K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

The TZIDC Control Unit contains the electronics and pneumatics

along with the following options (where applicable):

• Analog position feedback

• Digital position feedback

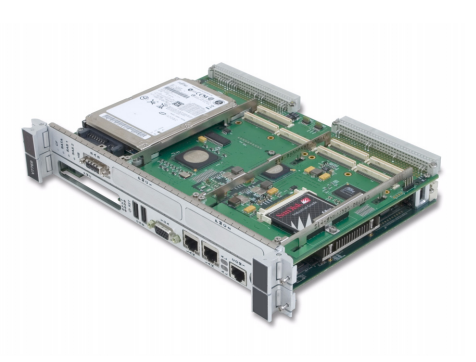

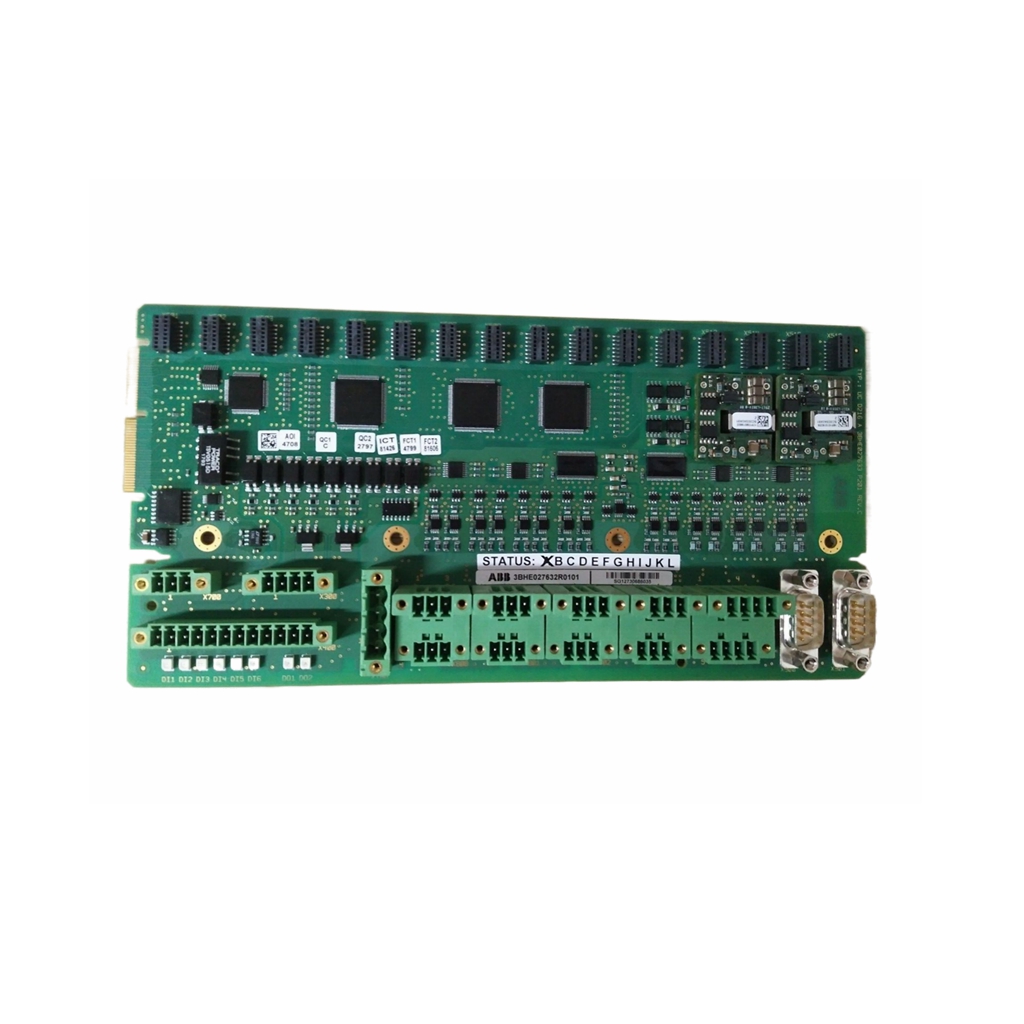

ABB 07KT97F1 Programmable Processor Unit

With the TZIDC designed for remote position sensors, thepositioner is supplied without a position sensor.

The TZIDC Control Unit contains the electronics and pneumatics

along with the following options (where applicable):

• Analog position feedback

• Digital position feedback

Any position sensor (4 to 30 kΩ, with line break detection

4 to 18 kΩ) can be connected.

Connect the positioner (TZIDC Control Unit) and remote position

sensor while observing the following instructions:

• A shielded 3-wire cable with a maximum length of 10 m (33 ft)

must be used for the connection.

• Route the cable into the terminal compartment through the

EMC cable glands. Ensure that the shielding is secured

correctly in the EMC cable glands.

• Connect the cables in accordance with the electrical

connections and tighten the screws of the terminals so that

they are hand-tight.

• The electrical connection of the TZIDC Control Unit and the

optional modules are described in Positioner /

TZIDC Control Unit Electrical Connection on page 19.

• If the TZIDC Control Unit is fastened such that it is it non conductive, the housing must be grounded (TZIDC Control

Unit and remote position sensor housing with the same

electric potential); otherwise control deviations could occur

with regard to analog position feedback.

• Use wire end ferrules when connecting.

Pneumatic connections

Note

The positioner must only be supplied with instrument air that is

free of oil, water, and dust.

The purity and oil content must meet the requirements of

Class 3 in accordance with DIN/ISO 8573-1.

NOTICE

Damage to components!

Contamination on the air pipe and positioner can damage

components.

• Dust, splinters, and any other particles of dirt must be

blown-out before the pipe is connected.

NOTICE

Damage to components!

Pressure above 6 bar (90 psi) can damage the positioner or

actuator.

• Provisions must be made (e.g. by using a pressure

reducer) to make sure that the pressure does not rise

above 6 bar (90 psi)*, even in the event of a fault.

* 5.5 bar (80 psi) (marine version)

Information on double acting actuators with spring return mechanism

On double-acting actuators with spring-return mechanism, a

pressure that significantly exceeds the supply air pressure value

can be generated during operation by the springs in the

chamber opposite the springs.

This may damage the positioner or adversely affect control of

the actuator.

To eliminate the possibility of this occurring, it is recommended

to install a pressure compensation valve between the springless

chamber and the supply air for these types of applications. It

enables the increased pressure to be transferred back to the air

inlet line.

The opening pressure of the check valve should be < 250 mbar

(< 3.6 psi).

Connection on the device

Figure 23: Pneumatic connections

Marking Pipe connection

IN Supply air, pressure 1.4 to 6 bar (20 to 90 psi)

Marine version:

• Supply air, pressure 1.4 to 5.5 bar (20 to 80 psi)**

OUT1 Output pressure to the actuator

OUT2 Output pressure to the actuator

(2. Connection with double acting actuator)

** (marine version)

Join the pipe connections according to the designation,

observing the following points:

• All pneumatic piping connections are located on the

right-hand side of the positioner. G¼ or ¼ 18 NPT tap

holes are provided for the pneumatic connections. The

positioner is labeled according to the tap holes available.

• We recommend that you use a pipe with dimensions of

12 × 1.75 mm.

• The supply air pressure required to apply the actuating

force must be adjusted in line with the output pressure in

the actuator. The operating range of the positioner is

between 1.4 to 6 bar (20 to 90 psi)***.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923