K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

The PACSystems* RX3i Redundancy CPU can be used to perform real time control of machines, processes, and material handling systems. The CPU communicates with the programmer and HMI devices via a serial port using SNP Slave protocol. It communicates with I/O and smart option modules over a dual backplane bus that provides:

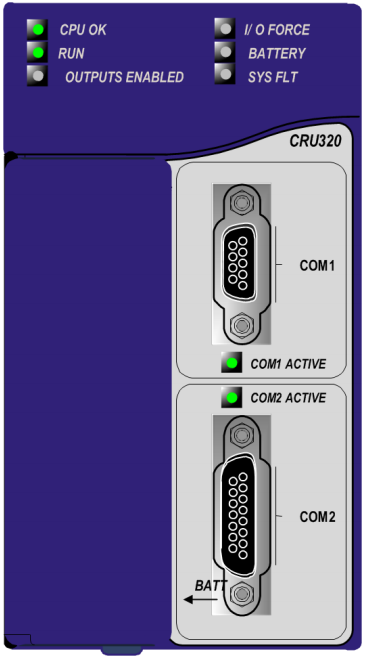

GE IC695CRU320 Redundancy CPU

High-speed PCI backplane for fast throughput of new

advanced I/O.

▪ Serial backplane for easy migration of existing

Series 90*-30 I/O.

Features

▪ Hot standby (HSB) redundancy. Two redundant units

make up a redundancy system. Each unit requires one

Redundancy CPU (IC695CRU320) and a redundancy

Memory Xchange module (IC695RMX128/228) configured

as a redundancy link.

▪ Contains 64 Mbytes of battery-backed user memory and

64 Mbytes of non-volatile flash user memory.

▪ Provides access to bulk memory via reference table %W.

▪ Configurable data and program memory.

▪ Programming in Ladder Diagram, Structured Text,

Function Block Diagram, and C. Refer to PACSystems RX7i

& RX3i CPU Programmer’s Reference Manual, GFK-2950.

▪ Supports auto-located Symbolic Variables that can use

any amount of user memory.

▪ Reference table sizes include 32Kbits for discrete %I and

%Q and up to 32K words each for analog %AI and %AQ.

▪ Supports most Series 90-30 modules and expansion

racks. For a list of supported I/O, Communications,

Motion, and Intelligent modules, refer to the PACSystems

RX3i System Manual, GFK-2314F or later.

▪ Supports up to 512 program blocks. Maximum size for a

block is 128KB.

▪ CPU firmware may be upgraded in the field.

▪ CPU supports firmware upgrades of modules in its

backplane.

▪ Two serial ports: an RS-485 serial port and an RS-232

serial port.

▪ Ethernet communications via the rack-based Ethernet

Interface module (IC695ETM001). For details on Ethernet

capabilities, refer to PACSystems RX7i & RX3i TCP/IP

Ethernet Communications User Manual, GFK-2224.

▪ Time Synchronization to SNTP Time Server on Ethernet

network when used with Ethernet Release 5.0 or later.

▪ Compliant with EU RoHS Directive 2002/95/EC using the

following exemp

Ordering Information

Catalog Number Description

IC695CRU320 RX3i 1GHz Celeron M CPU with 64MB User Memory

IC695ACC302 Smart Auxiliary Battery for Memory Retention

IC693ACC302 Auxiliary Battery for Memory Retention

IC690RBT001 Rechargeable Battery for Memory Retention

Warning – Use only GEIP approved auxillary battery packs listed above. Use of another battery may

present a risk of fire or explosion.

Hot Standby CPU Redundancy Features

For details on the configuration and operation of a Hot Standby CPU redundancy system, refer to the PACSystems

Hot Standby CPU Redundancy User’s Manual, GFK-2308.

▪ Supports single and redundant Ethernet remote I/O LANs through Ethernet Network Interface Unit (ENIU)

modules

▪ Supports simplex and redundantly controlled PROFINET remote IO (requires firmware version 8.00 or later)

▪ Survives any one single point of failure

▪ Bumpless switching

o Synchronized CPUs

o One scan switching

o Transfer data size up to 2Mbytes; selected in CPU hardware configuration and in variable properties

▪ Supports two redundancy communications links

▪ Online repair of failed component

▪ Online programming

▪ Redundancy Memory Xchange Module

o Manual toggle switch for role switching, which transitions control from the active unit to the backup unit

o Redundancy status LEDs

▪ Application-initiated role switching to switch the active unit to backup status

▪ Redundancy status bits and message logging

▪ Memory error checking and correction (ECC) single bit correcting and multiple bit checking

▪ Background diagnostics

HSB Control Strategy

The HSB control strategy has the following characteristics:

▪ Active unit does not automatically switch to primary on resynchronization

▪ Critical control data plus all redundant outputs must be included in the output data transfer

▪ Bumpless switchover from active unit to backup unit

Specifications: CRU320

CPU Performance For CRU320 performance data, refer to Appendix A of the PACSystems CPU Reference

Manual, GFK-2222V or later.

Battery: Memory retention For battery selection, installation and estimated life, refer to the PACSystems RX3i and RX7i

Battery and Energy Pack Manual, GFK-2741

Program storage Up to 64 MB of battery-backed RAM

64 MB of non-volatile flash user memory

Power requirements +3.3 Vdc: 1.0 Amps nominal

+5 Vdc: 1.2 Amps nominal

Operating Temperature 0 to 60°C (32°F to 140°F)

Floating point Yes

Time of Day Clock accuracy Maximum drift of 2 seconds per day

Elapsed Time Clock (internal

timing) accuracy

0.01% maximum

Embedded communications RS-232. RS-485

Serial Protocols supported Modbus RTU Slave, SNP, Serial I/O

Backplane Dual backplane bus support: RX3i PCI and high-speed serial bus

PCI compatibility System designed to be electrically compliant with PCI 2.2 standard

Program blocks Up to 512 program blocks. Maximum size for a block is 128KB.

Memory %I and %Q: 32Kbits for discrete

%AI and %AQ: configurable up to 32Kwords

%W: configurable up to the maximum available user RAM

Symbolic: configurable up to 64 Mbytes

Flash memory endurance

rating

100.000 write/erase cycles minimum

Memory error checking and

correction (ECC)

Single bit correcting and multiple bit checking.

Switchover Time1 Maximum 1 logic scan, minimum 3.133 msec.

Typical Base Sweep Time

(Reference Data Transfer List

Impact)2

3.66 msec: 1K Discrete I/O, 125 Analog I/O and 1K Registers

3.87 msec: 2K Discrete I/O, 250 Analog I/O and 2K Registers

4.30 msec: 4K Discrete I/O, 500 Analog I/O and 4K Registers

5.16 msec: 8K Discrete I/O, 1K Analog I/O and 8K Registers

Maximum amount of data in

transfer list

Up to 2 Mbytes

Number of redundancy links

supported

Up to two IC695RMX128/228 synchronization links are supported.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923