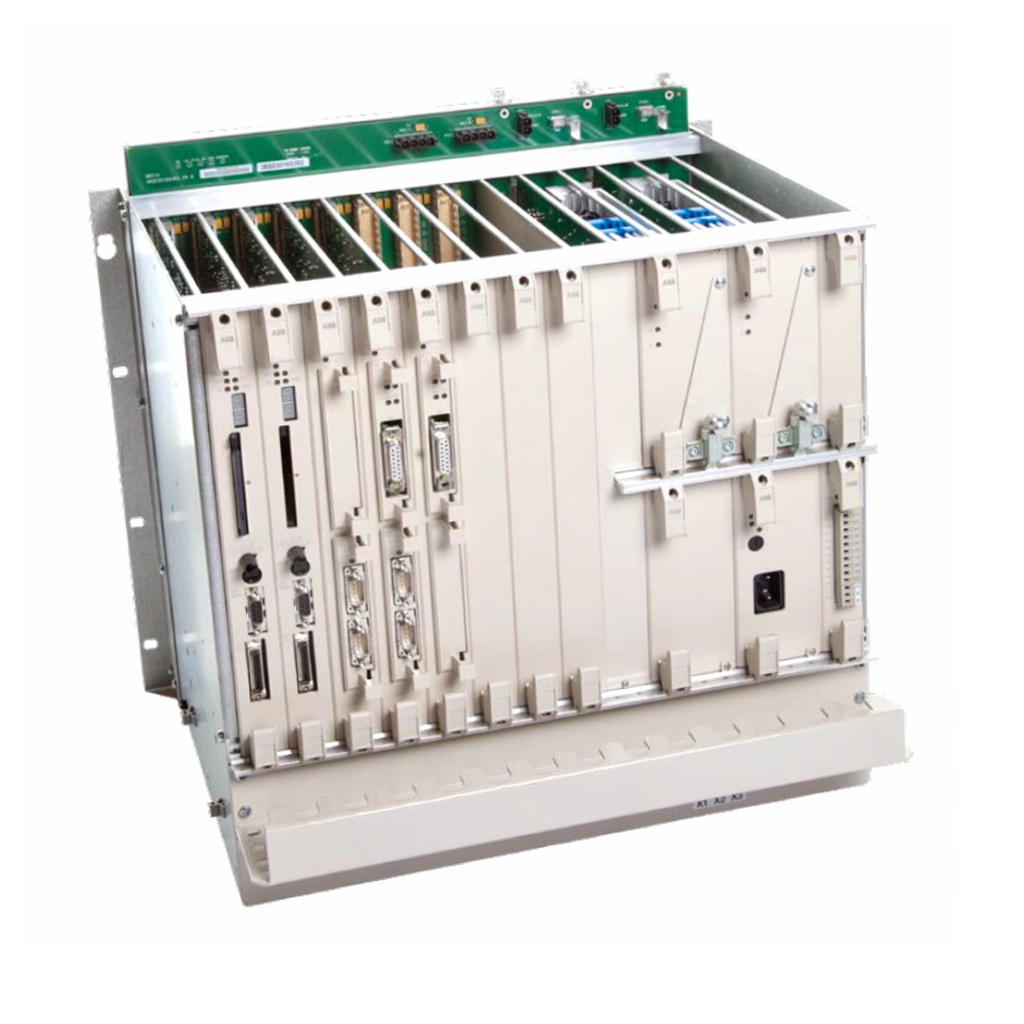

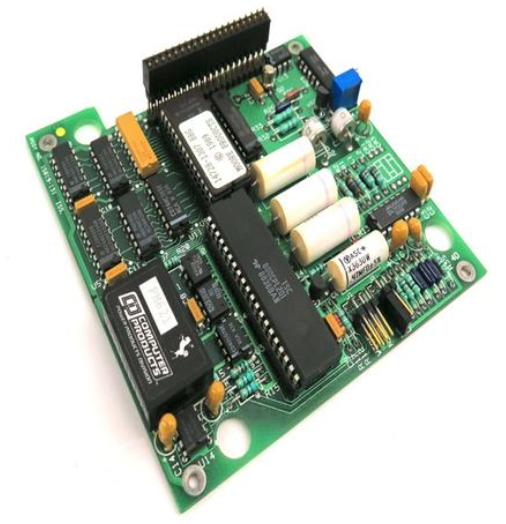

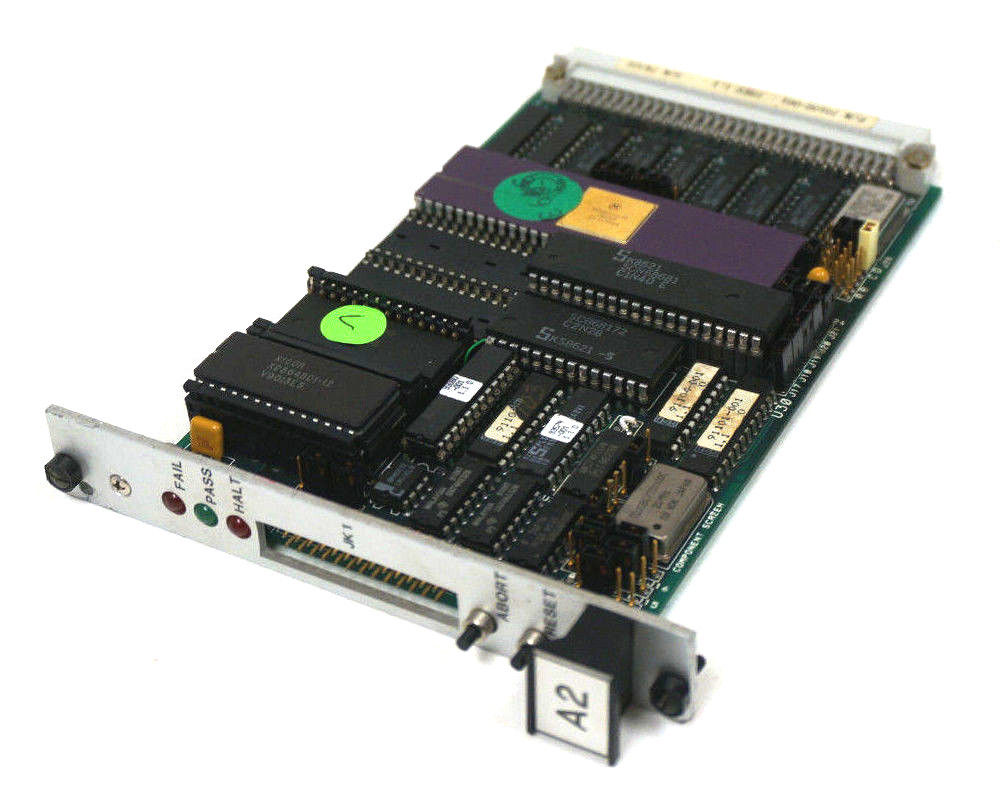

GE HE693PBM101 Profibus Master Module

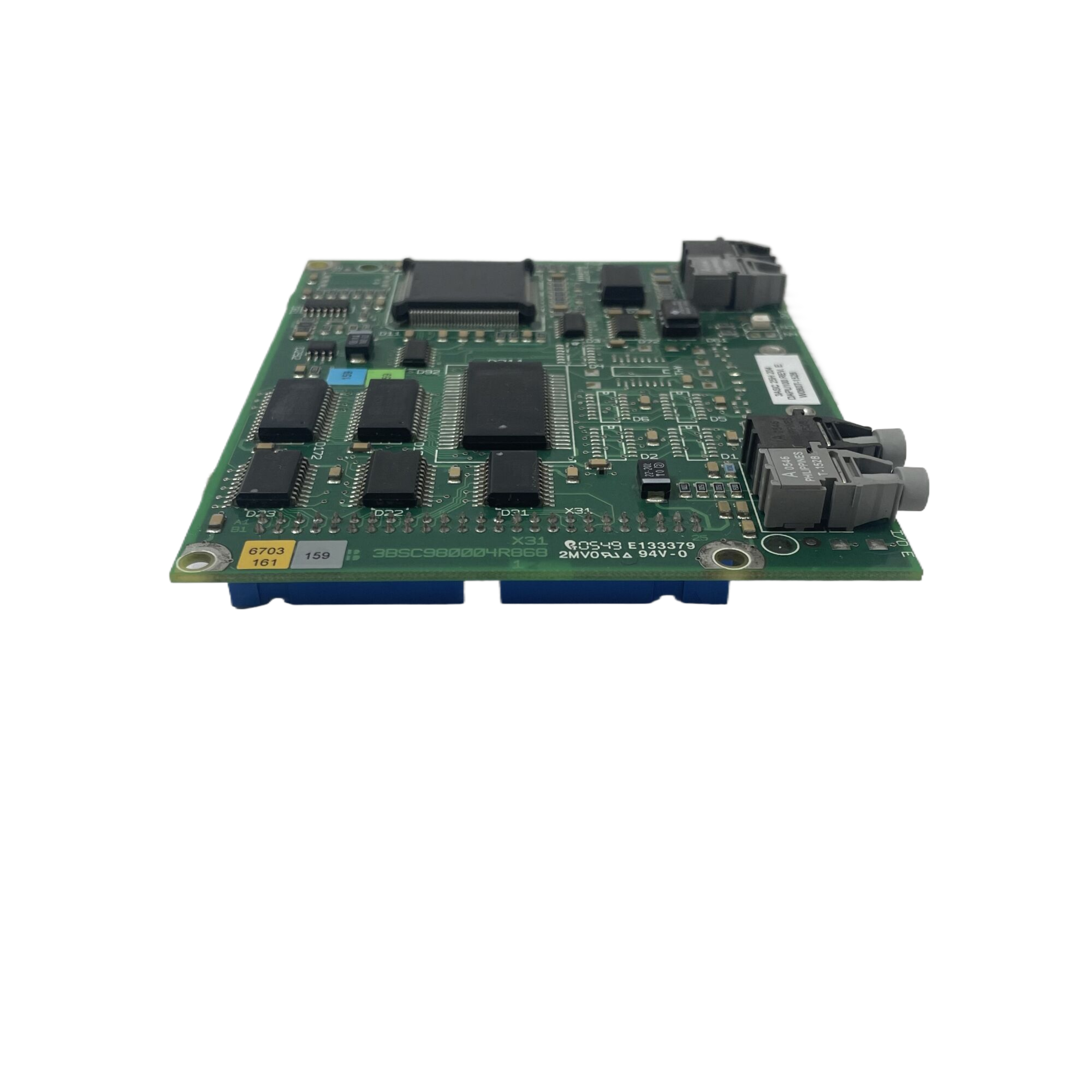

The PBM101/PBM101-12 function similarly except that PBM101 operates at 24MHz while the PBM101-12 operates at 48MHz. Profibus uses a Master-Slave type of communication with the PBM101/ PBM101-12 functioning as the master device. The PBM101/ PBM101-12 communicates with slave devices such as input/output devices, drives, valves, and measuring transmitters via a Profibus network. The PBM101/ PBM101-12 (when used with HE-APG Profibus Slave Modules) also allows communication between modules located in different PLC racks via the Profibus network. (For information covering HE-APG Slave Modules, see the User Manuals for the PBS105 and the PBM106.) 1.2 Profibus Overview Profibus, a token-passing network, supports one master (Type I) controlling the network and writing to the slave devices. Multiple masters (Type II), however, can read information simultaneously off the Profibus network. Master devices (PBM101/ PBM101-12) are used to determine the data communication on the bus. Slave devices are peripherals such as input/output devices, valves, drives, and measuring transmitters, etc. Slaves devices also include HE-APG Profibus Slave Modules located in PLCs that the PBM101/ PBM101-12 reads or writes to over the Profibus network. Slaves do not have bus access rights and only acknowledge received messages or send messages to the master when requested to do so. Data from the slave devices can be read by any master. All connected Slaves have the same priority. Up to 32 devices (masters or slaves) can be connected in one segment without using repeaters or up to 64 devices can be connected using repeaters.

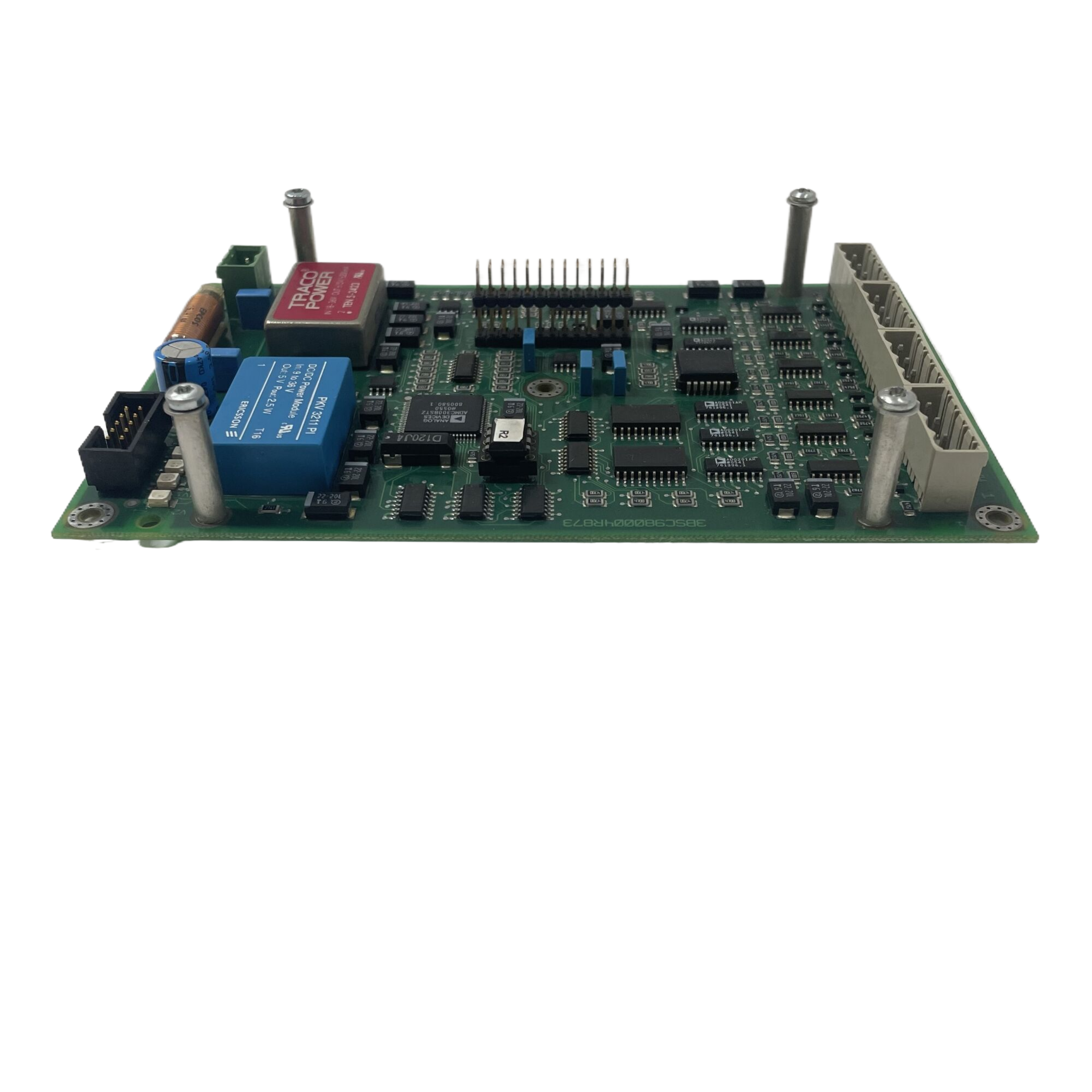

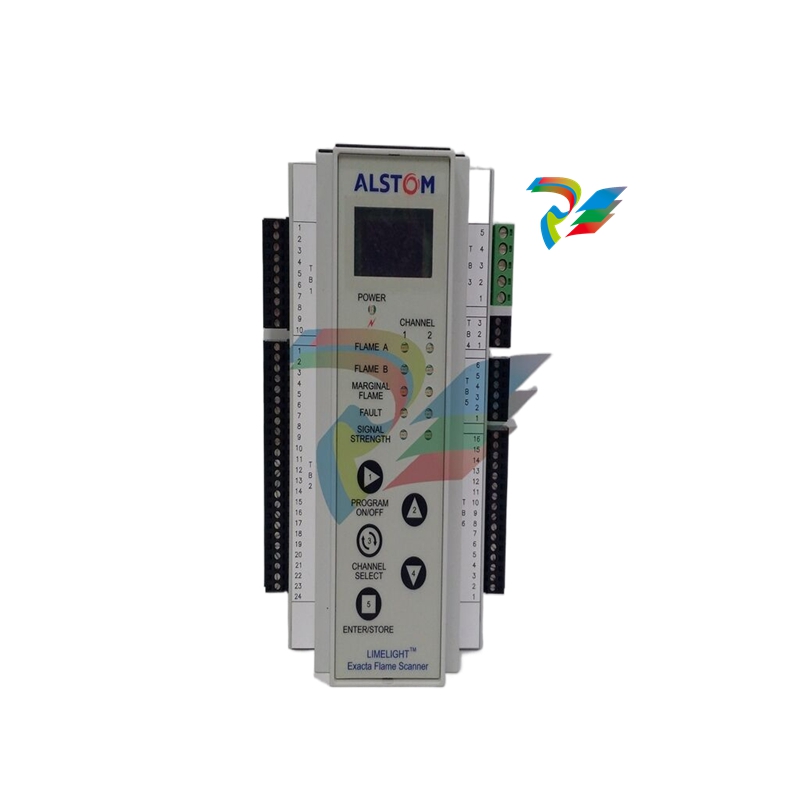

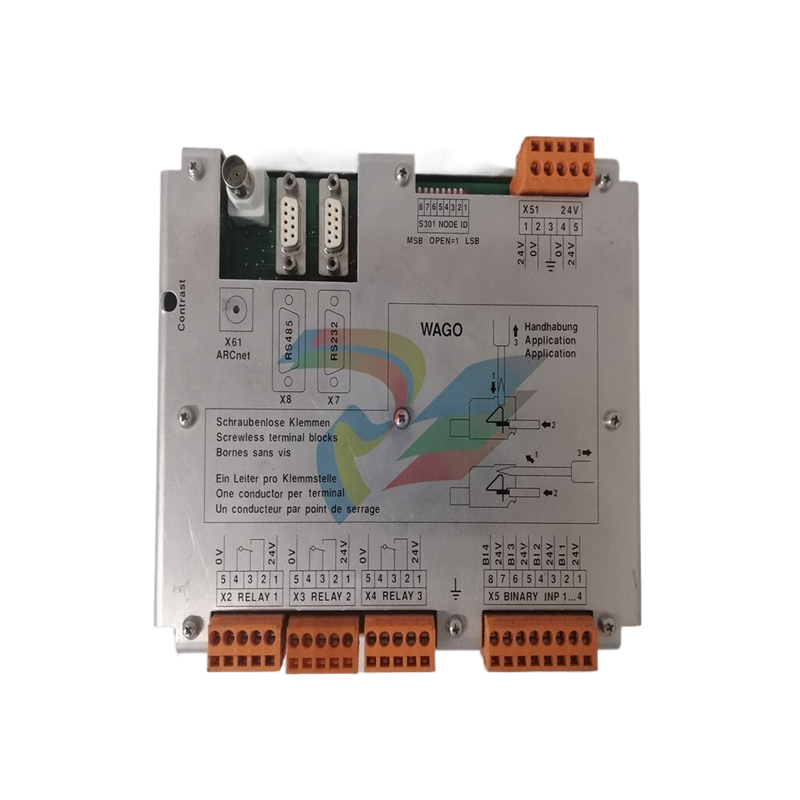

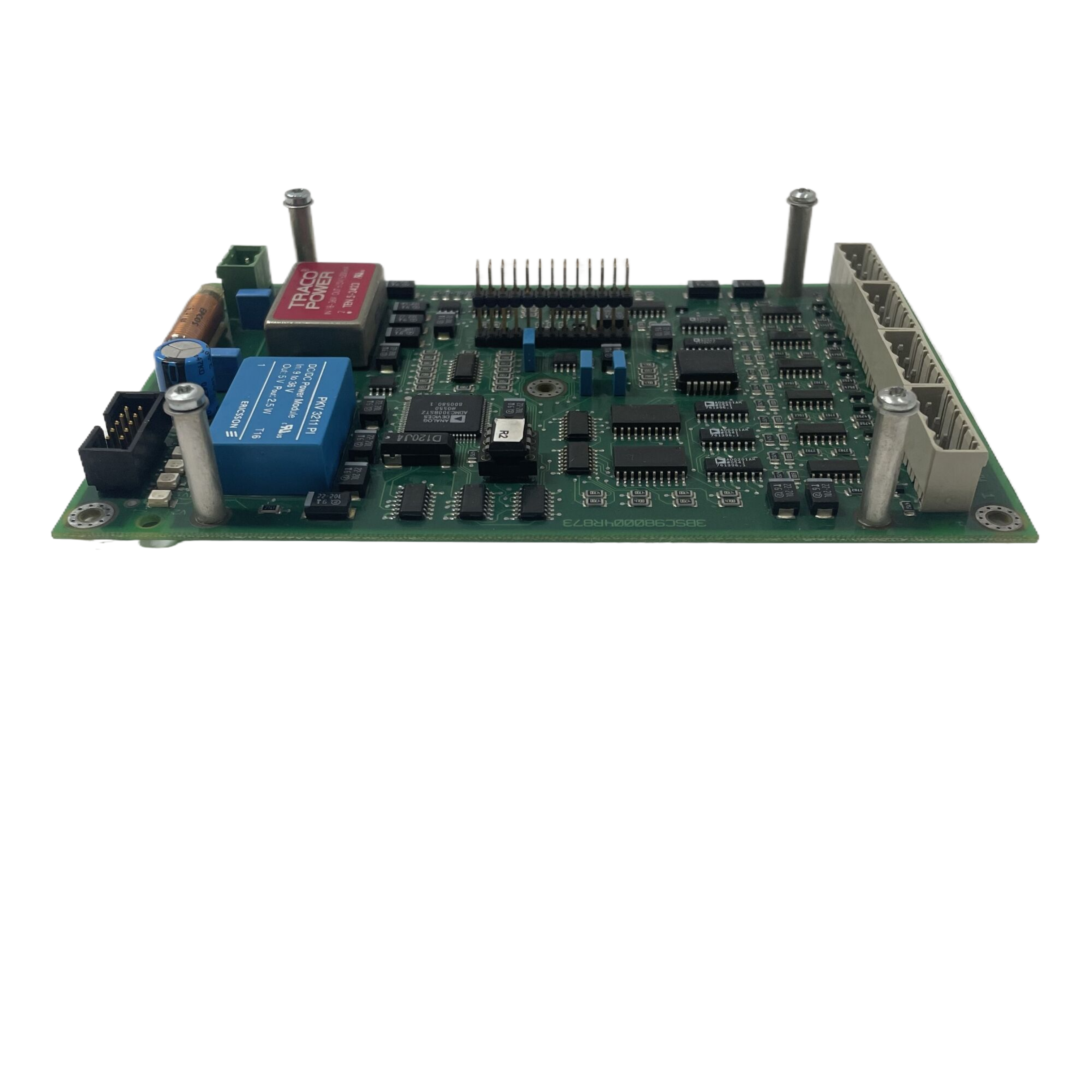

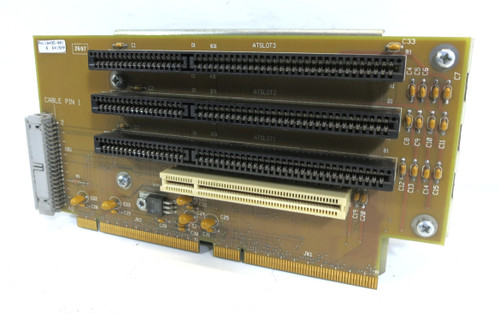

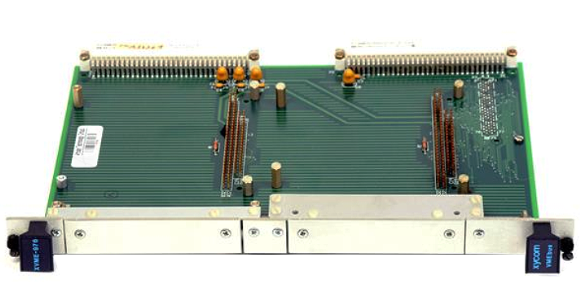

System Requirements and Limitations a. The PBM101/PBM101-12 require a CPU350 (or higher) with Firmware Version 8.0 (or higher). PBM101/PBM101-12: Up to 32 devices (masters or slaves) can be connected in one segment without using repeaters or up to 64 devices can be connected using repeaters. b. PBM101/PBM101-12: The number of slave devices on the network depends on the amount of total slave data produced and consumed on the network. Up to 504 bytes of total data can be produced on the network and up to 504 bytes of total data can be consumed from the network. Consumed data is reduced 2 bytes for every 1 word of diagnosis data. c. PBM101/PBM101-12: VersaPro Software (1.10) or Cimplicity Control (Version 2.20 or later) are required to configure the modules. The Series 9030 PLC is limited to 25 bytes of Extra Parameter Data. d. Logicmaster software and earlier versions of CPU Firmware do NOT support these modules. 1.4 Physical Layout of PBM101/PBM101-12 PROFIBUS DP MASTER PWR PROFIBUS DP OK RUN Figure 1.2 – Side View Figure 1.1 - Front Cover RS-232 SERVICE PORT PROFIBUS DP PORTMAN0219-05 15 APR 2003 PAGE 11 CH. 2 CHAPTER 2: INSTALLATION 2.1 PBM101/ PBM101-12 Mounting Requirements The PBM101/ PBM101-12 Module is designed to plug into any Series 90-30 local slot. The PBM101/ PBM101-12 requires at least a CPU350 model or higher with Firmware Revision 8. The PBM101/ PBM101-12 can not operate correctly with a lower version Firmware. Please refer to the appropriate manufacturer’s installation manual. 2.2 Profibus DP Connector The 9-pin Profibus DP connector is for physical connection between the slaves and the master. For further information on the cable and connectors, see Chapter 4 in this manual. 2.3 RS-232 Connector The RS-232 Service Port is used to upgrade the firmware specific to the slave. This port uses a standard RS-232 9-pin connector. 5 4 3 1 9 6 RI DTR RTS RXD CTS TXD DSR DCD Figure 2.1- Pin-out for the RS-232 2.4 LED Operation of PBM101/PBM101-12 There are three visible LED’s on the PBM101/ PBM101-12. the OK LED, RUN LED, and the POWER LED. Various combinations of these LED’s will indicate different states of the master. See Table 2.1 for the states indicated by the LED’s. Table 2.2 indicates fault conditions.

PBM101/ PBM101-12 Status Error/Diagnosis Reporting 2.5.1 PLC Status Bit Definition The PBM101/ PBM101-12 has 128 bits of diagnosis and status information reported to the PLC CPU. 64 bits are assigned as status bits, and 64 are assigned as diagnosis bits. The 64 status bits are by default assigned to the top of the existing memory map in the Settings tab of the PBM101/ PBM101-12 parameters screen (see Figure 3.4). The following explanation describes the Slave Status and indicates the information needed to setup the Slave Status parameters in the program language being used (such as Ladder Logic or C-Programming). The Slave Diagnosis inputs contain additional information about the slaves, which is useful for slave specific issues

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)