K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

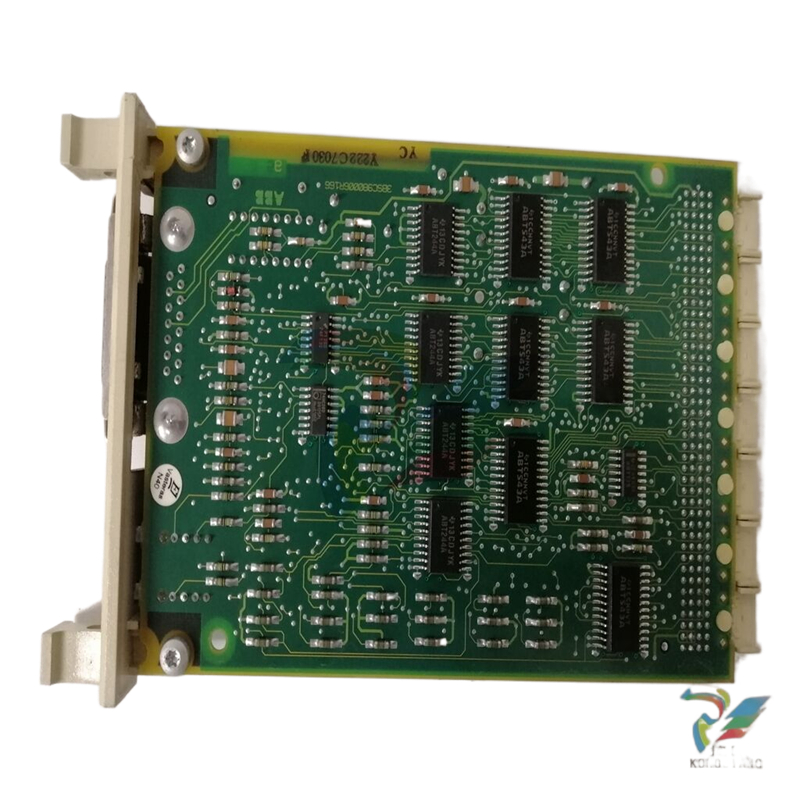

Congratulations on your purchase of a QuickPanel View, the most advanced

compact HMI computer available. The QuickPanel View is available in different

configurations to suit your requirements. Equally at home in a networked

environment or as a stand-alone unit, the QuickPanel View is the ideal solution for

factory floor HMI.

GE IC754VBI10MTD 10/12QuickPanel View

Powered by Microsoft Windows® CE .NETTM, today’s embedded operating system

of choice, the QuickPanel View provides a fast track for application program

development. The commonality with other versions of Windows simplifies porting

your existing program code. Another benefit of Windows CE is the familiarity of

the user interface, shortening the learning curve for operators and developers alike.

The availability of third-party application software makes this operating system

even more attractive.

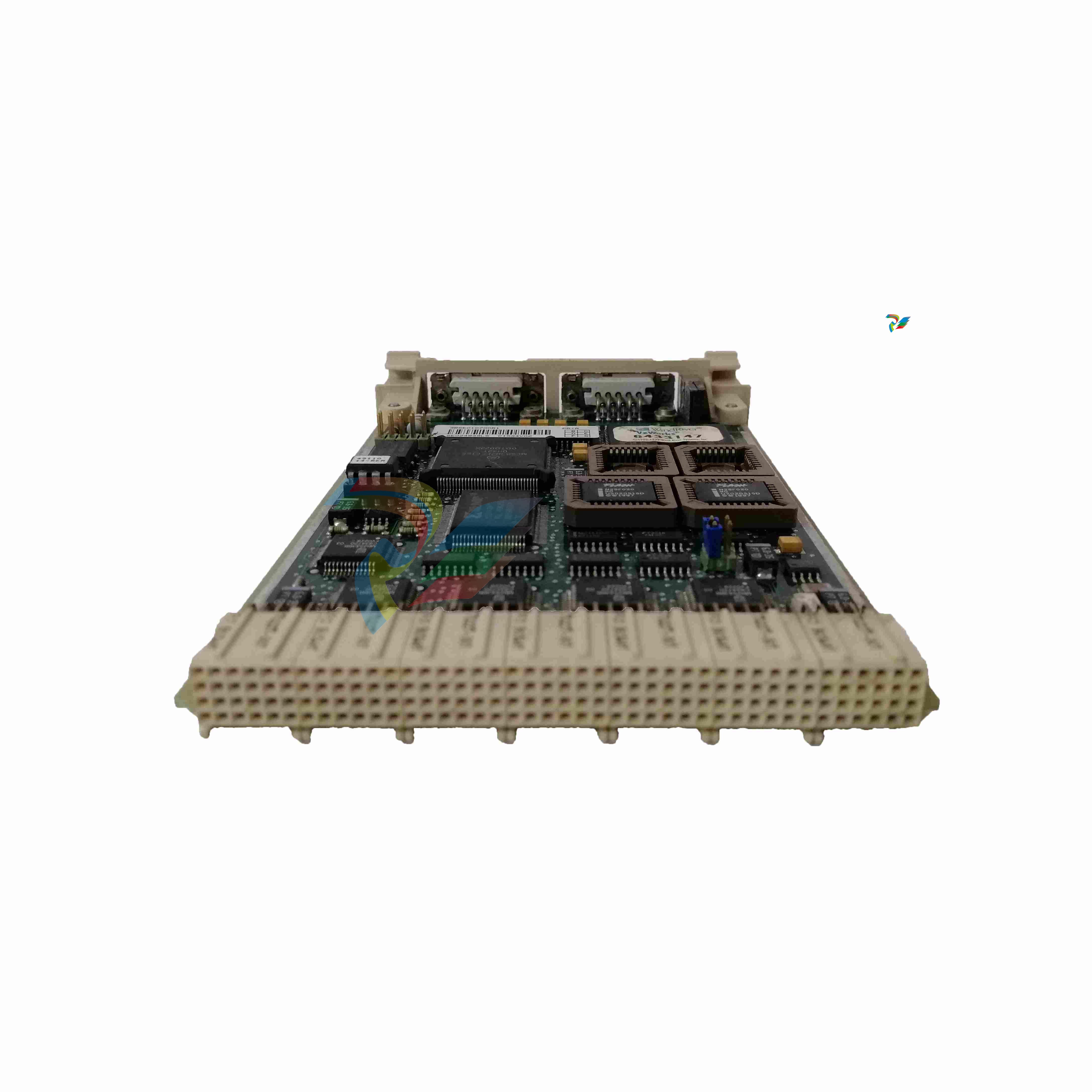

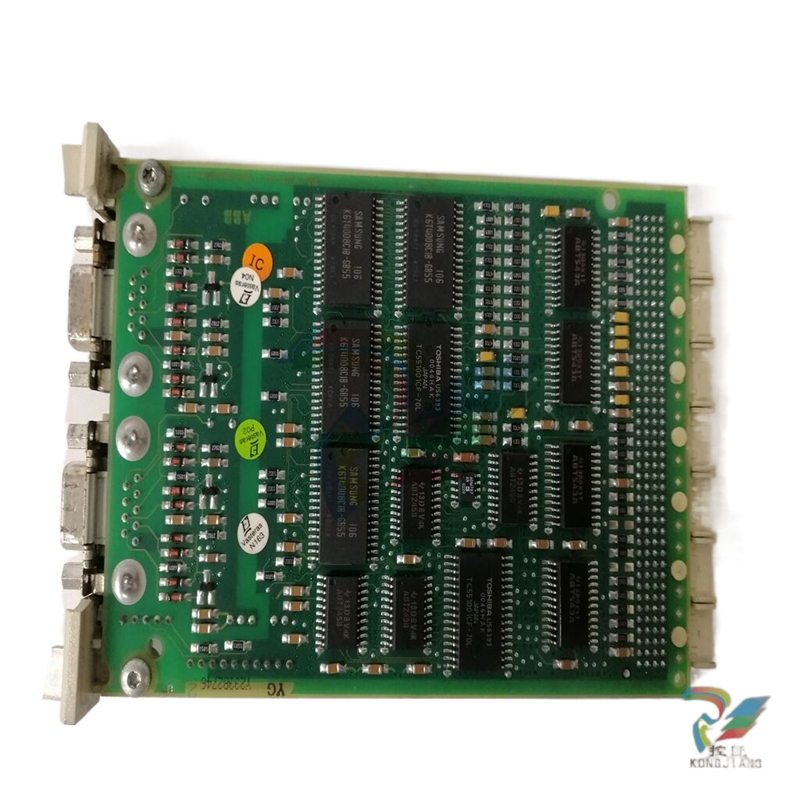

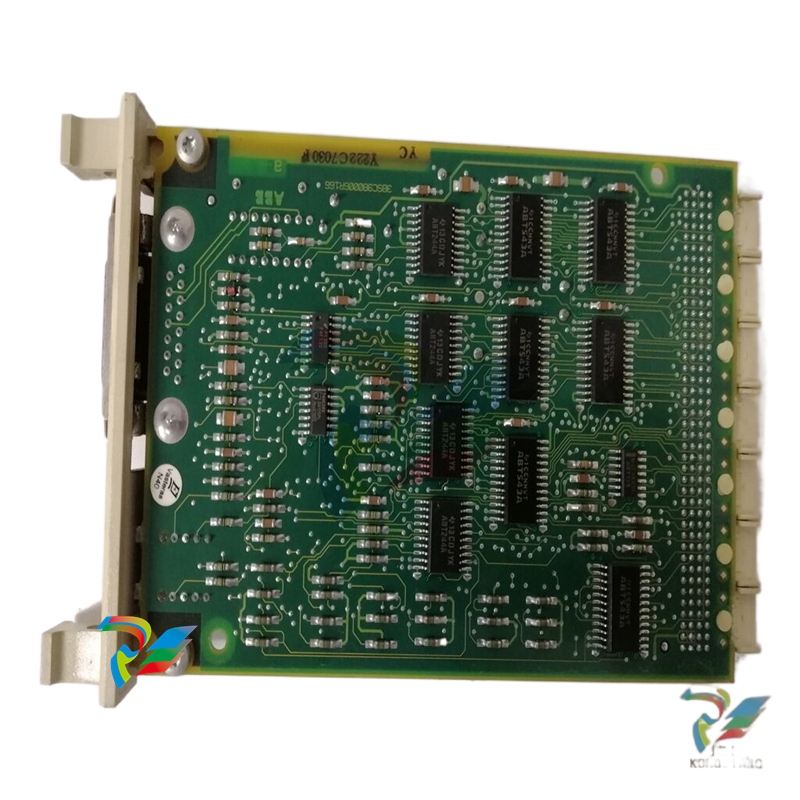

The 10"/12" QuickPanel View is an all-in-one microcomputer designed for

maximum flexibility. The design, based on an advanced Intel® microprocessor,

brings together a high-resolution touch-screen operator interface with a variety of

I/O options. With many standard ports and expansion busses from which to

choose, you can connect to most industrial equipment.

The QuickPanel View is equipped with several memory types to satisfy even the

most demanding applications. A 32MB section of DRAM is split between the

operating system, an object store, and application memory. A 32MB section of

non-volatile FLASH memory, functioning as a virtual hard drive, is divided equally

between the operating system and persistent storage for application programs. The

retentive memory consists of 512 KB of battery-backed SRAM for data storage,

ensuring your valuable data will never be lost, even during a power failure.

The many features of the QuickPanel View make it an obvious choice for a world

of applications. Your smart choice will provide reliable operation for years to

come

GETTING STARTED

Basic Setup

Your 10" or 12" QuickPanel View is shipped ready for use after a few configuration

steps. To power up all you need to do is connect a DC power supply via the

supplied quick-connect plug. Depending on your application, you may also want

to configure communications ports (see page 28) and expansion adapters (see

page 39).

Caution - Electrical Shock Hazard: To avoid personal injury or damage to

equipment, ensure that the DC supply is disconnected from power and that the

leads are not energized before attaching them to the unit's power supply plug.

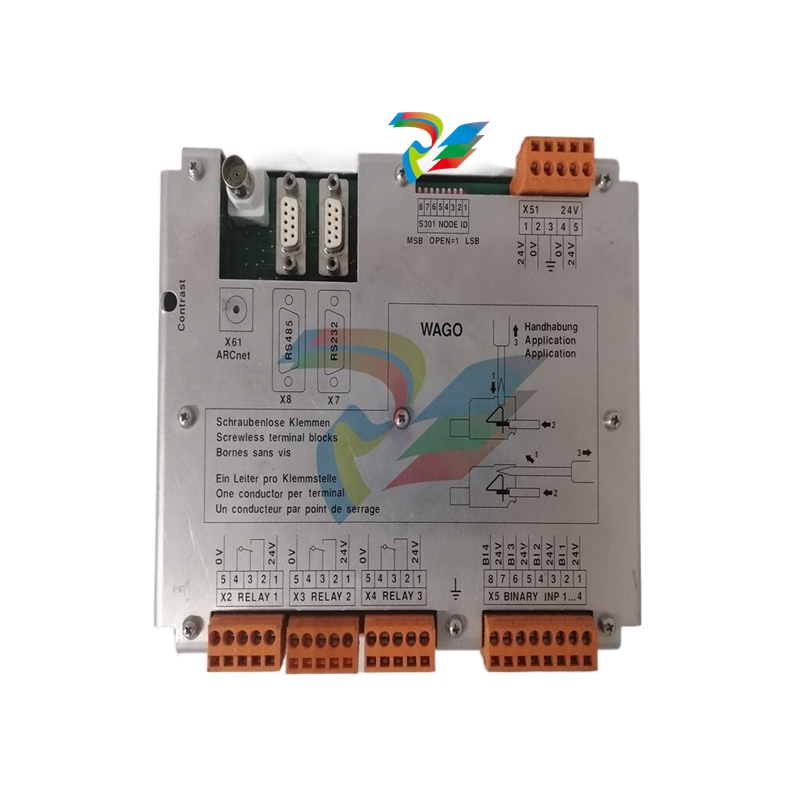

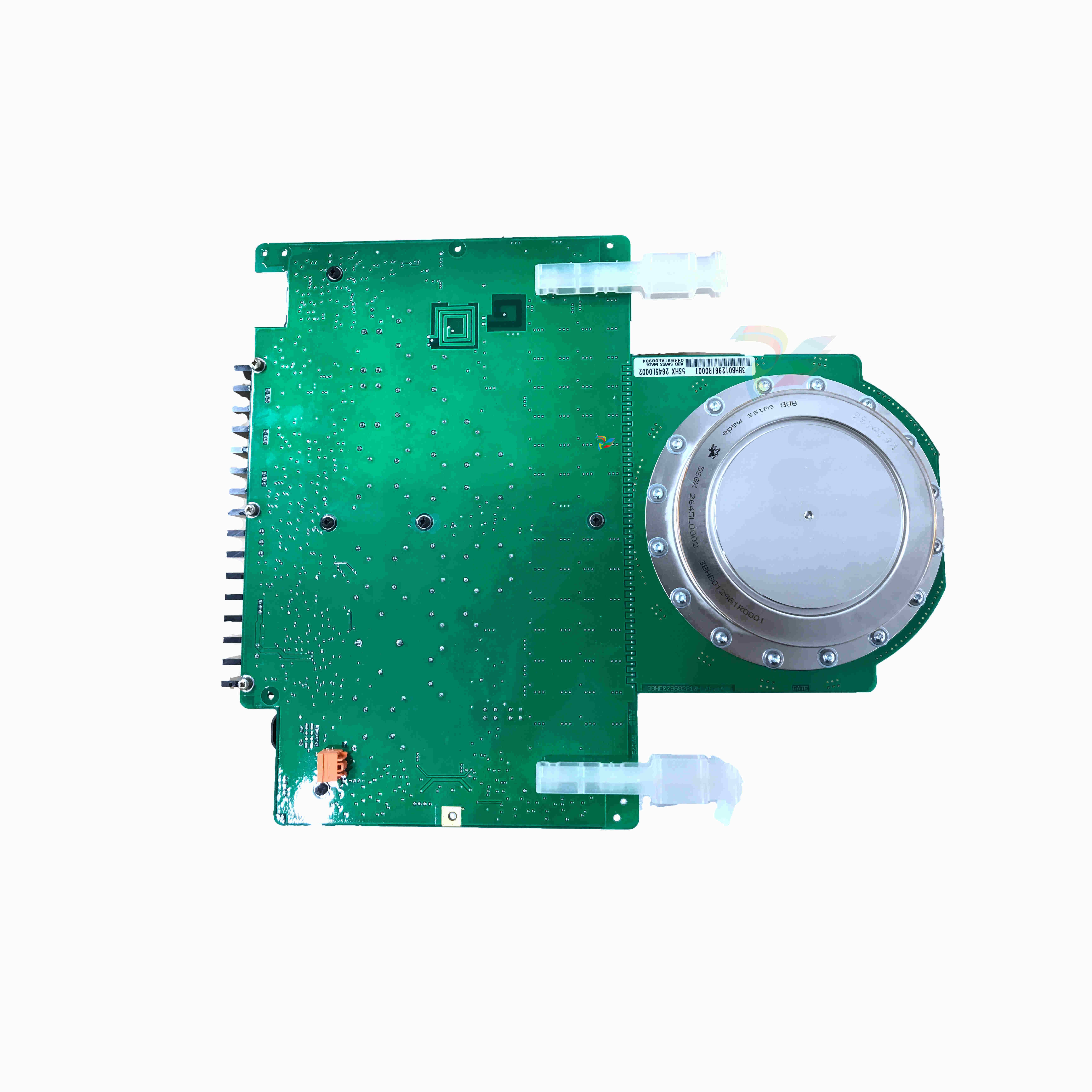

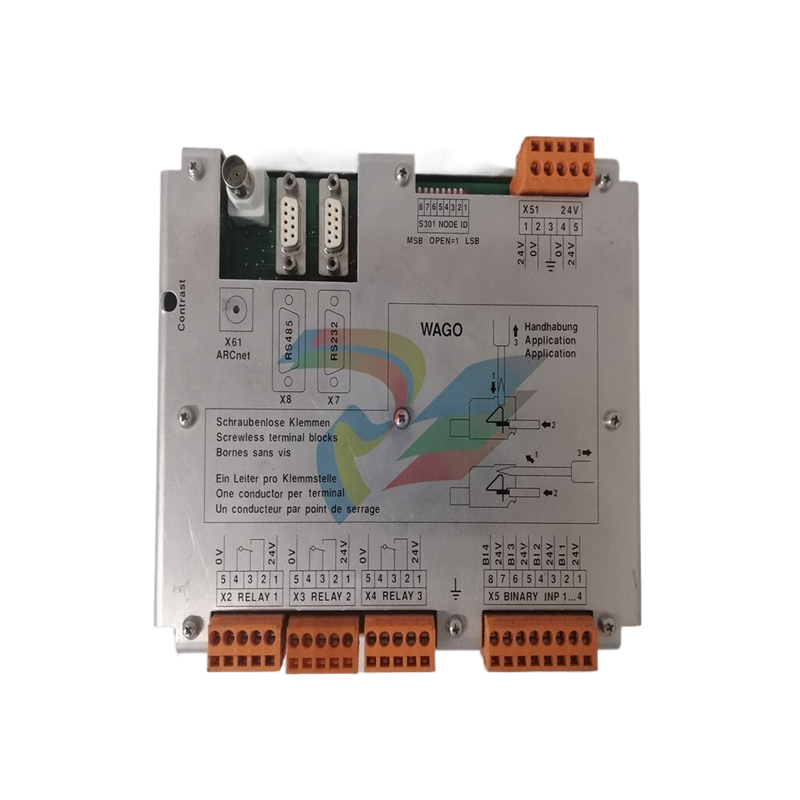

To connect a DC power supply

1. Using the three screw terminals shown in the following diagram, attach a 24VDC, 48W power supply to the plug

supplied with the QuickPanel View (see specifications on page 49 for conductor size requirements).

2. Insert the plug into the power supply socket and securely tighten the attaching screws.

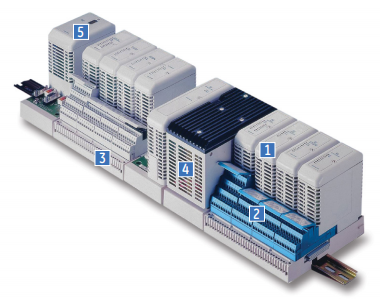

Optional Ethernet Connection Optional Expansion I/O

Power Supply

Power Supply Socket

Power Supply Plug

Insert leads in screw end

QuickPanel View Runtime Setup

To download a Machine Edition application to a QuickPanel View unit, you must

set up a data link between your development workstation and the QuickPanel unit.

For more information, see “Ethernet” (page 35) and look up “Downloading a

Machine Edition Project” in the Machine Edition online help.

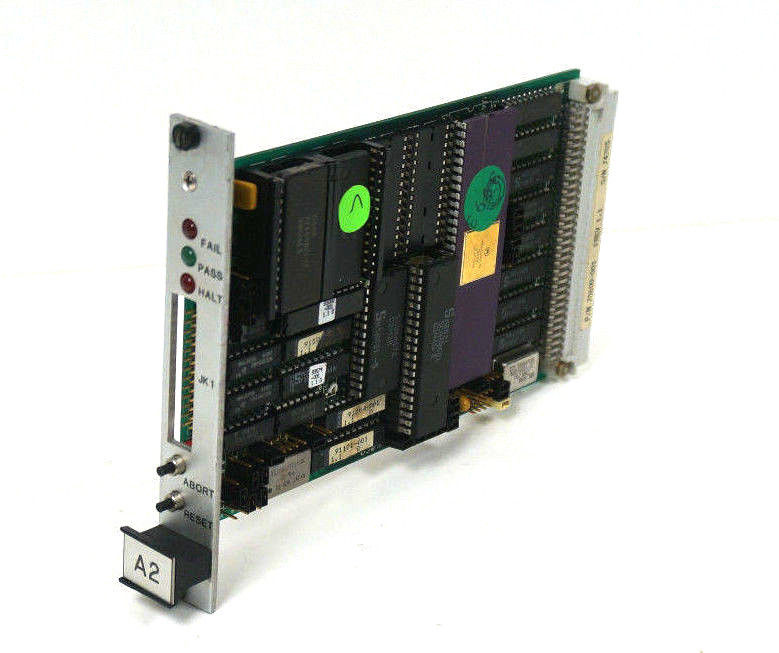

Startup

When you first start up the QuickPanel View, a few configuration steps are

necessary.

To start the QuickPanel View

1. Apply DC power to the QuickPanel View.

Once power is applied, the QuickPanel View begins initializing. The first thing to

appear on the display is the splash screen.

2. To skip running any programs included in the StartUp folder, tap Don’t run StartUp programs.

The splash screen disappears automatically after about 5 seconds. The Windows

CE desktop then becomes visible.

3. Tap Start, point to Settings and then tap Control Panel.

4. In the Control Panel, double-tap Display to configure the LCD display (see page 21).

5. In the Control Panel, double-tap Stylus to configure the touch screen (see page 23).

6. In the Control Panel, double-tap Date and Time to configure the system clock (see page 47).

7. In the Control Panel, double-tap Network and Dial-up Connections to configure network settings (see

page 36).

8. On the desktop, double-tap Backup to save any new settings through a power cycle (see page 12).

IC754VGI10MTD

IC754VSI10MTD

IC754VBI12CTD

IC754VGI12CTD

IC754VSI12CTD

IC754VSI12MTD

IC754VBI12MTD

IC754VGI12MTD

To avoid gasket degradation, limit repeated insertions or removals of the unit and

retightening of the mounting clips. For full protection, always use a fresh gasket.

The unit will not fit through this cutout with a CF card inserted in the port, with any

cables connected, or with the power supply plug inserted in the socket.

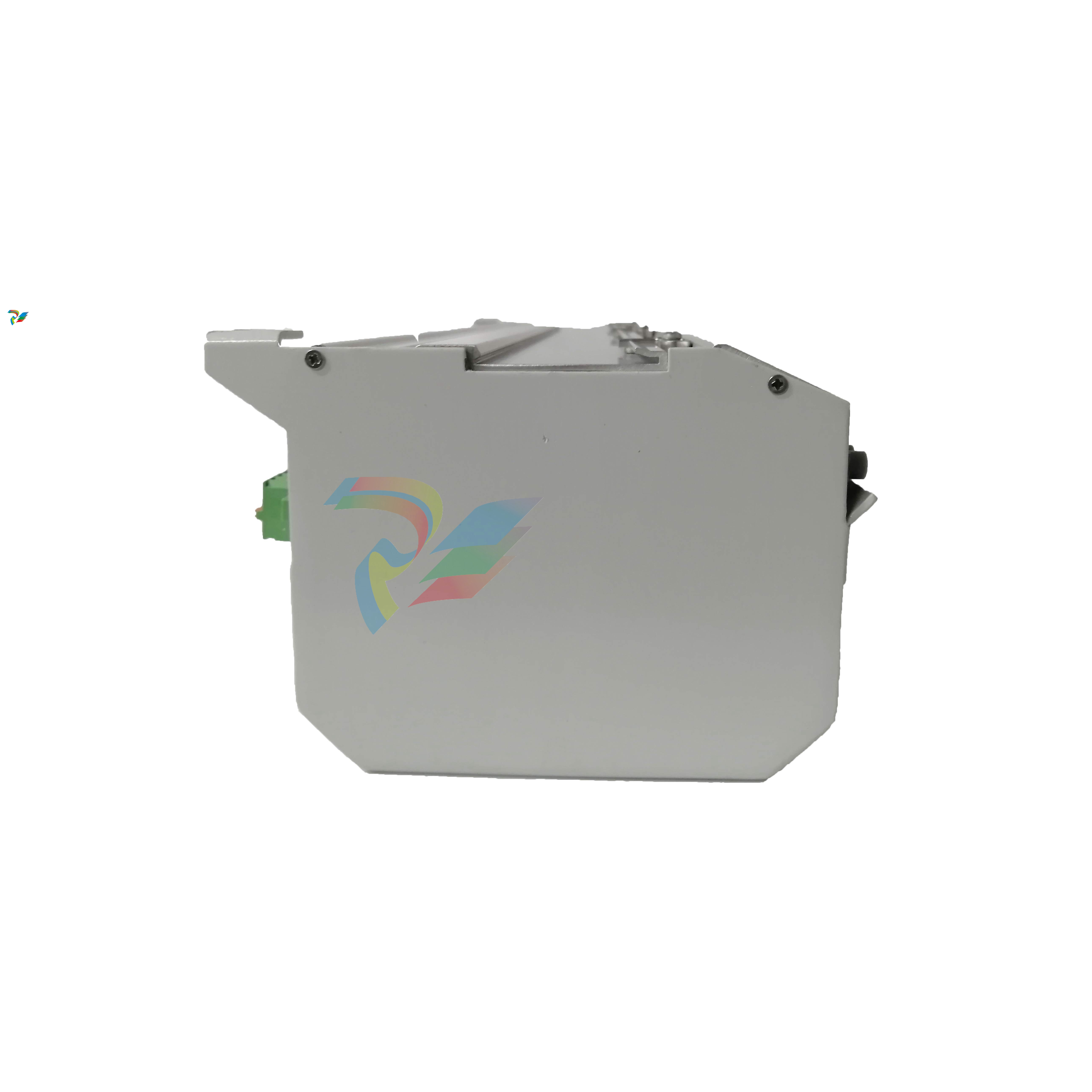

To secure the QuickPanel View to a panel, use the 10 included mounting clamps.

They hook into openings located on the top, bottom, and sides of the housing.

To mount the QuickPanel View in a panel

1. Insert the unit into the panel cutout (without a CF card in the CF port).

2. Insert the hook of each mounting clamp into the housing openings as shown below.

3. Ensure that the gasket is properly seated in the bezel channel and firmly tighten the clamp screws.

Note: The torque range for the mounting clamp screws is 2.6-4.4 inch/lbs

(0.3-0.5 Nm)

The mounting clamps hold the unit in place by tension alone. No drilling is

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)