K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

In the case of the ‘TZIDC Control Unit with TZIDC Remote Sensor’

design, the components are supplied in two housings, which

together form one harmonized unit.

Housing 1 (TZIDC Control Unit) contains the electronics and

pneumatics along with the following options (where applicable):

• Analog position feedback

• Digital position feedback

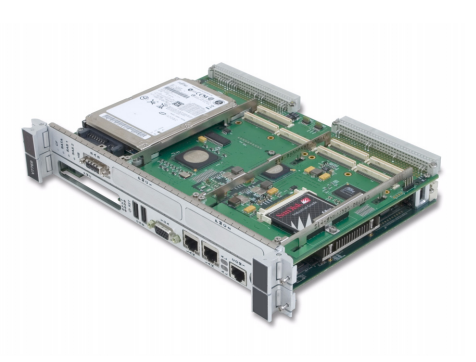

ABB 07KT95 Programmable Processor Unit

In the case of the ‘TZIDC Control Unit with TZIDC Remote Sensor’

design, the components are supplied in two housings, which

together form one harmonized unit.

Housing 1 (TZIDC Control Unit) contains the electronics and

pneumatics along with the following options (where applicable):

• Analog position feedback

• Digital position feedback

Housing 2 (TZIDC Remote Sensor) contains the position sensor

and is suitable for mounting on linear or part-turn actuators.

If necessary, the following options can be installed if required:

• Optical position indicator

• Mechanical feedback contacts designed as proximity

switches or microswitches.

Connect the positioner (TZIDC Control Unit, housing 1) and

remote position sensor (TZIDC Remote Sensor, housing 2) while

following the instructions below:

• The sensor and the electronics have been matched. Ensure

that only devices with the same serial number are connected.

• A shielded 3-wire cable with a maximum length of 10 m (33 ft)

must be used for the connection.

• Route the cable into the terminal compartment through the

EMC cable glands. Ensure that the shielding is secured

correctly in the EMC cable glands.

• Connect the cables in accordance with the electrical

connections and tighten the screws of the terminals so that

they are hand-tight.

• The electrical connection of the TZIDC Control Unit and the

optional modules are described in Positioner /

TZIDC Control Unit Electrical Connection on page 19.

• If the TZIDC Control Unit is fastened so that it is it nonconductive, the housing must be grounded (TZIDC Control

Unit and TZIDC Remote Sensor housing with the same

electric potential); otherwise control deviations could occur

with regard to analog position feedback.

• Use wire end ferrules when connecting.

With the TZIDC designed for remote position sensors, the

positioner is supplied without a position sensor.

The TZIDC Control Unit contains the electronics and pneumatics

along with the following options (where applicable):

• Analog position feedback

• Digital position feedback

Any position sensor (4 to 30 kΩ, with line break detection

4 to 18 kΩ) can be connected.

Connect the positioner (TZIDC Control Unit) and remote position

sensor while observing the following instructions:

• A shielded 3-wire cable with a maximum length of 10 m (33 ft)

must be used for the connection.

• Route the cable into the terminal compartment through the

EMC cable glands. Ensure that the shielding is secured

correctly in the EMC cable glands.

• Connect the cables in accordance with the electrical

connections and tighten the screws of the terminals so that

they are hand-tight.

• The electrical connection of the TZIDC Control Unit and the

optional modules are described in Positioner /

TZIDC Control Unit Electrical Connection on page 19.

• If the TZIDC Control Unit is fastened such that it is it non conductive, the housing must be grounded (TZIDC Control

Unit and remote position sensor housing with the same

electric potential); otherwise control deviations could occur

with regard to analog position feedback.

• Use wire end ferrules when connecting.

5 Installation

Electrical connections

Wire cross-sectional areas

Basic device

Electrical connections

4 to 20 mA input Screw terminals max. 2.5 mm2 (AWG14)

Options Screw terminals max. 1.0 mm2 (AWG18)

Cross section

Rigid / flexible wires 0.14 to 2.5 mm2 (AWG26 to AWG14)

Flexible with wire end sleeve 0.25 to 2.5 mm2 (AWG23 to AWG14)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 1.5 mm2 (AWG23 to AWG17)

Flexible with wire end sleeve

with plastic sleeve

0.14 to 0.75 mm2 (AWG26 to AWG20)

Multi-wire connection capacity (two wire with the same cross-section)

Rigid / flexible wires 0.14 to 0.75 mm2 (AWG26 to AWG20)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 0.75 mm2 (AWG23 to AWG20)

Flexible with wire end sleeve

with plastic sleeve

0.5 to 1.5 mm2 (AWG21 to AWG17)

Option modules

Cross section

Rigid / flexible wires 0.14 to 1.5 mm2 (AWG26 to AWG17)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 1.5 mm2 (AWG23 to AWG17)

Flexible with wire end sleeve

with plastic sleeve

0.25 to 1.5 mm2 (AWG23 to AWG17)

Multi-wire connection capacity (two wire with the same cross-section)

Rigid / flexible wires 0.14 to 0.75 mm2 (AWG26 to AWG20)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 0.5 mm2 (AWG23 to AWG22)

Flexible with wire end sleeve

with plastic sleeve

0.5 to 1 mm2 (AWG21 to AWG18)

Limit switch with proximity switches or 24 V microswitches

Rigid wire 0.14 to 1.5 mm2 (AWG26 to AWG17)

Flexible wire 0.14 to 1.0 mm2 (AWG26 to AWG18)

Flexible with wire end sleeve no

plastic sleeve

0.25 to 0.5 mm2 (AWG23 to AWG22)

Flexible with wire end sleeve

with plastic sleeve

0.25 to 0.5 mm2 (AWG23 to AWG22)

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923